Current location:

Links:

-

The Pivotal Role of Cylindrical Roller Bearings in Modern Industry One of the key factors that set spherical roller bearings apart from other types of bearings is their unique design. Unlike traditional bearings, which rely on point contacts, spherical roller bearings utilize a series of rollers arranged in a cage. This design allows the bearings to accommodate misalignment and angular misalignment, making them ideal for use in applications where the shaft axis and housing bore are not perfectly aligned. The design of the thrust ball bearing housing is also critical to its performance. The housing must be designed to provide adequate support for the bearing and its components, while also allowing for easy installation and removal. The size and shape of the housing will depend on the specific requirements of the application, including the size and type of bearing being used, the operating conditions, and the space constraints. The 6312 zz Bearing A Revolution in Rotary Motion

- Axial Load Support: While single row deep groove ball bearings are primarily intended for radial loads, they also have the capability to accommodate some degree of axial loads. The bearing's design enables it to withstand limited axial forces, making it suitable for applications where both radial and axial loads are present. The ID taper ratio, another critical aspect, determines the bearing's load distribution and performance The quality of a 6205 ball bearing is critical to its performance. Factors like material selection, heat treatment, and surface finish all contribute to its load-bearing capacity, speed capability, and lifespan. High-grade steel, often used for the balls and rings, provides strength and resistance to fatigue. Advanced lubrication systems further enhance their performance by reducing friction and wear. One of the key advantages of 4203/202RS bearings is their ability to handle both radial and axial loads, making them suitable for use in applications such as pumps, fans, and blowers. Furthermore, their self-aligning feature ensures that the bearing remains properly aligned even under misalignment or vibration, reducing wear and tear and extending its service life. The 6203Z bearing also features a double sealed design, which helps to keep out contaminants and moisture that can cause damage to the bearing over time. This design also helps to prevent the loss of lubricant, ensuring that the bearing remains properly lubricated and performs at its best. Material Types 6302RS bearings are a popular choice for their high precision, reliability, and durability. Whether you're working in the automotive, industrial, aerospace, or robotics industry, these bearings can provide the support and performance you need to keep your machinery running smoothly. Overall, the 6209 2RS bearing is an essential component in the world of industrial machinery, offering durability, reliability, and versatility for a wide range of applications. Its sealed design, high load-carrying capacity, and compatibility with various equipment types make it a popular choice among manufacturers and engineers seeking a reliable bearing solution for their operations. With its ability to withstand tough operating conditions and deliver consistent performance, the 6209 2RS bearing is a valuable asset in any industrial setting. Applications of the 51113 Bearing One of the key advantages of deep groove ball bearings is their ability to handle combined loads. While primarily designed for radial loads, they can also withstand axial loads in either direction up to about 55% of the radial load. This dual capacity makes them suitable for applications where both types of loads are present. Once the taper bearing number has been identified, it is important to select a high-quality bearing from a reputable manufacturer. Quality taper bearings are precision-engineered to provide reliable performance and long service life, even under extreme operating conditions. Introduction

Roller bearings are used in a wide range of applications across various industries due to their ability to support radial and axial loads. Some common uses of roller bearings include:

Understanding Needle Roller Thrust Bearing Size Chart A Comprehensive Guide The size chart for spherical plain bearings typically includes the following information Despite the increase in prices, bearing 6312 remains a crucial component in many industrial applications. Its high load-carrying capacity, durability, and versatility make it an essential part of various machinery and equipment. As such, businesses that rely on bearing 6312 are likely to absorb the higher costs to ensure the smooth operation of their equipment. One of the key advantages of the NN3020 bearing is its exceptional load capacity. It can withstand heavy loads with ease, making it an ideal choice for applications that require high stability and durability. Whether you're dealing with large machinery or demanding industrial processes, this bearing has the strength to get the job done. In addition to its durability and high performance, the 23048 bearing is also easy to install and maintain. This makes it a cost-effective option for many businesses that rely on machinery and equipment for their operations. With regular maintenance and proper care, the 23048 bearing can last for many years without needing to be replaced. Taper Roller Bearings Precision and Efficiency in Motion Control The 48548 bearing is widely used in various industries due to its versatility and performance. Some of the most common applications include

Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life

Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life 61908 bearing. Why is Radial Clearance Important?

61908 bearing. Why is Radial Clearance Important? A leading bearing manufacturer has announced that it will invest in new production technology to improve efficiency and quality. The investment will include the purchase of advanced machinery and equipment, as well as the implementation of new manufacturing processes.

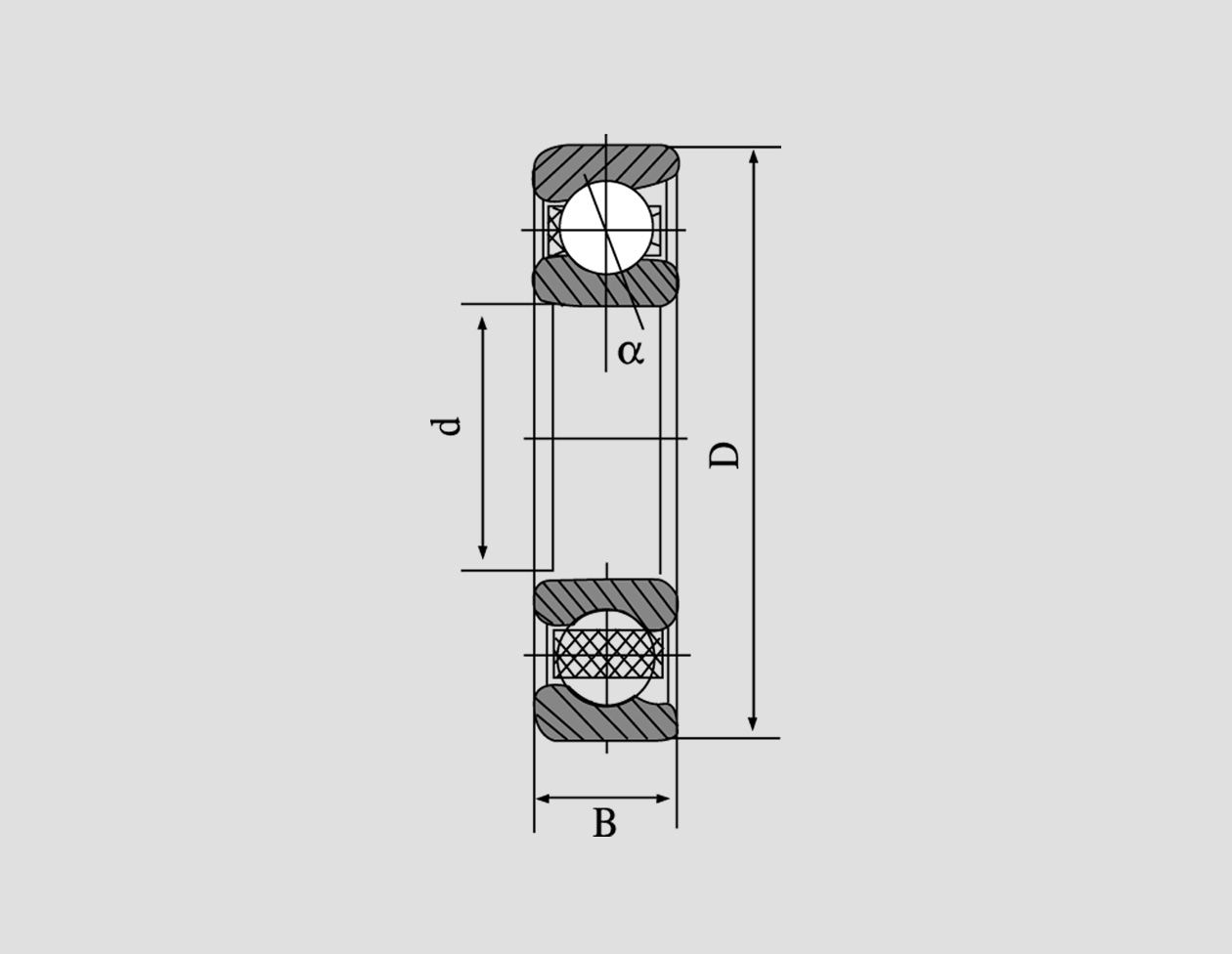

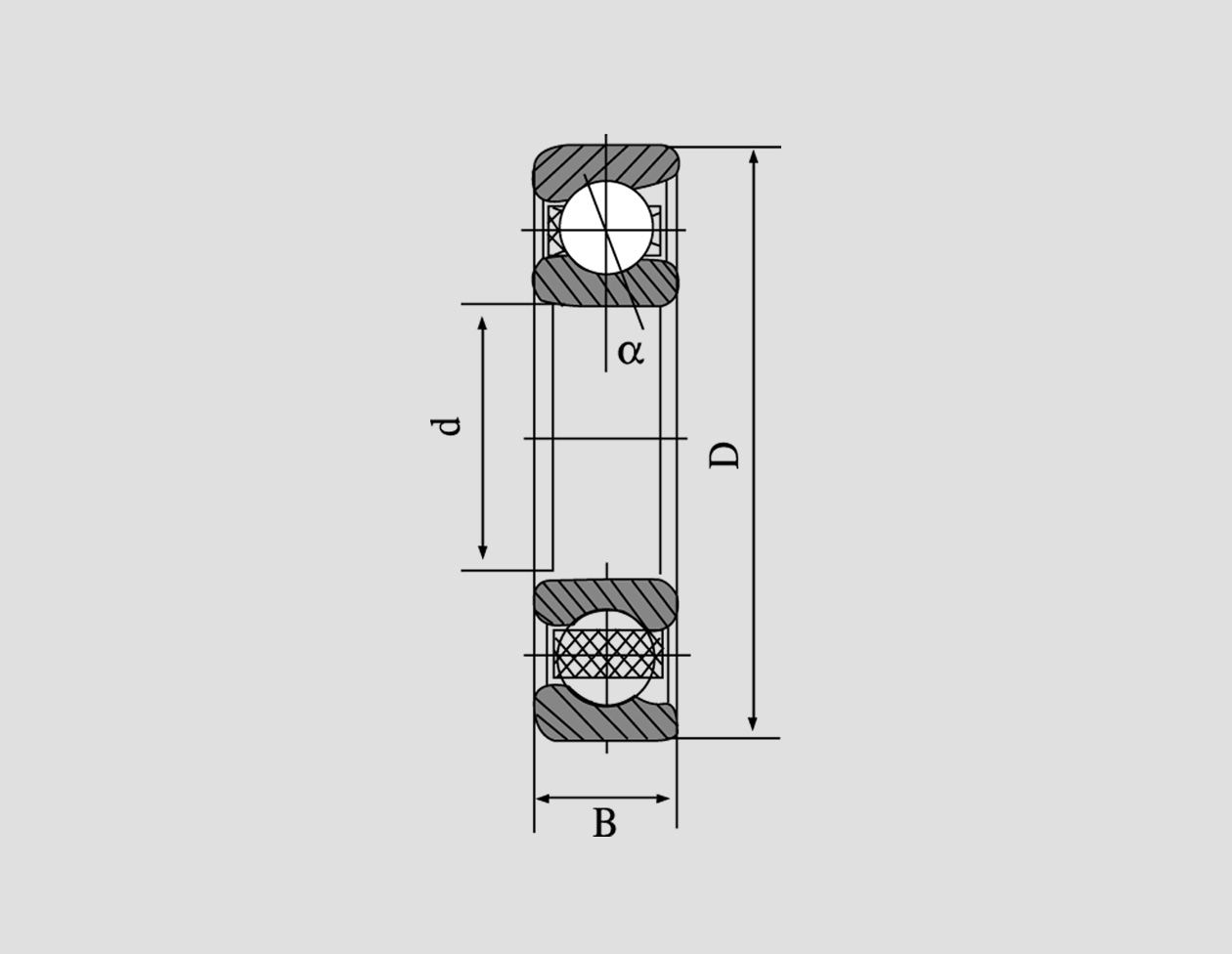

One of the key features of thrust angular contact ball bearings is their ability to handle high thrust capacities with a relatively small footprint. This makes them ideal for applications where space is limited but high thrust capacity is still required. They are often used in industries such as automotive, aerospace, and machinery where precise axial positioning and high load carrying capacity are essential. In addition to its high speed capability, the 6002 rz bearing also offers excellent durability and reliability 2. Material These bearings are typically made from high-quality steel, which ensures durability and long service life. The steel is subjected to rigorous heat treatment processes to enhance its hardness and resistance to wear. In conclusion, cylindrical roller bearings are indispensable in a wide range of applications due to their exceptional load-bearing capacity, speed capabilities, and durability. Their versatility and robustness make them a go-to choice for engineers and manufacturers seeking reliable solutions for heavy-duty and high-performance systems. As technology continues to evolve, the significance of cylindrical roller bearings in various industries will only continue to grow, shaping the future of mechanical engineering. Buyers should also consider the availability of the 22226 bearing, as a lower-priced bearing may be of little value if it is not readily available when needed. It is essential to ensure that the bearing is in stock and can be delivered in a timely manner to avoid delays in production or maintenance. The 20% deep groove ball bearing is widely used in a variety of applications due to its versatility and performance. Some of the most common applications include

The versatility of the 51100 bearing makes it suitable for a wide range of applications in various industries. Some of these include Design Innovation

Proper maintenance is essential to ensure the longevity and performance of 20% deep groove ball bearings. Some key maintenance practices include Bearing 6308 Z is a type of deep groove ball bearing that is commonly used in various industrial applications. Bearings are vital components that allow rotational movement while minimizing friction and supporting loads. They are ubiquitous in machinery ranging from tiny electronic devices to colossal industrial equipment. The 29675 bearing signifies a specific type or model, possibly denoting its unique design or application criteria. Its name might be an alphanumeric code or a deliberate play on words, symbolizing its breakthrough nature. The 20% Deep Groove Ball Bearing A Comprehensive Guide Bearing ID 80 OD 140 taper roller bearings are widely used in various industrial applications due to their excellent load capacity, high reliability, and long service life. These bearings consist of an inner ring, outer ring, tapered rollers, and a cage that keeps the rollers in position. In this article, we will provide a comprehensive guide to help you understand the specifications, selection, installation, maintenance, and troubleshooting of these bearings. One of the key advantages of single tapered roller bearings is their versatility. They can be used in both radial and axial applications, providing excellent stability under heavy loads. They are commonly employed in automotive hubs, axles, gearboxes, and industrial machinery where high load capacity and resistance to shock and vibration are essential. Benefits of the 6903 ZZ Bearing The 32238 bearing finds extensive use in heavy-duty applications such as automotive axles,, wind turbines, and even industrial machinery. Its ability to withstand high radial and axial loads makes it ideal for applications where substantial stress is anticipated. Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions

Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions

Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions 32238 bearing. Overall, the NN3020 bearing represents a major advancement in the world of bearings. Its combination of high load capacity, low friction, excellent precision, and practical benefits make it an ideal choice for a wide range of applications. As the industry continues to evolve, the NN3020 bearing is sure to play a leading role in shaping the future of mechanical systems and equipment.

32238 bearing. Overall, the NN3020 bearing represents a major advancement in the world of bearings. Its combination of high load capacity, low friction, excellent precision, and practical benefits make it an ideal choice for a wide range of applications. As the industry continues to evolve, the NN3020 bearing is sure to play a leading role in shaping the future of mechanical systems and equipment.