Links:

2. Reduced Time and Labor With its ability to sew through multiple layers at once, this machine dramatically reduces the time spent on projects. This efficiency is a boon for manufacturers who need to meet tight deadlines.

Additionally, the integration of smart technology into automatic sewing machines represents a significant advancement in the garment industry. Many of these machines are now equipped with sensors and software that monitor performance, predict maintenance needs, and even suggest optimal sewing settings based on fabric types. This level of intelligence not only enhances operational efficiency but also reduces downtime, ensuring that manufacturers can keep their production lines running smoothly.

The price of an industrial bag sewing machine can range from a few hundred dollars to several thousand dollars. The cost is influenced by factors such as the speed of the machine, the quality of the stitches it produces, and the level of automation it offers. Higher-end machines that can sew bags at faster speeds and with greater precision tend to have a higher price tag.

Warranty

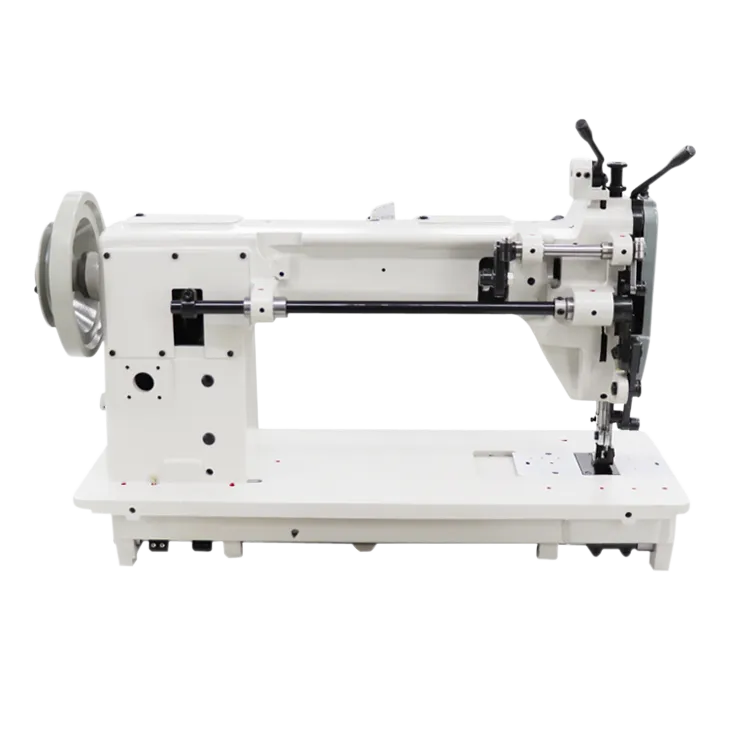

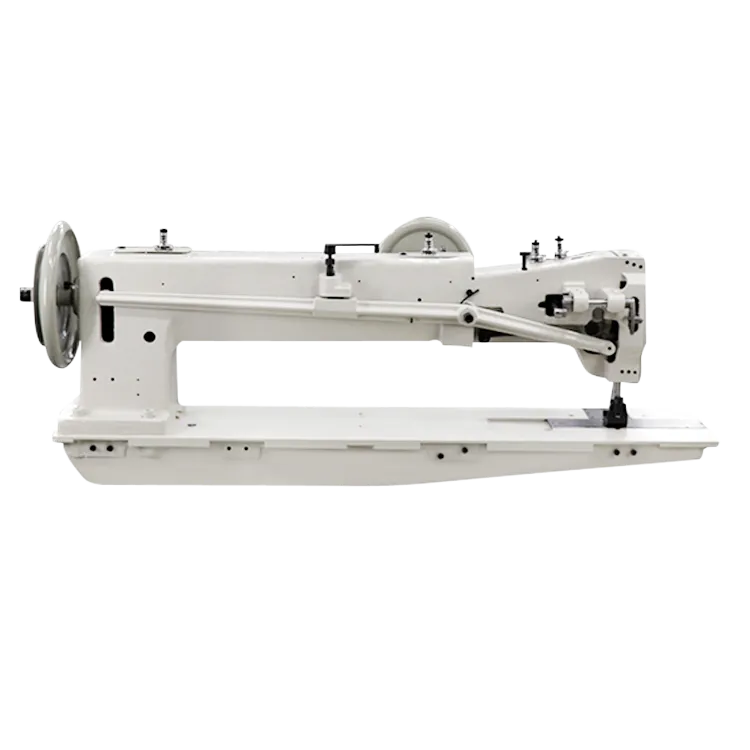

Long arm upholstery sewing machines are essential tools for professionals in the upholstery and furniture industry. These machines are designed with an extended arm that allows for easy maneuvering of large and bulky fabrics, making them ideal for sewing upholstery, draperies, and other heavy-duty materials.The applications of double needle walking foot industrial sewing machines are vast. In the garment industry, they are commonly used for sewing hems, seams, and decorative stitches on a wide range of clothing items, from shirts to jackets. In upholstery, these machines are invaluable for creating strong seams in sofas, chairs, and other furniture pieces that require durability. Additionally, they find utility in leather goods production, where the quality of stitching is paramount for both aesthetic and functional reasons.