Links:

One of the primary advantages of aluminum bar grating is its weight. Compared to steel or other materials, aluminum is significantly lighter, making it easier to handle, transport, and install. This lightweight nature does not compromise its strength; in fact, aluminum bar grating is designed to withstand heavy loads and intense operating environments, making it a smart choice for walkways, platforms, and other structures that bear weight.

Understanding Marine Grating Importance and Applications

Though the initial investment in GRP insulated water tanks may be higher compared to traditional tanks, the long-term savings often outweigh these costs. Their durability leads to lower maintenance requirements, while the insulation minimizes energy costs in temperature regulation. Over time, the total cost of ownership for GRP tanks tends to be significantly lower, making them an economically viable option for water storage.

Welded bar grating is typically manufactured from materials such as steel, aluminum, or stainless steel. The process involves welding cross bars at regular intervals to the main bars, creating a grid-like structure that is both robust and lightweight. The spacing between the bars can be customized based on the specific load requirements and application, ensuring maximum efficiency and performance.

In conclusion, galvanized stock tanks represent a practical and effective solution for farmers and ranchers looking to improve their animal husbandry practices. With their durability, versatility, and low-maintenance requirements, these tanks are an investment that not only serves the immediate needs of livestock but also contributes to the overall efficiency of farm operations. By carefully considering size, location, and cost, you can find the perfect galvanized stock tank for your needs, ensuring your animals stay hydrated and healthy.

3. Non-Magnetic and Non-Conductive FRP rebar is non-magnetic and non-conductive, making it suitable for applications where electromagnetic interference must be minimized, such as in certain industrial and medical facilities.

frp rebar

1. Water Systems In residential and agricultural setups, pressure tanks are integral to water distribution systems. They help maintain consistent water pressure for household plumbing fixtures by acting as a buffer to balance demand, reducing the need for the pump to cycle frequently.

3. Secondary Treatment Equipment This is where biological processes come into play. Activated sludge systems, trickling filters, and biofilm reactors are common examples. These systems utilize microorganisms to break down organic matter. Secondary treatment is essential for removing biodegradable contaminants and is often a significant focus in wastewater treatment facilities.

Factors to Consider When Choosing Steel Channels

steel chs sizes

2. Aesthetic Appeal The smooth and sleek design of CHS tubes allows for a modern look in both construction and furniture design. Their aesthetic versatility makes them a preferred choice for designers and architects.

5. Environmental Benefits Many FRP products are made from recyclable materials, contributing to sustainability efforts. Moreover, their long lifespan means less frequent replacements, which translates to reduced waste and environmental impact.

The complexity of the manufacturing process can impact the cost of 1465 FRP vessels. Advanced techniques such as vacuum infusion or resin transfer molding reduce production defects and enhance performance but may require higher initial investments in machinery and technology.

2. Salt-Free Softeners These systems work by conditioning the water rather than removing minerals. They are ideal for those concerned about sodium intake but may be less effective in certain situations.

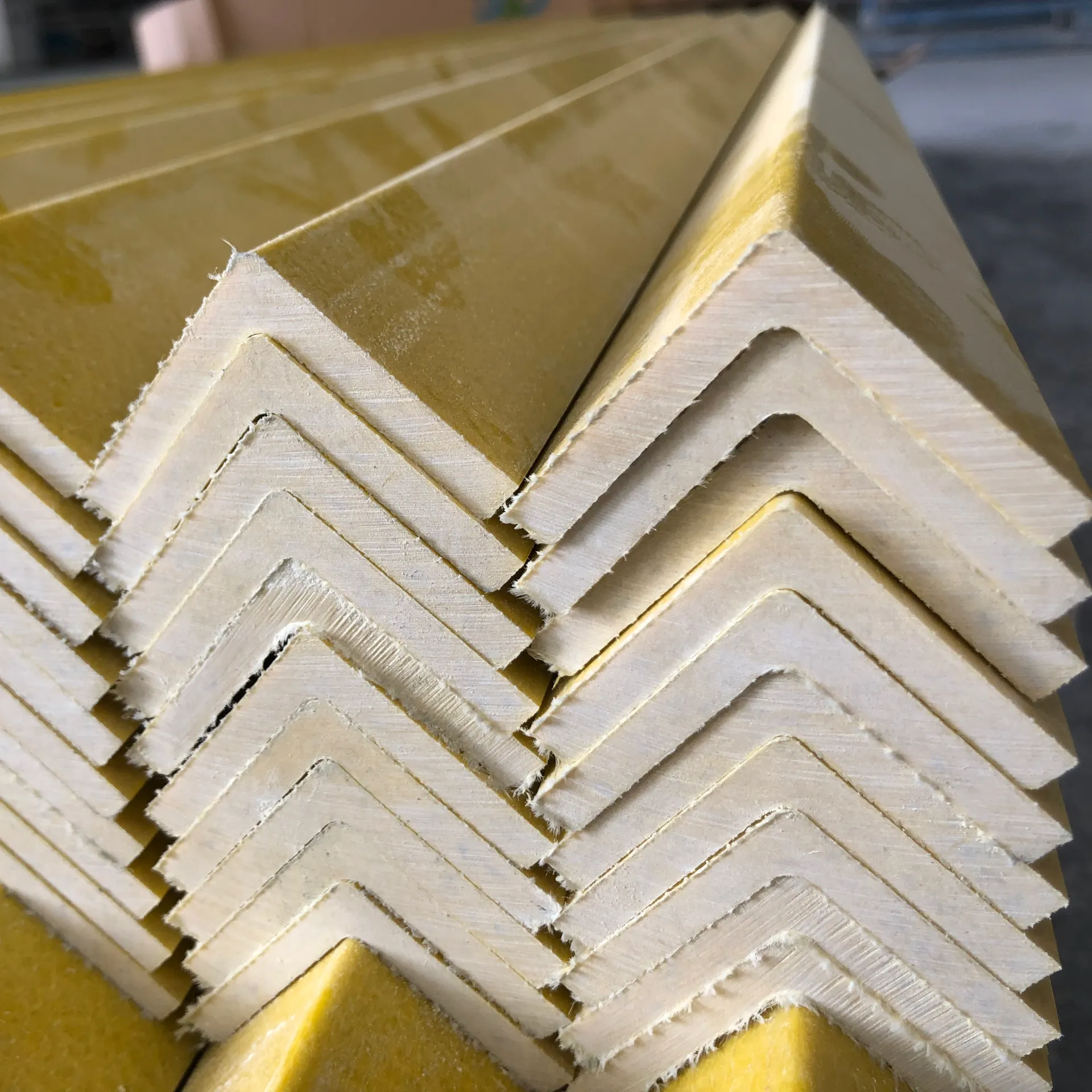

Pultruded FRP Grating A Strong and Versatile Solution

- Commercial Spaces Restaurants, grocery stores, and shopping centers utilize these gratings in kitchens, bathrooms, and entrance areas where moisture is prevalent.

Sectional tanks are a versatile and efficient way to store liquids in a secure and organized manner. These tanks are made up of individual panels that can be easily assembled on site, making them the perfect solution for situations where access is limited or space is restricted.

Reverse osmosis is a filtration process that uses a semi-permeable membrane to separate contaminants from water. When water is subjected to high pressure, pure water molecules are forced through the membrane, while dissolved solids, bacteria, and other impurities are left behind. This process results in two separate streams the purified permeate and the concentrated reject water. The efficiency of an industrial RO system can reach up to 99% in contaminant removal, making it a favored solution for water purification.

4. Fire Resistance Many GRP gratings are manufactured with fire-retardant properties, making them compliant with fire safety standards. This quality is essential for industries that require stringent safety measures, such as oil and gas, chemical plants, and manufacturing facilities.

Applications of Bar Grating

The Importance of Floor Drain Grating Ensuring Safety and Hygiene

Factors Influencing FRP Channel Prices

The Advancement of Grating in FRP Applications and Benefits

In conclusion, the importance of anti-slip treads in promoting safety and reducing the risk of slips and falls cannot be overlooked. As society becomes increasingly aware of the need for safety in shared spaces, anti-slip treads offer a straightforward and effective solution. The combination of functionality, aesthetic appeal, and compliance with safety regulations makes them an indispensable feature in any environment. By prioritizing safety through the installation of anti-slip treads, property owners can create safer spaces that protect individuals and foster peace of mind.

In many parts of the world, the availability and management of water resources are crucial issues. Reliable and efficient water storage solutions are needed to ensure that communities and industries can meet their water demands sustainably. One of the most effective solutions has been the use of galvanized sectional water tanks. These tanks offer a combination of durability, ease of installation, and adaptability, making them a popular choice in various applications.

At its core, a grating is an optical component that diffracts light into various beams based on its wavelength. Classic gratings are typically made from a single material, such as glass or plastic, featuring a periodic structure that can scatter light in specific directions. Composite gratings, however, integrate multiple materials with varying refractive indices, allowing more complex interactions with light. By cleverly designing these interactions, researchers can engineer gratings that offer improved efficiency, reduced losses, and enhanced spectral performance.

Durability and Longevity

The Functional Role of Grating Clamps

3. Customization Pressure vessel filters can be tailored to meet specific filtration needs. Different media types can be used depending on the contaminants present in the water source, allowing for customized filtration solutions.

The Importance of Water Treatment

1. Durability Fiberglass treads are highly resistant to impact, wear, and tear. Unlike traditional materials such as wood or metal, fiberglass does not rot, rust, or corrode, ensuring a longer lifespan. This durability translates into lower maintenance costs and less frequent replacements.

3. Durability FRP handrail systems are designed to withstand extreme weather conditions, including UV radiation, high temperatures, and freezing temperatures. This durability ensures that they maintain their integrity and aesthetics over time, making them a long-term investment for any facility.

frp handrail system

The Advantages of FRP Pultruded Sections in Modern Engineering

The Rise of Walkway FRP A Sustainable Solution for Modern Infrastructure

2. Material Quality Not all fiber tanks are created equal. The type of fiber used, the thickness of the material, and the overall design can impact the durability and, consequently, the price. High-quality tanks may come with a higher initial investment but can save money in the long term due to their longevity.

fiber water tank price

One of the key benefits of expanded metal floor grating is its superior strength-to-weight ratio. The manufacturing process, which involves cutting and stretching the metal sheet, creates a structural lattice that provides exceptional load-bearing capabilities while remaining lightweight. This characteristic not only facilitates easier handling and installation but also minimizes the overall load on support structures, enhancing the safety and stability of the flooring system.

Conclusion

The surface finish of fibreglass grating is another factor that can influence pricing. Options such as grit surface or smooth surface grating can vary in cost. Grit surfaces are often required in environments where slip-resistance is critical, making them slightly more expensive due to the additional manufacturing processes involved. Smooth surfaces, while less expensive, may not be suitable for all applications.

One of the primary benefits of FRP decking is its exceptional durability. Unlike traditional wood decking, which is prone to rot, splintering, and warping, FRP decking is resistant to moisture and harsh environmental conditions. This makes it an ideal choice for areas subject to extreme weather, such as coastal regions where saltwater can wreak havoc on conventional materials. The longevity of FRP decking means that homeowners and businesses can enjoy their outdoor spaces without the constant worry of maintenance and replacement.

Key Features of FRP Mini Mesh Grating

There are several types of machine guards, each designed for specific types of machinery and processes. Fixed guards are permanent and provide a solid barrier against moving parts. Adjustable guards can be modified for different tasks and machinery setups. Interlocking guards are designed to be connected to the machine’s operation; they ensure that the machine cannot operate if the guard is not properly positioned. Moreover, electronic safety systems exist, which use sensors. These systems can detect the presence of a worker in a hazardous area and immediately shut down the machinery to prevent an accident.

machine guarding systems

2. Design and Customization

The Versatility and Applications of Grating Floor Plates

Understanding the Pricing of FRP Gratings

When selecting decking material, it is vital to consider not only aesthetic qualities but also safety features. Treated wood can be a safe option if properly maintained, as it provides good traction. However, the porous nature of wood means it can absorb moisture, potentially leading to mold growth and degradation, which can compromise safety. Composite materials, on the other hand, are engineered for durability and mostly prevent splinters and decay, making them a safer choice in the long run.

What is a GRP Sectional Water Tank?

The production of FRP moulded gratings involves the use of a resin matrix, typically unsaturated polyester or vinyl ester, reinforced with fiberglass. This process not only enhances the structural integrity of the material but also provides it with excellent corrosion resistance. The moulding technique often used includes the pultrusion process, where the resin-soaked fiberglass is pulled through a heated die to create a strong, solid product. This method allows for the creation of complex designs and dimensions tailored to specific project requirements.

1. Durability One of the standout features of FRP vessels is their ability to resist corrosion and chemical attacks. This is particularly important in industries dealing with harsh chemicals, as FRP does not rust or corrode like traditional metal materials.

In summary, fiberglass fencing offers a compelling blend of durability, low maintenance, aesthetic versatility, environmental sustainability, security, and cost-effectiveness. Whether you are looking to enhance your property’s aesthetics, increase privacy, or ensure long-term value, fiberglass fencing could very well be the ideal solution. As homeowners continue to seek innovative materials for outdoor spaces, fiberglass stands out as a modern alternative that meets a variety of needs and preferences. Investing in fiberglass fencing is not just about surrounding your property; it’s about making a smart choice for today and the future.

3. Market Demand The demand for FRP channels fluctuates based on market conditions, project requirements, and strength specifications. When demand exceeds supply, prices tend to rise, while an oversupply can lead to price reductions. Seasonal construction trends and infrastructure projects can heavily influence this aspect.

One of the most significant advantages of GRP insulated water tanks is their superior insulation properties. The insulation layer minimizes heat transfer, maintaining the temperature of the stored water, whether hot or cold. This is particularly beneficial in areas with extreme weather conditions, where the temperature can significantly alter the water’s quality. With effective insulation, GRP tanks help in preserving the water's integrity, making them ideal for both potable and non-potable water applications.