Links:

-

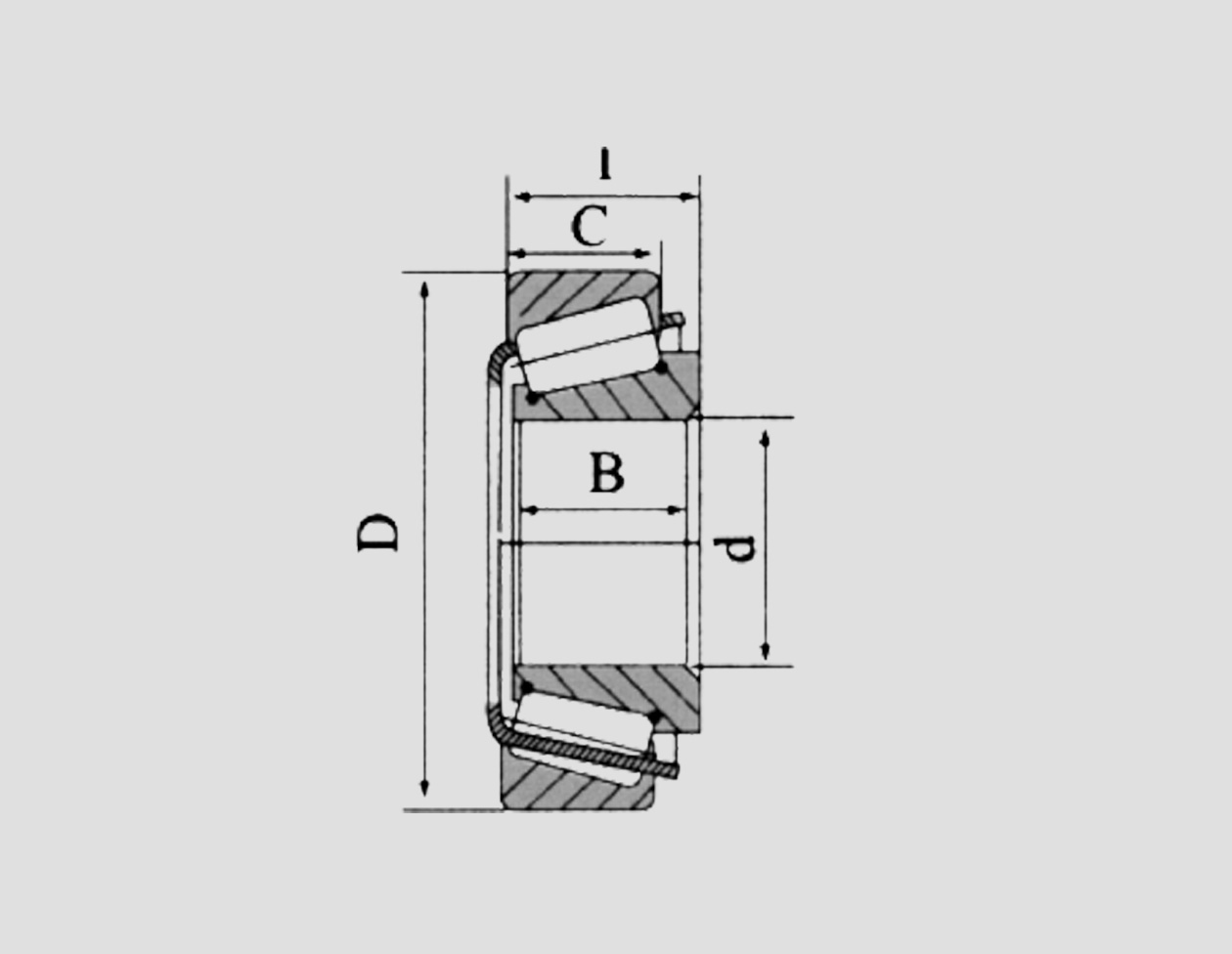

A taper bearing, also known as a tapered roller bearing, is a type of bearing that is designed to handle both radial and thrust forces. Taper bearings are commonly used in machinery that requires support for heavy loads at high speeds, such as automotive applications, industrial equipment, and agricultural machinery. In mining and construction, the 6310zz bearing is utilized in equipment such as crushers, conveyors, and pumps, where it can handle the tough conditions of these industries. The dimensions of the 6310zz bearing ensure that it can support heavy loads and operate smoothly in demanding applications, making it a reliable choice for various industrial needs. The 6003z bearing is a commonly used component in various mechanical devices and machines. Understanding its dimensions is crucial to ensuring proper fit and optimal performance. The selection of the right tapered roller bearing series is critical to ensure optimal performance and longevity. Factors like load, speed, temperature, and environmental conditions must be considered during the decision-making process. Regular maintenance and proper installation further contribute to the effective functioning of these bearings. * Reduced downtime The maintenance-free design of the bearing reduces downtime caused by maintenance or repairs

- Minimal Friction and Heat Generation: Cylindrical roller bearings are designed to reduce friction and heat generation, contributing to their efficiency and longevity. This characteristic is essential for maintaining the performance and reliability of machinery and equipment over extended periods of operation.

- Plain Bearings: Also known as bushings or sleeve bearings, plain bearings consist of a simple cylindrical design without rolling elements. They rely on a sliding motion to reduce friction and are often used in low-speed, high-load applications such as in agricultural machinery, construction equipment, and industrial machinery. Plain bearings are valued for their ability to handle heavy loads and operate in harsh environments.

The LM501349 bearing cone is designed to be easy to install and compatible with a wide range of shafts and housings. This versatility makes it a popular choice for a variety of applications, including automotive, agricultural, and industrial machinery. Whether it is used in a heavy-duty truck or a precision cutting machine, the LM501349 bearing cone provides smooth and reliable operation under heavy loads.. This versatility makes it an ideal choice for applications where the direction of the load may vary, such as in a conveyor belt or a machine tool

The LM501349 bearing cone is designed to be easy to install and compatible with a wide range of shafts and housings. This versatility makes it a popular choice for a variety of applications, including automotive, agricultural, and industrial machinery. Whether it is used in a heavy-duty truck or a precision cutting machine, the LM501349 bearing cone provides smooth and reliable operation under heavy loads.. This versatility makes it an ideal choice for applications where the direction of the load may vary, such as in a conveyor belt or a machine tool

lm501349. The LM501349 bearing cone is also capable of operating at high speeds without sacrificing performance, making it a top choice for applications that require precision and efficiency. Fafnir angular contact ball bearings are precision-engineered components used in a variety of industries, including automotive, aerospace, and manufacturing. These bearings are designed to provide high levels of stiffness and rigidity, making them ideal for applications that require precise positioning and smooth rotation. In conclusion, the spherical roller bearing size chart PDF is an essential resource for anyone involved in the selection, maintenance, or procurement of industrial bearings. Its systematic layout, precise measurements, and regular updates make it an indispensable asset in ensuring that the right bearing is selected for the job at hand. By utilizing this tool, professionals can avoid costly mistakes and extend the lifespan of their machinery, making it a wise investment for any operation dependent on rolling element bearings. Moreover, SolidWorks provides robust simulation capabilities that enable engineers to test their designs under different loads and speeds. For DGBBs, this means evaluating factors such as contact stresses between the balls and races, fatigue life, and heat generation. Such simulations are invaluable for iterating designs before physical prototypes are manufactured, saving time and reducing costs associated with trial-and-error approaches. In addition to the main dimensions, the 6807 bearing may have other specifications that are important for proper installation and operation. These may include the number of balls, cage material, and lubrication specifications. It is essential to consult the manufacturer's specifications for the exact dimensions and requirements of the bearing you are using. Design and Functionality Magnetic Bearings Theory Design and Application to Rotating Machinery When it comes to choosing the right ball bearings for your application, it is important to consider factors such as load capacity, speed, and precision. R8 2RS ball bearings are a popular choice due to their versatility and reliability. In addition to its performance benefits, the 6002zz ball bearing is also easy to install and maintain

ball bearing 6002zz. With its standardized dimensions and simple design, it can be quickly and easily replaced when needed, minimizing downtime and reducing maintenance costs. Low-price bearings are those that are offered at a lower cost compared to other bearings within the same category. These bearings are typically manufactured using cost-effective materials and processes, which may result in reduced performance or durability compared to higher-end bearings. However, it is important to note that not all low-price bearings are created equal, and some may still offer satisfactory performance for certain applications. The 6228 bearing also features a deep groove design, allowing it to accommodate not only radial loads but also a certain degree of axial loads in both directions

ball bearing 6002zz. With its standardized dimensions and simple design, it can be quickly and easily replaced when needed, minimizing downtime and reducing maintenance costs. Low-price bearings are those that are offered at a lower cost compared to other bearings within the same category. These bearings are typically manufactured using cost-effective materials and processes, which may result in reduced performance or durability compared to higher-end bearings. However, it is important to note that not all low-price bearings are created equal, and some may still offer satisfactory performance for certain applications. The 6228 bearing also features a deep groove design, allowing it to accommodate not only radial loads but also a certain degree of axial loads in both directions Axial cylindrical roller bearings are a type of rolling element bearing that is designed to withstand heavy loads and high speeds in a single direction. These bearings consist of a cylindrical outer ring, an inner ring, and a series of rollers that are arranged in a straight line along the axis of the bearing. The rollers are held in place by a cage, which ensures that they remain evenly spaced and properly aligned. In conclusion, the world of thrust bearings by size is a diverse one, with each size offering unique advantages and suited for particular applications. It underscores the importance of careful consideration when selecting a thrust bearing, as the right size can significantly impact efficiency, lifespan, and overall system performance. Whether in the intricate mechanisms of a wristwatch or the massive turbines of a power plant, thrust bearings, regardless of size, continue to be the unsung heroes ensuring seamless motion in our modern world. One of the primary advantages of thin tapered roller bearings is their ability to handle combined radial and axial loads. The conical roller and raceway configuration distributes the load evenly across the bearing, enhancing its load-bearing capacity and service life. Furthermore, they offer good alignment capabilities, absorbing misalignments that can occur in the shaft and housing. The Intricacies of Deep Groove Ball Bearings in SolidWorks Lubrication and Maintenance The 33118 bearing is a specific type of tapered roller bearing, a class of bearings that excel in handling combined radial and axial loads. It is designed with a unique configuration that enables it to distribute forces evenly, reducing stress points and enhancing durability. The '33118' in the name refers to its dimensional series, which indicates the size and load capacity of the bearing. This particular model typically features an outer diameter of 90mm, an inner diameter of 40mm, and a width of 25mm, making it suitable for a wide range of industrial applications. Moreover, the NJ206 bearing offers superior axial displacement capabilities, allowing for slight misalignments in the shaft and housing. This adaptability is crucial in real-world scenarios where perfect alignment might be challenging to achieve. It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration

Axial cylindrical roller bearings are a type of rolling element bearing that is designed to withstand heavy loads and high speeds in a single direction. These bearings consist of a cylindrical outer ring, an inner ring, and a series of rollers that are arranged in a straight line along the axis of the bearing. The rollers are held in place by a cage, which ensures that they remain evenly spaced and properly aligned. In conclusion, the world of thrust bearings by size is a diverse one, with each size offering unique advantages and suited for particular applications. It underscores the importance of careful consideration when selecting a thrust bearing, as the right size can significantly impact efficiency, lifespan, and overall system performance. Whether in the intricate mechanisms of a wristwatch or the massive turbines of a power plant, thrust bearings, regardless of size, continue to be the unsung heroes ensuring seamless motion in our modern world. One of the primary advantages of thin tapered roller bearings is their ability to handle combined radial and axial loads. The conical roller and raceway configuration distributes the load evenly across the bearing, enhancing its load-bearing capacity and service life. Furthermore, they offer good alignment capabilities, absorbing misalignments that can occur in the shaft and housing. The Intricacies of Deep Groove Ball Bearings in SolidWorks Lubrication and Maintenance The 33118 bearing is a specific type of tapered roller bearing, a class of bearings that excel in handling combined radial and axial loads. It is designed with a unique configuration that enables it to distribute forces evenly, reducing stress points and enhancing durability. The '33118' in the name refers to its dimensional series, which indicates the size and load capacity of the bearing. This particular model typically features an outer diameter of 90mm, an inner diameter of 40mm, and a width of 25mm, making it suitable for a wide range of industrial applications. Moreover, the NJ206 bearing offers superior axial displacement capabilities, allowing for slight misalignments in the shaft and housing. This adaptability is crucial in real-world scenarios where perfect alignment might be challenging to achieve. It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration

It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration It also features a cage, usually made from high-strength brass, that separates and guides the rollers, preventing them from touching each other and reducing noise and vibration nj 206 bearing. Understanding the dimensions of the 6002Z bearing is essential for selecting the right bearing for your specific application. By considering factors such as inner diameter, outer diameter, width, cage material, and lubrication type, you can ensure that the chosen bearing meets your requirements in terms of performance, reliability, and longevity. With this comprehensive guide, you can make an informed decision when selecting the 6002Z bearing for your next project. Step 4 Seating The interpretation of 6207 2rsr is largely dependent on the context in which it appears. It could be a typo or a code representing a specific message or concept. Without further information, it is challenging to assign a definitive meaning to this sequence Without further information, it is challenging to assign a definitive meaning to this sequence

nj 206 bearing. Understanding the dimensions of the 6002Z bearing is essential for selecting the right bearing for your specific application. By considering factors such as inner diameter, outer diameter, width, cage material, and lubrication type, you can ensure that the chosen bearing meets your requirements in terms of performance, reliability, and longevity. With this comprehensive guide, you can make an informed decision when selecting the 6002Z bearing for your next project. Step 4 Seating The interpretation of 6207 2rsr is largely dependent on the context in which it appears. It could be a typo or a code representing a specific message or concept. Without further information, it is challenging to assign a definitive meaning to this sequence Without further information, it is challenging to assign a definitive meaning to this sequence Without further information, it is challenging to assign a definitive meaning to this sequence Without further information, it is challenging to assign a definitive meaning to this sequence

Without further information, it is challenging to assign a definitive meaning to this sequence Without further information, it is challenging to assign a definitive meaning to this sequence 6207 2rsr. Understanding the Pricing Dynamics of 22215 bearings An In-depth Analysis On the other hand, the increased cost of bearings can also be passed down to consumers through higher equipment prices

6207 2rsr. Understanding the Pricing Dynamics of 22215 bearings An In-depth Analysis On the other hand, the increased cost of bearings can also be passed down to consumers through higher equipment prices Cylindrical roller bearings like the NUP type consist of the inner ring, outer ring, roller, and cage assembly. The rollers are cylindrical in shape, which allows for line contact with the raceways, reducing rolling friction and enabling higher speeds compared to spherical roller bearings. The use of high-quality materials, such as through-hardened steel, further enhances their resistance to wear and fatigue. Proper maintenance is crucial to ensure the longevity and performance of bearing 32211

Cylindrical roller bearings like the NUP type consist of the inner ring, outer ring, roller, and cage assembly. The rollers are cylindrical in shape, which allows for line contact with the raceways, reducing rolling friction and enabling higher speeds compared to spherical roller bearings. The use of high-quality materials, such as through-hardened steel, further enhances their resistance to wear and fatigue. Proper maintenance is crucial to ensure the longevity and performance of bearing 32211

The 51113 Bearing A Comprehensive Guide Proper maintenance is crucial for the longevity and performance of the 592A bearing. Regular inspection of the bearing for signs of wear, damage, or contamination is essential. Cleaning the bearing and surrounding areas to remove dirt and debris can help prevent premature failure. It is also important to ensure that the bearing is properly lubricated to reduce friction and wear. If any issues arise, such as unusual noise, vibration, or reduced performance, immediate action should be taken to prevent further damage. Common troubleshooting techniques include visual inspection, listening for unusual sounds, and measuring bearing temperature and vibration levels. LM603049 bearing is a type of tapered roller bearing commonly used in machinery and equipment. It is designed to support radial and axial loads in both directions, making it ideal for a wide range of applications. When incorporated into machinery, the 6006 2RS bearing becomes an unsung hero

6006 2rs bearing. It might power the rotary movement of a conveyor belt in a factory, spin the wheels of an electric scooter, or even support the rotation of a helicopter's critical components. In each scenario, the bearing operates silently, reliably, and efficiently, often going unnoticed by those who benefit from its functionality. Another area of innovation is in the field of magnetic bearing systems, where thrust ball bearing housings have been adapted to work in conjunction with magnetic levitation. This technology is particularly useful in high-speed applications, such as dental drills and turbomachinery, where traditional bearings would suffer from excessive wear and tear. 1. Automotive components The bearing is commonly used in automotive components such as wheel hubs, transmission systems, and suspension systems. However, it's important to note that cylindrical roller bearings have limited thrust load capacity due to their design. They are primarily designed for radial loads and may not perform optimally under significant axial loads They are primarily designed for radial loads and may not perform optimally under significant axial loads

6006 2rs bearing. It might power the rotary movement of a conveyor belt in a factory, spin the wheels of an electric scooter, or even support the rotation of a helicopter's critical components. In each scenario, the bearing operates silently, reliably, and efficiently, often going unnoticed by those who benefit from its functionality. Another area of innovation is in the field of magnetic bearing systems, where thrust ball bearing housings have been adapted to work in conjunction with magnetic levitation. This technology is particularly useful in high-speed applications, such as dental drills and turbomachinery, where traditional bearings would suffer from excessive wear and tear. 1. Automotive components The bearing is commonly used in automotive components such as wheel hubs, transmission systems, and suspension systems. However, it's important to note that cylindrical roller bearings have limited thrust load capacity due to their design. They are primarily designed for radial loads and may not perform optimally under significant axial loads They are primarily designed for radial loads and may not perform optimally under significant axial loads They are primarily designed for radial loads and may not perform optimally under significant axial loads They are primarily designed for radial loads and may not perform optimally under significant axial loads

They are primarily designed for radial loads and may not perform optimally under significant axial loads They are primarily designed for radial loads and may not perform optimally under significant axial loads what is cylindrical roller bearing. For applications requiring both radial and axial support, thrust cylindrical roller bearings or combined bearings can be employed. One of the key features of needle thrust roller bearings is their ability to accommodate both radial and axial loads simultaneously. This makes them ideal for applications where high load capacities and space limitations are a concern. The needle rollers in these bearings are much thinner than traditional rollers, allowing for a higher load capacity while maintaining a compact design.

what is cylindrical roller bearing. For applications requiring both radial and axial support, thrust cylindrical roller bearings or combined bearings can be employed. One of the key features of needle thrust roller bearings is their ability to accommodate both radial and axial loads simultaneously. This makes them ideal for applications where high load capacities and space limitations are a concern. The needle rollers in these bearings are much thinner than traditional rollers, allowing for a higher load capacity while maintaining a compact design. In addition to its performance benefits, the 6002zz ball bearing is also easy to install and maintain