Links:

-

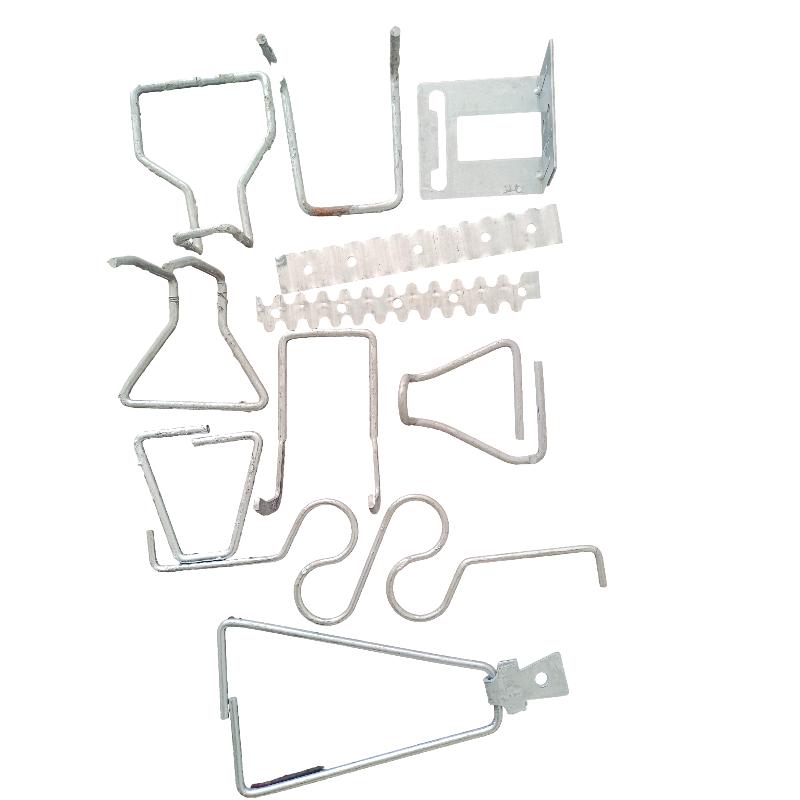

As we gaze upon the towering edifices and humble abodes that dot our skylines and landscapes, it's worth pondering the invisible threads—the masonry ties—that quietly hold together our physical world. They are not merely products of engineering but links between eras, connecting us to the past while securing our future in stone, brick, and mortar. Another advantage of the white grid wall organizer is its durability 2. Emsco Garden Cages - These cages are made from powder-coated steel and come in a variety of sizes. They are easy to assemble and provide excellent support for tomato plants. Green wire mesh fencing is a versatile and durable fencing option that provides security and aesthetic appeal to a variety of spaces. This type of fencing is commonly used in residential, commercial, and industrial applications due to its strength, durability, and cost-effectiveness. Tall plants support stakes A harmonious coexistence Stainless steel wire cloth, also known as stainless steel mesh or woven wire mesh, is a highly versatile material that has found its way into numerous industrial, commercial, and even domestic applications due to its exceptional properties. This unique fabric is essentially a woven network of fine wires, primarily made from various grades of stainless steel, such as 304, 316, and 317, offering an ideal blend of strength, durability, and corrosion resistance.

Use Of Wire Mesh In Concrete

5. Cost-Effective Despite its high quality, 1.6mm garden wire is relatively affordable compared to other types of gardening materials. This makes it an excellent choice for budget-conscious gardeners who still want to achieve great results. Before purchasing compression springs, it is important to consider factors such as the size, material, and load capacity of the springs. The size of the compression springs should be selected based on the application requirements, such as the amount of force that needs to be applied or the space available for the springs. The material of the compression springs should be chosen based on factors like temperature, corrosion resistance, and durability. Finally, the load capacity of the springs should be matched to the weight or force that the springs will need to support. Installation of 200mm wall ties requires precision and adherence to building regulations One of the key advantages of rotary springs is their ability to store and release energy in a controlled manner. When a rotary spring is wound up, it stores potential energy that can be released gradually as the spring unwinds. This allows for smooth and continuous rotation, which is important for many applications where jerky or abrupt movements would be problematic.Stainless steel reinforcement is another option that offers superior durability and resistance to corrosion. This type of reinforcement is often used in harsh environments or where high strength is required.

ladder joint reinforcement

Plaster Beading A Timeless Art Form

Lastly, don't forget about aesthetics. While functionality is key, a visually appealing fence can enhance the look of your property. Wood, for instance, can blend seamlessly into a rural setting, while a colorful plastic fence might add a touch of whimsy to a more urban or playful environment. Agriculture is another sector that greatly benefits from galvanizing wire. It is extensively used in making livestock fences, providing a sturdy yet cost-effective solution. The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time

The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time

The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time The zinc coating ensures that the fences remain rust-free, maintaining their integrity and safety features over time galvanizing wire. Overall, concrete wire mesh chair support is an essential component in modern construction and plays a vital role in ensuring the strength and durability of concrete structures. Its versatility, cost-effectiveness, and ability to provide structural reinforcement make it a popular choice for engineers and builders around the world. By incorporating wire mesh reinforcement into concrete structures, construction projects can benefit from improved strength, durability, and longevity, ultimately leading to safer and more resilient buildings and infrastructure. - **Case Study 3 Product Photography** - A product photographer uses wire grid photo display to display a variety of jewelry pieces, creating an eye-catching and visually appealing display. Top 20 Rated Tomato Cages A Comprehensive Review Secondly, half-inch wire mesh offers excellent visibility while maintaining privacy. The small openings in the mesh allow light to pass through while obstructing direct views of the interior. This feature makes it perfect for use in residential and commercial settings where natural light is desired but privacy is a concern. For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside

galvanizing wire. Overall, concrete wire mesh chair support is an essential component in modern construction and plays a vital role in ensuring the strength and durability of concrete structures. Its versatility, cost-effectiveness, and ability to provide structural reinforcement make it a popular choice for engineers and builders around the world. By incorporating wire mesh reinforcement into concrete structures, construction projects can benefit from improved strength, durability, and longevity, ultimately leading to safer and more resilient buildings and infrastructure. - **Case Study 3 Product Photography** - A product photographer uses wire grid photo display to display a variety of jewelry pieces, creating an eye-catching and visually appealing display. Top 20 Rated Tomato Cages A Comprehensive Review Secondly, half-inch wire mesh offers excellent visibility while maintaining privacy. The small openings in the mesh allow light to pass through while obstructing direct views of the interior. This feature makes it perfect for use in residential and commercial settings where natural light is desired but privacy is a concern. For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside

For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside half inch wire mesh. Similarly, in office buildings, half-inch wire mesh can be installed on balconies or terraces to create a secure yet open environment for employees to enjoy their breaks. Galvanized Tomato Cage Heavy-Duty and Practical

half inch wire mesh. Similarly, in office buildings, half-inch wire mesh can be installed on balconies or terraces to create a secure yet open environment for employees to enjoy their breaks. Galvanized Tomato Cage Heavy-Duty and Practical One of the key benefits of stake wire fencing is its versatility. It can be used to create a variety of different fencing designs and styles, making it a flexible option for homeowners looking to customize the look of their property. Whether you're looking for a simple, no-frills fence to keep pets contained or a more decorative option to enhance your curb appeal, stake wire fencing can be easily adapted to meet your needs.

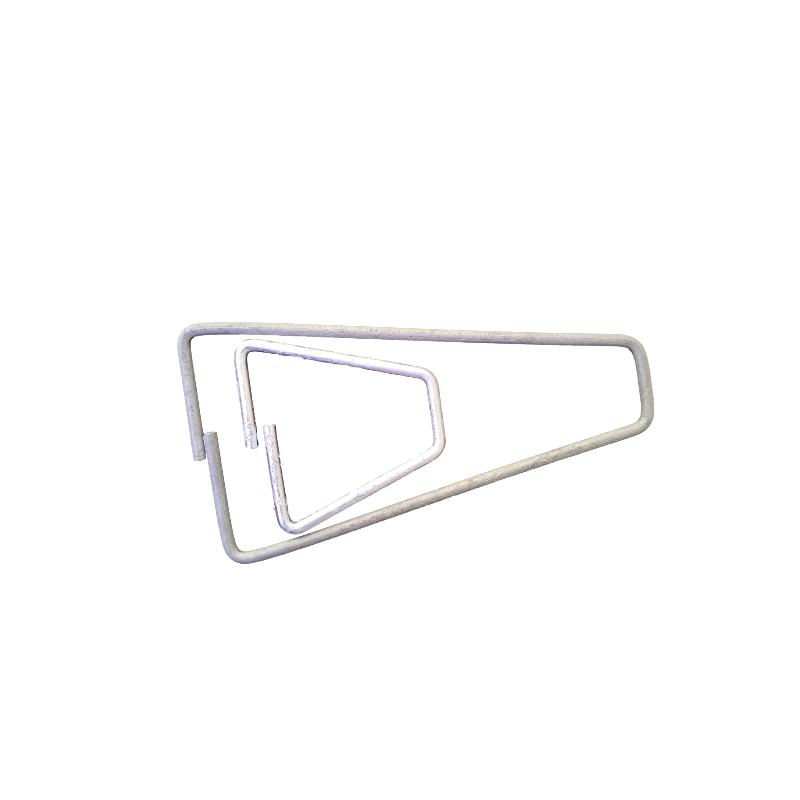

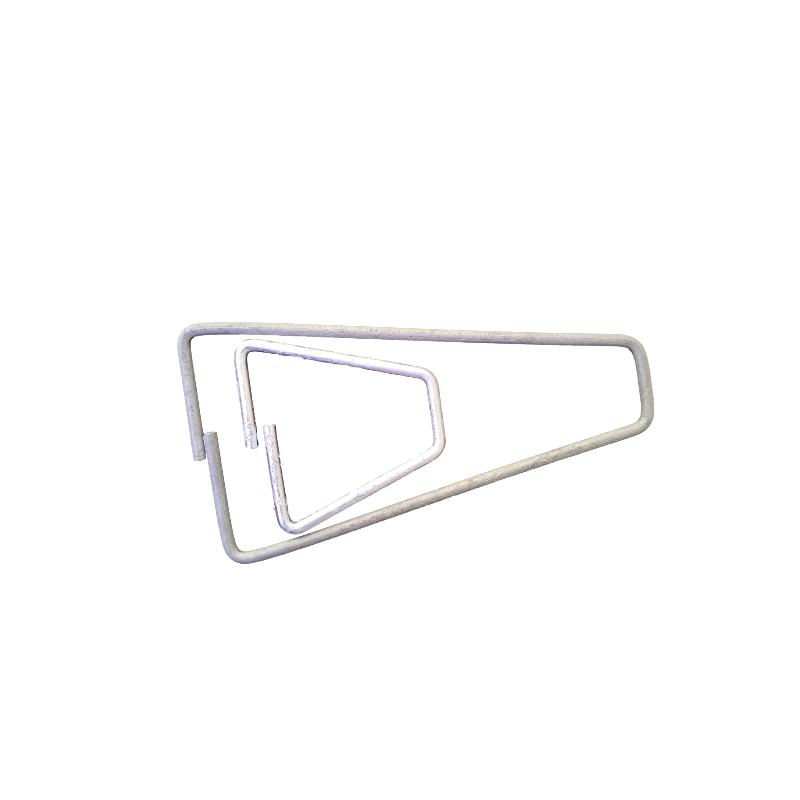

In some cases, wall ties may need to be replaced or reinforced due to changes in the building structure or the discovery of defects during inspections. This can be a costly and time-consuming process, especially if the ties are located in hard-to-reach areas or if extensive repairs are required. Regular maintenance and inspections can help catch potential issues early and prevent the need for major repairs in the future. What Are Coil Springs? In conclusion, welded wire mesh sheets are a highly adaptable and resilient material with a wide range of applications. Their strength, versatility, and customization options make them a preferred choice in construction, agriculture, industry, and architecture. As technology advances, we can expect even more innovative uses for this indispensable engineering marvel. A stud wall, typically made from timber or metal studs, is a lightweight construction method commonly used in residential and commercial buildings. It provides a versatile and efficient framework for interior and exterior walls. However, when a brick facade is added to this structure, brick ties come into the picture to provide the necessary strength and stability. Design Considerations 4. Construction Springs are used in construction equipment, such as bulldozers and pile drivers, to absorb shock and protect sensitive components. As the market for stucco wire continues to expand, innovations in manufacturing and application techniques are likely to emerge. Advancements in wire technology could lead to stronger, lighter, or more flexible meshes, further enhancing the appeal of stucco as a finish. Additionally, educational resources and tutorials may become more prevalent, empowering novices to tackle stucco projects with confidence. It's also worth noting that different materials and designs of brick ties can influence their effectiveness and spacing requirements. For example, stainless steel ties are commonly used due to their resistance to corrosion, while mechanical ties may be preferred in certain situations for their immediate load-bearing capacity.

In addition to their durability, corrugated metal wall ties are also easy to install. They can be quickly and securely attached to the walls using screws or other fastening methods, saving time and labor costs during the construction process. This ease of installation makes them a popular choice among contractors and builders.

corrugated metal wall ties

Installing brick reinforcement mesh is a relatively straightforward process that can be completed by skilled tradespeople or experienced DIYers. The mesh is typically attached to the surface of the brick wall using wall ties or clips, ensuring a secure and reliable connection. Once in place, the mesh can be covered with a layer of plaster, rendering, or other finishing materials to create a seamless and professional-looking surface. 1. Durability 1.6mm garden wire is made from high-quality materials that provide excellent durability and resistance to corrosion. This means that it can withstand harsh weather conditions, such as heavy rain and strong winds, without breaking or losing its shape. As a result, it can be used for an extended period without the need for replacement. Not only are these cages functional, but they are also visually appealing. Their sleek, metallic finish can complement any garden design, adding a touch of modernity to the traditional gardening setup. When not in use, they can be conveniently stored flat, saving precious garden space. Galvanized iron wire is also commonly used in the electrical industry

Green Mesh Fencing Panels

Another common use of galvanized wire is for industrial applications, such as in the construction industry. Galvanized wire can be used to reinforce concrete structures, providing additional strength and durability. It is also used in the manufacturing of wire mesh, which is commonly used for various applications, including security fencing, animal enclosures, and industrial filters. In agriculture, the 2x2 mesh serves as an efficient animal enclosure, providing a safe environment for livestock while enabling easy monitoring This process results in a flexible yet incredibly strong material that can be easily shaped and formed to fit a wide range of applications. WWF is commonly used in concrete reinforcement, but it also finds applications in soil stabilization, earth retaining structures, and even as a barrier material. Beyond functionality, the finish of the wire can imbue a piece with its own unique character. A polished finish offers a sleek, modern look, whereas a rustic or antiqued finish provides a vintage charm. Some wires even come pre-coated with enamel or plated with gold to add a luxurious touch. These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike

This process results in a flexible yet incredibly strong material that can be easily shaped and formed to fit a wide range of applications. WWF is commonly used in concrete reinforcement, but it also finds applications in soil stabilization, earth retaining structures, and even as a barrier material. Beyond functionality, the finish of the wire can imbue a piece with its own unique character. A polished finish offers a sleek, modern look, whereas a rustic or antiqued finish provides a vintage charm. Some wires even come pre-coated with enamel or plated with gold to add a luxurious touch. These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike

These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike wholesale wire for jewelry making. The humble chicken netting fence, a structure often underestimated, stands as a testament to the ingenuity and practicality that agricultural advancements have bestowed upon modern poultry husbandry. This unassuming barrier is not merely a partition; it embodies the principles of safety, efficiency, and sustainability that are paramount in today’s farming practices.

wholesale wire for jewelry making. The humble chicken netting fence, a structure often underestimated, stands as a testament to the ingenuity and practicality that agricultural advancements have bestowed upon modern poultry husbandry. This unassuming barrier is not merely a partition; it embodies the principles of safety, efficiency, and sustainability that are paramount in today’s farming practices. Rolled steel bars are indispensable in reinforcing concrete structures. These bars come in two main types: hot rolled and cold rolled. Hot rolled steel bars are processed at high temperatures, making them easier to work with and ideal for large-scale construction projects. Cold rolled steel bars, on the other hand, are processed at room temperature, resulting in a smoother finish and higher tensile strength. Cold rolled steel bars are perfect for applications requiring precise dimensions and superior strength.

Despite its many benefits, the maintenance of a galvanized wire fence is relatively low. Regular cleaning to remove dirt and debris is usually sufficient, with occasional touch-ups of the zinc coating if needed. This low maintenance requirement further contributes to its overall cost-effectiveness.