Links:

- Choose packaged foods that are certified organic, whenever possible. These products must meet strong standards that protect consumers from exposure to potentially harmful additives. Certified organic foods cannot contain artificial colors such as titanium dioxide.

- Choose packaged foods that are certified organic, whenever possible. These products must meet strong standards that protect consumers from exposure to potentially harmful additives. Certified organic foods cannot contain artificial colors such as titanium dioxide.

- cis-5-Dodecenyl acetate

How pure TiO2 is extracted from titanium-containing molecules depends on the composition of the original mineral ores or feedstock. Two methods are used to manufacture pure TiO2: a sulphate process and a chloride process.

In recent years, the manufacturing industry has come under scrutiny for its environmental impact. The production process of titanium dioxide is no exception. Traditional methods often involve energy-intensive procedures and the use of chemicals that can pose risks to both human health and the environment. As awareness grows about these issues, manufacturers are compelled to reevaluate their processes and adopt more eco-friendly techniques. The pharmaceutical industry, for instance, utilizes Zinc Barium Sulphate in the formulation of tablets and capsules due to its ability to act as a filler or binder. It also finds use as an absorbent in medical applications. In the realm of paints and coatings, it serves as a, enhancing the durability and opacity of the final product.

This property not only improves air quality around buildings but also helps maintain the cleanliness of the painted surface by breaking down dirt and grime This property not only improves air quality around buildings but also helps maintain the cleanliness of the painted surface by breaking down dirt and grime

This property not only improves air quality around buildings but also helps maintain the cleanliness of the painted surface by breaking down dirt and grime This property not only improves air quality around buildings but also helps maintain the cleanliness of the painted surface by breaking down dirt and grime titanium dioxide for interior and exterior wall paint material factories. Another important factor to consider when choosing a TiO2 supplier is their commitment to sustainability and environmental responsibility

titanium dioxide for interior and exterior wall paint material factories. Another important factor to consider when choosing a TiO2 supplier is their commitment to sustainability and environmental responsibility

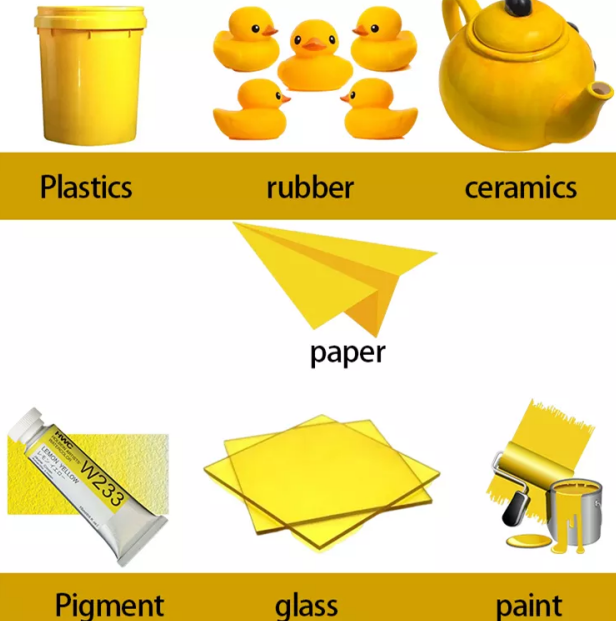

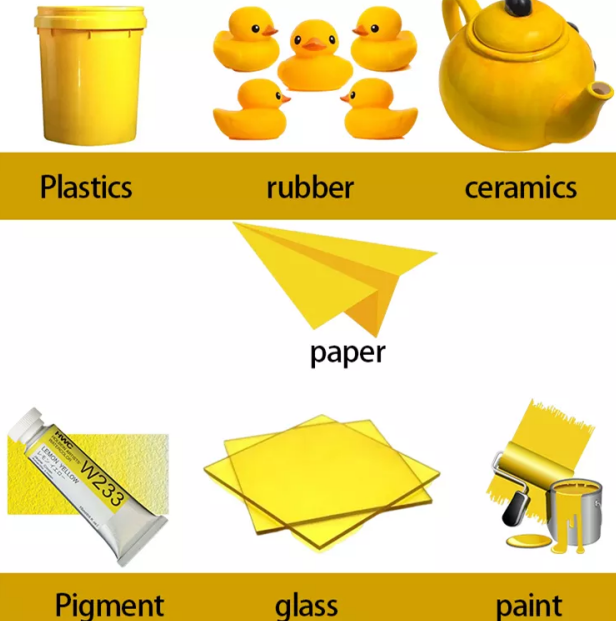

excellent white tio2 supplier. The production of TiO2 can have significant environmental impacts, so it is crucial to work with a supplier that prioritizes sustainable practices and minimizes their environmental footprint. An excellent white TiO2 supplier will have certifications and initiatives in place to demonstrate their commitment to sustainability and responsible sourcing. In the plastics industry, titanium dioxide is added to polymer resins to enhance their whiteness and brightness. This is particularly important for products that are exposed to sunlight or harsh environmental conditions, as the pigment helps to prevent yellowing and deterioration over time. TiO2 is also used in food packaging materials to create a white appearance that is appealing to consumers. In addition to its optical properties, rutile titanium dioxide is also known for its excellent durability and weather resistance. This makes it a popular choice for outdoor applications, such as in construction materials and automotive coatings. Its UV-absorbing properties also make it a valuable ingredient in sunscreens and other skincare products

rutile titanium dioxide manufacturer.

There seems to be a lot of misunderstanding about titanium dioxide, which can be used as a colorant in foods. While headlines may suggest titanium dioxide is a health concern, scientific research has actually shown titanium dioxide to be safe. So what is it used for and why is it used? Read on to learn more!

Our manufacturing process for lithopone involves carefully selecting high-quality raw materials and utilizing advanced technology to ensure consistent and superior product quality. We take great pride in our state-of-the-art facilities and skilled workforce that help us maintain strict quality control measures throughout the production process.Above 20%, it is recommended to replace 1 kg TiO2 with 1.3 kg of Lithopone 30%.

What is the FDA limit for titanium dioxide?

Titanium dioxide is an inert earth mineral used as a thickening, opacifying, and sunscreen ingredient in cosmetics. It protects skin from UVA and UVB radiation and is considered non-risky in terms of of skin sensitivity. Because it is gentle, titanium dioxide is a great sunscreen active for sensitive, redness-prone skin. It’s great for use around the eyes, as it is highly unlikely to cause stinging.

In the warehouse, proper storage facilities are critical to prevent dust accumulation and potential fire hazards. This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area

This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards. When selecting a supplier of titanium dioxide for nitrile gloves, it is crucial to consider several factors. These include

wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards. When selecting a supplier of titanium dioxide for nitrile gloves, it is crucial to consider several factors. These include The conventional surface treatment methods of titanium alloy include glow discharge plasma deposition, oxygen ion implantation, hydrogen peroxide treatment, thermal oxidation, sol-gel method, anodic oxidation, microarc oxidation, laser alloying, and pulsed laser deposition. These methods have different characteristics and are applied in different fields. Glow discharge plasma deposition can get a clean surface, and the thickness of the oxide film obtained is 2 nm to 150 nm [2–8]. The oxide film obtained from oxygen ion implantation is thicker, about several microns [9–14]. Hydrogen peroxide treatment of titanium alloy surface is a process of chemical dissolution and oxidation [15, 16]. The dense part of the oxide film is less than 5 nm [17–21]. The oxide film generated from the thermal oxidation method has a porous structure, and its thickness is commonly about 10-20 μm [22–25]. The oxide film from the sol-gel method is rich in Ti-OH, a composition that could induce apatite nucleation and improve the combining of implants and bone. It has a thickness of less than 10 μm [26–28]. Applied with the anodic oxidation method, the surface can generate a porous oxide film of 10 μm to 20 μm thickness [29–31]. Similarly, the oxide film generated from the microarc oxidation method is also porous and has a thickness of 10 μm to 20 μm [32, 33].

A1:

1345-05-7

3. Ceramics

For years scientists have raised concerns about the potential toxicity of titanium dioxide.

Production Process of Lithopone Whether you are a small business or a large corporation, our factory can cater to all your lithopone needs. We have the capabilities to handle bulk orders and deliver them promptly to your desired location. With our reliable logistics network, you can trust us to deliver your lithopone B301 and B311 on time, every time.Some websites maintain titanium dioxide is inferior to zinc oxide, another mineral sunscreen ingredient whose core characteristics are similar to those of titanium dioxide. The reality is that titanium dioxide is a great broad-spectrum SPF ingredient and is widely used in all manner of sun-protection products. What gets confusing for some consumers is trying to decipher research that ranks sunscreen ingredients by a UV spectrum graph. By most standards, broad-spectrum coverage for sunscreen ingredients is defined as one that surpasses 360 nanometers (abbreviated as “nm” - how the sun’s rays are measured). Titanium dioxide exceeds this range of protection, but depending on whose research you read, it either performs as well as or slightly below zinc oxide.

In conclusion, lithopone 28B301 and 30B311 are versatile pigments with a wide range of applications in various industries. Understanding their properties, applications, and manufacturing processes can help manufacturers make informed decisions when selecting the right pigment for their specific needs. Physical and Chemical Properties Lithopone is a white pigment that is widely used in various industries such as paint, ink, plastics, and paper. It is a mixture of barium sulfate and zinc sulfide, and is known for its excellent covering power and brightness. Titanium dioxide, commonly known as titanium white, is a versatile and widely used pigment in various industries. It is renowned for its excellent whiteness, opacity, and chemical stability, making it an essential component in paints, plastics, coatings, and other applications. The production of titanium dioxide involves several complex processes, and understanding these processes is crucial for anyone interested in the industry.Chloride process. This process requires a high titanium feedstock. Rutile is reacted with hydrochloric acid to produce titanium tetrachloride, which can be hydrolyzed with steam or oxidized with air to render the dioxide. A rutile form of titanium dioxide is obtained.

Subsequently, barium sulfate, another crucial ingredient, is derived from barite, a naturally occurring mineral rich in barium. The barium sulfate is then mixed with the synthesized zinc sulfide in precise proportions to create the desired lithopone pigment. The mixture undergoes a series of processes, including grinding and classification, to achieve the required particle size distribution and enhance its performance characteristics.To be added to food, this additive must achieve 99% purity. However, this leaves room for small amounts of potential contaminants like lead, arsenic, or mercury (1Trusted Source).

Caiqing Technology is a specialized production of titanium dioxide enterprises, the company will titanium dioxide this product as the company's core industry. Caiqing technology with the regional sulfuric acid scale advantage, with titanium ore as raw material, actively introduce the top technology at home and abroad, the use of mature sulfuric acid titanium dioxide production process to produce high quality rutile titanium dioxide products and anatase titanium dioxide products, its production process, equipment and automation control are in the domestic leading level. Caiqing technology will pay attention to the technology of titanium dioxide research and development, to provide high-quality titanium dioxide for the paint industry to contribute their own strength. Thank the China Paint Association visit, we must live up to the trust of Caiqing technology titanium dioxide brand! Thanks!

In conclusion, the determination of sulphate as TiO2 manufacturers is a critical process that ensures the quality and purity of their products. By using sensitive and reliable analytical techniques and following strict protocols, manufacturers can accurately quantify sulphate levels and maintain high standards of product quality. Titanium Dioxide A Versatile Chemical Compound with Numerous ApplicationsIt offers several advantages in various applications. Its excellent opacity and brightness make it a popular choice in the production of paints, coatings, and printing inks, providing a cost-effective alternative to titanium dioxide. Lithopone's chemical stability enhances its durability in outdoor environments, making it suitable for outdoor coatings. Additionally, its low reactivity and compatibility with other pigments contribute to its versatility. Beyond coatings, lithopone finds utility in plastics, rubber, and paper industries. Overall, its multifaceted advantages and broad applications underscore this compound's significance in diverse industrial sectors.