Links:

2. Styles of Motorcycle Belts

El cinturón de transmisión es un elemento esencial en el funcionamiento de muchos sistemas automotrices. Su correcto mantenimiento no solo asegura un rendimiento eficiente, sino que también contribuye a la seguridad y la fiabilidad del vehículo. No escatimes en el cuidado de esta importante pieza y asegúrate de realizar un mantenimiento adecuado para disfrutar de un viaje seguro y placentero.

- Use Quality Parts When replacements are necessary, opting for high-quality parts—either OEM or reputable aftermarket—can make a significant difference.

Another significant benefit is their versatility. V ribbed belt pulleys are used across a wide range of industries, from automotive to manufacturing. In the automotive sector, they are utilized in both gasoline and diesel engines, while in industrial settings, they can power conveyor systems, pumps, and more. This adaptability makes them a valuable component in diverse applications.

In automotive applications, the V-belt B60 is often utilized in engine systems to drive various components, including the alternator, water pump, and air conditioning compressor. Its reliability and efficiency are crucial for maintaining the optimal performance of these systems.

v-belt b60

The Toyota HiAce has long been a favored vehicle among businesses and families due to its reliability, spaciousness, and versatility. However, like any vehicle, it requires routine maintenance to ensure optimal performance. One of the crucial components that often gets overlooked during maintenance is the V-belt. In this article, we’ll delve into the significance of V-belts specifically for the Toyota HiAce, and how choosing the right V-belt can lead to improved performance and longevity of the vehicle.

V-belt manufacturers are pivotal in the supply chain, providing high-quality belts that meet stringent industry standards. The efficiency and reliability of machinery depend heavily on these components, emphasizing the need for trustworthy manufacturers. V-belt manufacturers not only focus on production but also adhere to rigorous testing protocols, ensuring that each belt can withstand the demands of its intended application.

5. Quiet Operation Due to their design, synchronous belts operate quietly. This feature is especially valuable in applications where noise reduction is a priority, such as in robotics and HVAC systems.

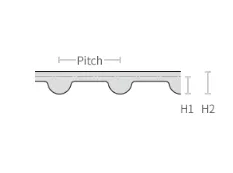

synchronous belt

Conclusion

Innovative Features

Investing in an OEM timing belt is not just about compliance; it is about ensuring the longevity and reliability of your vehicle's engine. Whether you're a casual driver or a performance enthusiast, the importance of quality cannot be overstated. The potential cost of an engine failure due to a problematic timing belt is far greater than the price of an OEM replacement.

5. Electrical Parts The rise of electric and hybrid vehicles has transformed the electrical components used in cars. Batteries, electric motors, and regenerative braking systems are essential in these vehicles, marking a shift towards sustainable transportation solutions.

Cogged belts may not be the first component that comes to mind when discussing mechanical engineering, but their impact on efficiency and reliability is undeniable. With their unique design, versatile applications, and numerous advantages, cogged belts prove to be indispensable in the world of power transmission. As technology continues to advance, the demand for high-performance cogged belts will likely grow, further solidifying their status as one of the essential elements in modern machinery. For engineers and manufacturers alike, recognizing the value of cogged belts is crucial in designing systems that are both efficient and effective.

As correias de poliuretano são uma escolha popular devido à sua durabilidade e resistência a temperaturas extremas e produtos químicos. Elas são frequentemente utilizadas em sistemas de transporte e em indústrias onde a resistência ao desgaste é crítica. Além disso, as correias de poliuretano oferecem uma excelente aderência e são menos propensas a esticar, o que aumenta a eficiência do funcionamento das máquinas.

Comparison with Traditional V-Belts

Understanding the Hyundai H100 V-Belt A Comprehensive Guide

In conclusion, V-ribbed belt pulleys offer an effective and versatile solution to power transmission challenges across numerous industries. Their efficiency, compact design, and durability make them indispensable in both automotive and industrial applications. As technology advances and demands for energy efficiency continue to rise, the role of V-ribbed belt systems is likely to expand, reinforcing their significance in modern engineering and manufacturing practices.

Variable drive belts play a critical role in the mechanics of various machinery and vehicles. These belts are designed to manage power transmission between the engine and its components, adjusting their functionality according to the mechanical demands. Whether it’s in automotive applications, industrial machinery, or agricultural equipment, understanding the intricacies of variable drive belts can greatly enhance performance and efficiency.

Conclusion

4. Environmental Conditions Factors such as temperature, humidity, and exposure to chemicals or abrasives can affect the performance and lifespan of a timing belt. Selecting a belt designed for the specific operating environment is essential.

The working principle of a belt conveyor is relatively straightforward. The belt moves in a loop around the pulleys, allowing items placed on it to be transported from the starting point to the designated endpoint. The speed of the belt can be adjusted based on the operational requirements, and the inclination of the conveyor can also be modified to accommodate various layouts, including horizontal, inclined, or declined positions.

In the realm of automotive engineering, the efficiency and functionality of the vehicle are significantly impacted by various components, among which the V-ribbed belt and PK belt are indispensable. These belts play a critical role in ensuring that the engine and other systems operate smoothly. Understanding their design, function, and applications is vital for anyone involved in vehicle maintenance or automotive engineering.

.

2. Interchangeability V-belts come in various sizes, materials, and designs, making interchangeability crucial. Standards define dimensions, profiles, and performance characteristics, allowing users to replace belts from different manufacturers without compromising functionality. This interchangeability simplifies maintenance and reduces downtime in industrial applications.

One of the main advantages of rubber V-belts is their flexibility. This flexibility allows them to handle significant loads and adapt to various operating conditions without breaking or stretching excessively. Furthermore, rubber V-belts exhibit excellent resistance to wear and tear, which contributes to their longevity and reduces the frequency of replacements.

rubber v belts

1. Locate the Tensioner The serpentine belt is held under tension by a belt tensioner. Use a wrench or a belt tensioner tool to relieve this tension.

A timing belt is a reinforced rubber belt that connects the crankshaft to the camshaft in an internal combustion engine. Its primary function is to synchronize the rotation of these shafts, ensuring that engine valves open and close at the correct times during each cylinder's intake and exhaust strokes. A double timing belt, as the name implies, features two sets of teeth or tracks, which provide improved engagement with the gears it drives. This design enhances stability and reduces the risk of slippage, which is crucial for maintaining optimal engine performance.

Conclusion

Conclusion

Features of Poly V-Belts

Signs of a Failing Timing Belt

In the realm of mechanical systems, flat belts play a pivotal role, providing an efficient means of transmitting power between various components. From industrial machinery to DIY projects, flat belts come with various specifications and designs tailored for diverse applications. This article aims to delve into the world of flat belts for sale, highlighting their features, types, and tips for choosing the right one for your needs.

Components of Variable Belt Drives

- Automotive In vehicles, 3pk belts are often employed in engines to drive components like water pumps, alternators, and air conditioning compressors. Ensuring these belts are in good condition is crucial for vehicle performance.

3. Reduced Wear and Tear Traditional belt systems can experience excessive wear due to sudden speed changes and operational stress. Variable speed belts, on the other hand, allow for gradual transitions, resulting in less strain on both the belt and associated components. This longevity translates to lower maintenance costs and fewer replacements, further enhancing cost-effectiveness.

Applications of Poly-V TB2 Belts

टायमिंग बेल्ट का महत्व

The Essential Role of V-Belt Manufacturers in Modern Industry

- Manufacturing Equipment Timing belts are used in conveyor systems and other machinery for precise motor control. These conveyors are essential for transporting goods, packaging products, and automating assembly lines.

The globalization of the automotive industry has also had profound effects on auto parts. Manufacturers often source components from various countries, creating a complex supply chain. International cooperation has become crucial for maintaining quality and efficiency, as companies strive to combine cost-effectiveness with cutting-edge technology. This interconnectedness allows manufacturers to benefit from advancements in materials and design, ultimately leading to better vehicles for consumers.

auto auto parts

Dây curoa quạt là một phần không thể thiếu trong việc duy trì hiệu suất và độ bền của xe Mercedes. Bằng cách thực hiện các biện pháp bảo dưỡng đúng cách và kịp thời, bạn sẽ giúp xe của mình luôn hoạt động trong tình trạng tốt nhất và đảm bảo an toàn khi lái xe. Hãy luôn chú ý đến tình trạng của dây curoa quạt để có những chuyến đi an toàn và thú vị.

3. Home Appliances Found in various devices, such as washing machines and lawn equipment, where reliability and durability are essential.

One of the significant advantages of working with established V-belt manufacturers is their capacity to provide custom solutions. Many companies have unique requirements based on their specific machinery and operational conditions. Customized V-belts can be designed to fit unique pulley sizes, heights, and even specific load-bearing requirements. This adaptability not only enhances efficiency but also minimizes the risk of equipment failure, ultimately leading to reduced downtime and maintenance costs.

- Agricultural Equipment In farming machinery, TB2 Poly V belts are crucial for driving equipment such as combines and tractors. They enhance performance and reduce maintenance needs, directly impacting productivity in agricultural operations.

2. Enhanced Performance A new serpentine belt can also improve the performance of your vehicle. Older belts can stretch, wear down, or crack, leading to slippage and reduced efficiency in powering essential components. A fresh serpentine belt maintains optimal tension, ensuring that all driven accessories operate at peak efficiency, which can improve fuel economy and enhance overall vehicle performance.

new serpentine belt

One of the most compelling reasons for importing used auto parts is the cost savings involved. New car parts are often prohibitively expensive, particularly for older or rare vehicles. Used parts can be significantly cheaper, allowing car owners to perform necessary repairs without breaking the bank. This cost-effectiveness is especially beneficial for those who rely on older vehicles, which may require frequent repairs. Importing used parts from overseas can further enhance these savings, as prices can vary significantly between regions.

The 5PK belt is a vital component in both automotive and industrial applications. Understanding belt sizes and knowing how to choose the right one can significantly impact the efficiency and longevity of your machinery. By taking the time to measure and consult with professionals, you can ensure optimal performance and reduce the likelihood of costly breakdowns. Whether you are a mechanic or a maintenance manager, knowing about 5PK belts will empower you to make informed decisions that enhance your operations.

Conclusion

One key characteristic of rubber canvas flat belts is their flat surface, which allows for efficient material movement. Unlike V-belts or other belt types designed for pulleys, flat belts can operate over a wide range of pulley diameters and are especially effective in applications that require a linear movement. Additionally, their flat design minimizes slippage, ensuring a consistent power transfer and reducing the likelihood of misalignment.

The Versatility and Durability of Leather Flat Belts