Links:

-

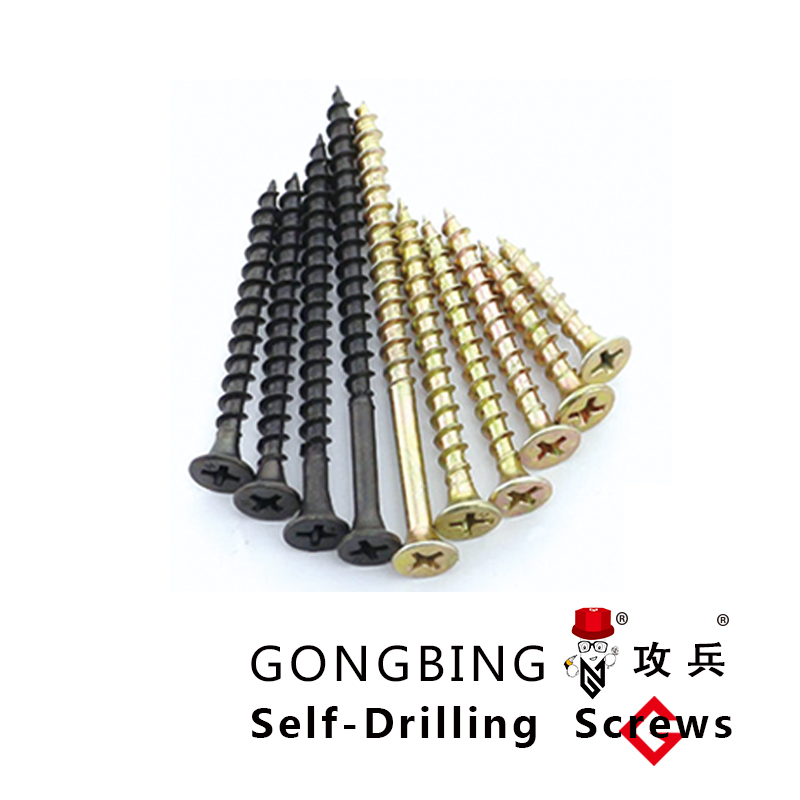

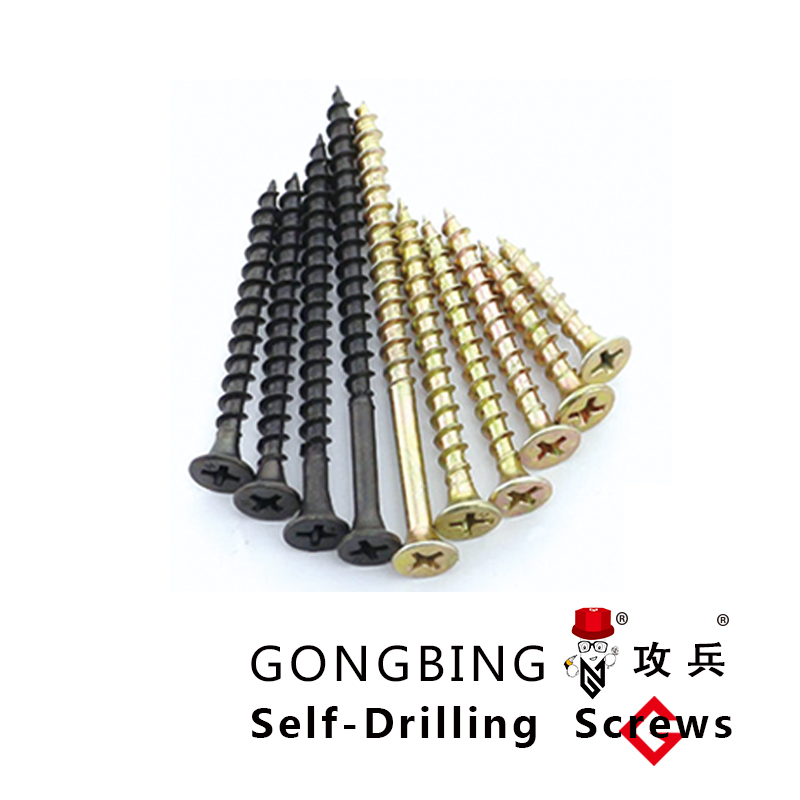

Self-drilling screws, also known as Tek screws, eliminate the need for pre-drilling, saving time and effort on site. They feature a sharp point and unique thread design that allows them to pierce through the UPVC surface without damaging it, while also providing a secure hold. TheUPVC,。 One of the key benefits of hex tek screws is their superior holding power compared to traditional screws. The hexagonal head provides a larger contact area with the material being fastened, resulting in a more secure and stable connection. This makes hex tek screws ideal for heavy-duty applications that require a strong and reliable fastening solution.

The versatility of these bolts allows them to be manufactured in various sizes and specifications, accommodating the specific needs of each project. They can be produced as anchor bolts, tie rods, or any other configuration required to meet the engineering demands.

In conclusion, resin bolt fixings offer a range of benefits and features that make them an attractive alternative to traditional metal fixings. By following the proper usage guidelines and considering the specific requirements of your application, you can ensure the successful integration of these fasteners into your project. Introduction

In the United States, ASTM (American Society for Testing and Materials) standards define the specifications for shear studs. For instance, ASTM A108 has specifications for carbon steel shear studs, which are often used due to their strength and ease of welding. The tolerances for size are usually specified to ensure consistency in performance and reliability in construction.

Conclusion

2. Precast Concrete In precast concrete applications, resin anchor studs facilitate the connection of precast elements with existing structures, allowing for easy adjustment and secure fastening.

Rigid insulation nails are typically made of durable materials such as galvanized steel or stainless steel to ensure they can withstand the elements and provide long-lasting support for the insulation board. They are available in a variety of lengths to accommodate different thicknesses of insulation board and come with a washer or base plate to help distribute the weight of the insulation evenly and prevent it from pulling away from the substrate over time.

When it comes to securing objects to masonry or concrete surfaces, nail expansion anchors are a popular choice among contractors and DIY enthusiasts alike. These anchors are designed to provide a reliable and durable solution for attaching various fixtures, fittings, and equipment to solid substrates. In this article, we will explore the functionality, types, installation procedures, advantages, and considerations associated with nail expansion anchors.

In conclusion, the 5 8% wedge bolt is an essential fastener in the mechanical engineering landscape. Its unique design and numerous advantages make it a preferred choice for securing connections in a wide range of applications. However, like any fastener, proper material selection, installation, and maintenance are critical for maximizing its performance. As industries continue to evolve, the importance of reliable and efficient components like the 5 8% wedge bolt will remain at the forefront, contributing to the advancement of technology and engineering. Understanding and utilizing such components is vital for engineers, manufacturers, and operators alike, ensuring that they can meet the demands of modern machinery and construction while prioritizing safety and efficacy.

However, proper usage is crucial. Always ensure that the material you're working with can handle the screw's length and force. Over-tightening can cause damage, while under-tightening may lead to loose connections. Using a drill with adjustable torque control can help prevent over-tightening. Simply put, steel stud wall bracing refers to the use of metal strapping or beams to reinforce the vertical and horizontal components of walls made of wood or masonry. These braces are strategically placed to distribute loads evenly across the wall system, reducing the risk of deformation or failure under heavy loads such as wind or seismic forces. In summary, countersunk screws are a versatile and useful fastener that can be used in a wide range of applications. By understanding their proper use, care, and maintenance, you can ensure that your countersunk screws provide a strong and secure fastening for many years to come.Advantages of the 7% 2016 Self-Drilling Screw

One of the key advantages of using hex head self-drilling screws is their versatility. They are available in various sizes, lengths, and materials, including stainless steel, zinc-plated steel, and other alloys, making them suitable for a wide range of applications. Whether it’s fastening metal roofing panels, securing wood to metal frames, or assembling machinery, these screws can be tailored to meet specific needs.

hex head self drilling

Understanding the 5 8% Wedge Bolt A Key Component in Mechanical Engineering

In conclusion, steel cross bracing is not just a structural element but a testament to the harmonious blend of form and function in engineering. It symbolizes the human ability to harness the power of materials to create safe, resilient, and visually appealing structures. As technology advances, the role of steel cross bracing in the future of construction is expected to become even more critical, as we strive to build higher, stronger, and more sustainable edifices.

Applications

One of the key features of hex head self-tapping wood screws is their hexagonal head. This design allows for greater torque and control during installation, making it easier to drive the screw into the wood without the risk of stripping the head. Additionally, the hex head provides a larger surface area for the driver to grip onto, reducing the likelihood of slipping or camming out. The self-drilling capability of these screws eliminates the need for pre-drilling, which significantly speeds up installation. Equipped with a sharp point and cutting threads, they can easily penetrate through metal sheets without requiring a pilot hole. This feature is particularly advantageous in applications where time and precision are crucial, such as in automotive, construction, and manufacturing industries. In addition to their practical benefits, PVC butterfly wall plugs also offer a sleek and attractive appearance. Their low-profile design sits flush against the wall, creating a clean and unobtrusive look that won't detract from the aesthetics of the room. This makes them a popular choice for homeowners and designers who want to achieve a polished and professional finish without compromising on functionality. One of the key features of chemical stud bolts is their ability to maintain their strength and integrity at high temperatures

The Significance of 1 202 wedge anchor bolt

The Significance of 1 202 wedge anchor bolt The Significance of 8% Drywall Screws

In addition to material selection, the chemical properties of anchor fasteners also play a crucial role in their performance. Various chemical coatings and treatments can be applied to anchor fasteners to improve their strength, durability, and resistance to corrosion. For example, zinc plating is commonly used to protect anchor fasteners from rust and corrosion, extending their lifespan and ensuring long-term reliability

anchor fastener chemical.

Furthermore, the widespread adoption of self-drilling screws has contributed to the overall improvement of construction and engineering practices. By streamlining the fastening process and reducing the need for additional tools and equipment, self-drilling screws have helped minimize waste and enhance safety on job sites. This has led to more efficient project timelines and reduced construction costs, benefitting both businesses and clients.

To maximize the effectiveness of Tek screws in cladding projects, consider the following best practices

The Art of Precision in Wafer Head Metal Screws The traditional flat wafer head has been the mainstay of semiconductor processing for decades. However, as devices continue to shrink in size and increase in complexity, the limitations of this design have become increasingly apparent. The ribbed wafer head addresses these limitations by introducing a unique ribbed structure that enhances heat transfer and uniformity across the wafer surface. But even as we embrace change and growth, we must also find stability and grounding. This is where the anchor comes in. The anchor represents the foundation upon which we build our lives, the values and beliefs that guide us and give us a sense of purpose and direction. It is what keeps us grounded and prevents us from drifting aimlessly in the stormy seas of life.

In the field of engineering and manufacturing, the role of fasteners cannot be underestimated. Among these fasteners, black hex head bolts stand out due to their versatility, strength, and aesthetic appeal. This article explores the importance of black hex head bolts, their applications, and the materials used to manufacture them.

4. Reduced Risk of Damage Because these screws do not require a pilot hole, there is a decreased risk of splitting materials, particularly in wood.

Resin anchor bolts are also easy to install, making them a convenient option for contractors and builders

resin anchor bolts. The bolt is inserted into a pre-drilled hole in the surface and the resin material is then injected into the hole. As the resin cures, it bonds with the surrounding material and secures the bolt in place. This simple installation process allows for quick and efficient fastening, saving time and effort on the job site.

Another key advantage is the material composition. The 7% 2016 self-drilling screws are often made from high-strength steel, which provides increased durability and resistance to corrosion. This aspect is essential for applications involving outdoor structures or environments where moisture and exposure to elements could compromise the integrity of standard screws.

7 16 self drilling screw

Self-Drilling Screws Revolutionizing Construction Efficiency However, despite their numerous advantages, the successful implementation of self-drilling anchors relies heavily on proper design, selection, and installation. Engineers must consider factors such as the ground conditions, load requirements, and the specific characteristics of the anchor system to ensure optimal performance. 1

self drilling screw 1. Select the appropriate self-drilling screw for your project based on the material and application.

- Strong Connection The ability to form threads in the base material ensures a strong and secure connection, capable of withstanding various forces and loads.

A 3/8 self-drilling screw is a testament to the marriage of convenience and efficiency in modern hardware. The '3/8' denotes the diameter of the screw, which is a common size used in various applications due to its strength and versatility. These screws are engineered to drill their own hole and tap threads simultaneously, eliminating the need for a separate drilling process, hence the term 'self-drilling.' But it's not just the efficiency and productivity of the factory that sets it apart; it's also the commitment to quality. Every screw that leaves the factory is subjected to rigorous testing to ensure that it meets the highest standards. This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market

This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market

This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market chipboard screw factory. Despite their many benefits, it is important to use self-drilling nails correctly to ensure a secure and reliable attachment. Proper technique, including selecting the right size and type of nail for the job, as well as using the appropriate tools, is essential for achieving the best results. It is also important to follow manufacturer recommendations and guidelines for installation to ensure the nails perform as intended. In industrial applications, 3 8 full threaded rods are commonly used in various scenarios A 1% 2% wedge bolt consists of a threaded rod with a wedge-shaped end that is used to anchor the bolt securely in place. This design allows for easy installation by simply inserting the bolt into a pre-drilled hole and tightening it with a wrench. The wedge shape of the bolt helps to create a strong grip on the surrounding material, preventing it from loosening or pulling out under heavy loads. The key benefit of self-drilling drywall anchors is their convenience. Traditional anchors require the use of a drill and potentially a separate drill bit to create a pilot hole before the anchor can be inserted. This can be a time-consuming and cumbersome process, especially for those who do not have much experience with power tools. Self-drilling anchors eliminate the need for drilling pilot holes, making the process of hanging items on drywall faster and simpler. As the final chapter of my academic journey draws to a close, I find myself standing at the precipice of a new beginning - the end of my studies. This pivotal moment, marked by a mixture of excitement and trepidation, is not merely the termination of one phase but the commencement of another. It's an end that signifies the transition from being a student to stepping into the real world, a world where the lessons learned in the classroom will be tested in the crucible of life. Moreover, their self-tapping nature reduces the risk of stripped threads, ensuring a clean and precise fit. The hex head also provides better grip and resistance against loosening, ensuring durability and reliability in various environmental conditions. Tek screws also boast excellent corrosion resistance, often featuring a zinc plating or other protective coatings 5. Hex Lag Bolts These bolts have a threads that are designed to bite into the material they are screwed into, providing a strong hold even in soft or uneven surfaces.

chipboard screw factory. Despite their many benefits, it is important to use self-drilling nails correctly to ensure a secure and reliable attachment. Proper technique, including selecting the right size and type of nail for the job, as well as using the appropriate tools, is essential for achieving the best results. It is also important to follow manufacturer recommendations and guidelines for installation to ensure the nails perform as intended. In industrial applications, 3 8 full threaded rods are commonly used in various scenarios A 1% 2% wedge bolt consists of a threaded rod with a wedge-shaped end that is used to anchor the bolt securely in place. This design allows for easy installation by simply inserting the bolt into a pre-drilled hole and tightening it with a wrench. The wedge shape of the bolt helps to create a strong grip on the surrounding material, preventing it from loosening or pulling out under heavy loads. The key benefit of self-drilling drywall anchors is their convenience. Traditional anchors require the use of a drill and potentially a separate drill bit to create a pilot hole before the anchor can be inserted. This can be a time-consuming and cumbersome process, especially for those who do not have much experience with power tools. Self-drilling anchors eliminate the need for drilling pilot holes, making the process of hanging items on drywall faster and simpler. As the final chapter of my academic journey draws to a close, I find myself standing at the precipice of a new beginning - the end of my studies. This pivotal moment, marked by a mixture of excitement and trepidation, is not merely the termination of one phase but the commencement of another. It's an end that signifies the transition from being a student to stepping into the real world, a world where the lessons learned in the classroom will be tested in the crucible of life. Moreover, their self-tapping nature reduces the risk of stripped threads, ensuring a clean and precise fit. The hex head also provides better grip and resistance against loosening, ensuring durability and reliability in various environmental conditions. Tek screws also boast excellent corrosion resistance, often featuring a zinc plating or other protective coatings 5. Hex Lag Bolts These bolts have a threads that are designed to bite into the material they are screwed into, providing a strong hold even in soft or uneven surfaces. Neoprene washers are rubber washers made from a synthetic rubber compound known for its resistance to different environmental factors. These washers serve as a sealant, offering benefits that complement the functionality of self-tapping screws. When paired together, the combination of self-tapping screws and neoprene washers provides an optimal solution for fastening applications that require both strength and weather resistance.