The additive under assessment is hydroxypropyl methyl cellulose (HPMC). It is intended to be used as a technological additive in feed for all animal species.

Another advantage of using HPMC in building coatings and adhesives is its ability to control moisture movement. As a hydrophilic polymer, it can absorb and release water, helping to regulate the drying time of the coating or adhesive. This can be particularly beneficial in environments with fluctuating humidity levels, as it helps to prevent cracking or peeling caused by rapid changes in moisture content. The gelation temperature of HPMCP refers to the temperature at which the polymer undergoes a phase transition, changing from a solid state to a gel-like consistency. This transition is crucial for controlling the release of drugs encapsulated within HPMCP-coated formulations. When exposed to body temperatures during digestion, the HPMCP coating begins to soften and eventually forms a gel layer. This layer acts as a barrier, preventing premature drug release in the stomach while allowing controlled release in the intestine. In addition to its gelling properties, HPMC also exhibits good film-forming capabilities. It can be used as a coating agent to protect drugs from moisture and oxygen, as well as to modify the release profile of active ingredients. The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs

The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs The film-forming properties of HPMC are influenced by factors such as its molecular weight and degree of substitution, making it possible to fine-tune the release rate of drugs hpmc meaning. Understanding HPMC The Comprehensive Guide to Buying High Purity Methacrylate Copolymer

hpmc meaning. Understanding HPMC The Comprehensive Guide to Buying High Purity Methacrylate Copolymer EFSA has verified the European Union Reference Laboratory (EURL) report as it relates to the methods used for the control of HPMC in animal feed. The Executive Summary of the EURL report can be found in Annex A.6

in the pharmaceutical industry due to its unique properties and compatibility HPMC, or Hydroxypropyl Methylcellulose, is a widely used polymer in various industries due to its unique properties. One of the most important aspects of HPMC is its solubility in water. Understanding the factors that affect HPMC's solubility in water is crucial for its effective application in different formulations. For pharmaceutical companies, the cost of HPMC can have a significant impact on their bottom line, especially when producing large quantities of drugs. Therefore, it is important for these companies to carefully evaluate the price of HPMC and consider factors such as bulk purchasing discounts, long-term contracts, and alternative excipients that may be less expensive but still meet regulatory requirements. 1. Viscosity HPMC's viscosity can vary depending on its molecular weight, degree of substitution, and concentration. It can range from low viscosity to high viscosity, making it suitable for a variety of applications. In the field of textiles, HPMC is employed in the printing and dyeing process, improving colorfastness and fabric quality. It is also used in the paper industry to enhance paper strength and printability. HPMC is widely used in the personal care industry as an emulsifier and thickening agent 3. Hypoallergenic

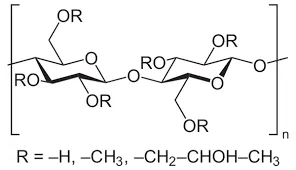

3. Hypoallergenic HPMC, on the other hand, is Hydroxypropyl Methylcellulose. It is produced by alkali treatment of refined cotton and further etherified using epichlorohydrin and chloromethane as etherifying agents, resulting in a nonionic mixed ether of cellulose. The degree of substitution is typically between 1.2 and 2.0, and its properties vary based on the ratio of methoxy and hydroxypropoxy groups.

(1)HPMC or Hydroxypropyl methylcellulose (INN name: Hypromellose), also simplified as hydroxypropyl methylcellulose (HPMC), is a kind of non-ionic cellulose mixed ether. It is a semi-synthetic, inactive, viscoelastic polymer. Hydroxypropyl methylcellulose is widely used in construction, food, medicine, and other industries.

The food industry also benefits from HPMC's non-toxicity and emulsifying properties Liquid thickeners are also a great option for people who have dietary restrictions, as they are often gluten-free and can be used in place of traditional thickeners like flour or cornstarch HPMC is a semi-synthetic polymer derived from cellulose. It consists of a glucose unit backbone with methyl and hydroxypropyl groups attached to it. This combination of substituents gives HPMC its water-soluble nature and thickening ability. On the other hand, HEC is also a cellulose derivative but with hydroxyethyl groups instead of hydroxypropyl groups. This subtle difference in chemical structure results in distinct physical and chemical properties between the two polymers.

HPMC is a semi-synthetic polymer derived from cellulose. It consists of a glucose unit backbone with methyl and hydroxypropyl groups attached to it. This combination of substituents gives HPMC its water-soluble nature and thickening ability. On the other hand, HEC is also a cellulose derivative but with hydroxyethyl groups instead of hydroxypropyl groups. This subtle difference in chemical structure results in distinct physical and chemical properties between the two polymers. In the food industry, HPMC is used as a thickener and stabilizer in a wide range of products, from sauces to bakery items. The food-grade HPMC is non-toxic and odorless, making it safe for consumption. Its ability to form a gel at low temperatures and maintain stability at high temperatures makes it a popular ingredient in processed foods

vae powder. In the construction industry, VAE powder is used in adhesives, sealants, and coatings for a variety of applications, such as bonding materials, sealing joints, and protecting surfaces from moisture and weather damage. In the automotive industry, VAE powder is used in paints, coatings, and sealants for vehicle bodies, interiors, and exteriors, where durability, flexibility, and weather resistance are essential. In the packaging industry, VAE powder is used in adhesives, sealants, and coatings for packaging materials, cartons, and labels, where adhesion, water resistance, and durability are important. In the textiles industry, VAE powder is used in adhesives, coatings, and finishes for fabrics, garments, and accessories, where flexibility, water resistance, and durability are key properties. Hydroxypropyl Methylcellulose exhibits excellent solubility in cold and hot water, making it versatile for various uses. It is noteworthy that the dissolution rate is generally faster in hot water than in cold, a trait common to many soluble polymers. The solubility percentage ( ) can vary depending on factors such as the degree of hydroxypropylation and methylation, particle size, and the temperature of the water. In conclusion, China's redispersible powder industry plays a pivotal role in shaping the global construction landscape. Its commitment to innovation, quality, and sustainability positions it as a major player in this sector. As the world continues to seek efficient and environmentally friendly building solutions, China's redispersible powder industry is poised to make a substantial contribution to meeting these needs. 1. Quality When purchasing HPMC, it is essential to ensure that it meets the required quality standards. Look for manufacturers who have certifications such as ISO, FDA, or Kosher to ensure product quality and safety. The use of HPMC in building coating adhesives offers numerous benefits, including In the construction industry, HPMC is predominantly used as a thickener and a binding agent in mortar and plaster formulations. It enhances the workability of cementitious materials, improves their setting time, and reduces water demand, thus increasing the overall strength and durability of structures. Moreover, it acts as an effective water-repellent and anti-crack agent, contributing to better quality finishes. Moreover, HPMC 4000 is used in the paint and coatings sector, where it improves the flow and leveling properties of paints, reduces brush marks, and enhances the film's adhesion and resistance to water and chemicals. It also finds application in the cosmetic industry, particularly in hair care and skincare products, due to its moisturizing and film-forming abilities. The market dynamics also play a crucial role. Global demand for HEC is primarily driven by the construction, oil & gas, and pharmaceutical sectors. In the construction industry, HEC is used in cementitious products, while in oil & gas, it serves as a drilling fluid additive. A rise in infrastructure projects or drilling activities can increase the demand for HEC, pushing up its price.

vae powder. In the construction industry, VAE powder is used in adhesives, sealants, and coatings for a variety of applications, such as bonding materials, sealing joints, and protecting surfaces from moisture and weather damage. In the automotive industry, VAE powder is used in paints, coatings, and sealants for vehicle bodies, interiors, and exteriors, where durability, flexibility, and weather resistance are essential. In the packaging industry, VAE powder is used in adhesives, sealants, and coatings for packaging materials, cartons, and labels, where adhesion, water resistance, and durability are important. In the textiles industry, VAE powder is used in adhesives, coatings, and finishes for fabrics, garments, and accessories, where flexibility, water resistance, and durability are key properties. Hydroxypropyl Methylcellulose exhibits excellent solubility in cold and hot water, making it versatile for various uses. It is noteworthy that the dissolution rate is generally faster in hot water than in cold, a trait common to many soluble polymers. The solubility percentage ( ) can vary depending on factors such as the degree of hydroxypropylation and methylation, particle size, and the temperature of the water. In conclusion, China's redispersible powder industry plays a pivotal role in shaping the global construction landscape. Its commitment to innovation, quality, and sustainability positions it as a major player in this sector. As the world continues to seek efficient and environmentally friendly building solutions, China's redispersible powder industry is poised to make a substantial contribution to meeting these needs. 1. Quality When purchasing HPMC, it is essential to ensure that it meets the required quality standards. Look for manufacturers who have certifications such as ISO, FDA, or Kosher to ensure product quality and safety. The use of HPMC in building coating adhesives offers numerous benefits, including In the construction industry, HPMC is predominantly used as a thickener and a binding agent in mortar and plaster formulations. It enhances the workability of cementitious materials, improves their setting time, and reduces water demand, thus increasing the overall strength and durability of structures. Moreover, it acts as an effective water-repellent and anti-crack agent, contributing to better quality finishes. Moreover, HPMC 4000 is used in the paint and coatings sector, where it improves the flow and leveling properties of paints, reduces brush marks, and enhances the film's adhesion and resistance to water and chemicals. It also finds application in the cosmetic industry, particularly in hair care and skincare products, due to its moisturizing and film-forming abilities. The market dynamics also play a crucial role. Global demand for HEC is primarily driven by the construction, oil & gas, and pharmaceutical sectors. In the construction industry, HEC is used in cementitious products, while in oil & gas, it serves as a drilling fluid additive. A rise in infrastructure projects or drilling activities can increase the demand for HEC, pushing up its price.