Links:

Moreover, these filters find utility in the oil and gas industry, where they are employed to filter drilling fluids and process fluids, ensuring operational efficiency and safety. Their application in aquaculture for water filtration ensures that aquatic ecosystems are maintained effectively.

4. Durability and Longevity The materials used in constructing sectional tanks ensure high durability and resistance to corrosion. For instance, stainless steel tanks offer exceptional longevity and are less susceptible to environmental factors compared to plastic alternatives. As a result, investments in sectional cold water storage tanks can yield significant returns over their lifespan.

What is a Whole House RO System?

In the realm of modern infrastructure, effective water management has become increasingly crucial, particularly in urban areas prone to flooding and waterlogging. One innovative solution that has gained popularity is the Fiber-Reinforced Polymer (FRP) trench drain. This system combines advanced materials with intelligent design to provide an efficient mechanism for surface water drainage. In this article, we will explore the advantages, applications, and considerations of FRP trench drains.

Hygiene and Maintenance

Applications of GRP Water Storage Tanks

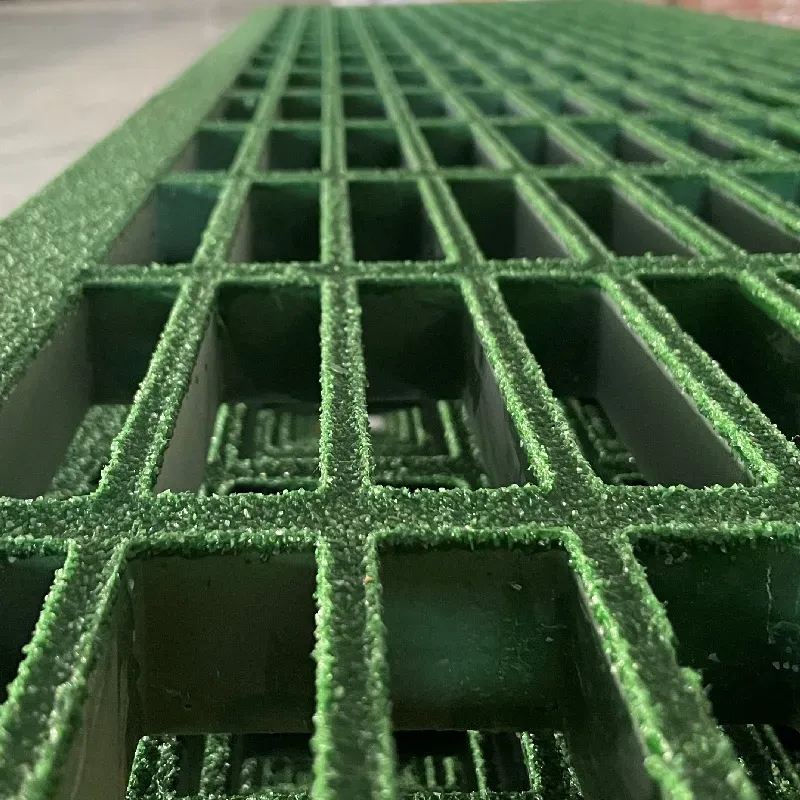

GRP (Glass Reinforced Plastic) open mesh grating has gained significant popularity across various industries due to its unique characteristics and benefits. This versatile material, composed of fiberglass and resin, is engineered to provide strength, durability, and lightweight properties. Its applications range from industrial environments to commercial settings, making it a preferred choice for many architects and engineers.

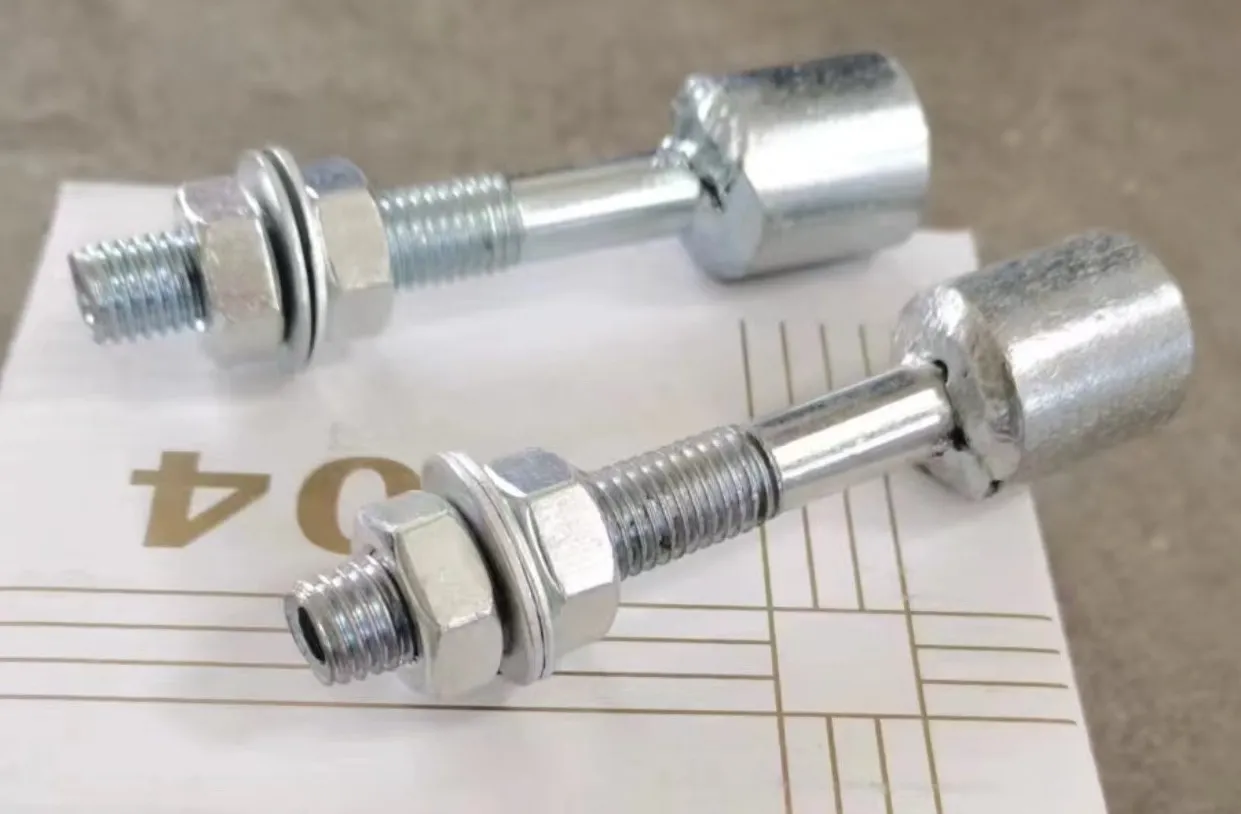

1. Safety The primary purpose of floor grating clamps is to secure grating panels to their supporting structures. This secures the panels in place, preventing accidental displacement that could lead to slips, trips, or falls, which are common hazards in industrial environments. A securely fastened grating system reduces the risk of injury to personnel working on or around the area.

Considerations When Choosing GRP Grating

As sustainability becomes an increasingly important consideration in construction, fiberglass stairs present an eco-friendly option. Many manufacturers utilize recycled materials in their fiberglass products, reducing the environmental impact associated with traditional stair materials such as wood and metal. Additionally, fiberglass stairs do not require regular treatments or paints that can be harmful to the environment. This aspect of fiberglass not only contributes to a reduction in toxic waste but also means less maintenance, further minimizing the ecological footprint.

One of the standout features of the 2472 FRP vessel is its impressive strength-to-weight ratio. Compared to traditional materials like steel or aluminum, FRP vessels are significantly lighter while maintaining comparable or even superior structural integrity. This weight reduction can lead to lower transportation costs, easier handling, and improved operational efficiency. Moreover, the corrosion resistance of FRP means that these vessels can be utilized in harsh environments where metal counterparts would quickly deteriorate.

Another noteworthy consideration is the ease of installation associated with FRP grating. Due to its lightweight nature, FRP grating is easier to handle, cut, and fit compared to heavier materials like steel. This property not only reduces labor costs during installation but also minimizes the need for heavy lifting equipment, thereby further curtailing expenditures. Additionally, the ease of installation can lead to decreased project completion times, which can be a significant advantage in terms of overall project management and cost control.

frp grating cost

While the benefits of FRP rebar are compelling, some challenges exist. The initial cost of FRP rebar can be higher than that of steel rebar, which may deter some project managers. However, considering the long-term savings from reduced maintenance and replacement, the investment often pays off. Furthermore, there is a need for more extensive research and design codes specific to FRP rebar to ensure its widespread acceptance and understanding within the engineering community.

Conclusion

Poorly maintained or clogged drains can lead to stagnant water, fostering an environment for mold and bacteria growth. Therefore, selecting the right type of grate and ensuring it is regularly maintained can prevent not only unpleasant odors but also health risks associated with contaminated water.

One of the standout features of FRP stair treads is their durability. Unlike traditional materials such as wood or metal, FRP is resistant to corrosion, rust, and deterioration caused by exposure to chemicals and moisture. This makes them particularly suitable for outdoor staircases or environments where exposure to harsh conditions is likely. Furthermore, FRP treads are UV-stabilized, ensuring that they will not fade or degrade from sunlight exposure over time.

frp stair treads

As urbanization accelerates and populations grow, the demand for efficient water storage solutions becomes increasingly critical. One such solution that has gained popularity in recent years is the Glass Reinforced Plastic (GRP) sectional water tank. These tanks provide a range of benefits for both residential and commercial applications, making them a preferred choice for many water supply needs.

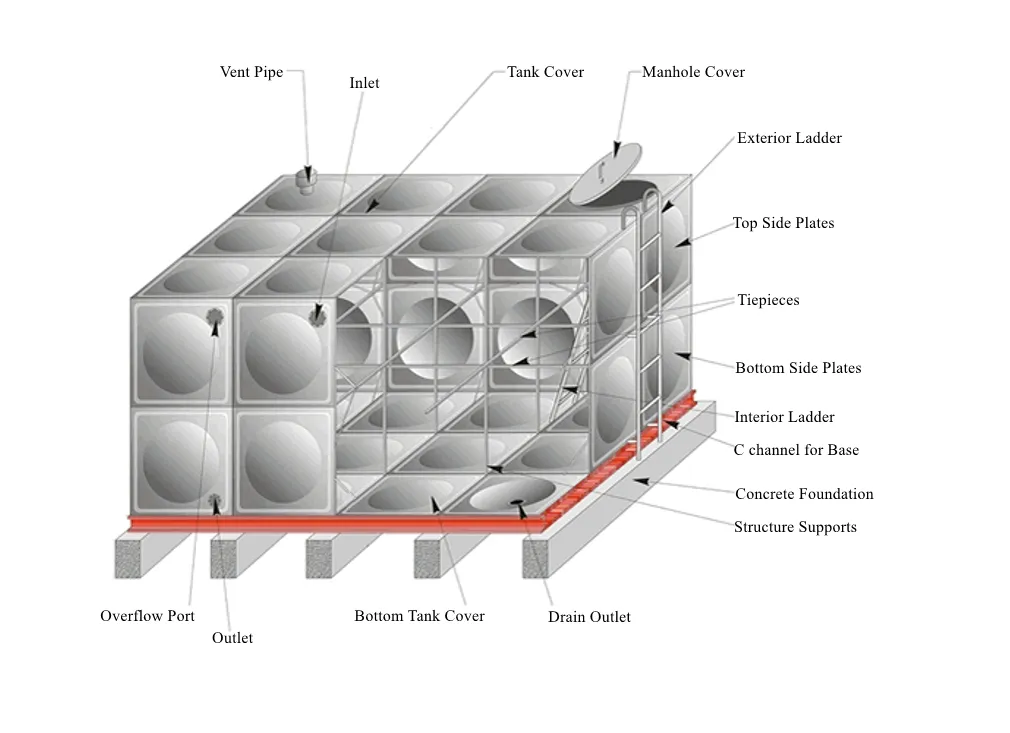

In contemporary urban settings, the efficient management of water resources is paramount. One innovative solution emerging in this regard is the square water tank with a cage system. This design not only optimizes space but also enhances water quality and accessibility, making it a significant advancement in civil infrastructure.

5. Minimal Maintenance UV water treatment systems are relatively easy to maintain. Regular cleaning of the quartz sleeve that houses the UV lamp is usually sufficient, and the lamps need to be replaced only once a year or as recommended by the manufacturer.

Moreover, the non-magnetic nature of FRP bars makes them suitable for applications in situations where magnetic interference is a concern, such as in certain medical facilities or data centers. Their low thermal conductivity is another asset that helps prevent issues related to heat transfer within structures.

frp bar

4. Longevity and Low Maintenance The durability of GFRP means that it does not require frequent replacement, which can be a significant cost-saving factor in the long run. Its resistance to decay, rot, and UV radiation ensures that it maintains its structural integrity and appearance over time, requiring minimal maintenance.

2. Low Maintenance GRP fencing panels require minimal maintenance compared to traditional materials. There’s no need for regular painting, staining, or sealing, which not only saves time but also reduces long-term costs. A simple wash with soap and water is usually enough to keep the panels looking fresh and vibrant.

grp fencing panels

Current research in micro mesh grating technology is focused on further enhancing their performance and expanding their applications. Innovations such as adaptive gratings, which can change their configuration depending on the light they encounter, are paving the way for more versatile optical devices. Additionally, the integration of micro mesh gratings with emerging technologies like quantum optics and photonic devices promises to unlock new potentials.

One of the standout features of molded grating is its ability to resist environmental challenges. In sectors such as chemical processing, waste management, and marine environments, the durability of materials is paramount. Molded grating is engineered to withstand harsh chemicals, extreme temperatures, and heavy loads. As a result, it is extensively used in walkways, platforms, and stair treads where both safety and longevity are critical.

The pressure tank works by storing water from the well pump and using compressed air to maintain a constant pressure in the system. When water is drawn from the tank, the air pushes the water out, ensuring a steady flow of water at the required pressure.

Fiber Reinforced Polymer rebar is a composite material that consists of a polymer matrix reinforced with fibers. The types of fibers typically used include glass, carbon, and aramid, each offering unique properties that enhance the performance of the rebar. The polymer matrix, often made from epoxy or polyester, provides excellent binding characteristics and protects the fibers from environmental damage.

Moreover, FRP rods are highly customizable, allowing for tailored solutions to meet specific engineering demands. They can be manufactured in various shapes and sizes, providing flexibility for designers and engineers to optimize their applications. Whether reinforcing concrete, supporting structures, or serving as tension elements in prestressed applications, FRP rods can be adapted to suit diverse project requirements.

frp rod

In summary, the price of 1465 FRP vessels is influenced by a myriad of factors, including material and labor costs, manufacturing processes, and market dynamics. As the industry evolves, understanding these dynamics is crucial for stakeholders. The long-term benefits of investing in FRP technology, particularly in the 1465 vessel model, could outweigh initial costs, making it a valuable asset in marine operations. Potential buyers should consider not just the purchase price but also the total cost of ownership when evaluating the economics of FRP vessels. The future of maritime transport looks promising with continued advancements in material science and engineering.

4. Thermal Insulation The composition of FRP materials provides excellent thermal insulation properties. This characteristic is particularly beneficial for applications where temperature control of the stored liquid is critical.

pentair frp tank

1. Durability and Longevity One of the standout features of GRP palisade fencing is its exceptional durability. The composite material stands up well against harsh weather conditions, including heavy rain, UV exposure, and temperature fluctuations. Unlike metal fencing, it will not rust, ensuring that it retains its structural integrity and appearance for years without significant maintenance.

In the industrial sector, HDG tanks are employed to store chemicals, wastewater, and even fuels. Their ability to prevent leaks and punctures is critical in protecting the environment and minimizing the risks associated with hazardous materials. Additionally, the food and beverage industry utilizes HDG tanks for the storage of liquids, benefiting from the non-reactive nature of the zinc coating which prevents any contamination of the stored products.

Despite the significant advantages, the adoption of FRP bars is not without its challenges. One of the primary concerns is the initial cost; while the long-term savings may be substantial due to reduced maintenance and increased lifespan, the upfront investment can be higher compared to traditional steel reinforcement. Additionally, the bond between FRP bars and concrete can differ from that of steel, requiring adjustments in design and engineering practices.

1. Space Efficiency Square tanks maximize storage capacity within a given footprint, making them suitable for urban environments where space is at a premium.

While the initial cost of fiberglass rebar is typically higher than that of steel, the overall expense can be mitigated by considering several factors. On average, the price of fiberglass rebar can range from $0.40 to $1.00 per pound, whereas steel rebar generally falls between $0.25 and $0.70 per pound, depending on market conditions. It's crucial to note that these figures can fluctuate based on location, demand, and the specific type of rebar.

Conclusion

3. Durability and Longevity FRP trench drains are designed to withstand heavy loads and can endure significant wear and tear over time. Their resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations further enhances their lifespan, making them a cost-effective solution in the long run.

Conclusion

Positioning your grill correctly is crucial. Always place your grill at least 10 feet away from your home and any flammable materials such as wooden decking, railings, or patio furniture. Avoid grilling under low-hanging branches or overhangs that could catch fire. A well-ventilated area reduces the risk of fire and allows for the safe dispersal of smoke and fumes.

grill on deck safe

One of the primary advantages of fiberglass floor grating is its exceptional strength-to-weight ratio. Fiberglass is significantly lighter than steel, making it easier to handle and install while still providing the resilience needed to withstand heavy loads. The inherent properties of fiberglass make it resistant to corrosion, which is particularly advantageous in environments exposed to harsh chemicals, moisture, and extreme temperatures. Unlike steel, which may rust and weaken over time, fiberglass maintains its longevity and structural integrity, resulting in lower maintenance costs and extended lifespans for the flooring systems.

Despite the relatively higher initial cost compared to traditional materials like steel or aluminum, FRP grating offers numerous long-term benefits that can justify the investment

At the outset, it is essential to recognize that the initial cost of FRP grating is generally higher than traditional materials like steel or aluminum. This higher upfront expenditure often comes as a barrier for some organizations, particularly those with tight budgets. Nevertheless, when analyzing the cost of FRP grating, it is paramount to adopt a holistic perspective that factors in long-term benefits, lifecycle costs, and potential savings over time.

Choosing a fiberglass water tank is a decision that pays off in many ways. Their exceptional durability, lightweight design, and cost-effectiveness make them an ideal solution for anyone in need of a reliable water storage system. With a variety of sizes and configurations available, finding the right tank for your specific requirements is easier than ever. As you consider your options, remember that fiberglass water tanks not only serve practical purposes but also contribute to a more sustainable and environmentally friendly future. Investing in a fiberglass tank today means investing in peace of mind for years to come.

Once you've assessed your organization's needs, the next step is to define clear objectives for the GRP implementation. What do you hope to achieve? Whether it’s improving operational efficiency, enhancing data accuracy, or fostering better communication across departments, having well-defined goals provides direction and helps measure success. Ensure that these objectives are aligned with the larger strategic goals of the organization.

Molded FRP A Revolution in Material Technology

The Role of Safety Guard Systems in Different Sectors

safety guard system

In addition to safety and durability, fiberglass floor grating is an environmentally friendly option. The manufacturing process of fiberglass grating is energy-efficient compared to other materials, and it is often produced using recycled materials. Furthermore, fiberglass itself is recyclable, making it a sustainable choice for eco-conscious organizations.

In conclusion, grating floor plates are an indispensable element in contemporary architecture and construction. Their combination of strength, safety features, aesthetic versatility, and sustainability makes them a preferred choice for a variety of applications. As industries continue to evolve, it is likely that the use of grating floor plates will expand, further solidifying their place as a vital component in the built environment. Whether in industrial settings, commercial spaces, or public infrastructures, these plates embody a balanced blend of function and style, ensuring that they meet the demands of today’s architectural challenges.

Home water treatment systems come in various forms, catering to the specific needs of households. The following are the most common methods used for treating water at home

water treatment for home

FRP tanks are constructed using a combination of fiberglass and resin, making them exceptionally strong and lightweight. Unlike traditional materials such as concrete or steel, FRP tanks resist the effects of corrosion, rust, and environmental damage, making them suitable for various applications, including agricultural, industrial, and municipal uses. Their lightweight nature also simplifies installation, often requiring less labor and equipment compared to heavier counterparts.

Pultruded FRP Grating A Strong and Versatile Solution