Links:

Creating a habitat for small birds is both an art and a science. One crucial aspect of designing comfortable and safe enclosures for our feathered friends is the choice of materials, particularly wire mesh. The importance of selecting the right wire mesh for small bird cages cannot be understated. This article explores the benefits of using wire mesh, different types available, and considerations for selecting the best option for your avian companions.

A stainless steel water tank is a practical and durable solution for storing and transporting water in various settings. With a capacity of 20 gallons, this type of tank can hold a significant amount of water for use in homes, businesses, and even in emergency situations.

2. Request Samples If possible, request samples of the wire mesh you intend to purchase. This allows you to assess the quality and suitability for your specific application before committing to a larger order.

- Consider Quality Over Price While saving money is important, the quality of nail wire can impact the integrity of your project. Investing in higher-quality wire may save costs in the long run by reducing the likelihood of failures.

The hot-dipped galvanization process involves dipping the iron wire into a molten zinc bath, which creates a metallurgical bond between the zinc and the iron. This results in a protective layer of zinc that helps prevent rust and corrosion, even in harsh environments. The zinc coating also acts as a barrier against moisture and other corrosive elements, extending the lifespan of the wire

china hot dipped galvanized iron wire.

With such diverse applications, the demand for sophisticated pultrusion machinery has risen sharply. Manufacturers specialized in these machines are increasingly facing the challenge of meeting the evolving requirements of their clients while maintaining competitive pricing.

The Chinese fiberglass mesh industry is characterized by its rapid expansion. Factories are often equipped with automated production lines that enhance efficiency and output while minimizing labor costs. As environmental concerns grow, many Chinese manufacturers are also adopting eco-friendly practices and sustainable materials, aligning their operations with global standards.

Iron wire coil is a commonly used product in various industries, such as construction, manufacturing, and agriculture. To regulate the trade and import/export of iron wire coils, a specific HS code has been assigned to this product by international customs authorities. In agriculture, this wire mesh is commonly used as animal pens, protecting livestock from predators and preventing them from escaping

10×10 welded wire mesh. In civil engineering, it is frequently seen reinforcing soil walls or supporting grass on slopes to prevent erosion. Additionally, the construction industry employs it as a reinforcement in concrete slabs or culverts to enhance strength and stability.

10×10 welded wire mesh. In civil engineering, it is frequently seen reinforcing soil walls or supporting grass on slopes to prevent erosion. Additionally, the construction industry employs it as a reinforcement in concrete slabs or culverts to enhance strength and stability. Economic Impact

Overall, glass reinforced plastic water tanks are a practical and cost-effective solution for storing water in a variety of applications. Their strength, durability, corrosion resistance, versatility, ease of installation and maintenance, and environmental friendliness make them a popular choice among industry professionals and homeowners alike. Whether you need to store water for industrial processes, firefighting, or residential use, GRP water tanks are a reliable option that will provide you with safe and secure water storage for years to come. Another benefit of China coiled nails is their durability. Made from high-quality materials, these nails are designed to withstand tough conditions and heavy use. Whether exposed to extreme weather or high-impact activities, China coiled nails are built to last. This durability not only ensures the longevity of the fastening but also helps to maintain the integrity of the overall structure. Fiberglass flanges are an essential component in various industries, including chemical processing, water treatment, and oil and gas. These flanges are made from a composite material called fiberglass, which is known for its strength, durability, and resistance to corrosion.

2mm fibreglass rod. Fibreglass rods are also known for their durability and resistance to harsh environmental conditions, making them suitable for use in aerospace applications. In conclusion, nails may seem like a simple tool, but they have played a vital role in the development of firearms and forensic science. From their use in bullet manufacturing to their contribution to the field of ballistics, nails continue to shape our understanding of these complex and often deadly weapons. As technology advances and new materials are introduced, the role of nails in the world of bullets and heads is likely to evolve, but their impact on our history and society will undoubtedly remain significant for years to come.

Shijiazhuang Iron and Steel A Pillar of Industrial Growth

In addition to its resistance to corrosion, galvanized iron wire coil is also known for its strength and durability. The process of galvanization not only protects the iron wire from rust, but also adds an extra layer of strength to the metal. This makes galvanized iron wire coil a popular choice for applications where a high level of tensile strength is required, such as in construction, agriculture, and manufacturing.

Conclusion

Understanding Electro Galvanized Barbed Wire

In conclusion, stainless steel water tanks present a range of advantages that make them a superior choice for water storage. Their durability, hygienic qualities, aesthetic appeal, and environmental impact position them as a prime option for various applications. As water conservation and quality become increasingly important, investing in stainless steel water tanks may be one of the most prudent decisions for ensuring a safe, reliable, and sustainable water source for future generations.

mill test certificate for steel plate. It serves as a quality assurance document that demonstrates the compliance of the steel plate with industry standards and specifications. One industry where large fiberglass tubes are widely used is the aerospace industry. These tubes are often used in the construction of aircraft structures, such as wings and fuselages. Their high strength-to-weight ratio allows for lighter aircraft, which translates to better fuel efficiency and lower operating costs. Additionally, the corrosion-resistant nature of fiberglass tubes helps to ensure the longevity of the aircraft. In addition to the raw materials and production processes, the design features of the tank can affect its cost

In addition to their use in carpentry, iron nails are also commonly used in masonry work. They can be driven into concrete or brick walls to hang heavy objects like mirrors, shelves, or cabinets. Iron nails are strong enough to support the weight of these objects without bending or breaking, making them a reliable choice for hanging items securely. Another advantage of galvanized iron wire coil is its affordability. Despite its strength and durability, galvanized iron wire coil is relatively inexpensive compared to other types of metal wire. This makes it an attractive option for businesses and individuals looking for a cost-effective solution for their wire needs. In the world of industrial storage solutions, the stainless steel storage tank stands out for its durability, versatility, and resistance to corrosion. These tanks are an essential component in a wide array of industries, from food and beverage to pharmaceuticals and beyond. Their ability to withstand the test of time and harsh conditions makes them invaluable assets.

In addition to their use in carpentry, iron nails are also commonly used in masonry work. They can be driven into concrete or brick walls to hang heavy objects like mirrors, shelves, or cabinets. Iron nails are strong enough to support the weight of these objects without bending or breaking, making them a reliable choice for hanging items securely. Another advantage of galvanized iron wire coil is its affordability. Despite its strength and durability, galvanized iron wire coil is relatively inexpensive compared to other types of metal wire. This makes it an attractive option for businesses and individuals looking for a cost-effective solution for their wire needs. In the world of industrial storage solutions, the stainless steel storage tank stands out for its durability, versatility, and resistance to corrosion. These tanks are an essential component in a wide array of industries, from food and beverage to pharmaceuticals and beyond. Their ability to withstand the test of time and harsh conditions makes them invaluable assets. Common concrete nail sizes include

On a larger scale, electro galvanized barbed wire is also utilized in perimeter fencing for military and government installations, where security is paramount. The ability to customize the design allows for creating complex barrier systems that can include additional security measures, such as alarms or surveillance systems.

The advantages of small coil black iron are manifold. First and foremost, its strength makes it a reliable choice for various applications. It can withstand significant loads and impacts, ensuring longevity and durability, which is crucial in both construction and artistic applications. Additionally, the material is relatively cost-effective compared to other metals, making it accessible for a wide range of projects.

2. Finishing Nails Finishing nails are smaller and have a smaller head than common nails. They are used in situations where the nail head needs to be inconspicuous, such as in furniture assembly or trim work.

Overall, the 20-gauge coil galvanized iron wire is a reliable and versatile material that is widely used in various industries. Its strength, durability, and ease of use make it a preferred choice for many applications. Whether you are working on a construction project, building a fence, or creating a piece of art, this type of wire is sure to meet your needs and exceed your expectations.

FRP pipes are composite materials made from a polymer matrix reinforced with fiberglass. This combination makes them highly durable, robust, and suitable for transporting corrosive substances, which traditional materials like metal or concrete cannot effectively handle. These properties have paved the way for FRP pipes to be extensively used in sectors like construction, chemical processing, oil and gas, and water treatment.

Conclusion

The fiberglass production process begins with raw materials, primarily silica sand, alumina, and various additives. These materials undergo a melting process at extremely high temperatures, typically around 1,400 to 1,600 degrees Celsius. The melted glass is then formed into fibers using several methods, including the traditional plunge method and more advanced techniques like the blow method. The choice of method often depends on the desired fiber diameter and application.

Smaller mesh sizes, such as 1/4 inch or 1/2 inch, are ideal for projects that require a higher level of security or containment. These smaller mesh sizes are often used in applications such as fencing, security cages, and animal enclosures. The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection

The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection

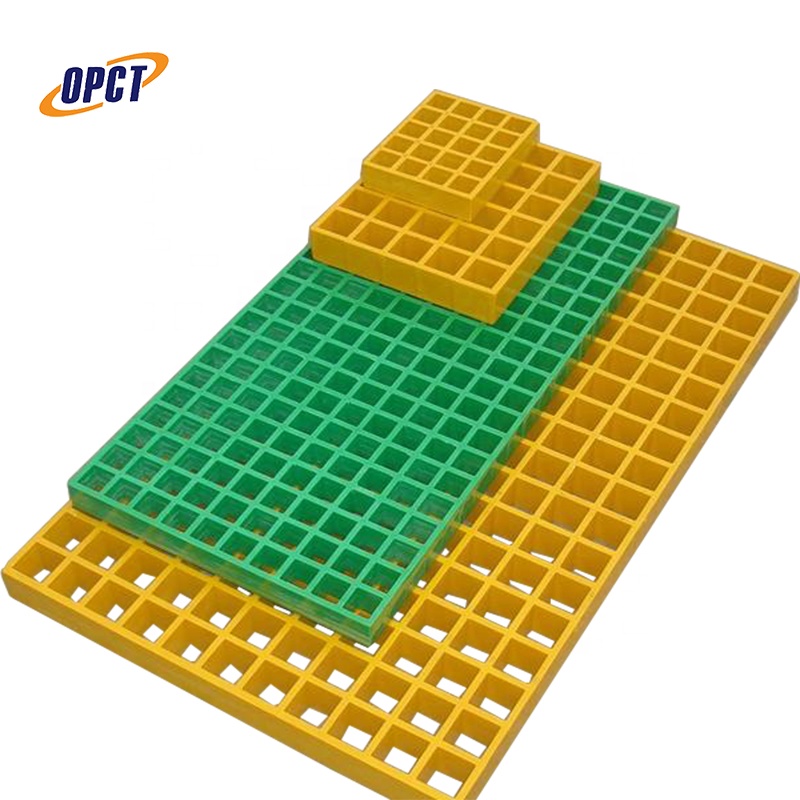

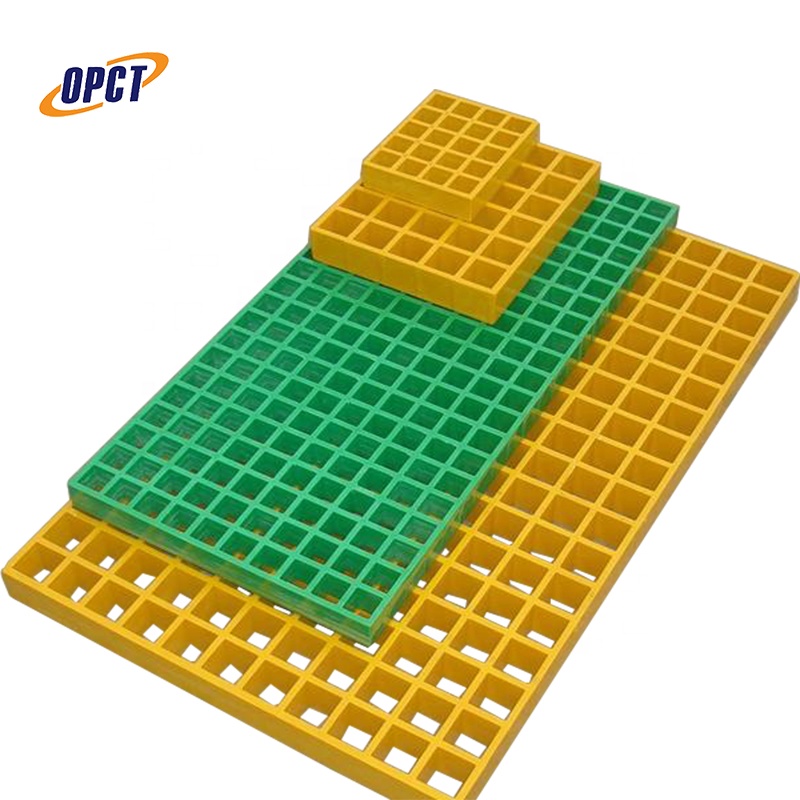

The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection The smaller spacing between the wires makes it difficult for intruders or animals to pass through, providing added security and protection welded wire mesh sizes. Overall, choosing the right grating supplier is essential for the success of any construction project. By considering factors such as material selection, manufacturing capabilities, experience, and communication, clients can ensure they find a reliable partner who can provide high-quality grating solutions for their needs. With the right supplier on board, projects can proceed smoothly and safely, with confidence in the performance and durability of the grating materials used. One of the key advantages of frp fiberglass pipes is their high strength-to-weight ratio. Fiberglass is known for its incredible tensile strength, making it suitable for applications where high pressure and loading conditions are present. Despite its strength, fiberglass is lightweight, making it easier to transport and install compared to traditional piping materials such as steel or concrete.

welded wire mesh sizes. Overall, choosing the right grating supplier is essential for the success of any construction project. By considering factors such as material selection, manufacturing capabilities, experience, and communication, clients can ensure they find a reliable partner who can provide high-quality grating solutions for their needs. With the right supplier on board, projects can proceed smoothly and safely, with confidence in the performance and durability of the grating materials used. One of the key advantages of frp fiberglass pipes is their high strength-to-weight ratio. Fiberglass is known for its incredible tensile strength, making it suitable for applications where high pressure and loading conditions are present. Despite its strength, fiberglass is lightweight, making it easier to transport and install compared to traditional piping materials such as steel or concrete. The Cost of Stainless Steel Water Tanks A Comprehensive Overview

In conclusion, sourcing wholesale chicken wire mesh in the Philippines requires careful consideration of several factors, including supplier reputation, quality, type, and delivery options. By working with reputable suppliers and selecting the right type of chicken wire mesh for your specific needs, you can ensure that your poultry operation runs smoothly and efficiently. In addition to their safety and durability, fibreglass ladders are lightweight, making them easy to install and move around. Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels

Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels

Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels fibreglass cable ladder. Chicken Wire Mesh Specifications A Comprehensive Guide Furthermore, spiral razor fence factories prioritize environmental sustainability, using eco-friendly materials and processes to minimize their carbon footprint. By incorporating green practices into their operations, these factories demonstrate a commitment to both quality and environmental responsibility.

fibreglass cable ladder. Chicken Wire Mesh Specifications A Comprehensive Guide Furthermore, spiral razor fence factories prioritize environmental sustainability, using eco-friendly materials and processes to minimize their carbon footprint. By incorporating green practices into their operations, these factories demonstrate a commitment to both quality and environmental responsibility.