Links:

-

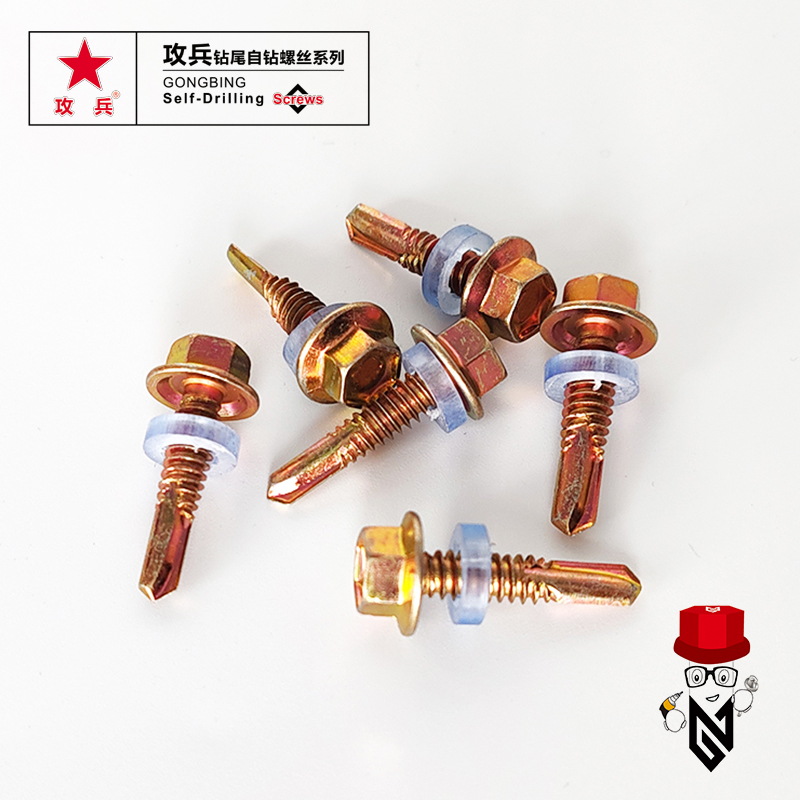

Self-drilling screws, as the name suggests, are designed to drill their own hole while being driven into materials, eliminating the need for pre-drilling. This not only saves time but also reduces the number of tools required for a job. The 75mm size is particularly popular because it strikes a balance between length and strength, making it suitable for a wide range of applications.

Advantages of Using Wedge Anchor Bolts

1 wedge anchor bolts

Moreover, the role of foundation bolts and nuts extends beyond the construction phase. They are crucial in maintenance and repair works, allowing easy disassembly and reassembly of structures, reducing downtime, and facilitating future modifications. A self-drilling screw, as the name suggests, is designed with a cutting tip that eliminates the need for a pre-drilled hole. This feature saves time and effort on job sites, enhancing productivity and reducing labor costs. The unique design of these screws allows them to penetrate through metal, wood, and even plastic, making them ideal for diverse projects.

5. Resistance to Vibration and Shock M6% resin anchors are designed to withstand vibrations and dynamic loads, making them suitable for applications in industries such as construction, automotive, and manufacturing, where movement is constant.

One of the main functions of bracing steel is to prevent buildings from swaying or collapsing during extreme weather events or seismic activity. By connecting various parts of a building together, bracing steel helps to distribute the forces acting on the structure evenly, reducing the risk of damage or failure. In conclusion, nylon self-tapping screws are a practical and efficient choice for numerous applications where lightweight, non-conductive, and vibration-absorbing properties are desired. From DIY projects to industrial manufacturing, their ease of use, resilience, and specialized characteristics make them a valuable addition to any toolbox. As technology continues to evolve, it's likely that we will see even more innovative uses for these versatile fasteners in the future. In the realm of construction and engineering, innovation is paramount to achieving efficiency, safety, and durability. One such innovation that has garnered significant attention in recent years is the ceramic-coated self-drilling screw. These screws, with their unique coating, offer a multitude of benefits that make them an invaluable tool for various applications in the construction industry. The fundamental principle behind resin anchor bolts lies in their unique installation process. The bolt, usually made from high-strength steel, is inserted into a pre-drilled hole, followed by the injection of a two-part epoxy or polyester resin. The resin then cures, creating an incredibly strong bond between the bolt and the surrounding material, effectively becoming an integral part of the structure. In the world of construction and engineering,,、。,,。,,,、。 However, proper selection and installation are crucial for optimal performance. Factors like the size of the bolt, the type of concrete, and the expected load must be considered when choosing the appropriate wedge anchor. Moreover, the drilling process must be precise to ensure the bolt can expand fully and create a secure grip. In conclusion, selecting the right screws for roofing is an important task that requires careful consideration of several factors. By choosing screws that are appropriate for the material of your roof, the size and length of the screws, the quality of the screws, and the price, you can ensure that your roof remains secure and free from leaks and other problems. In conclusion, the 60mm self-drilling screw is a remarkable tool that brings convenience, strength, and efficiency to various building and manufacturing endeavors. Its ability to combine drilling and fastening into a single action showcases a clever application of mechanical principles, making it an indispensable item in the modern toolkit for those who seek to build and connect with precision and speed.

With their ease of use, 2-inch self-drilling screws can also contribute to reduced labor costs. By speeding up the installation process, fewer labor hours are required to complete a project. This efficiency can lead to significant savings, particularly in large-scale construction endeavors. Furthermore, with fewer tools needed—thanks to the elimination of pre-drilling—there is less reliance on multiple laborers to manage different aspects of the fastening process.

2. Length and Diameter The dimensions of the fasteners should suit the thickness of the chipboard. Generally, fasteners should penetrate at least half the thickness of the material to ensure a secure hold.

The primary advantage of using a full thread stud bolt lies in its ability to provide an equal distribution of clamping force. The continuous threading allows for the application of nuts on either end, which can be tightened independently, providing a more stable and robust connection. This dual-nut system not only enhances the holding power but also minimizes the risk of loosening due to vibration or stress. 1. Remove the Failed Anchor If you suspect that a resin anchor has failed, carefully remove it from the surface using a drill and bit designed for the specific anchor type. Be sure to avoid damaging the surrounding area during the removal process Be sure to avoid damaging the surrounding area during the removal process

Be sure to avoid damaging the surrounding area during the removal process Be sure to avoid damaging the surrounding area during the removal process

Be sure to avoid damaging the surrounding area during the removal process Be sure to avoid damaging the surrounding area during the removal process fixing resin anchors.

fixing resin anchors. Considerations When Using M6 Hex Head Bolts

When selecting fine thread collated drywall screws for your project, it is important to consider the specific requirements of the job. Factors such as the thickness of the drywall, the type of studs or surfaces being used, and the size of the screws will all impact the type of screws needed. It is also recommended to choose high-quality screws from reputable manufacturers to ensure a secure and reliable installation.

5. Installation Instructions Detailed installation guidelines, including hole diameter, depth, and cleaning procedures for the base material, must be included to maximize the effectiveness of the chemical bond.

1. High Stability One of the most significant advantages of butterfly screws is their ability to distribute weight over a larger area. When the wings expand behind the wall, they create a supportive base that can hold heavier objects securely.

2. Prepare the Mounting Bracket Attach the TV mount to the wall according to the manufacturer's instructions. Ensure that the mounting bracket is securely attached and level before proceeding. Overall, the structure of a bolt is essential in determining its performance and reliability. By selecting the appropriate material, thread, head, and shank design, engineers can ensure that the bolt will meet the specific requirements of the application in which it will be used. A well-designed bolt structure not only provides a secure connection but also contributes to the overall safety and longevity of the assembly. Tek Screws Manufacturer A Comprehensive Guide

A tek screw, also known as self-drilling screw, is equipped with a drill-like point that allows it to create its pilot hole as it is driven into materials. This eliminates the need for pre-drilling, which can streamline the construction process significantly. The 5 designation typically refers to specific measurement protocols related to the screw's dimensions and strength characteristics. However, the specific meaning of 5 often involves manufacturer specifications or industry standards, allowing for slight variations in size and application based on regional or production practices.

In conclusion, self-tapping screws with neoprene washers represent an essential component in modern fastening technologies. Their combined benefits of ease of use, effective sealing, and vibration resistance make them a reliable choice for many applications across different industries. As technology progresses and materials continue to evolve, the demand for efficient and durable fastening solutions like self-tapping screws with neoprene washers will undoubtedly grow, proving their significance in both everyday tasks and specialized industrial applications. Whether you're a contractor, engineer, or DIY enthusiast, understanding the advantages of these fasteners can lead to better project outcomes and increased reliability in your work.

- Automotive They are frequently employed in automotive applications for assembling panels and components, thanks to their strength and reliability.

Self-drilling screws, also known as tek screws, are designed with a sharp point and unique thread configuration that allows them to penetrate through metal without requiring a pre-drilled hole. This feature significantly reduces the need for additional tools and increases efficiency in construction and manufacturing projects. Hexagonal head bolts come in a wide range of sizes and materials to suit different applications. The size of a bolt is typically specified by its diameter and length, with the diameter measured in millimeters (mm) or inches (in). Common materials used for hexagonal head bolts include carbon steel, stainless steel, alloy steel, and aluminum. Each material offers its own set of advantages and disadvantages, depending on the specific requirements of the application.

In conclusion, galvanized expansion anchor bolts are a versatile and durable fastening solution that offers strength, reliability, and visual appeal. Whether used for construction projects or DIY home improvements, these bolts provide a secure hold that can withstand heavy loads and harsh environmental conditions. With their ease of installation and low maintenance requirements, galvanized expansion anchor bolts are a popular choice for securing heavy items to concrete or masonry surfaces.

When selecting a self-drilling screw for roofing, factors such as the thickness and type of roofing material must be considered to choose the appropriate screw length and diameter. Proper alignment during installation is also key to achieving optimal performance. Contractors and DIY enthusiasts alike appreciate the ease of use, which comes with a caveat the correct tool, typically an electric drill or impact driver, is necessary to drive these screws effectively. Applications of Flat Head Self-Drilling Screws

When installing drywall, it is important to use the correct type and size of screws to ensure a professional finish. Using screws that are too short or too long can result in an insecure installation and may lead to cracking or sagging of the drywall over time. The 5/8 inch size is ideal for attaching standard 1/2 inch thick drywall panels to wood studs that are 16 inches apart.

drywall screws 5 8

1. Material Composition The “1% 201% 4%” typically indicates a specific ratio of metals used in the alloy, such as stainless steel or another corrosion-resistant material, which enhances durability. Stainless steel screws resist rust and corrosion, making them ideal for settings exposed to moisture or chemicals.

- Wood Cladding When fastening wooden boards or panels, specially designed Tek screws can prevent splitting and ensure a seamless attachment to the framing.

Overall, hex head self-tappers are a versatile and reliable fastening solution for a wide range of applications. Their self-tapping design, high torque resistance, and clean finish make them a popular choice for professionals and DIY enthusiasts alike. Whether you are working on a construction project, repairing a vehicle, or building furniture, hex head self-tappers are sure to make your job easier and more efficient.

In conclusion, the chemical composition of anchor fasteners is a critical factor in determining their strength, durability, and performance. By selecting the right type of anchor fastener based on the specific requirements of the project and following proper installation procedures, a strong and reliable connection can be achieved. Anchor fasteners play a vital role in ensuring the safety and stability of structures in various industries, making them an essential component in construction and manufacturing applications.

2. Follow Manufacturer Guidelines Always refer to the manufacturer’s specifications for proper installation techniques. This can include recommendations for torque settings and any specific pre-drilling instructions for very thick materials.

Pan head chipboard screws are a popular type of fastener that is commonly used in woodworking and construction projects. These screws have a flat, disc-shaped head with a raised center and a drive recess for easy installation with a screwdriver or power drill. In conclusion, 16mm chipboard screws are an indispensable tool in woodworking and construction, offering a reliable and efficient solution for joining chipboard and similar materials. Their design, combined with their robust construction, makes them a go-to choice for professionals and DIY enthusiasts alike, ensuring sturdy and durable structures that stand the test of time. Whether you're building furniture, constructing cabinets, or undertaking larger woodworking projects, understanding and utilizing these screws can significantly enhance the quality and longevity of your work. When it comes to installation, heavy-duty tek screws are relatively easy to use

heavy duty tek screws. They can be driven into place using a variety of tools, including power drills and screwdrivers. However, it is important to note that these screws require a certain level of expertise to install correctly, as improper installation can lead to premature failure. In the vast expanse of engineering innovations, one small yet significant component often goes unnoticed - the long tek screws. These humble fasteners, with their elongated bodies and specialized design, play a crucial role in numerous applications where strength, precision, and durability are paramount. Hex washer head screws come in various materials, each suited for specific applications. Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments

heavy duty tek screws. They can be driven into place using a variety of tools, including power drills and screwdrivers. However, it is important to note that these screws require a certain level of expertise to install correctly, as improper installation can lead to premature failure. In the vast expanse of engineering innovations, one small yet significant component often goes unnoticed - the long tek screws. These humble fasteners, with their elongated bodies and specialized design, play a crucial role in numerous applications where strength, precision, and durability are paramount. Hex washer head screws come in various materials, each suited for specific applications. Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments

Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments hex washer screw. Zinc-plated steel screws provide a sacrificial layer of zinc that protects the underlying steel from rust, making them suitable for indoor use. Tek screws are designed to withstand considerable stress and strain. Made from high-quality steel, many 25mm tek screws feature coatings that enhance their resistance to rust, corrosion, and wear. This durability makes them suitable for both indoor and outdoor applications.

hex washer screw. Zinc-plated steel screws provide a sacrificial layer of zinc that protects the underlying steel from rust, making them suitable for indoor use. Tek screws are designed to withstand considerable stress and strain. Made from high-quality steel, many 25mm tek screws feature coatings that enhance their resistance to rust, corrosion, and wear. This durability makes them suitable for both indoor and outdoor applications.- Strong Connection The ability to form threads in the base material ensures a strong and secure connection, capable of withstanding various forces and loads.

Bracing steel beams are typically made from high-strength steel, which ensures durability and resilience. The manufacturing process involves precise cutting, welding, and assembling to create components that meet exact specifications. Innovations in steel fabrication have led to the development of prefabricated bracing systems, which allow for faster installation and reduced construction costs. These pre-engineered solutions are particularly advantageous in large-scale projects, where efficiency and speed are paramount.

3. **Corrosion** Self-drilling screws can rust or corrode if not stored properly. Store them in a dry, cool place to prevent this issue. What Are Threaded Rod Chemical Anchors? Stainless Steel Bracing A Durable Solution for Strength and Beauty

Installation Process