Current location:

Links:

-

Despite these limitations, carbon steel drill bits are still widely used due to their ease of sharpening. With a file or bench grinder, you can restore their sharpness, extending their usability significantly. Moreover, their simplicity and robustness make them a reliable choice for basic workshop tasks. The drilling process begins with the anchoring drilling rig being positioned at the desired location. The drilling rod is then inserted into the ground, and the drilling rig rotates it at high speeds. The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

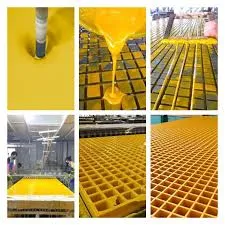

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure anchoring drilling rod and bits. In the world of composite materials, FRP (Fiber-Reinforced Plastics) laundering is a specialized technique that involves cleaning and rejuvenating fiberglass-reinforced plastic surfaces. This process not only restores the aesthetic appeal of the material but also enhances its structural integrity and prolongs its lifespan. Moreover, these rods also contribute to operational flexibility. With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites

anchoring drilling rod and bits. In the world of composite materials, FRP (Fiber-Reinforced Plastics) laundering is a specialized technique that involves cleaning and rejuvenating fiberglass-reinforced plastic surfaces. This process not only restores the aesthetic appeal of the material but also enhances its structural integrity and prolongs its lifespan. Moreover, these rods also contribute to operational flexibility. With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites

With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites rock drill extension rod. They can adapt to different drilling angles and configurations, making them adaptable to diverse geological conditions. Safety is another key feature of the air rock drill. The design incorporates several safety mechanisms to protect operators from injury. For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries

rock drill extension rod. They can adapt to different drilling angles and configurations, making them adaptable to diverse geological conditions. Safety is another key feature of the air rock drill. The design incorporates several safety mechanisms to protect operators from injury. For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries

For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries For instance, it has an anti-vibration system that reduces user fatigue and the risk of vibration-related injuries air rock drill for sale. Additionally, the drill bit is shielded, protecting operators from flying debris and reducing the likelihood of accidents. It is also worth noting that the cost of a jackhammer can be a worthwhile investment for businesses and contractors that frequently require heavy-duty demolition and construction work. A high-quality jackhammer can help increase productivity, efficiency, and overall project quality, ultimately saving time and money in the long run. The portable rock drill, as the name suggests, is designed for easy mobility, allowing it to operate in even the most remote and challenging terrains. Its compact size and lightweight design make it possible to transport and deploy with remarkable ease, enhancing operational flexibility. Unlike their larger, stationary counterparts, these drills can be effortlessly moved from one drilling site to another, saving time and resources. In terms of safety, FRP flanges excel as well. They have excellent fire resistance and emit no toxic fumes when exposed to heat, ensuring a safer working environment. Their non-sparking nature also makes them suitable for combustible or explosive environments. One brand that has consistently delivered high-quality hardened drill bits is Dewalt. Their extensive line of drill bits is made from top-grade materials and are subjected to rigorous testing to ensure optimal performance. Whether you're a professional contractor or a DIY enthusiast, Dewalt's hardened drill bits are sure to get the job done right. Once the drilling is complete, the hole must be cleaned and inspected for any irregularities or defects. If necessary, additional finishing work may be required to smooth out any rough edges or imperfections. Finally, the hole can be filled with a suitable material such as concrete or grout to provide structural support and enhance its durability. The key advantage of using FRP in pipeline architecture is its ability to handle events and state changes in a more deterministic and predictable manner. With FRP, changes in input automatically propagate through the pipeline, updating the output without requiring explicit control flow. This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical

air rock drill for sale. Additionally, the drill bit is shielded, protecting operators from flying debris and reducing the likelihood of accidents. It is also worth noting that the cost of a jackhammer can be a worthwhile investment for businesses and contractors that frequently require heavy-duty demolition and construction work. A high-quality jackhammer can help increase productivity, efficiency, and overall project quality, ultimately saving time and money in the long run. The portable rock drill, as the name suggests, is designed for easy mobility, allowing it to operate in even the most remote and challenging terrains. Its compact size and lightweight design make it possible to transport and deploy with remarkable ease, enhancing operational flexibility. Unlike their larger, stationary counterparts, these drills can be effortlessly moved from one drilling site to another, saving time and resources. In terms of safety, FRP flanges excel as well. They have excellent fire resistance and emit no toxic fumes when exposed to heat, ensuring a safer working environment. Their non-sparking nature also makes them suitable for combustible or explosive environments. One brand that has consistently delivered high-quality hardened drill bits is Dewalt. Their extensive line of drill bits is made from top-grade materials and are subjected to rigorous testing to ensure optimal performance. Whether you're a professional contractor or a DIY enthusiast, Dewalt's hardened drill bits are sure to get the job done right. Once the drilling is complete, the hole must be cleaned and inspected for any irregularities or defects. If necessary, additional finishing work may be required to smooth out any rough edges or imperfections. Finally, the hole can be filled with a suitable material such as concrete or grout to provide structural support and enhance its durability. The key advantage of using FRP in pipeline architecture is its ability to handle events and state changes in a more deterministic and predictable manner. With FRP, changes in input automatically propagate through the pipeline, updating the output without requiring explicit control flow. This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical

This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical frp pipeline. The construction industry is constantly evolving, with new tools and technologies emerging to improve efficiency and effectiveness. One such tool that has recently gained popularity is the extreme power jackhammer. This powerful machine is designed for heavy-duty demolition tasks, making it an essential piece of equipment for any construction project. Furthermore, tunnel bench drilling bits are essential for ensuring the accuracy and precision of tunnel construction

frp pipeline. The construction industry is constantly evolving, with new tools and technologies emerging to improve efficiency and effectiveness. One such tool that has recently gained popularity is the extreme power jackhammer. This powerful machine is designed for heavy-duty demolition tasks, making it an essential piece of equipment for any construction project. Furthermore, tunnel bench drilling bits are essential for ensuring the accuracy and precision of tunnel construction tunnel bench drilling bit. These bits are designed to create straight and uniform boreholes, which are necessary for the alignment of the tunnel. By maintaining precision in the drilling process, tunnel bench drilling bits help to ensure that the tunnel is built according to specifications and meets safety standards. Drilling Anchor Drill Bits A Comprehensive Guide When evaluating potential jackhammers, consider factors such as weight, vibration control, power output, and accessory compatibility. A lighter jackhammer is easier to maneuver, but a heavier one may provide more force. Vibration control is crucial for reducing user fatigue and potential injuries. Also, ensure the jackhammer you choose can accommodate the bits and attachments you'll need for your specific tasks. Understanding Impact Drill Bits The Key to Enhanced Drilling Efficiency

tunnel bench drilling bit. These bits are designed to create straight and uniform boreholes, which are necessary for the alignment of the tunnel. By maintaining precision in the drilling process, tunnel bench drilling bits help to ensure that the tunnel is built according to specifications and meets safety standards. Drilling Anchor Drill Bits A Comprehensive Guide When evaluating potential jackhammers, consider factors such as weight, vibration control, power output, and accessory compatibility. A lighter jackhammer is easier to maneuver, but a heavier one may provide more force. Vibration control is crucial for reducing user fatigue and potential injuries. Also, ensure the jackhammer you choose can accommodate the bits and attachments you'll need for your specific tasks. Understanding Impact Drill Bits The Key to Enhanced Drilling Efficiency

The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs

The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.