Links:

-

The significance of Down Pipe Connectors in Plumbing Systems Overall, the 4000 PSI Sewer Jetter is a versatile and effective tool for cleaning and maintaining sewer lines and pipes. Its high pressure and high volume water flow make it suitable for a wide range of cleaning tasks, while its durable construction and safety features ensure operator safety and prevent damage to pipes and fixtures. Whether you're a professional plumber or a homeowner dealing with a clogged drain, the 4000 PSI Sewer Jetter is sure to get the job done right. Replacing a faulty power steering hose in a Toyota Avalon is a task best left to professional technicians due to the complexity involved. They will drain the old fluid, remove the damaged hose, and install a new one, ensuring all connections are secure and leak-free. Regular maintenance, including checking for leaks and replacing hoses at recommended intervals, can prevent unexpected failures and prolong the life of the power steering system. Finally, replace the cap on the service port and turn off the car's engine. Give the system a few minutes to stabilize before testing the AC to ensure that it's blowing cold air. If everything is working properly, congratulations - you've successfully refilled your car's AC system using the CRC AC Charge Refrigerant R134a Refill & Hose kit. Moreover, the GM Power Steering Hose Kit also enhances the longevity of the entire power steering system. High-quality hoses reduce the strain on the pump, reducing the likelihood of premature wear and tear. Regular maintenance and timely replacement of hoses as part of the kit can save you from costly repairs down the line. High-Pressure Power Steering Hose Repair Services in Your Local Area A Comprehensive Guide

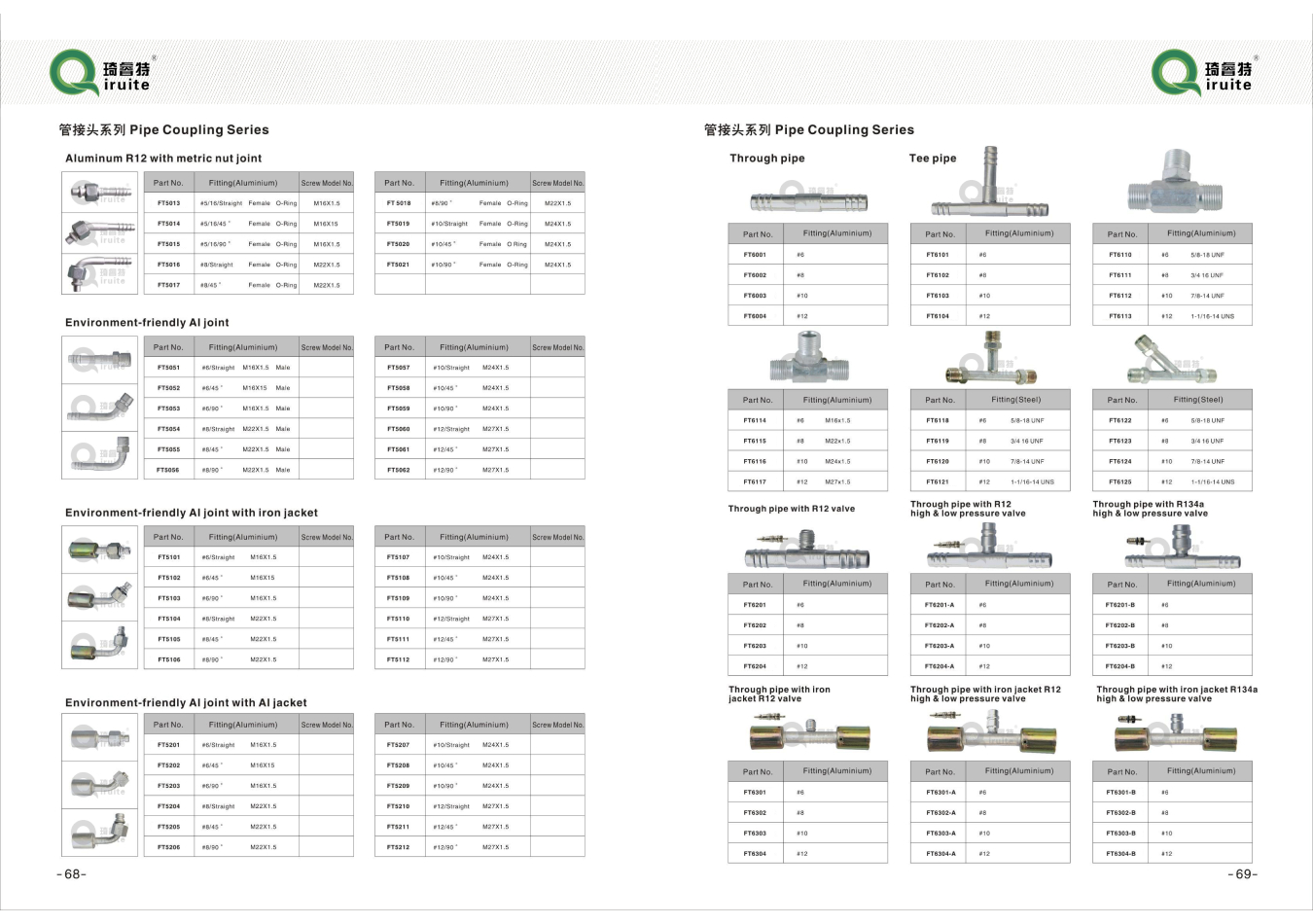

At present, Qiruit has occupied the international markets in Asia, America and the Middle East, and its products are exported to dozens of countries such as Brazil, Chile, Mexico, Panama, Australia, Russia, India, Turkey, etc., which are widely praised by customers. In China, Qirui Te has established a good partnership with Lovol, XCMG, Heavy Duty Truck, FAW and other brands of OEMs. Air conditioning system manufacturers to establish a good partnership.

But perhaps the most impressive feature was the power steering system When a power steering hose is damaged or leaking, it can lead to a loss of power steering fluid, which in turn can cause difficulty in steering and potential damage to the power steering system. If you notice signs of a leaking power steering hose, such as a puddle of fluid under your car or stiff steering, it is important to get it repaired as soon as possible. Replacing a brake booster vacuum line is a relatively simple procedure that can be done by a qualified mechanic. Here are the general steps involved However, over time, these hoses can develop leaks due to wear and tear or other factors. When a power steering hose starts to leak, it can cause a loss of power steering fluid, leading to difficulty in turning the steering wheel. This can be not only inconvenient but also dangerous, as it affects the driver's ability to control the vehicle. In addition to price and supplier reputation, it is important to consider the specific requirements of your plumbing system when choosing a PPR Coupling 1 2. Factors such as pipe diameter, water pressure, and temperature should all be taken into account to ensure the coupling will perform efficiently and effectively. In conclusion, rubber power steering hoses are a critical component in a vehicle's power steering system. These hoses are designed to withstand high pressures and temperatures while providing flexibility and durability for reliable performance. Regular maintenance and proper replacement of power steering hoses are essential to ensure the continued safety and efficiency of the steering system. By using high-quality rubber hoses and following recommended maintenance practices, drivers can enjoy smooth and responsive steering in their vehicles. Conclusion In conclusion, the power steering hose in a Toyota Corolla is a vital element that enhances driving comfort and safety. Its regular inspection and timely maintenance are essential to avoid potential issues that could compromise the overall performance of your vehicle. By staying vigilant and proactive, you can ensure your Corolla's power steering system operates smoothly, providing you with the reliable and effortless driving experience that Toyota vehicles are renowned for. Constructed from durable materials such as reinforced rubber or synthetic compounds, the power steering hose is built to resist wear, leaks, and high pressure. However, like any mechanical component, it can degrade over time due to normal usage, exposure to harsh conditions, or simply aging. Signs of a failing power steering hose may include fluid leaks, steering wheel stiffness, or a whining noise from the power steering pump - all indicating a potential issue that needs immediate attention. It is important to regularly inspect and maintain the power steering hose to prevent premature failure and ensure the safety and comfort of the driver. Regular fluid changes, thorough cleaning, and avoiding exposure to extreme temperatures can help extend the life of the hose and prevent costly repairs.Secure Mounting: Ensure that the hoses are securely fastened and properly supported along their length. Use suitable clamps or brackets to prevent vibration or rubbing against other components.

Air conditioning lines, often unseen but ever so crucial, form the lifeblood of modern buildings in our summer days. These intricate networks of pipes and conduits, carrying chilled refrigerant, silently weave their way through walls, ceilings, and floors, delivering comfort and respite from scorching temperatures. The female hose pipe connector, also known as a hose barb or adapter, is specifically designed to facilitate the connection between a hose and various fixtures or pipes. Its primary function is to provide a secure, leak-proof seal when joining two different diameters or materials. Historically, these connectors were predominantly male (threaded) counterparts, but the advent of female hose pipe connectors marked a significant shift in design efficiency. 7. Start the engine and let it run for a few minutes to allow the fluid to circulate. Types of 25mm Hose Pipe Connectors 9. **Test the System** Turn off the engine and check for leaks or unusual noises. If everything is functioning correctly, you've successfully replaced the power steering hose. A pipe connector fitting is a specialized device designed to join pipes together, allowing for changes in direction, size, or branching off from the main line. They come in a myriad of types, each with its unique function and application. For instance, elbows are used to change the direction of flow, tees are employed for branching, reducers adjust pipe diameter, and couplings connect two pipes of the same size.Additionally, worn or cracked hoses can also cause the power steering hose to blow off. Over time, hoses can deteriorate due to exposure to heat, oil, and other contaminants. If the hoses are not replaced in a timely manner, they can become weakened and prone to blowing off.

In conclusion, the 40mm pipe coupler is a fundamental component in various plumbing and construction projects. Its functionality, versatility, and ease of use make it an indispensable tool in pipe connections. It underscores the importance of understanding the right fittings for different pipe sizes and applications, as it significantly impacts the performance and longevity of the entire piping system. Whether it's in residential water supply or large-scale industrial operations, the humble 40mm pipe coupler continues to play a crucial role, silently ensuring the smooth flow of our daily lives. The repair process for a power steering hose leak in a Honda CR-V typically involves locating the source of the leak, replacing the damaged hose, and topping up the power steering fluid. It is important to use the correct type of power steering fluid recommended by the manufacturer to ensure proper functioning of the system. 6. **Reconnect Components** Reinstall the bolts, tightening them to the manufacturer's specifications using an adjustable torque wrench. Double-check the hose for any tangles or kinks before reconnecting the power steering pump. When using a charge hose with a gauge, it is important to follow a few key steps to ensure that the refrigerant is added correctly. First, you will need to locate the low-pressure service port on your vehicle's air conditioning system. This port is typically located on the larger of the two refrigerant lines coming from the compressor.

lFebruary 2021, Qirui Te help the development of the countryside, love donations of 20,000 yuan to repair roads;

The power steering hose plays a vital role in the proper functioning of your vehicle's steering system. Without it, the steering would become heavy and difficult to control, making it dangerous to drive. Additionally, a faulty power steering hose can lead to leaks, which can cause the fluid to evaporate, further reducing the efficiency of the system. Over time, these leaks can also damage other components of the power steering system, leading to additional repair costs. When it comes to industrial plumbing, one of the important components often used is a 3% 4% NPT half coupling. This type of coupling plays a crucial role in connecting pipes and fittings together, ensuring a secure and leak-free seal. In conclusion, custom extended brake lines are a worthwhile investment for car enthusiasts looking to elevate their vehicle's braking performance. With their superior durability, enhanced responsiveness, and resistance to pressure, they provide a safer and more enjoyable driving experience. Whether for daily driving or high-performance pursuits, upgrading to custom extended brake lines can truly make a difference in how your car stops and performs. Firstly, custom brake lines are built with high-quality materials that ensure durability and reliability. They typically feature a Teflon inner lining, which is resistant to both heat and pressure, ensuring consistent brake performance even under extreme conditions. The outer covering is usually made of stainless steel braiding, which not only adds an aesthetic appeal but also provides extra protection against abrasion, corrosion, and expansion under pressure. To prevent these problems from occurring, it is important to regularly inspect the high-pressure power steering hose for any signs of wear or damage. This includes checking for leaks, cracks, or bulges in the hose, as well as ensuring that all connections are secure. If any issues are detected, it is crucial to replace the hose immediately to maintain the proper functioning of the power steering system. Moreover, these connectors are often equipped with features that enhance functionality Furthermore, stainless steel pipe couplings offer a leak-proof seal, ensuring that there are no unwanted leaks or spills

Furthermore, stainless steel pipe couplings offer a leak-proof seal, ensuring that there are no unwanted leaks or spills

stainless pipe couplings. This is particularly important in industries where safety and environmental concerns are paramount. With their tight seal and high-pressure rating, these couplings provide peace of mind knowing that the pipes are securely connected and protected against potential leaks. There are two primary types of power steering hoses in a Corolla the high-pressure hose, which carries fluid from the pump to the steering gear, and the low-pressure hose, which returns the fluid back to the reservoir. Any damage or wear to these hoses can lead to leaks, resulting in reduced power steering assistance and potentially causing steering difficulty.

With the summer months upon us, a functioning air conditioning system is essential for staying comfortable while on the road. However, over time, refrigerant levels can become depleted, leading to a decrease in cooling performance. This is where A/C Pro R134a Synthetic Refrigerant comes in.

In the world of plumbing maintenance and repair, a sewer jetter hose is an invaluable tool for clearing clogged or blocked pipes. This high-pressure hose, equipped with a powerful water jet, can effectively flush out debris and build-up, ensuring smooth flow in your drainage system. If you're in need of a sewer jetter hose nearby, this guide will walk you through the process. The Isuzu power steering hose, with its brand's reputation for reliability, is designed to transmit hydraulic pressure from the steering pump to the steering rack. It is made of high-quality materials, typically a combination of reinforced rubber and steel, which makes it resistant to wear, corrosion, and extreme temperatures. This durability ensures that it can withstand the rigors of daily driving, even in harsh conditions. Conclusion 3. **Easy Installation** Bauer pipe couplings are designed for easy installation, reducing the time and effort required for connecting pipes. R134a Recharge Hose for Self-Sealing Cans An Essential Tool for Efficient AC Maintenance 5

saab power steering hose replacement. Disconnect the old power steering hose from the pump and the steering rack by using a socket wrench. Pay attention to the direction of the threads to ensure proper installation of the new hose. 3

saab power steering hose replacement. Disconnect the old power steering hose from the pump and the steering rack by using a socket wrench. Pay attention to the direction of the threads to ensure proper installation of the new hose. 3 However, it's important to note that regular inspection and timely replacement of these hoses are crucial. Wear and tear over time can compromise their integrity, so regular checks for signs of wear, swelling, or cracks are necessary. Moreover, high pressure within the system can also contribute to the problem

However, it's important to note that regular inspection and timely replacement of these hoses are crucial. Wear and tear over time can compromise their integrity, so regular checks for signs of wear, swelling, or cracks are necessary. Moreover, high pressure within the system can also contribute to the problem In conclusion, when shopping for PPR Coupling 1 2, it is important to consider the price, supplier reputation, and specific requirements of your plumbing system. By taking these factors into account, you can make an informed decision and choose a high-quality coupling that will provide long-lasting performance. Remember that investing in a quality PPR coupling is an investment in the future of your plumbing system. Another important feature to consider when selecting a sewer jetter hose is the length and diameter of the hose. The length of the hose will determine how far you can reach into your sewer lines, while the diameter will affect the water flow and pressure. It is important to choose a hose that is long enough to reach the blockage but not too long that it becomes difficult to maneuver. Additionally, a larger diameter hose will provide more water flow and pressure, making it easier to clear out tough blockages

In conclusion, when shopping for PPR Coupling 1 2, it is important to consider the price, supplier reputation, and specific requirements of your plumbing system. By taking these factors into account, you can make an informed decision and choose a high-quality coupling that will provide long-lasting performance. Remember that investing in a quality PPR coupling is an investment in the future of your plumbing system. Another important feature to consider when selecting a sewer jetter hose is the length and diameter of the hose. The length of the hose will determine how far you can reach into your sewer lines, while the diameter will affect the water flow and pressure. It is important to choose a hose that is long enough to reach the blockage but not too long that it becomes difficult to maneuver. Additionally, a larger diameter hose will provide more water flow and pressure, making it easier to clear out tough blockages

best sewer jetter hose.