Links:

Conclusion

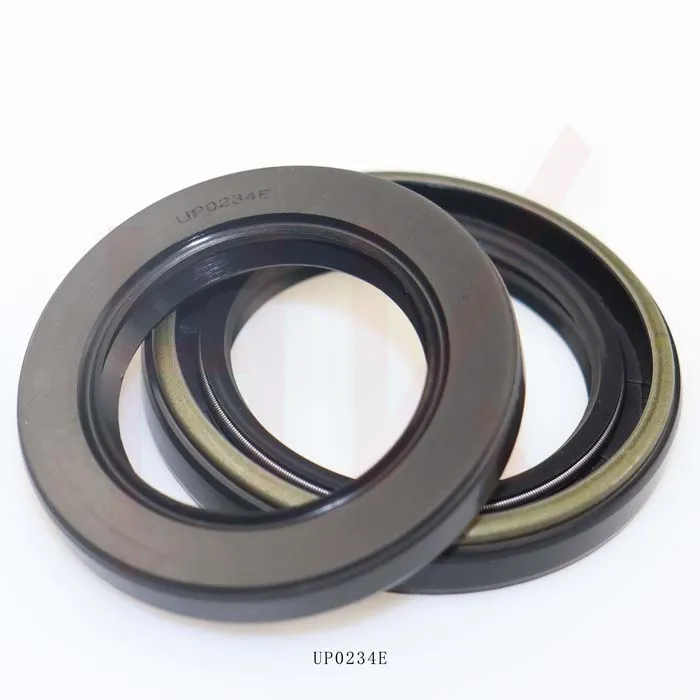

In summary, TCN oil seals are a vital component in both automotive and industrial systems, thanks to their innovative triple-chamber design and the excellent properties of nitrile rubber. By providing robust sealing performance and superior chemical resistance, these seals help enhance the reliability and efficiency of various machines and vehicles. Whether in a car, a manufacturing plant, or an aircraft, TCN oil seals are integral to the smooth operation and longevity of equipment, making them an indispensable element in modern engineering.

There are several reasons why it's important to use high-quality seal kits for your backhoe cylinders. First and foremost, seals play a critical role in preventing hydraulic fluid from leaking out of the cylinders. Leaks can not only reduce the efficiency of your backhoe but also pose a safety hazard to operators and other workers on the job site. In the realm of mechanical engineering and industrial machinery, the role of oil seals cannot be overstated. A seemingly small component, the 30x42x7 oil seal, holds significant importance in ensuring optimal performance and longevity of various equipment. This specific oil seal, with its dimensions of 30mm outer diameter, 42mm inner diameter, and a of 7%, plays a crucial part in preventing oil leaks and maintaining lubrication integrity. In conclusion, the 35x47x7 oil seal is a vital element in numerous industrial applications. Its precise dimensions, material composition, and robust design contribute significantly to the efficient operation and maintenance of complex machinery. Understanding the significance of this component underscores the need for quality oil seals in ensuring the reliability, safety, and overall performance of systems that rely on precise fluid management. As technology advances, so too does the development of oil seals, ensuring they continue to meet the evolving demands of modern industry.

The 40% - 80% - 10% Principle

Rebuilding your engine hoist's hydraulic cylinder might sound daunting, but it can be a straightforward process if you follow the right steps

- Oil and Gas Essential in drilling and production equipment where high pressures are commonplace.

Importance of Wheel Bearing Grease Seals

2. Depressurize the System Carefully release pressure from the hydraulic system. This may involve using release valves or following specific procedures outlined in the machine’s manual.

2. Maintain Proper Lubrication Ensure that the axle is appropriately lubricated with the manufacturer-recommended fluid. Insufficient lubrication can lead to overheating and premature seal failure.

In conclusion, the importance of forklift hydraulic cylinder seals cannot be overstated. They are the unsung heroes of efficient and reliable material handling. By prioritizing their maintenance and replacement, businesses can extend the lifespan of their forklift fleet and guarantee safe, seamless operations. As with many aspects of machinery upkeep, an ounce of prevention in the form of diligent seal care truly equals a pound of cure in terms of operational excellence and economic benefits. Hydraulic shaft seals are a critical component in many industrial applications, playing a pivotal role in maintaining the integrity and efficiency of machinery. These specialized seals prevent lubricants from leaking out and contaminants from entering the system, ensuring smooth operation and longevity of mechanical equipment.

The primary function of oil seals is to retain lubricant within a mechanical assembly. In the absence of an effective seal, lubricants can escape from the machinery, leading to increased wear and tear on moving parts, reduced efficiency, and potential failures. In industries where machinery operates under high temperatures and pressures, such as automotive, aerospace, and manufacturing, the significance of oil seals is magnified.

14x24x6 oil seal

1. Enhanced Durability Protecting equipment from the ingress of dust extends the lifespan of machinery, reducing replacement costs and downtime.

Fortunately, replacing wiper seals is a relatively simple and affordable process

wiper seal. Most auto parts stores carry a wide range of wiper seals designed to fit a variety of vehicles. It is important to choose the correct size and type of wiper seal for your specific vehicle to ensure a proper fit and maximum effectiveness.

wiper seal. Most auto parts stores carry a wide range of wiper seals designed to fit a variety of vehicles. It is important to choose the correct size and type of wiper seal for your specific vehicle to ensure a proper fit and maximum effectiveness. Hydraulic systems play a crucial role in various industrial and mechanical applications by using pressurized fluids to transmit power efficiently. At the heart of these systems lies the hydraulic cylinder, a vital component that converts hydraulic energy into linear motion. To ensure the smooth operation of hydraulic cylinders, one must pay special attention to the oil seal kits utilized in these systems.

Types of Cylinder Gland Seals

Hydraulic seals, often made of materials like rubber, polyurethane, or PTFE, serve as barriers against fluid leakage and contamination ingress. They ensure efficient operation by maintaining pressure within the system and preventing the entry of dirt or debris that could damage internal components. Over time, seals can wear out due to friction, exposure to harsh chemicals, or excessive heat, leading to leaks, reduced efficiency, or even system failure.

Rotary lip seals also contribute to cost savings. By preventing leaks, they reduce the need for frequent maintenance and replacement of lubricants or hydraulic fluids. This not only enhances the overall efficiency of mechanical systems but also minimizes environmental impact by limiting fluid waste.

Furthermore, agricultural seals can help to boost consumer confidence in the agricultural industry

Oil seals play a critical role in hydraulic motors by preventing hydraulic fluid leakage and protecting the motor components from contaminants such as dirt, dust, and moisture. A compromised oil seal can lead to fluid loss, reduced system efficiency, and can even cause catastrophic failures, leading to costly repairs and downtime. Therefore, understanding the function and upkeep of oil seals is essential for anyone involved in maintaining hydraulic systems.

The dkb seal is also known for its intelligence and cunning. It is always one step ahead of its prey, able to anticipate their every move and outmaneuver them with ease. Its sharp reflexes and quick thinking make it a formidable hunter, able to catch fish and other prey with ease

dkb seal.

Importance of Hydraulic Cylinder Seals

Oil seals are typically made of elastomeric materials such as rubber or synthetic polymers, which provide excellent resistance to wear and tear. They are designed to withstand high temperatures, pressures, and speeds, making them ideal for use in various industrial applications. The seal's primary function is to create a barrier between the lubricant and the external environment, preventing any fluid loss that could lead to reduced efficiency and increased maintenance costs. 2. Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime

Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime

Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime Extended Equipment Life The seal's ability to withstand harsh operating conditions helps to extend the life of the equipment it protects, reducing maintenance costs and downtime 12x22x7 oil seal. Maintaining the integrity of the hydraulic seal kit requires regular inspection and prompt replacement of worn or damaged components

12x22x7 oil seal. Maintaining the integrity of the hydraulic seal kit requires regular inspection and prompt replacement of worn or damaged components hydraulic seal kit. Neglecting these tasks can have far-reaching consequences, not just for the machinery involved but also for the production processes that depend on them. In industrial settings where uptime is paramount, such as manufacturing or construction, a faulty hydraulic seal kit can grind operations to a halt, impacting productivity and profitability.

hydraulic seal kit. Neglecting these tasks can have far-reaching consequences, not just for the machinery involved but also for the production processes that depend on them. In industrial settings where uptime is paramount, such as manufacturing or construction, a faulty hydraulic seal kit can grind operations to a halt, impacting productivity and profitability. Specifications and Features

The Importance of Hydraulic Seal Replacement A Comprehensive Guide Many suppliers offer custom-designed seals to meet unique application needs. These seals can be tailored in terms of material, shape, and size to provide a tailored solution for any hydraulic cylinder. It's always advisable to consult with experts who can guide you in selecting the right seals based on your machinery's specifications.

Dimensions and Specifications

The deep blue ocean stretches out endlessly, the waves gently lapping against the shore. A group of seals lay basking in the sun, their sleek bodies glistening with droplets of water. Among them is a particularly special seal - the dkb seal. The importance of oil seals in hydraulic systems cannot be overstated When selecting a hydraulic oil seal, it's important to consider the specific requirements of your application However, the effectiveness of a hub grease seal depends on several factors. Proper installation, regular inspection, and timely replacement are vital. Misalignment, overloading, or exposure to extreme temperatures can compromise the seal's integrity, necessitating attention. Moreover, selecting the right type of seal for specific operating conditions is paramount, as different seals have varying tolerances to temperature, pressure, and chemical exposure. The high-pressure oil rail, also known as a common rail, is a part of the fuel injection system that supplies pressurized fuel to the injectors. It operates at very high pressures, sometimes exceeding 2,000 bar (approximately 29,000 psi). Such conditions demand a robust sealing solution to prevent leaks that could lead to performance issues or even catastrophic failure. Secondly, the expertise and reputation of the manufacturer cannot be underestimated. Look for companies with a track record of innovation and commitment to quality assurance. Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards

Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards

Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards Many leading manufacturers invest heavily in research and development to create seals that not only meet but exceed industry standards hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system. It is also important to consider the reputation of the brand when purchasing a hydraulic seal kit. Some brands may be more reputable and reliable than others, so it is worth paying a little extra for a kit from a trusted brand. Oil seals, also known as shaft seals, are essential components in machinery and equipment to prevent the leakage of fluids, such as oil or grease, and to protect the internal components from contamination. The selection of oil seals plays a critical role in maintaining the efficiency and performance of the machinery. Among the various types of oil seals available in the market, the 20% 32% 6% oil seal stands out as one of the most commonly used and trusted options.

hydraulic cylinder seal kits manufacturers. They also provide comprehensive support, offering technical assistance to ensure that their seal kits align perfectly with the requirements of your hydraulic system. It is also important to consider the reputation of the brand when purchasing a hydraulic seal kit. Some brands may be more reputable and reliable than others, so it is worth paying a little extra for a kit from a trusted brand. Oil seals, also known as shaft seals, are essential components in machinery and equipment to prevent the leakage of fluids, such as oil or grease, and to protect the internal components from contamination. The selection of oil seals plays a critical role in maintaining the efficiency and performance of the machinery. Among the various types of oil seals available in the market, the 20% 32% 6% oil seal stands out as one of the most commonly used and trusted options. Applications of the 31x43x10 5 Oil Seal

In conclusion, hydraulic lip seals play a critical role in the efficient operation of hydraulic systems by preventing the leakage of hydraulic fluids and reducing friction and wear on the components. By choosing high-quality seals and ensuring proper installation and maintenance, hydraulic systems can operate smoothly and efficiently for years to come. In conclusion, combi oil seals represent a vital element in modern industrial machinery. Their dual-purpose functionality, compact design, and versatility make them a preferred choice for engineers seeking reliable sealing solutions. By preventing oil leaks and protecting critical components, combi oil seals contribute significantly to the overall efficiency, safety, and longevity of various machines and systems. As technology continues to evolve, we can expect further advancements in the design and materials of combi oil seals, ensuring they remain a cornerstone of effective sealing strategies in the years to come. In conclusion, hydraulic lift cylinder seal kits are critical components in maintaining the efficiency and safety of hydraulic lifting systems. By choosing the right kit for your specific system and following proper installation and maintenance procedures, you can help to ensure the longevity and reliability of your hydraulic equipment. The Intricacies of 31x43x10 Oil Seal Selection and Maintenance 4. Consider the warranty and support offered by the manufacturer or supplier, as this can provide additional peace of mind.

Applications of 50x90x10 Oil Seal

The primary function of high pressure shaft seals is to maintain a tight seal between moving components, such as rotating shafts, and the housings in which they operate. This is achieved through the use of durable materials and precision engineering that ensure a reliable seal under extreme pressure conditions. Selecting the right rotary oil seal is crucial. Factors to consider include the operating conditions, shaft speed, pressure, temperature, and the type of fluid being sealed. A poorly chosen seal can lead to premature failure, causing costly downtime and maintenance. A hydraulic ram seal kit is an essential component in maintaining the efficiency and performance of hydraulic ram systems. These systems use the force of flowing water to pump water from a lower to a higher elevation without requiring electricity or fuel.