Links:

- differences in production

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters door sliding wheel.

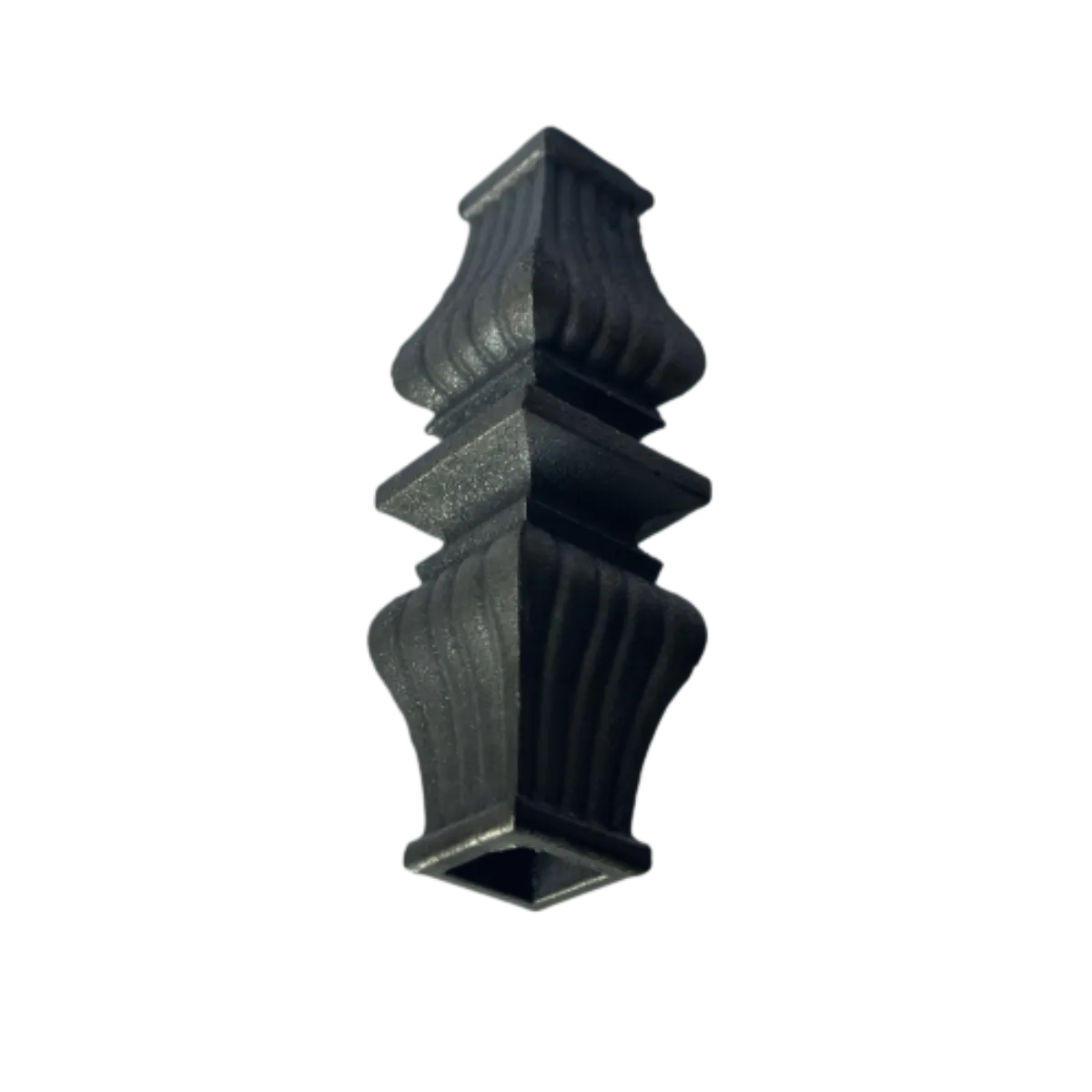

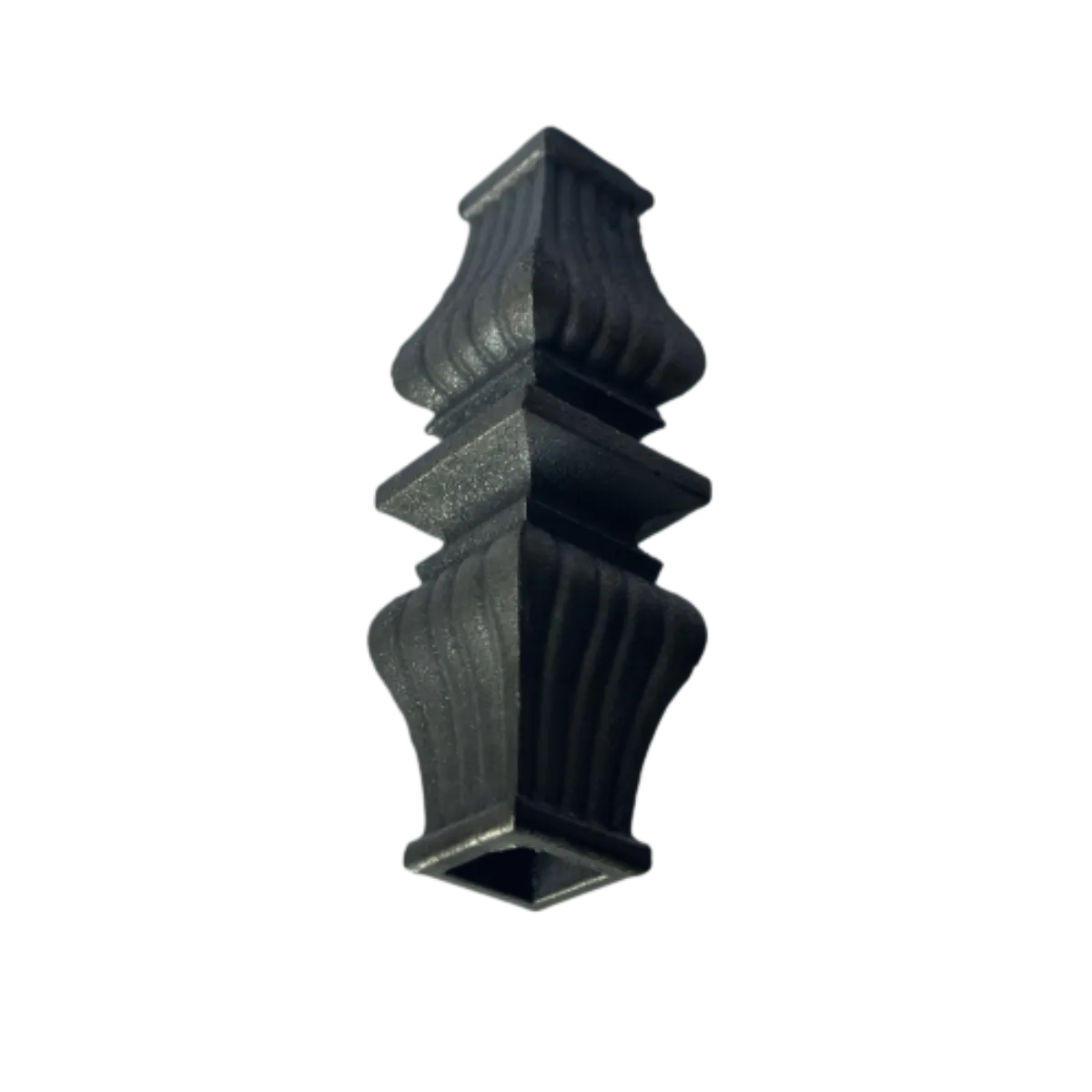

door sliding wheel.  metal box with key lock. It speaks of a time when people believed in the sanctity of physical locks over digital passwords, when the weight of a key in one's pocket was a reassuring reminder of the safety of their belongings. It is a symbol of our innate desire for privacy, a safeguard against the intrusive nature of modern life. The Art of Decorative Collars

metal box with key lock. It speaks of a time when people believed in the sanctity of physical locks over digital passwords, when the weight of a key in one's pocket was a reassuring reminder of the safety of their belongings. It is a symbol of our innate desire for privacy, a safeguard against the intrusive nature of modern life. The Art of Decorative Collars Conclusion Choosing the Right Tap for the Job

The performance of windows and doors depending on the range of use, but the following aspects are usually considered: strength, which is mainly reflected in the selection of materials for windows and doors, whether it can withstand ultra-high pressure; air tightness, mainly in the structure of windows and doors, whether the inner and outer frames of the windows and doors are tight, and the doors and windows are tight.

The bottom line here is that modern aluminium profiles are absolutely no worse insulated than wooden or, even more so, plastic ones. On the contrary, modern aluminium window profiles are distinguished by the best thermal performance and are often used in the construction of passive houses. As a result, the price of aluminium windows and doors has risen considerably in recent years, and we currently have to pay more for them than for wooden windows!

Conclusion

In conclusion, replacement wheels for a sliding screen door are an important component to ensure the smooth operation and functionality of the door. By selecting the correct replacement wheels and properly installing them, you can improve the performance of your screen door and extend its lifespan. Regular maintenance and care of your sliding screen door will help prevent any issues and keep your door working efficiently for years to come. Moreover, steel key boxes are not just limited to residential use. They find extensive application in commercial settings, such as hotels, car rental agencies, and property management companies. In these environments, they streamline key management processes, reduce the chances of lost keys, and enhance overall security. 2. Databases In database systems, roller sliding window can be used to efficiently retrieve and update large datasets. By limiting the amount of data stored in memory, the system can improve query performance and reduce memory consumption.

Starting from the overall home decoration style, the color, size and style of windows and doors need to be considered. Buying a set of beautiful windows and doors with keeping styles with the whole house will not destroy the whole decoration effect. For example, the color of windows and doors should be close to the color of furniture, and the color of wall can maintain the contrast of correspondence. At the same time, the novelty and functionality of aluminium window and door can be customized, which can be used for reference standard to select good aluminium windows&doors.

If you want to keep the aesthetic appeal of your property, you will need to paint the wrought iron fence at your property at least once every couple of years at the absolute least. However, you will need to prepare the wrought iron fence to put a new coat of paint on it before you begin.

In conclusion, cast iron corner castings are essential components that contribute to the strength, durability, and stability of structures and equipment in various industries. With their impressive strength-to-weight ratio, durability, ease of installation, and versatility, cast iron corner castings are a reliable choice for applications that require robust support and reinforcement. By using cast iron corner castings, engineers, builders, and manufacturers can ensure the longevity and performance of their projects, ultimately leading to safer and more durable structures for years to come. A wrought iron fence parts catalog is a valuable resource for anyone who owns or is considering installing a wrought iron fence. This catalog typically includes detailed descriptions and illustrations of the various components that make up a wrought iron fence, such as posts, rails, pickets, finials, gates, and decorative accents. By familiarizing yourself with these different parts, you will be better equipped to identify any issues or damage that may occur and to make informed decisions about repairs or replacements. Screen door top rollers, as the name suggests, are mechanisms situated at the top of a screen door that facilitate smooth opening and closing. They are designed to glide along a track, ensuring the door moves effortlessly and seals securely when closed. These rollers not only contribute to the ease of use but also protect your main entry door from constant wear and tear. However, it's important to note that while cast iron is robust, it requires regular maintenance to prevent rusting and ensure its longevity. This includes periodic painting, lubrication of moving parts, and prompt repair of any damage. Despite this, the investment in a cast iron gate is often seen as worthwhile due to its durability and the value it adds to a property. Moreover, the versatility of cast iron allows for customization. Artists and blacksmiths can mold it into almost any shape or form, catering to individual preferences and architectural requirements. Whether one desires a classic, rustic look or a more contemporary design, cast iron gate ornaments can accommodate these variations. Next, detach the old wheel assembly. This usually involves removing screws or clips that secure the roller to the door frame. Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly wheel replacement for sliding screen door. Together, Platenová, Sporaková, and Liatina created a performance that was nothing short of magical. Their individual talents blended seamlessly, creating a harmonious whole that was greater than the sum of its parts. The audience left the concert hall with a sense of awe and admiration for these talented artists, who had managed to touch their hearts and evoke a wide range of emotions through their performances. Steel Door Rollers The Ultimate Solution for Smooth Operation

wheel replacement for sliding screen door. Together, Platenová, Sporaková, and Liatina created a performance that was nothing short of magical. Their individual talents blended seamlessly, creating a harmonious whole that was greater than the sum of its parts. The audience left the concert hall with a sense of awe and admiration for these talented artists, who had managed to touch their hearts and evoke a wide range of emotions through their performances. Steel Door Rollers The Ultimate Solution for Smooth Operation  In conclusion, the significance of cast iron bases transcends time and function. They are not just materials; they are a testament to human ingenuity and the enduring power of traditional craftsmanship. Despite the advancements in technology, the appeal and utility of cast iron bases remain undiminished, serving as a bridge between our past and present, and a symbol of strength and endurance in our ever-evolving world.

In conclusion, the significance of cast iron bases transcends time and function. They are not just materials; they are a testament to human ingenuity and the enduring power of traditional craftsmanship. Despite the advancements in technology, the appeal and utility of cast iron bases remain undiminished, serving as a bridge between our past and present, and a symbol of strength and endurance in our ever-evolving world. In a nutshell, the main difference between these two types of surface finish is the oxide layer. Anodized finish has a layer of oxide, whereas mill finish does not have the oxide layer.

Sturdy

In addition to their strength and durability, aluminum window frame extrusion profiles are also customizable Furthermore, aluminum glazing bead is an environmentally friendly option. Aluminum is a highly recyclable material, which means that at the end of its life cycle, it can be repurposed and reused rather than ending up in a landfill. This eco-friendly aspect is important for those who are looking to reduce their carbon footprint and make sustainable choices in their building projects. Once you have the proper replacement wheels, the process of replacing them is relatively simple. Begin by removing the screen door from the track and laying it flat on a clean surface. Next, locate the screws that are securing the old wheels to the bottom of the door. Using a screwdriver, remove these screws and lift the old wheels off of the door. Clean any debris or dirt that may have accumulated in the wheel housing before installing the new wheels

replacement wheels sliding screen door. Installing wrought iron fence spears is a wise investment that will not only increase the value of your property but also enhance its curb appeal. The timeless beauty and elegance of these spears will never go out of style, making them a long-lasting and timeless addition to your property. The design of aluminum sliding window wheels has evolved to minimize friction, allowing for smoother operation. This is crucial for large expanses of glass often seen in contemporary architecture, where ease of movement is paramount. The reduced friction also means less strain on the window mechanism, which translates into fewer maintenance requirements over time.

aluminium window wheels price. Cheaper wheels may need to be replaced more frequently, leading to higher maintenance costs in the long run. By investing in higher-priced, quality wheels, you can ensure that your windows operate smoothly for years to come, reducing the need for costly repairs or replacements. The Significance of Window Aluminium Profiles in Modern Architecture The Ubiquitous Cosulet and Bulb A Tale of Two Household Essentials