Links:

- Ink

Hydroxypropyl Methyl Cellulose in Supplements A Useful Additive

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from the natural polymer cellulose. It is produced by the etherification of cellulose, which involves the substitution of hydroxyl groups in cellulose with hydroxyethyl groups. This modification enhances the solubility of cellulose in cold water, making HEC a versatile and valuable compound in various industries. This article explores the characteristics, production process, and applications of HEC cellulose.

In addition to quality control during the manufacturing process, it is also crucial to ensure proper packaging and storage of MHEC. Proper handling and storage conditions must be maintained to prevent degradation of the product and preserve its properties. As a manufacturer, it is important to provide clear instructions to customers on the proper handling and storage of MHEC to ensure its optimal performance.

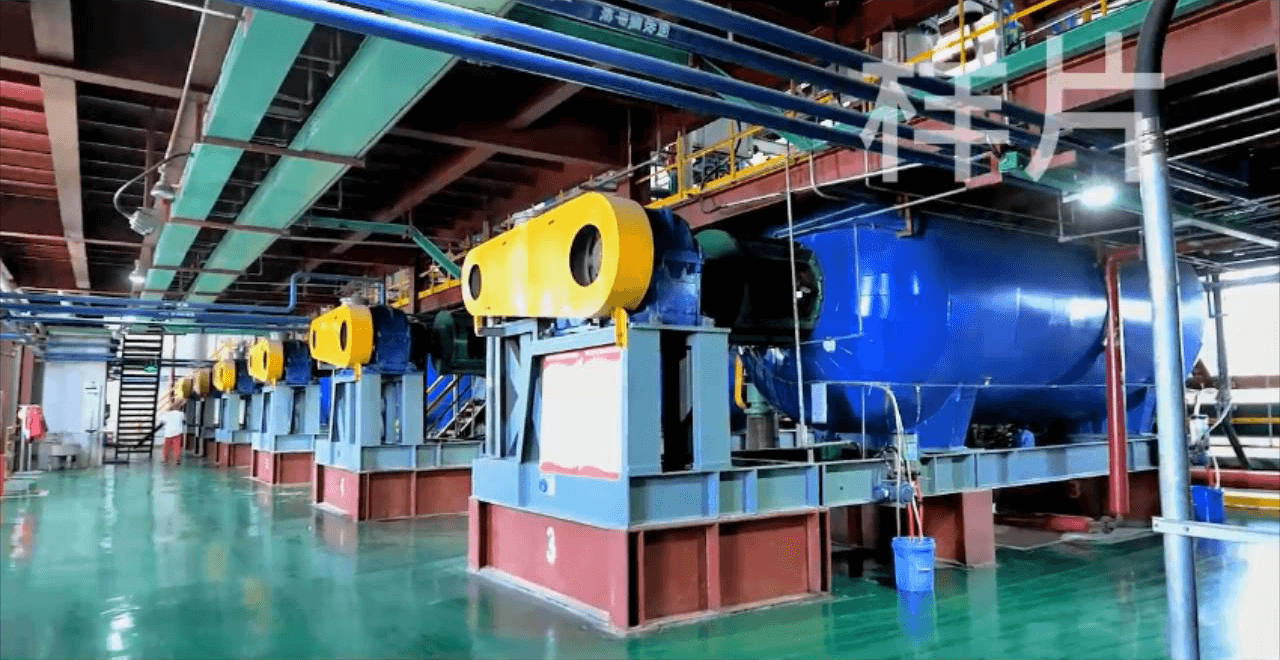

Our company prides itself on providing high-quality HPMC products that meet the strictest industry standards. We have a state-of-the-art production facility and a team of experienced professionals who ensure that every batch of HPMC is manufactured to the highest specifications. Our products undergo rigorous quality control testing to guarantee consistency and reliability.

Hydroxyethyl cellulose (HEC) is a cellulose derivative that has gained considerable attention in various industries due to its unique properties and versatility. This water-soluble polymer is derived from the natural polymer cellulose, which is abundant in plant cell walls. By chemically modifying cellulose, HEC achieves enhanced features that make it suitable for a wide range of applications, particularly in the fields of pharmaceuticals, cosmetics, construction, and food.

2. Water Retention HPMC is known for its excellent water-retaining properties. In construction, this means that mortar and plaster can maintain the necessary moisture for longer periods, allowing for better hydration and curing of concrete and masonry. Proper curing is crucial for achieving optimal strength and durability, reducing the risk of cracking and other structural failures.

Understanding Hydroxyethyl Cellulose Properties and Applications

HEC cellulose is also gaining attention in the food industry, where it is used as a thickening agent and stabilizer in sauces, dressings, and ice creams. Its non-toxic nature and ability to improve texture make it an attractive ingredient for food manufacturers.

5. Technological Advancements Innovations in production techniques can alter the cost dynamics. For example, more efficient manufacturing processes can reduce costs and, if passed on to the consumer, can lead to lower prices.

rdp powder price

The production of redispersible polymer powders typically involves emulsion polymerization, wherein various monomers are polymerized in an aqueous dispersion. The resulting polymer particles are then dried using methods such as spray drying or freeze drying. These processes help to form a powder that retains the properties of the emulsion—primarily the ability to be redispersed in water and to reform the original polymer film upon curing.

In the pharmaceutical industry, HPMC 4000 is commonly used as a tablet binder and a sustained-release agent. Its high viscosity and adhesive properties make it an effective binder for compressing powders into solid tablets. Additionally, its controlled-release abilities help to regulate the release of active ingredients in the body, ensuring a consistent and prolonged effect.

5. Agricultural Applications HPMC sheets are also finding their way into agriculture. They can be used in seed coatings and plant growth media, providing a controlled release of nutrients and protecting seeds from environmental stressors.

HPMC is an essential additive in the construction industry, providing multiple benefits that enhance the performance and durability of construction materials. Its properties of water retention, workability, adhesion, and stability make it a favorite among manufacturers and contractors alike. As the construction industry continues to evolve, the demand for high-performance materials will likely increase, solidifying HPMC's role as a key component in modern construction practices.

Manufacturers invest in research and development to innovate and enhance the properties of HEC. This continuous improvement not only elevates the quality of the product but also expands its range of applications.

The global demand for Hydroxypropyl Methylcellulose continues to grow, driven by its wide-ranging applications and benefits across various industries. China, as a leading supplier, offers a wealth of resources for businesses seeking high-quality HPMC. By selecting the right supplier and ensuring compliance with quality standards, companies can harness the advantages of HPMC in their products, ultimately enhancing performance and satisfying customer demands. As industries evolve, the role of HPMC is expected to expand, solidifying its importance in modern manufacturing and formulation processes.

Additionally, HPMC is used in the production of sauces and dressings, imparting a desirable viscosity without altering the color or flavor of the food. It is also found in ice cream and other frozen desserts, where it helps prevent the formation of ice crystals, resulting in a smoother product.

HPMC wird auch als Überzug für Tabletten und für Tabletten mit verzögerter oder regulierter Freisetzung der Inhaltsstoffe wie zeitverzögertes Vitamin C verwendet. HPMC-Kapseln werden zur Nahrungsergänzungsmittel verwendet. Sie sind daher resistent gegen äußere Umwelteinflüsse. Auch die Qualität der Zutaten ist optimal geschützt.

Conclusion

Additionally, HPMC is used in personal care products such as shampoos, conditioners, and skincare items. It provides a silky texture, enhances spreadability, and acts as a thickening agent, improving the overall formulation of these products.

In the pharmaceutical industry, HPMC is often used as a coating for tablets and capsules. Its film-forming properties help protect the active ingredients from degradation, improve the appearance of the tablets, and control the release of the drug into the body. HPMC is also used as a thickening agent in oral liquids, suspensions, and topical formulations.

As the demand for hydroxypropyl methyl cellulose continues to expand across various industries, manufacturers are tasked with meeting evolving consumer needs while navigating complex market dynamics. By focusing on innovation, sustainability, and quality, HPMC manufacturers are poised to remain at the forefront of this critical industry. The ongoing developments in technology and production processes will likely shape the future of HPMC, ensuring its place as an essential ingredient in numerous applications around the globe.

HPMC is a semi-synthetic polymer that is derived from cellulose, the main component of plant cell walls. It is water-soluble and non-ionic, making it highly versatile in a wide range of applications. As a manufacturer of HPMC, we produce different grades and types of HPMC to cater to the specific needs of different industries.

HPMC

In conclusion, the HPMC contact number is more than just a string of digits; it symbolizes accessibility, support, and collaboration in a dynamic industry. Its importance cannot be overstated, as it serves as a vital tool for communication between manufacturers, suppliers, and consumers. By recognizing the significance of effective communication through reliable contact methods, businesses can create stronger relationships, drive innovation, and ensure smooth operations across various applications of HPMC.

Beyond conventional uses, hydroxyethylcellulose is finding applications in various industrial sectors. It serves as a dispersing agent in paints and coatings, contributing to even pigment distribution. In the oil and gas industry, HEC is utilized in drilling fluids, where it enhances the viscosity and stability of mud systems. Its versatility extends to the textile industry, where it is used as a sizing agent to improve the performance and finish of fabrics.

It's also worth noting that HPMC is considered safe for use in food and pharmaceutical applications, as it is non-toxic and free from allergens. This safety profile adds to its attractiveness as an ingredient across various sectors.

In the realm of food science, HPMC's solubility in methanol can be beneficial for food preservation and texture modification. As a thickening agent, HPMC plays a vital role in stabilizing emulsions and enhancing the texture of food products. The use of methanol as a solvent in the extraction process of food compounds can impact the solubility of HPMC, ultimately influencing the quality and stability of the final product.

Furthermore, HPMC Limited recognizes the importance of sustainability in today’s business landscape. The company is committed to minimizing its environmental impact and actively seeks ways to incorporate sustainable practices into its operations. From utilizing eco-friendly materials to adopting energy-efficient manufacturing processes, HPMC Limited demonstrates that profitability and responsibility can go hand in hand. This dedication to sustainability not only appeals to environmentally conscious consumers but also positions HPMC as a forward-thinking leader in the industry.