Links:

-

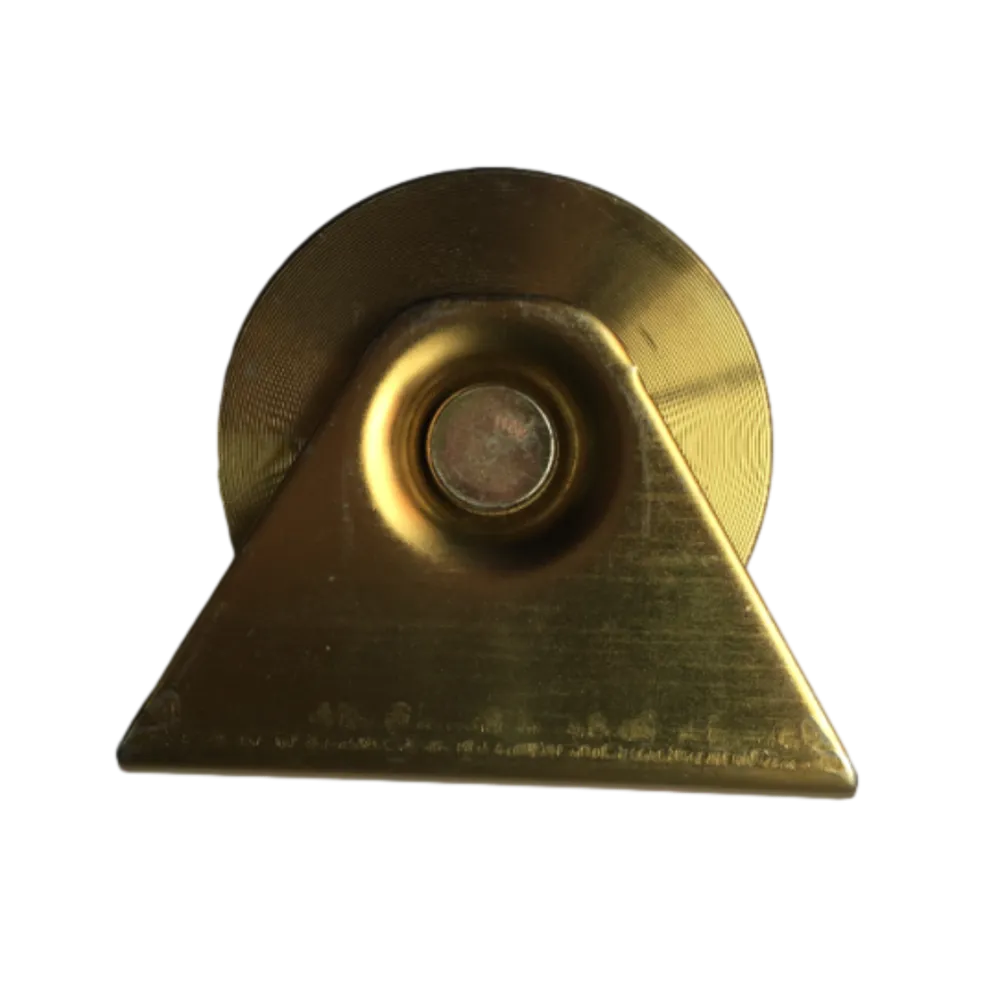

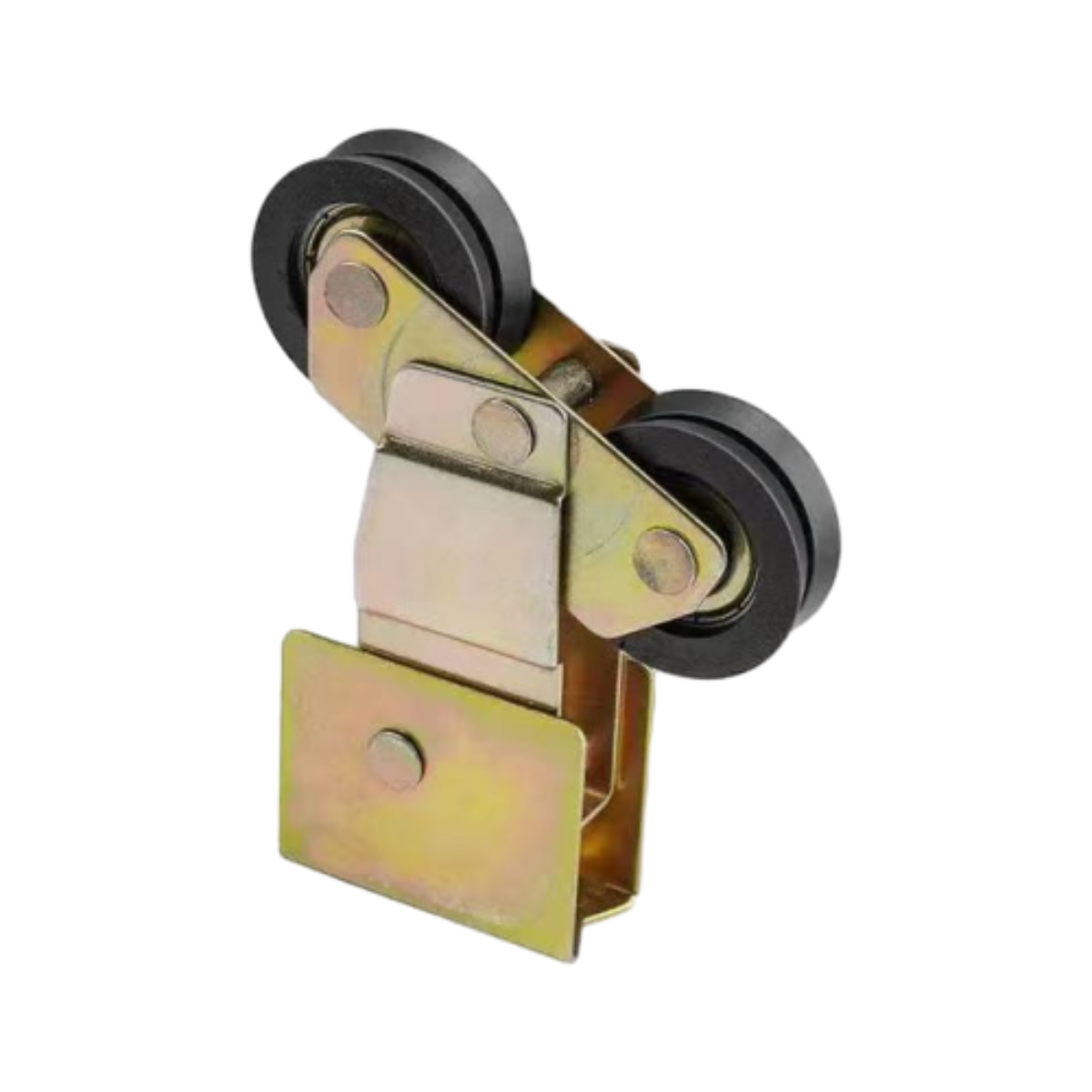

Replacement roller wheels for sliding screen doors are designed to rectify this issue. Made from high-quality materials, these wheels are built to withstand the test of time and heavy usage. They are engineered for durability, ensuring a seamless glide every time you use your door. Whether you're dealing with rust, damage, or just the natural wear from everyday use, a set of replacement roller wheels can breathe new life into your sliding screen door.

- Resistance to moisture, pollutants and ultraviolet rays. In conclusion, decorative iron castings are more than mere decorations; they are artistic expressions in metal, a blend of form and function. They symbolize the harmonious coexistence of tradition and innovation, reminding us of our past while contributing to the aesthetic of our present. Whether serving as a grand entryway statement or a subtle accent piece, these castings continue to captivate and inspire, enriching our built environment with their timeless elegance.

- Whilst the slimmest windows are desirable, they don’t always offer the required functionality. Cast Iron Panel Casting A Comprehensive Guide Another benefit of round bar door handles is their durability. Made from high-quality materials such as stainless steel or brass, they are built to last and can withstand daily wear and tear. This makes them a cost-effective choice in the long run, as they won't need to be replaced as frequently as lower-quality door handles. Furthermore, aluminum extrusion profiles are environmentally friendly. They are made from recycled materials, reducing waste and conserving natural resources. Additionally, they are recyclable at the end of their lifespan, making them a sustainable choice for construction projects.

The material of an aluminium window profile is primarily aluminium. This metal provides a strong, lightweight, and durable framework for the window. Aluminium window profiles are often extruded, meaning they are formed by pushing aluminium through a die to create a long, seamless profile that can be cut to size.

Aluminum window profiles are made of aluminum alloys such as 6063, 6060, 6061, 6005, and 6082 12. These alloys are known for their corrosion resistance and strength-to-weight ratio. The aluminum billet used to make these profiles is typically of national standard .

To enhance the performance characteristics of the window profile, aluminium may be alloyed with other elements, such as copper or zinc, to increase its strength. Additionally, the surface of the aluminium can be coated with paint, anodized, or finished with a powder coating to improve its appearance, resistance to wear, and protection against the elements.

In some cases, other materials may be used in conjunction with the aluminium, such as polyamide or thermal breaks to improve insulation and reduce heat transfer. These materials are often integrated into the design of the window profile to create a more energy-efficient product.

Aluminium Extrusion Profiles and Their Applications in the Windows and Doors Segment

Investing in high-quality aluminum sliding door rollers offers several advantages

aluminum sliding door rollers

Silver, champagne, Bronze, Golden, Black, White, Gray, Sand coating, Anodized Acid, Alkali, and wood texture, or Customized

Another benefit of using a metal storage box with lock is its portability metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility. The versatility of metal storage lock boxes is another significant advantage. They can be used in a variety of environments—from homes, schools, and offices to warehouses and outdoor settings. For homeowners, these lock boxes can serve as a safe place for important documents like passports, birth certificates, and property deeds. For businesses, they can securely hold cash, sensitive paperwork, or crucial equipment, safeguarding them from theft or damage.

Regularly Inspect Your Iron Fence

The Sliding Door Wheel A Revolution in Modern ArchitectureCorner guards can come in various sizes, depending on the homeowner’s preference, for example. They may prefer shorter corner guards as a way of protecting just a small portion of a wall corner. On the other hand, they can also make use of an aluminum corner guard with thicker dimensions to retain the quality of the wall material used.

Cast Iron Railing Panel

Maintenance of sliding door roller wheels is crucial for their longevity and optimal performance

This rating system helps consumers choose a safe that suits their specific needs This rating system helps consumers choose a safe that suits their specific needs

This rating system helps consumers choose a safe that suits their specific needs This rating system helps consumers choose a safe that suits their specific needs steel fireproof safe.

steel fireproof safe. “Wrought iron is forged and hammered, bent and shaped while hot”, describes Mac McCarthy of Welded Sculptures by Mac.

Once you've identified the roller type, purchase a replacement set. Make sure they are compatible with your door frame and have the same specifications as the old ones. You may find these at hardware stores or online retailers. Furthermore, weldable steel gate lock boxes are convenient and easy to install. They can be welded directly onto the gate, providing a secure and permanent attachment

gate lock box weldable steel. This eliminates the need for additional hardware or tools, making the installation process quick and hassle-free. Once installed, the lock box will blend seamlessly with the gate, maintaining its sleek and unobtrusive appearance.

The Best Aluminum Profiles Doors and Windows Manufacturer

When it comes to installation, cast iron panels are also relatively easy to work with. These panels can be easily attached to a railing using screws or brackets, making it a straightforward process for most contractors or DIY enthusiasts. Additionally, cast iron panels can be easily removed and replaced if necessary, allowing for easy repairs or updates to a railing system. In the world of hardware and home improvement, the 400mm pull handle is a remarkable piece of equipment that often goes unnoticed. Its sleek design and functional purpose make it an indispensable tool for various applications, from cabinetry to industrial use. This article will explore the multifaceted uses of the 400mm pull handle and how it enhances our daily lives with its simplicity and strength.The process of welding metal leaves requires a high level of precision and skill. Due to their thinness, they can easily distort or burn through under intense heat, making the welding process a delicate balancing act between power and control. TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, with their ability to provide precise control over the heat source, are commonly employed for such tasks. The use of protective gases helps to prevent oxidation and maintain the integrity of the metal leaves during the process.

metal leaves for welding

For materials to be able to serve as constructional support, they need to be durable, stable, and strong, to contribute to a particular building’s structural integrity.

In conclusion, changing the wheels on a sliding screen door is a practical home maintenance task that saves both time and money. By doing it yourself, you not only learn about the mechanics of your home but also ensure your door operates efficiently, providing you with unhindered access to fresh air and beautiful views. Remember, regular maintenance and timely replacements can prevent bigger issues down the line, making your sliding screen door a reliable and functional part of your home for years to come.The surface of the profile is free of open air bubbles and ash. The reason is that the thickness of the anodised film is thin or the thickness is different, which will directly affect the corrosion resistance of the aluminium profile products. The surface color will change over time, seriously affecting the decorative effect.