Links:

Advances in Timing Belt Technology

Conclusion

Recognizing the signs of a failing belt can save you time, money, and trouble. For serpentine belts, you might notice

Environmental concerns are also shaping the future of conveyor technology. Manufacturers are increasingly seeking sustainable materials and energy-efficient designs to meet regulatory standards and consumer demand. This shift towards eco-friendly practices may also lead to innovative developments in conveyor belt design and operation.

Why Choose Leather?

The growing trend towards automation and robotics in industries has further fueled the demand for small toothed drive belts. Their ability to provide precise control and reliability makes them indispensable in high-tech applications, including 3D printers and CNC machines.

2. Measure the Old Belt If you're replacing an existing belt, measure its length, width, and thickness. However, be cautious, as belts can stretch over time, potentially skewing measurements.

In conclusion, belts on sale are an excellent opportunity to upgrade your fashion accessories. They are economically friendly, offer versatility, and can significantly enhance your overall style. As you navigate these sales, remember to choose pieces that resonate with your personal style and that can stand the test of time. This season, take advantage of the fabulous deals on belts and watch your wardrobe transform! Happy shopping!

3. Cost-Effectiveness Investing in high-quality PK belts can be cost-effective in the long run. While they might have a higher upfront cost compared to lower-quality options, their durability and reliability mean fewer replacements and repairs over time.

4. Medical Equipment In the medical field, precision is paramount. Timing belt motors are integral in devices such as MRI machines and robotic surgical instruments, where accurate movements are crucial for delivering high-quality care.

Flat belts are utilized in a wide array of applications across various industries. Some of these applications include

What is a Serpentine Belt?

To ensure the longevity and effectiveness of your 4PK fan belt, regular maintenance is essential. Here are some tips

- Efficiency These belts are designed for high efficiency with minimal energy loss, making them more economical in the long run. Their ability to maintain their form and function even under high loads reduces the need for frequent replacements.

- Elongation The measure of how much the belt can stretch before it breaks

. A higher elongation percentage indicates greater flexibility, which may be necessary for certain applications.flat rubber belt material

- Width and Thickness A common standard is a belt measuring between 4 to 6 inches in width and approximately 10mm to 13mm in thickness. Thicker belts provide more support but may limit mobility, so it’s essential to find a balance that suits your lifting style.

In the realm of mechanical engineering and machinery design, transmission elements play a pivotal role in ensuring efficient power transfer. Among various types of belts used in these systems, Poly V-belts have gained significant prominence due to their unique design and functionalities. This article explores the characteristics, advantages, applications, and maintenance of Poly V-belts to provide a thorough understanding of this essential component.

For those who are environmentally conscious, using genuine parts is also a more sustainable choice. Fiat’s original parts are manufactured with eco-friendly practices in mind, ensuring that they are produced with minimal environmental impact. Furthermore, when these parts are used, they help the vehicle operate more efficiently, leading to better fuel economy and reduced emissions. This is crucial in our ongoing effort to combat climate change and promote sustainable practices in the automotive industry.

Conveyor belts have become one of the most essential components in the manufacturing and logistics sectors. This technology, which seems simple at first glance, has transformed the way goods are produced, transported, and distributed across various industries. From the assembly lines of automobile manufacturing to the warehousing operations of e-commerce companies, conveyor belts play a critical role in streamlining processes and enhancing productivity.

There are several types of V-belts used in automotive applications, each designed for specific purposes and configurations

1. Increased Efficiency Due to their design, narrow V-belts can transmit power more effectively than traditional flat belts. The wedging action reduces slippage, leading to higher efficiency in power transfer.

4. Belt Material V-belts are made from different materials, including rubber, neoprene, and polyester. Each material has distinct properties and suitability for various applications.

3. मालिकको इतिहास पुराना गाडीहरूको इतिहास जान्नु महत्त्वपूर्ण छ। हराइएका मूल्य र मर्मतको रेकर्ड जाँच गर्नुहोस्।

Applications of V-Belt Drives

The first and foremost factor contributing to the popularity of used auto parts in Korea is the economic benefit. New auto parts can be prohibitively expensive, especially for older or less common vehicle models. This is particularly true for consumers who may own a vehicle that is no longer in production, making new parts scarce and costly. Used parts offer a viable solution, allowing consumers to maintain and repair their vehicles without breaking the bank.

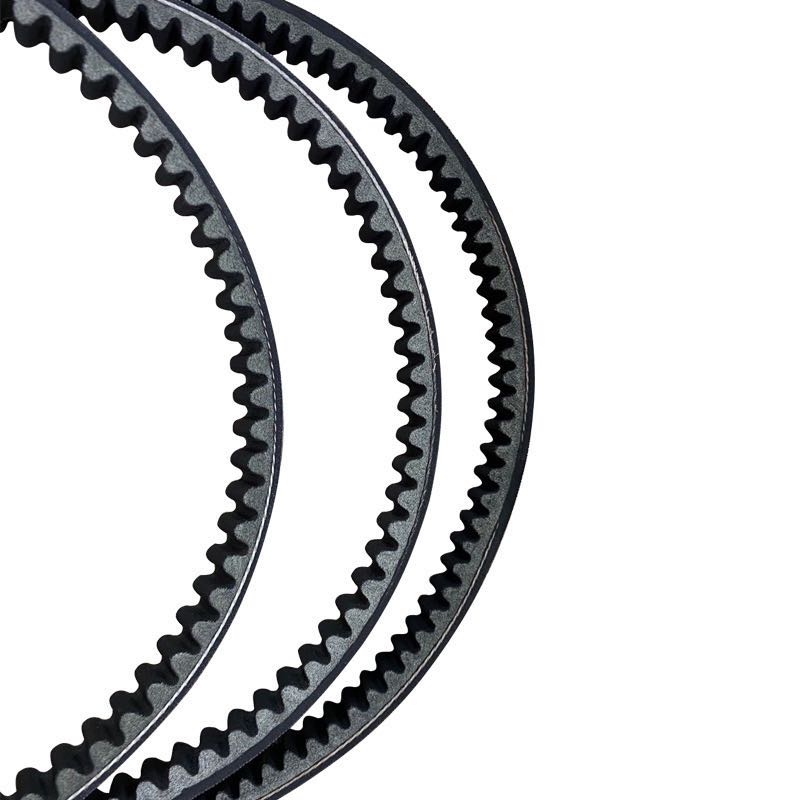

Understanding Cogged Belts The Unsung Heroes of Mechanical Engineering

Understanding V-Ribbed Belts and PK Belts An Overview

4. Labor Costs Installation labor varies widely depending on the garage or dealership's rates. Labor costs can add significantly to the total price, especially for timing belt replacements, which may require more extensive work. On average, you might pay anywhere from $70 to $150 for labor, so it’s important to consider this when budgeting for the replacement.

Additionally, global supply chain disruptions and fluctuations in raw material prices can impact the availability and affordability of V-belts. Manufacturers must navigate these challenges while maintaining high standards of quality and performance.

The serpentine belt is a crucial component of your vehicle's engine, playing an essential role in driving multiple peripheral devices. This single, continuous belt is responsible for powering essential systems such as the alternator, power steering pump, water pump, air conditioning compressor, and more. Over time, serpentine belts can wear out and may need to be replaced. Understanding how to select and purchase the right serpentine belt for your vehicle is key to maintaining optimal performance.

3. Oil Leaks Check for oil leakage around the front of the engine, as a failing timing belt can lead to seal wear.

Moreover, the compact design of ribbed belts contributes to a quieter operation. They function with lower noise levels owing to their smooth and continuous surface contact with the pulleys, making them an ideal choice for manufacturers focused on comfort and noise reduction in their vehicles.

ribbed belt

4. Noise Reduction One of the standout features of the Cummins Belt 3289930 is its ability to reduce noise during operation. This is particularly important in industries where noise pollution can be a concern. A quieter engine not only improves working conditions but also contributes to a more pleasant environment for operators and surrounding areas.

The biker belt's origins can be traced back to the mid-20th century, particularly during the rise of the motorcycle subculture in the United States. With the post-war boom came a wave of returning soldiers who sought freedom and a sense of identity on the open highways. Motorcycling became synonymous with independence, and accessories like the biker belt quickly became essential gear for those who embraced the lifestyle.

In summary, both flat belt drives and V belt drives offer unique benefits that cater to specific industrial needs. Flat belts are ideal for simple, low-cost, high-speed applications, while V belts excel in high-power, compact designs with increased resistance to slippage. The choice between the two ultimately depends on the specific requirements of the application, including power needs, space considerations, and maintenance capabilities. Each type plays a vital role in the efficient operation of machinery across diverse industries.

2. Durability and Longevity The materials used in V ribbed belts are engineered to withstand harsh conditions, including extreme temperatures and exposure to oil or coolant. As a result, these belts typically have a longer lifespan compared to traditional belts.

5. Better Handling of Materials Different types of materials have varying handling requirements. For instance, fragile items may need slower speeds to ensure safety, while heavier goods might benefit from faster transport. Variable speed belts allow for precise handling, making them invaluable in numerous settings.

یکی دیگر از ویژگیهای منحصر به فرد کمربند کلیهای چرمی وینتیج، قابلیت تنظیم آن است. این ویژگی به شما این امکان را میدهد که کمربند را به اندازه دلخواه خود تنظیم کرده و از راحتی بیشتری برخوردار شوید. همچنین، طراحی خاص این کمربند به خوبی شکل بدن را در بر میگیرد و به آن جلوهای زیبا میبخشد.

4. Lack of Power Transmission If the machinery is not operating at its usual efficiency or power output, it may be due to belt slippage.

The primary function of a fan belt is to transfer rotational power from the engine's crankshaft to various engine accessories. This is done through a series of pulleys that the belt winds around, allowing multiple components to operate simultaneously. In modern vehicles, the serpentine belt design has largely replaced traditional V-belts due to its ability to drive multiple accessories with a single belt, which improves efficiency and reduces the weight of the engine compartment.

3. Increased Fuel Consumption A slipping belt can lead to increased friction and resistance, ultimately resulting in higher fuel consumption.

What is a Heavy Duty Serpentine Belt?

6. Resale Value Utilizing OEM parts can also help maintain or increase your vehicle's resale value. Prospective buyers often look for vehicles that have been well-maintained with high-quality parts. Providing documentation that your car has had OEM timing belts and other parts can be a selling point, demonstrating your commitment to maintenance.

- Power Steering Failure Difficulty in steering can suggest that the belt is slipping or has broken.

Conclusion

1. Precise Power Transmission One of the standout features of toothed conveyor belts is their ability to transmit power accurately. The interlocking design of the teeth ensures that the belt engages with drive pulleys without slipping. This is particularly beneficial in applications that require coordinated movement, such as automated assembly lines and robotic systems.

Timing chains offer several benefits due to their robust construction. They are generally more durable and can last much longer than timing belts, often surpassing 200,000 miles without needing replacement. This longevity translates to fewer maintenance costs over the life of the vehicle.

What is a Fan Belt?

The V-ribbed belt features multiple grooves or ribs that run parallel to its length. This design allows for increased surface area and improved grip, enabling it to transfer torque efficiently between the engine and various accessories such as the alternator, power steering pump, water pump, and air conditioning compressor. Due to its ribbed construction, the belt can accommodate a variety of pulleys while maintaining optimal traction and minimizing slippage.

.