Links:

In industrial settings and municipal applications, the need for effective water filtration is paramount. Among the various technologies available, pressure vessel water filters stand out for their efficiency and reliability. This article explores the functioning, benefits, and applications of pressure vessel water filters in modern water treatment processes.

2. Hygienic and Safe The non-porous surface of GRP tanks doesn’t allow for microbial growth, ensuring that the water stored remains clean and safe for consumption. GRP materials are also non-toxic and comply with stringent health and safety standards, making them ideal for potable water storage.

The Importance of Anti-Slip Stair Treads

Moulded gratings also offer ease of customization. Manufacturers provide a range of designs, colors, and sizes, enabling businesses to select the products that best fit their specific needs. Customization features can include varying sizes of openings in the grating, which can be designed to accommodate the safe passage of water while preventing debris accumulation. Such flexibility is essential for industries that require specific functional attributes in their flooring solutions.

moulded gratings

2. Durability Galvanized tanks are designed to withstand high pressure and heavy usage. Their robust construction allows them to endure harsh conditions without deteriorating, making them a cost-effective solution over the long term. Many galvanized tanks can last for several decades with minimal maintenance.

galvanized water storage tank

4. Thermal and Electrical Insulation Another essential feature of FRP walkways is their ability to insulate against heat and electricity. This property makes them ideal for use in electrical facilities, as workers can navigate these walkways without the risk of electrical hazards.

FRP protruded grating represents a significant advancement in material science, offering numerous benefits over traditional building materials. Its lightweight, corrosion-resistant, and slip-resistant properties make it an invaluable resource in many industrial applications. As industries seek to adapt to modern challenges, FRP protruded grating will undoubtedly play a crucial role in the infrastructure of the future. By investing in such innovative materials, companies can enhance safety, durability, and efficiency in their operations.

In addition to being lightweight, fibreglass access platforms boast a high strength-to-weight ratio. This means that they can support substantial loads while remaining light enough for easy handling. The strength of fibreglass platforms makes them suitable for a variety of applications, including industrial maintenance, construction projects, and even in the manufacturing of large machinery where access from various angles is necessary.

fibreglass access platforms

What is a Whole House RO System?

Design Flexibility

modular steel railing

The designation 4% 20 x 8 relates to the load characteristics and dimensions of the grating. The 4% refers to the open area of the grating, indicating that 4% of the surface is open space, allowing for the passage of light and airflow while still providing adequate load-bearing capacity. The 20 x 8 refers to the size of the panels, typically indicating dimensions of 20 inches by 8 inches. This structure makes fiberglass grating both lightweight and strong, ideal for a variety of environments.

When selecting a water softener system, consider factors such as the hardness level of your water, the size of your household, and any specific preferences for salt-free systems. While traditional systems are effective, alternatives like reverse osmosis and templates-assisted crystallization offer different benefits, particularly for those looking to avoid sodium.

Additionally, pressure tanks are vital in the energy sector, particularly for natural gas and oil storage. They are used to contain gases at high pressures, making it possible to transport fuel or supply energy efficiently. The aerospace industry also utilizes pressure tanks for fuel storage, where maintaining high pressure is essential for optimal performance during flight.

What is Heavy Duty Bar Grating?

Step 7 Continuous Improvement

Reverse Osmosis (RO) has become an essential technology in water purification, particularly in industrial settings where high-quality water is paramount. An industrial RO water system utilizes the principles of reverse osmosis to remove impurities and contaminants from water, ensuring that it meets strict quality standards necessary for various applications. In this article, we will explore the components, working principle, benefits, and applications of industrial RO water systems.

Modular systems are designed for simplicity and efficiency. Each component of a modular steel railing can be pre-fabricated off-site, allowing for more precise manufacturing and reducing on-site labor time. This not only speeds up the installation process but also minimizes disruption to the surrounding area during construction. Moreover, the modular nature of these railings means they can be easily assembled and disassembled as needed. This flexibility is particularly beneficial for temporary installations, such as trade show displays or event venues, where modifications might be required frequently.

The manufacturing process itself also plays a critical role. Advanced techniques such as filament winding or resin transfer molding are often used to produce FRP vessels. These processes require specialized equipment and skilled labor, further contributing to the cost. As such, companies that invest in state-of-the-art facilities and maintain high manufacturing standards often price their products accordingly.

Secondly, FRP bars contribute to sustainable construction practices. The reduced weight lowers transportation emissions, while their long lifespan diminishes the need for resource-intensive maintenance. Furthermore, the production process of FRP materials can be more energy-efficient compared to that of traditional materials, aligning with eco-friendly construction goals.

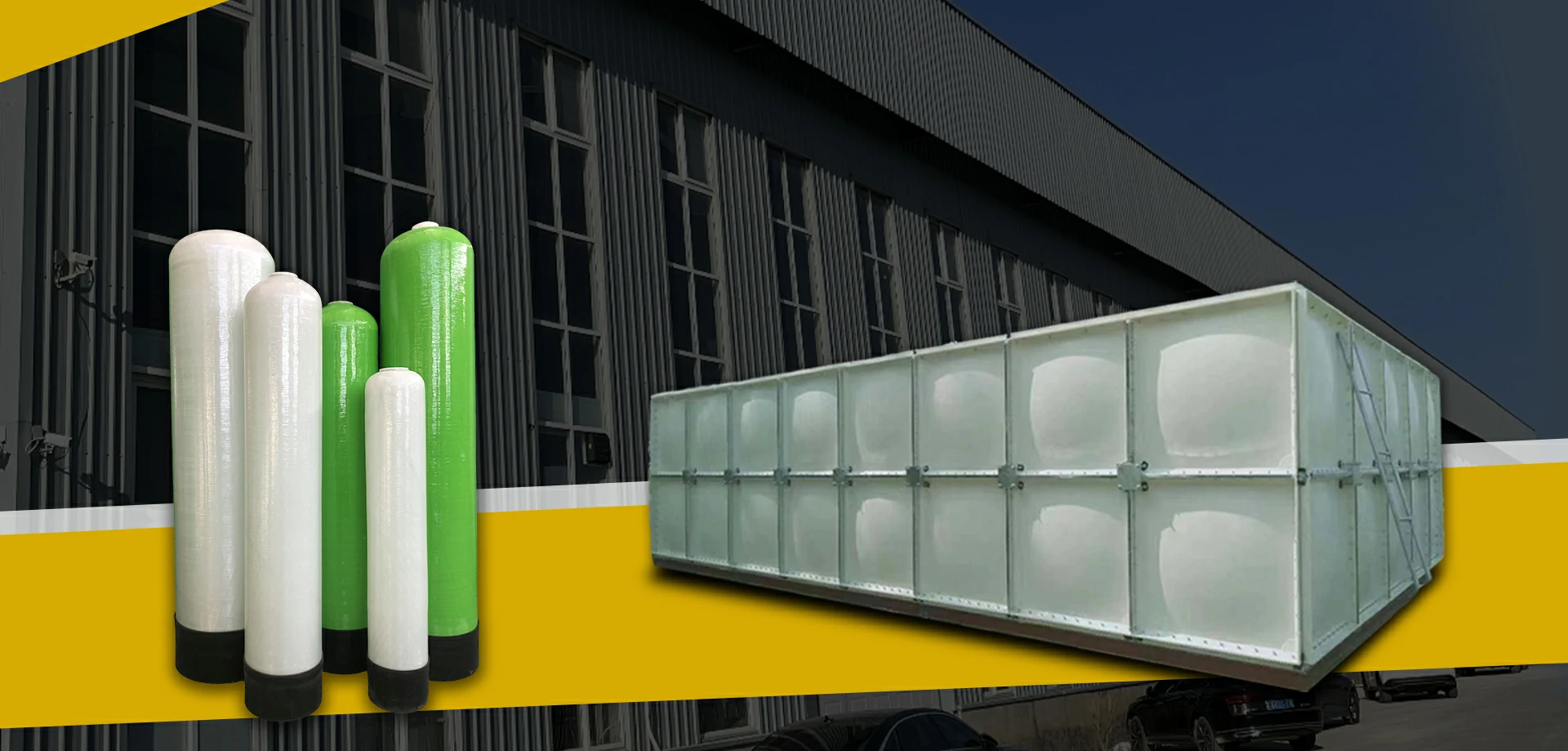

GRP sectional panel tank is a popular choice for storing water in various industries and applications due to its durability, flexibility, and cost-effectiveness. These tanks are made of fiberglass reinforced plastic (GRP) panels that are bolted together to create a water storage solution that can be customized to fit any space or capacity requirements.

In the energy sector, particularly in wind energy, FRP channels are used in turbine towers and support structures, where their strength-to-weight ratio contributes to efficient energy production. Similarly, in the oil and gas industry, FRP channels replace traditional materials to mitigate the risks associated with corrosion and wear.

Key Features

Fiber Reinforced Plastic (FRP) grating is rapidly becoming a preferred material in various industries due to its superior properties, combining strength, lightweight characteristics, and corrosion resistance. This innovative material is engineered to withstand harsh environments, making it ideal for applications in sectors such as construction, maritime, chemical processing, and more.

3. Sustainability With growing concerns over environmental impact, FRP sheet piling presents a sustainable choice. The manufacturing process of FRP can often be less energy-intensive than that of steel and concrete, and the longevity of FRP means less frequent replacements and reduced waste. Furthermore, many FRP products are recyclable, contributing to a circular economy.

Despite the significant advantages, the adoption of FRP bars is not without its challenges. One of the primary concerns is the initial cost; while the long-term savings may be substantial due to reduced maintenance and increased lifespan, the upfront investment can be higher compared to traditional steel reinforcement. Additionally, the bond between FRP bars and concrete can differ from that of steel, requiring adjustments in design and engineering practices.

Historically, tanks were predominantly constructed as large, single units, which could pose challenges in terms of transport and installation. As technology has advanced, the design of sectional tanks has evolved to incorporate innovative materials and improved engineering techniques. Modern sectional tanks often employ high-strength steel, corrosion-resistant coatings, and advanced welding methods, ensuring longevity and stability.

Benefits of RO Filter Systems

In conclusion, floor grating panels represent a versatile and practical flooring solution that caters to a wide range of applications. From enhancing safety and durability to offering environmental benefits and design flexibility, these panels meet the needs of contemporary architecture. As the industry continues to evolve, the incorporation of innovative flooring solutions like floor grating panels will undoubtedly play a key role in shaping safer, more functional, and aesthetically pleasing environments. Whether utilized in industrial settings or modern homes, floor grating panels are a testament to the ingenuity of modern design, proving that practicality can indeed harmonize with style.

Conclusion

One of the primary industries benefiting from fiberglass rods is construction. In this sector, fiberglass rods are commonly used as reinforcement materials in concrete structures. These rods help to enhance the tensile strength of concrete, which is typically strong in compression but weak in tension. By incorporating fiberglass rods, manufacturers can create structures that withstand various stresses and forces, thereby ensuring safety and longevity.

In various industrial settings, effective safety measures and operational efficiency are critical. One crucial component that often goes unnoticed is the floor grating clamp. These clamps play a vital role in securing grating systems, which are commonly used on walkways, platforms, and stairs in industries ranging from manufacturing to construction and beyond. Understanding the significance of floor grating clamps can help organizations enhance safety protocols and improve the functionality of their workspaces.

One of the most significant advantages of GFRP bars is their high resistance to corrosion. Steel reinforcement is susceptible to rust and degradation, especially when exposed to moisture and chemicals. In contrast, GFRP bars can withstand harsh environments, making them an ideal choice for projects in coastal areas, chemical plants, and regions with high humidity. This resistance not only prolongs the lifespan of the structure but also reduces maintenance costs over time.

FRP is a composite material made of a polymer matrix reinforced with fibers, which can be glass, carbon, or aramid. It is known for its excellent strength-to-weight ratio, corrosion resistance, and versatility. These attributes make FRP an ideal candidate for various applications, particularly in the construction of solar structures, such as mounting systems, solar trackers, and even the solar panels themselves.

Understanding GRP

In the world of commercial and industrial water treatment solutions, vessels play a critical role in ensuring efficiency and effectiveness. Among the notable products in this category is the Pentair Vessel 1465. Known for its robust design and advanced features, the Pentair Vessel 1465 is widely utilized in various applications, from municipal water treatment to industrial processes. In this article, we will delve into the pricing aspects of the Pentair Vessel 1465, its features, and the factors influencing its market position.

Customizable Designs

To ensure optimal performance, pressure vessel filters are typically equipped with backwashing systems. Backwashing involves reversing the flow of water to dislodge and remove accumulated contaminants from the filter media. This process not only extends the life of the filter but also maintains its efficiency, reducing the need for frequent replacements.

Maintenance of GRP gratings is another crucial aspect covered in the specification. Regular inspections, cleaning, and maintenance activities are essential to ensure the longevity and performance of the grating. The specification should outline the recommended maintenance procedures, including cleaning methods, inspection frequency, and repair guidelines. Failure to follow proper maintenance practices can result in degradation of the grating material, reducing its lifespan and performance.

Economic factors also favor the adoption of the 1054 FRP vessel. While initial costs may be slightly higher than some traditional materials, the total cost of ownership is significantly lower. This is attributed to its durability, reduced maintenance, and longevity. Industries can enjoy a greater return on investment, making it a financially sound choice.

- Industrial Applications Many factories and facilities use GRP tanks for process water, firefighting water storage, and wastewater treatment. Their resistance to chemicals makes them particularly suitable for these environments.

The Structure and Design

The lightweight nature of FRP makes it easier to transport and install sand filter systems. This can lead to lower installation costs and reduced labor time. Moreover, FRP's durability ensures that the sand filter can withstand harsh environmental conditions without the risk of rust or corrosion common with metal components.

Galvanized tanks are steel containers that have been coated with a layer of zinc to protect against corrosion. The galvanization process involves dipping the steel into molten zinc, which forms a robust and weather-resistant coating. This makes galvanized tanks exceptionally durable and suitable for a variety of storage needs, from water to chemicals.

- Parking Garages Metal gratings allow for efficient rainwater drainage while providing necessary structural support for vehicles.

What is FRP?

4. Manufacturing Process The method used to produce fiberglass tanks can also affect pricing. Tanks that are hand-laid often have a higher production cost compared to those made using automated processes. However, hand-laid tanks may offer superior quality control and craftsmanship.

In addition to being lightweight, fibreglass access platforms boast a high strength-to-weight ratio. This means that they can support substantial loads while remaining light enough for easy handling. The strength of fibreglass platforms makes them suitable for a variety of applications, including industrial maintenance, construction projects, and even in the manufacturing of large machinery where access from various angles is necessary.

fibreglass access platforms

Similarly, in the oil and gas industry, FRP grating is crucial in offshore platforms and refineries. The material’s ability to resist harsh and fluctuating environments ensures longevity and reduces the need for frequent replacements, ultimately leading to lower operational costs.

frp grating

3. High Strength-to-Weight Ratio Despite being lightweight, FRP bars possess exceptional tensile strength. This means that less material is required without compromising structural integrity, which is particularly beneficial in applications where weight is a critical consideration, such as bridges and high-rise buildings.

frp steel bar

In commercial settings, fiberglass grating finds its place in pedestrian walkways, balconies, and rooftop decks. Its lightweight nature simplifies installation while minimizing structural load on supporting beams. Moreover, it can be fabricated in various colors and patterns, providing aesthetic options that appeal to architects and designers.