Links:

Versatility in Applications

fiber reinforced plastic rod

One of the most compelling advantages of prefabricated handrails is their cost-effectiveness. Traditional handrail systems often require extensive onsite labor, resulting in higher labor costs and potential delays. In contrast, prefabricated handrails are manufactured offsite and delivered ready to install. This significantly reduces the time and labor required at the construction site, which translates to lower overall project costs. Moreover, the prefabrication process allows for bulk production, which can also lead to amenable pricing, making these systems an attractive option for budget-conscious projects.

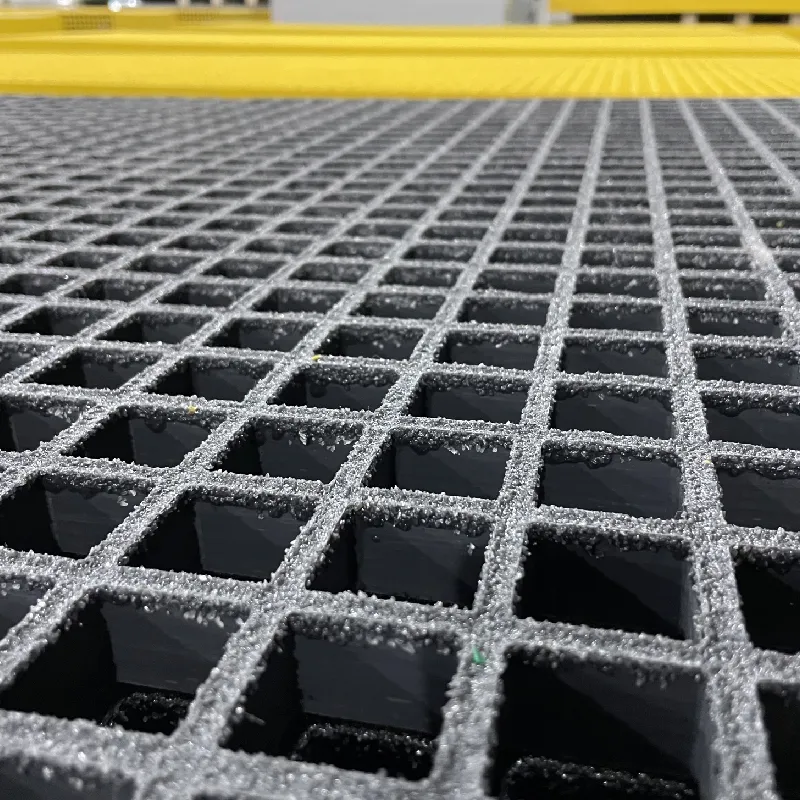

Fiberglass grating is a composite material made from a combination of fiberglass and resin, molded into a grid-like structure. This design allows for excellent load distribution while maintaining the lightweight nature of the product. Fiberglass grating comes in various configurations, including molded and pultruded styles, each suited for specific applications.

2. Flexibility The adaptable nature of modular systems makes them suitable for various environments. Whether it's a straight staircase, an outdoor ramp, or a complex multi-level installation, modular handrails can easily accommodate changes in design.

Environmentally Friendly

grp fence panels

Advantages of UV Water Treatment

1. Corrosion Resistance One of the most significant advantages of FRP grating is its resistance to corrosion. Unlike traditional materials such as steel, which can rust and decay in the presence of moisture and chemicals, FRP remains stable and maintains its integrity in aggressive environments. This property makes it particularly valuable in industries where exposure to corrosive substances is common, like wastewater treatment facilities and chemical plants.

Strength and Durability

2. Low Maintenance Requirements Unlike wooden or painted handrails, which may require regular upkeep such as painting or varnishing, stainless steel handrails necessitate minimal maintenance. A simple periodic cleaning with soap and water is often sufficient to keep them looking new. This low maintenance requirement is not only cost-effective but also time-saving for property owners.

In conclusion, GFRP grating stands out as a leading solution for a myriad of applications in modern industries. Its exceptional characteristics—corrosion resistance, lightweight, safety features, and environmental friendliness—make it a choice material for both new constructions and renovations. As the market for innovative materials continues to grow, GFRP grating is likely to gain even more traction for its ability to meet the diverse needs of various sectors, ensuring durability and safety without compromising on performance.

While the initial cost of FRP bars may be higher than traditional steel, the long-term benefits often outweigh the initial investment. The reduced maintenance costs, decreased material weight leading to lower transport costs, and the extended lifespan of FRP-reinforced structures contribute to overall cost savings in building projects. Additionally, the potential for fewer repairs and replacements enhances their appeal from a financial perspective.

The Role of Manufacturers

As environmental concerns become increasingly significant, FRP tanks present an eco-friendly option for water storage solutions. The materials used in creating FRP are often recyclable, and their longevity means fewer resources are used over time for replacements or repairs. Moreover, the efficient design and ability to maintain water quality contribute to sustainable water management practices, ultimately benefiting the environment.

The Importance of Fibergrate Stair Treads in Modern Architecture

Water is an indispensable resource for life, and its efficient storage is crucial for various applications, ranging from agricultural irrigation to industrial processes. One of the most effective and versatile solutions for water storage is the square poly (polyethylene) water tank. These tanks have gained popularity due to their durability, space efficiency, and cost-effectiveness, making them an ideal choice for both residential and commercial use.

Before fully launching the GRP platform, it's imperative to conduct rigorous testing. This phase involves simulating real-world scenarios to ensure that the system functions as expected. Gather feedback from users during this phase to identify any issues that need to be resolved. This iterative process can significantly enhance the system's usability and ensures a smoother transition when going live.

Understanding Pentair FRP Vessels A Key Component in Water Treatment

Structural FRP represents a significant advancement in material science, offering a combination of properties that address the challenges faced by traditional construction materials. Its applications across various sectors underscore the importance of adopting innovative solutions in engineering. As technology continues to evolve, structural FRP is expected to play an integral role in the future of construction, paving the way for sustainable and resilient infrastructure.

The Growth of FRP Grating Manufacturers

In today's industrial landscape, the need for effective storage solutions is paramount. Companies across various sectors require reliable, durable, and efficient storage tanks to handle a range of materials, from chemicals to wastewater. Among the available options, fiberglass storage tanks have emerged as a highly favored choice due to their unique properties and advantages. This article will delve into the benefits of fiberglass storage tanks, their applications, and considerations when looking for fiberglass storage tanks for sale.

Unlocking the Benefits of Whole House Water Filters and Softeners

4. Stairs and Platforms Many industrial stairs and platforms utilize galvanized bar grating for its strength and slip resistance. This ensures safe access to machinery and elevated areas.

Conclusion

In today's construction and architectural landscape, the choice of materials is critical not only for aesthetics but also for safety, durability, and maintenance. Among the various materials available, Fiber-Reinforced Polymer (FRP) has emerged as a popular choice for handrail systems. FRP handrail systems offer a plethora of advantages, making them an ideal solution for both commercial and industrial applications.

Benefits of FRP Rectangular Tubes

The modulus of elasticity of FRP bars varies depending on the type of fiber used. For instance, carbon fiber offers a higher modulus, providing excellent rigidity, while glass fiber is more economical and widely used in various applications. The low thermal conductivity of FRP also minimizes the risk of thermal cracking, which can be prevalent when using steel reinforcement in extreme temperature conditions.

Access to clean and safe drinking water is essential for health and wellbeing. For many rural and suburban communities, well water serves as the primary source of drinking water. However, well water is not always free from contaminants, which is why the implementation of effective well water purification systems is critical.

2. Reverse Osmosis This advanced filtration method uses a semipermeable membrane to remove ions, unwanted molecules, and larger particles from drinking water. It is particularly effective in desalination processes and is widely used in industries where ultrapure water is required, such as pharmaceuticals and electronics.

In conclusion, FRP bridge deck panels represent a significant evolution in bridge engineering. Their lightweight nature, corrosion resistance, design flexibility, and potential for sustainability make them an attractive choice for modern infrastructure projects. As technology and manufacturing processes improve and awareness of the benefits grows, FRP is poised to become a staple material in the future of bridge construction, leading to safer, longer-lasting, and more efficient infrastructure.

While the initial cost of FRP bars may be higher than traditional steel, the long-term benefits often outweigh the initial investment. The reduced maintenance costs, decreased material weight leading to lower transport costs, and the extended lifespan of FRP-reinforced structures contribute to overall cost savings in building projects. Additionally, the potential for fewer repairs and replacements enhances their appeal from a financial perspective.

Key Advantages of FRP Decking

Floor steel grating, often referred to as metal grating or floor grates, is a type of flooring made from a grid of metal bars. These bars are usually made of steel, which can either be hot-rolled or cold-rolled, depending on the requirements of the application. The grating is designed with spaces between the bars that allow for light, air, and drainage to pass through, making it particularly useful in environments where water accumulation is a concern.

The Value Proposition of 1465 FRP Vessels

Water softeners work by exchanging hardness minerals with sodium or potassium ions through a process called ion exchange. As a result, the water becomes soft, significantly reducing scale deposits and improving the performance of water-using appliances. Soft water also leads to less soap and detergent consumption, smoother skin, and softer fabrics.

whole house water filter and softener

2. Security Security is a primary concern for any property owner, and GRP palisade fencing excels in this area. The design is inherently difficult to climb, and when combined with additional security features such as spikes or barbed wire, it forms a formidable barrier against intruders. Furthermore, the transparent nature of GRP allows for clear visibility, deterring potential trespassers.

grp palisade fencing

FRP guardrails are not limited to one particular application. They are increasingly being adopted in various sectors

4. Cost-Effectiveness While the initial investment in quality floor grating and clamps may seem significant, the long-term benefits far outweigh the costs. By providing a durable and safe flooring solution, businesses can reduce the likelihood of workplace accidents, lower maintenance and replacement costs, and improve overall operational efficiency.

1. Positioning the Supports Start by placing the supporting framework or beams for the FRP grating. Ensure the supports are level and adequately spaced based on the manufacturer's recommendations, typically ranging from 24 to 36 inches apart, depending on the load requirements.

Corrosion resistance is a critical consideration in many industries, and FRP excels in this regard. With the ability to withstand a wide range of chemicals and hostile environmental conditions, FRP vessels have a longer lifespan than their metal counterparts. This longevity translates to lower maintenance costs and reduced downtime for businesses.

4. Versatility FRP drain channels can be tailored to meet specific project requirements, including size, shape, and loading capabilities. This versatility allows engineers and designers to customize solutions that fit various applications, from residential landscaping to heavy-duty industrial use.

Conclusion

Aesthetic Appeal

Moreover, FRP grating is lightweight compared to metal alternatives. This property not only simplifies installation but also reduces the burden on structural supports, potentially leading to overall cost savings in construction and maintenance. Additionally, the non-conductive nature of FRP makes it safer for electrical applications, as it minimizes the risk of electric shock.

grating de frp

5. Government Regulations and Incentives In some regions, government initiatives aimed at encouraging the use of sustainable materials can affect GFRP pricing. Subsidies or tax incentives for using environmentally friendly materials might reduce overall costs for consumers, making GFRP bars more appealing.

The second stage is the heart of the system the reverse osmosis membrane itself. As water is pushed through this special membrane under pressure, it leaves behind most dissolved solids, heavy metals, and other contaminants, allowing only purified water to pass.

Pricing Factors

Understanding Sand Filter Vessels Principles and Applications

FRP grating is a high-performance composite material that combines fiberglass with a resin matrix. This blend results in a product that is not only lightweight but also robust and resistant to corrosion, making it ideal for various environments. The manufacturing process involves pultrusion, where continuous strands of fiberglass are drawn through a resin bath and wound into sheets, which are then cured to form strong, durable panels.

4. Durability and Longevity The materials used in constructing sectional tanks ensure high durability and resistance to corrosion. For instance, stainless steel tanks offer exceptional longevity and are less susceptible to environmental factors compared to plastic alternatives. As a result, investments in sectional cold water storage tanks can yield significant returns over their lifespan.