Links:

- Machinery Requirements and Costs

- Impact of COVID-19 One of the top TiO2 suppliers in the industry is Tronox, a global leader in titanium technologies. Tronox offers a wide range of TiO2 products, including both rutile and anatase grades, to cater to the diverse needs of its customers

- Tridecanal In the area of photodynamic therapy, TiO2's photocatalytic properties have sparked interest Given the high demand for products containing titanium dioxide, there are numerous factories around the world that specialize in manufacturing these products. These factories employ advanced technologies and processes to produce high-quality titanium dioxide products that meet the specifications of their customers. One such factory is the Products with Titanium Dioxide Factory, which is known for its innovative approach to manufacturing titanium dioxide products.

Among the raw materials for coating production, titanium dioxide is more ideal, followed by lithopone. The covering power of lithopone is only that of titanium dioxide, and the price of lithopone is much lower than that of titanium dioxide, so lithopone still occupies a large market share.

Though the Food and Drug Administration (FDA) categorizes titanium dioxide as Generally Recognized as Safe (8), other organizations have issued warnings.

lithopone supplier in fillers, adhesives, joints and sealants

Exposure to titanium dioxide in utero and in breastfeeding children

Titanium dioxide particles help light scatter and reflect, Kelly Johnson-Arbor, MD, a medical toxicology physician at the National Capital Poison Center, told Health. Because of that, we often use it as a whitening agent.

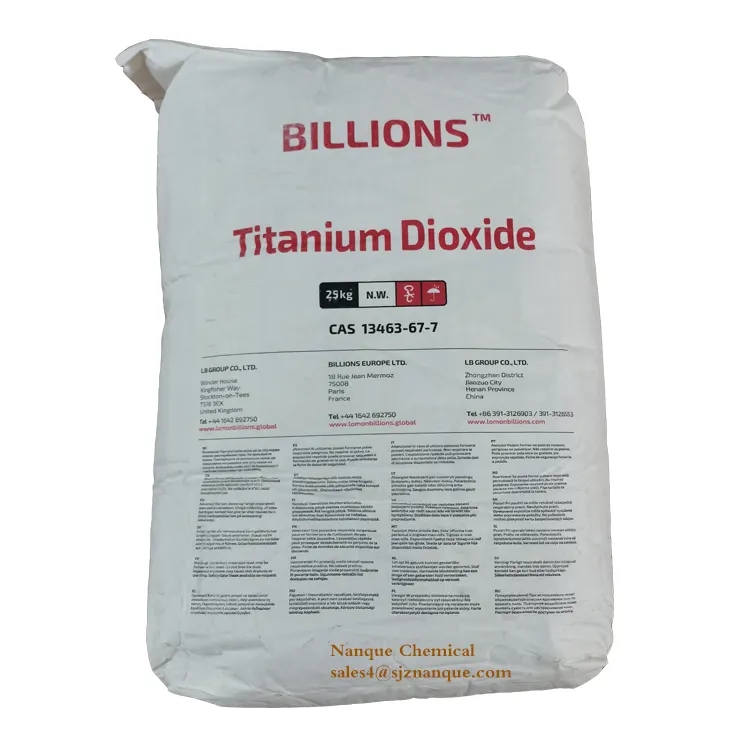

The production of rutile and anatase titanium dioxide involves several steps, including the extraction of titanium ore, purification, and finally, the conversion of the ore into the desired crystalline form rutile and anatase suppliers. The choice of production method depends on factors such as cost, availability of raw materials, and the desired properties of the final product. The paint industry is a dynamic and innovative sector that relies heavily on high-quality raw materials to produce pigments with exceptional performance characteristics. One such key ingredient is titanium dioxide (TiO2), and when we talk about TiO2 in the Chinese context, the name Lomon China stands out prominently. The R996 grade of titanium dioxide, produced by Lomon China, has become a benchmark for the global paint manufacturing sector due to its exceptional quality and application-specific benefits.

rutile and anatase suppliers. The choice of production method depends on factors such as cost, availability of raw materials, and the desired properties of the final product. The paint industry is a dynamic and innovative sector that relies heavily on high-quality raw materials to produce pigments with exceptional performance characteristics. One such key ingredient is titanium dioxide (TiO2), and when we talk about TiO2 in the Chinese context, the name Lomon China stands out prominently. The R996 grade of titanium dioxide, produced by Lomon China, has become a benchmark for the global paint manufacturing sector due to its exceptional quality and application-specific benefits. Currently, titanium dioxide as a food additive is classified as GRAS, or “generally recognized as safe.”

Acknowledgments

In the global market, titanium oxide rutile manufacturers are known for their commitment to innovation and quality assurance. They employ cutting-edge technology and rigorous processes to ensure that the rutile they produce meets the stringent requirements of their clients across diverse sectors. From mining the raw ore to refining it into a usable form, every step is optimized for efficiency and purity. China is one of the leading producers of titanium dioxide in the world, with a market share of over 40%. Titanium dioxide, also known as TiO2, is a white pigment widely used in various industries such as paints, coatings, plastics, and paper. China produces titanium dioxide with a purity level of 99%, making it one of the highest quality products available in the market.≤14

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications. While IARC listed titanium dioxide as “possibly carcinogenic to humans,” they also add that “there is inadequate evidence in humans for the carcinogenicity of titanium dioxide.” Of the four human studies that they reviewed, only one showed a potential risk for occupational workers inhaling titanium dioxide particles and lung cancer, while the other three showed no risk for cancer at all. And it’s key to note that IARC did not assess the effects of titanium dioxide found in foods.

In recent years, titanium dioxide (TiO2) has gained immense popularity across various industries due to its excellent properties, such as high opacity, brightness, and ultraviolet light absorption. As a result, the demand for titanium dioxide has increased significantly, prompting a surge in the number of manufacturers hoping to capitalize on this booming market. While quality remains a priority, cost-effectiveness has emerged as a crucial factor for consumers, leading to a growing interest in cheap titanium dioxide manufacturers.

The production process of lithopone involves several steps, including mixing barium sulfate and zinc sulfide in a specific ratio, followed by grinding the mixture into a fine powder. This powder is then treated with sulfide to form the final product. The factories where lithopone is produced are equipped with advanced machinery and equipment to ensure the quality and consistency of the pigment. The use of lithopone in the plastic industry also has environmental benefits. By improving the performance and longevity of plastic products, it helps to reduce the amount of waste generated and the resources consumed in the production process.

tio2 types suppliers. With a strong focus on research and development, Tronox is able to provide cutting-edge TiO2 solutions that meet the highest quality standards.

In conclusion, Sachtleben's TIO2 brand stands as a testament to the company's pioneering spirit and unyielding commitment to quality. As a leader in titanium dioxide production, they continue to push boundaries, seeking innovative solutions that contribute to both the advancement of their field and the broader industrial applications of TiO2. For those seeking a trusted partner in TiO2 pigments, Sachtleben remains an unrivaled choice, synonymous with excellence and reliability in the global marketplace. In conclusion, titanium dioxide is an indispensable additive for plastic factories due to its multifaceted benefits. From protecting against UV damage to enhancing physical strength and improving aesthetic qualities, TiO2 plays a critical role in producing high-quality plastic products that meet the demands of modern industry and consumer expectations. As research continues to explore new applications and improvements in this field, the significance of titanium dioxide in plastic manufacturing is poised to grow even further. In conclusion, anatase product factories play a vital role in meeting the growing demand for this versatile material. With their commitment to quality and innovation, these factories are not only contributing to environmental protection but also driving the advancement of various industries.