Links:

Benefits of Using a Long Arm Zig Zag Sewing Machine

One challenge faced with handheld sewing machines is their power and tension settings. Unlike traditional sewing machines, which typically provide adjustable tension, some handheld models may not offer the same versatility. Thus, it's crucial to practice and understand how your specific model handles thick fabrics. Testing on scrap pieces can help gauge how much pressure to apply and what settings yield the best stitch quality.

4. Stitch Types and Lengths

sewing machine to sew thick material

Moreover, this feature reduces the risk of errors. Traditional needle threading can often lead to misalignment, causing the thread to skip the needle's eye or become tangled. These mistakes can not only waste time but also lead to frustration and a loss of motivation, especially for beginners who may already feel overwhelmed. An automatic needle threader ensures precise alignment, allowing for a smooth start to any sewing project and reducing the need for frequent adjustments.

automatic needle threader sewing machine

Leather is a material prized for its durability and elegance, commonly used in crafting bags, shoes, belts, and furniture. Chinese hand crank sewing machines excel in leatherwork because of their robust engineering, which enables them to stitch through multiple layers of tough leather without straining the machine. This adaptability makes them a favorite among hobbyists, tailors, and professional leatherworkers alike. The machines can handle various types of stitches, allowing artisans to express their creativity and individual style through their work.

4. Elastic bands or cinching cords These materials will ensure your seat covers fit snugly and remain in place while you drive.

In conclusion, long arm sewing represents both a breakthrough in quilting technology and a creative outlet for enthusiasts worldwide. Whether you are a novice or an experienced quilter, embracing long arm sewing can enhance your craft, empower your creative expression, and open up new possibilities in your quilting journey. As the popularity of long arm quilting continues to soar, it’s clear that this technique is here to stay, establishing itself as a beloved practice in the quilting community.

The overlock stitch is widely used for finishing raw edges and seams, as it trims off excess fabric while simultaneously serging the edge to prevent fraying. This stitch is perfect for knit fabrics, woven fabrics, and even sheer fabrics. The rolled hem stitch, on the other hand, is ideal for creating a delicate and professional finish on lightweight fabrics such as chiffon or organza. It creates a narrow, rolled edge that adds a touch of elegance to your sewing projects.

Conclusion

3. Auction Sites and Used Equipment Outlets If you’re on a budget, consider browsing eBay or other classified ads where you may find quality used machines at a fraction of their original price.

Most sewing machines allow you to use a straight stitch or a zigzag stitch with a double needle. However, for a professional finish, a straight stitch is often preferred. Check your machine’s manual for settings specific to using a double needle.

how to use the double needle in sewing machine

The textile industry has seen countless innovations over the years, but few have been as impactful as the baffle sewing machine. This remarkable piece of machinery has revolutionized the way fabrics are stitched together, bringing efficiency, precision, and versatility to the world of garment and textile production.

The single lockstitch machine, an engineering marvel that revolutionized the textile and garment industry, is an essential tool in modern sewing. This innovative device, with its simple yet effective mechanism, has been a cornerstone of clothing production since its inception.

1. Remove Your Current Needle Turn off your sewing machine and remove the existing needle. Make sure you do this carefully to avoid any injuries.

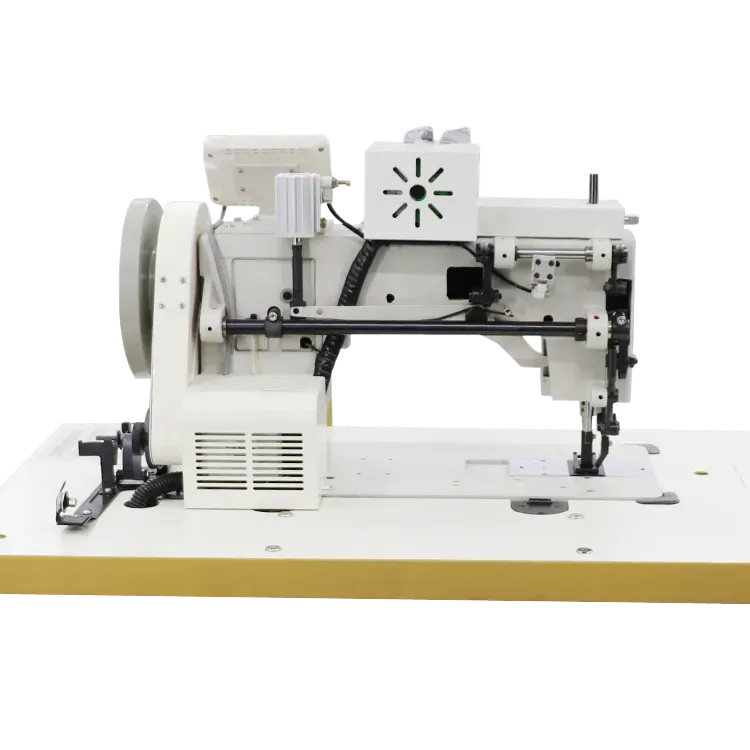

A cylinder arm sewing machine is a type of sewing machine that is commonly used in various industries for sewing cylindrical and other difficult-to-reach items. The cylinder arm refers to the cylindrical shape of the arm of the machine, which allows for easier maneuverability when sewing items such as bags, shoes, hats, and other cylindrical items.Many zigzag machines also include additional features such as automatic thread cutters, adjustable presser feet, and built-in stitch patterns. These elements simplify the sewing process, enabling users to produce high-quality work with less effort. Furthermore, the introduction of computerized models has revolutionized zigzag sewing. These machines allow users to select stitches easily, adjust settings with precision, and even save custom stitch patterns.

Advantages for Home Sewers

In addition to enhancing efficiency and reducing costs, these machines also prioritize safety and hygiene, especially in industries like food processing. Many automatic bag closer machines are equipped with features that comply with health and safety regulations, mitigating the risk of contamination. By automating the sealing process, the need for human contact with the product is minimized, ensuring that the integrity of the items remains intact.

Adjusting Your Machine Settings

how to use a double needle on a sewing machine

Advantages of Using Lock Stitch Machines

A double stitch machine, often referred to as a double needle sewing machine, utilizes two needles working in tandem, allowing it to create two parallel rows of stitching simultaneously. This feature is particularly advantageous for sewing thick materials, as it distributes the tension more evenly across the fabric. The dual needle setup not only saves time but also significantly improves the durability and strength of the seams, critical factors in the longevity of textile products.

Accessories and Parts Availability

On the other hand, heavy-duty machines may have a steeper learning curve due to their advanced features and capabilities. However, this shouldn't deter beginners. Many heavy-duty models, offer helpful tutorials and guides to assist newcomers in mastering their machine's functions.

Tips for Using a Walking Foot

Heavy duty sewing machines are designed for handling tough and demanding sewing tasks. These machines are built with powerful motors and sturdy construction to handle thick and heavy fabrics such as denim, canvas, leather, and upholstery materials. They are commonly used in industries such as upholstery, automotive, sail making, and leatherworking, as well as by home sewers who work with heavy fabrics or multiple layers.

Before diving into pricing, it's important to understand why one might choose an overlock machine with a table

. The table provides a stable work surface that enhances the sewing experience, allowing for more control and precision when handling larger pieces of fabric. Many belt-driven models have an adjustable workspace size, providing flexibility for various sewing projects.Not all hand crank sewing machines are created equal; choosing the right model is crucial for successful leatherwork. Artisans should look for machines specifically designed for heavy materials, with features such as adjustable presser foot pressure and robust needle systems.

3. Versatile Stitches These machines can accommodate a variety of stitches, including overlock, flatlock, and rolled hems. This versatility means that manufacturers can use the same machine for different types of garments, from simple t-shirts to complex activewear.

Overlock chain stitching is an invaluable technique in the world of sewing, providing a robust, flexible finish to a variety of textiles. Its efficiency in seam construction and its ability to prevent fraying make it a staple in both professional and home sewing environments. Whether you’re a seasoned seamstress or a beginner, mastering the overlock chain stitch can significantly enhance the quality of your sewing projects, providing both aesthetic appeal and structural integrity. Embrace this technique and explore its myriad applications in your creative endeavors!

3. Cost-Effectiveness Investing in gunny bag sewing machines can yield substantial cost savings in the long run. The durability of the stitched bags reduces losses due to spillage or contamination, while the speed of operation allows businesses to scale up production without a significant increase in labor costs.

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

One of the most compelling advantages of CNC upholstery sewing machines is their efficiency. Traditional sewing methods often require multiple operators to gather, cut, and sew fabric pieces together. In contrast, a CNC machine can perform these tasks in a streamlined workflow. This leads to a significant reduction in labor costs and production time, ultimately allowing manufacturers to meet increasing consumer demands without compromising on quality.

Studies and opinions from professionals in the field reinforce the idea that heavy duty sewing machines, with the right settings and techniques, can indeed sew light fabrics. Manufacturers also cater to this need by incorporating versatile features in many of their heavy-duty models.

Conclusion

1. Choose the Right Needle It is essential to select the appropriate needle for sewing leather. Leather needles are specifically designed with a wedge-shaped tip to penetrate the material without causing damage.

In conclusion, CNC machine sewing represents a significant advancement in the textile industry, providing numerous benefits ranging from enhanced precision to increased efficiency and sustainability. As this technology evolves, it holds the potential to reshape the landscape of garment production, making it an exciting time for manufacturers and designers alike. The future of sewing is not just about threads and fabrics but also about the integration of technology that can create a smarter, more efficient production process.