Current location:

Links:

-

Moreover, FRP tanks are also highly customizable Furthermore, the small fiberglass tanks offer a cost-effective solution in the long run. While the initial investment might be slightly higher than other materials, their low maintenance, durability, and resistance to corrosion lead to significant savings over time. Moreover, the lightweight nature of fiberglass ducts simplifies installation, reducing labor costs and time. Their flexibility allows for easier navigation through complex architectural designs, fitting seamlessly into tight spaces that might pose challenges for rigid metal ducts. Moreover, the customization possibilities with fiberglass tanks are extensive. They can be tailored to meet specific requirements, whether it's the size, shape, or thickness. The design flexibility extends to the internal lining and coatings, allowing the tanks to adapt to the properties of the stored substance, further enhancing their compatibility and longevity. The anchor drill bit is typically made from high-quality materials such as tungsten carbide or cobalt, which offer durability and longevity. These materials are carefully selected for their ability to withstand the high pressures and temperatures generated during drilling. The bit's cutting edges are designed to be extremely sharp, allowing it to easily penetrate through hard surfaces without causing damage or deformation. In the realm of engineering and construction, precision and adaptability are paramount. One component that significantly contributes to this is the shank adapter, and the manufacturers behind these critical tools play a vital role in ensuring operational efficiency and safety. A shank adapter, as the name suggests, is a device designed to connect two components with different shank sizes or types, enabling a wide range of applications in various industries. The M/F Speedrod, with its futuristic design and optimized functionality, is not just a tool; it's a revolution in the realm of sporting gear. The name itself denotes its core concept - the harmonious blend of masculinity (M) and finesse (F), combined with a 20% boost in speed (Speedrod). It's an embodiment of power and agility, tailored to enhance the performance of athletes across various disciplines. The Importance of Fiberglass Chemical Tanks in Industrial Applications 3. Enhanced Performance Handrails can also help participants improve their performance in group exercise classes. By using the rails for support, participants can focus on perfecting their form and technique, rather than worrying about maintaining their balance. This can lead to better results and a more effective workout. The operation of an frp demister hinges on its intricate structure. Comprising a series of parallel vanes, it creates a tortuous path for the gas to follow. As the gas passes through, the vanes cause the entrained liquid droplets to coalesce. Due to their increased size, these droplets then lose momentum and fall out of the gas stream under the influence of gravity, leading to efficient separation. In addition to the initial investment, consider the operating costs, including air compressor requirements, drill bits, and potential repair expenses. Some manufacturers provide energy-efficient models that can significantly reduce operational costs over time. Furthermore, FRP pipelines excel in managing user interfaces, where data changes continuously and in response to user actions. With FRP, UI updates become a natural consequence of changes in underlying data streams, ensuring a smooth and responsive user experience.

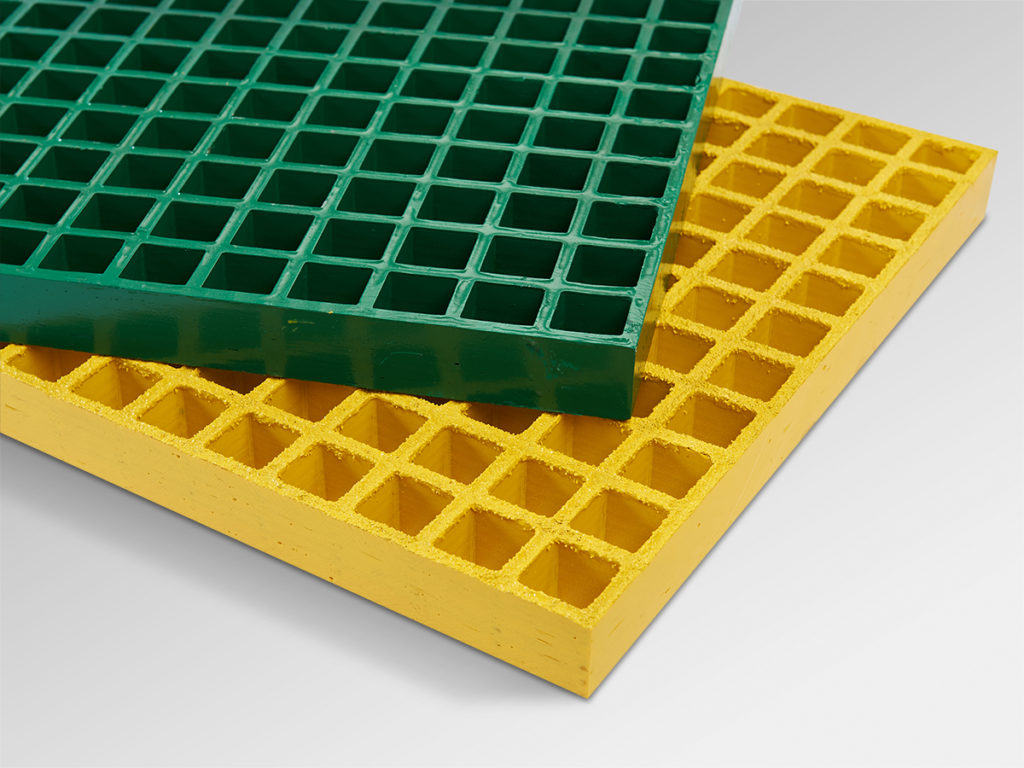

FRP Flooring A Revolutionary Material for a Sustainable Future In tunnel drilling, the rock drill tools are typically attached to a drilling rig and operated by skilled workers. The drill bit of the rock drill tools is pressed against the rock surface and rotated to create holes for explosives or other excavation methods. The drilling process requires precision and control to ensure the safety and stability of the tunnel structure. Flue Gas Desulfurization (FGD) is a critical process employed in power plants and other industrial facilities to mitigate the harmful effects of sulfur dioxide (SO2) emissions on the environment. It is a technology designed to remove sulfur dioxide from the exhaust flue gases produced by burning fossil fuels, primarily coal, oil, or gas. In addition to their robustness, FRP pipes offer design flexibility. They can be manufactured in different diameters, lengths, and thicknesses, allowing customization according to project requirements. Their non-conductive property makes them safe for use in areas with electrical hazards. In the energy sector, FRP gratings are utilized in solar panel support structures and heat exchanger plates due to their excellent thermal and electrical insulation properties. Their ability to maintain consistent performance in extreme temperature ranges makes them an ideal choice for applications where heat transfer is critical. In addition to being durable, fiberglass field tanks are lightweight and easy to install. This can result in cost savings for businesses, as installation and transportation costs are typically lower compared to heavier steel tanks. Furthermore, fiberglass tanks are easy to maintain and can be quickly repaired if damaged, reducing downtime and ensuring that liquids are stored safely and securely. A rock drill extension rod, as the name implies, is an additional shaft attached to a primary drill rod, designed to extend the drilling depth and range. It is primarily used with percussion or rotary rock drills, which are employed for drilling through hard and abrasive rock formations. These rods are made from high-strength materials like alloy steel, ensuring durability and resistance against the harsh conditions encountered in drilling applications. Conclusion Functionality is paramount in the design of a coupling sleeve One of the key challenges in drilling through rock is overcoming the immense pressure and heat encountered at great depths. Engineers and scientists have developed specialized drill bits made from hardened materials like tungsten carbide that can withstand these extreme conditions. Additionally, advanced lubrication systems ensure that the drill bit remains cool and efficient during operation. In the realm of mechanical engineering, the thread shank adapter serves as a vital link between threaded fasteners and the components they secure. This versatile component is designed to adapt various thread sizes and types, ensuring a secure and reliable connection in a wide range of applications. Tungsten Carbide Button Bits Revolutionizing Drilling Efficiency The advent of the gasoline-powered rock drill dates back to the early 20th century, a time when manual labor was the primary means of drilling through hard rock surfaces. The introduction of this technology marked a significant departure from the traditional hand drilling methods, which were not only slow but also physically demanding on workers. The gasoline engine, with its potent power source, offered an unprecedented level of efficiency and speed, thereby increasing productivity and reducing labor-intensive tasks. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants. In conclusion, the marble drill bit is not just a tool; it's a testament to the marriage of technology and artistry in the realm of marble work. It enables us to harness the beauty and strength of marble while preserving its integrity. With the right drill bit and careful handling, even the most challenging marble drilling tasks can be accomplished with ease and precision. So, whether you're a hobbyist or a seasoned artisan, investing in a high-quality marble drill bit is a wise decision that will pay off in the long run.

FRP Flooring A Revolutionary Material for a Sustainable Future In tunnel drilling, the rock drill tools are typically attached to a drilling rig and operated by skilled workers. The drill bit of the rock drill tools is pressed against the rock surface and rotated to create holes for explosives or other excavation methods. The drilling process requires precision and control to ensure the safety and stability of the tunnel structure. Flue Gas Desulfurization (FGD) is a critical process employed in power plants and other industrial facilities to mitigate the harmful effects of sulfur dioxide (SO2) emissions on the environment. It is a technology designed to remove sulfur dioxide from the exhaust flue gases produced by burning fossil fuels, primarily coal, oil, or gas. In addition to their robustness, FRP pipes offer design flexibility. They can be manufactured in different diameters, lengths, and thicknesses, allowing customization according to project requirements. Their non-conductive property makes them safe for use in areas with electrical hazards. In the energy sector, FRP gratings are utilized in solar panel support structures and heat exchanger plates due to their excellent thermal and electrical insulation properties. Their ability to maintain consistent performance in extreme temperature ranges makes them an ideal choice for applications where heat transfer is critical. In addition to being durable, fiberglass field tanks are lightweight and easy to install. This can result in cost savings for businesses, as installation and transportation costs are typically lower compared to heavier steel tanks. Furthermore, fiberglass tanks are easy to maintain and can be quickly repaired if damaged, reducing downtime and ensuring that liquids are stored safely and securely. A rock drill extension rod, as the name implies, is an additional shaft attached to a primary drill rod, designed to extend the drilling depth and range. It is primarily used with percussion or rotary rock drills, which are employed for drilling through hard and abrasive rock formations. These rods are made from high-strength materials like alloy steel, ensuring durability and resistance against the harsh conditions encountered in drilling applications. Conclusion Functionality is paramount in the design of a coupling sleeve One of the key challenges in drilling through rock is overcoming the immense pressure and heat encountered at great depths. Engineers and scientists have developed specialized drill bits made from hardened materials like tungsten carbide that can withstand these extreme conditions. Additionally, advanced lubrication systems ensure that the drill bit remains cool and efficient during operation. In the realm of mechanical engineering, the thread shank adapter serves as a vital link between threaded fasteners and the components they secure. This versatile component is designed to adapt various thread sizes and types, ensuring a secure and reliable connection in a wide range of applications. Tungsten Carbide Button Bits Revolutionizing Drilling Efficiency The advent of the gasoline-powered rock drill dates back to the early 20th century, a time when manual labor was the primary means of drilling through hard rock surfaces. The introduction of this technology marked a significant departure from the traditional hand drilling methods, which were not only slow but also physically demanding on workers. The gasoline engine, with its potent power source, offered an unprecedented level of efficiency and speed, thereby increasing productivity and reducing labor-intensive tasks. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants. In conclusion, the marble drill bit is not just a tool; it's a testament to the marriage of technology and artistry in the realm of marble work. It enables us to harness the beauty and strength of marble while preserving its integrity. With the right drill bit and careful handling, even the most challenging marble drilling tasks can be accomplished with ease and precision. So, whether you're a hobbyist or a seasoned artisan, investing in a high-quality marble drill bit is a wise decision that will pay off in the long run.