Current location:

Links:

-

The use of the 6301 bearing offers numerous benefits, including * Durability The high-quality materials and strict quality control during manufacturing ensure that the bearing is durable and resistant to wear and tear.

- Axial Load Support: While not the primary function, cylindrical roller bearings can also accommodate some axial loads, depending on the specific design and configuration. One of the primary advantages of axial angular contact ball bearings is their ability to withstand high thrust loads. The angled contact allows for a more even distribution of force across the balls, enhancing the bearing's load-carrying capacity. Furthermore, they can operate at high speeds due to the reduced friction generated by the angle of contact. Taper roller bearings are an essential component of many industrial applications, providing a means of transferring load and reducing friction in rotating machinery. The material selection for these bearings is crucial, as it directly affects the performance, durability, and reliability of the system they support. Conclusion Benefits of Using the 51108 Bearing Moreover, the Bearing 6301 AS 15 is often available in various materials and coatings, catering to specific environmental or operating conditions. This adaptability makes it a go-to choice for engineers looking to optimize their designs while maintaining reliability. Lastly, these bearings offer excellent speed capabilities. With proper lubrication, they can operate at high speeds without compromising on performance or safety. This versatility makes them suitable for both low-speed and high-speed applications. Bearing 29424 is a type of thrust spherical roller bearing that is designed to handle heavy axial loads. It consists of two symmetrical spherical roller raceways and a common spherical raceway on the outer ring. This unique design allows the bearing to accommodate misalignment and axial deflection, making it ideal for applications where high axial loads and shock loads are present.

- Each type of cylindrical roller bearing offers unique advantages, depending on the operational conditions and load requirements. Proper selection is crucial to ensure optimal performance, longevity, and efficiency in any mechanical system. Always consider factors like load capacity, speed, alignment, and maintenance needs when choosing the right cylindrical roller bearing for your application. With their versatility and robust design, cylindrical roller bearings continue to play a vital role in numerous industries, facilitating smooth and efficient operations. Introduction Exploring the Versatile Deep Groove Ball Bearing for Your Next Purchase Furthermore, the material and finish of the bearing also impact its performance. High-quality steel with heat treatment is commonly used for the balls and races, ensuring durability and resistance to wear. The surface finish minimizes friction and improves lubrication, enhancing the bearing's lifespan. When selecting a 6305 2RS bearing for a specific application, it is essential to consider factors such as load requirements, speed limitations, and operating conditions. The dimensions of the bearing will determine its ability to support radial and axial loads, maintain proper alignment, and withstand the forces and vibrations present in the application

- Spherical Roller Bearings: Spherical roller bearings are commonly used in applications where misalignment compensation, high load capacity, and the ability to handle dynamic or oscillating loads are required, such as in heavy industrial machinery, mining equipment, and vibratory screens.

In the realm of precision machinery, there exists a component that is paramount to its smooth operation and extended life the ball bearing. These tiny yet crucial devices are the unsung heroes of countless systems, from household appliances to state-of-the-art industrial machinery. One of the most notable attributes of this bearing is its optimized internal geometry. The carefully crafted inner and outer races, along with the precisely engineered rolling elements, work in harmony to reduce friction and enhance rotational speed. This results in increased equipment longevity and reduced energy consumption, which is crucial in today's push for more sustainable industrial practices. These bearings find extensive use in automotive applications, such as wheel hubs, differentials, and transmission shafts, as well as in industrial machinery like conveyor systems, wind turbines, and heavy-duty machinery. Their design allows for easy adjustment and compensation for misalignment, making them versatile and adaptable to various operating conditions. In conclusion, roller bearings play a crucial role in various industrial applications by providing support and reducing friction between moving parts. Each type of roller bearing has specific features and benefits that make them suitable for different applications. Understanding the characteristics of each type of roller bearing is essential for selecting the right bearing for a particular application. Whether it's cylindrical, spherical, tapered, or needle roller bearings, choosing the right type of roller bearing can improve the overall performance and efficiency of machinery and equipment. Width (W) The Significance of the 51124 Thrust Ball Bearing in Modern Industry Exploring the Beauty of Bearing, NJ 206 The design of these bearings includes a deep groove, which allows for increased ball capacity. This enhances the load-carrying capability and provides better contact stress distribution within the bearing. The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial high temperature deep groove ball bearing. The impact of the 22313 bearing extends beyond mere operational benefits Spherical Plain Bearings A Comprehensive Size Chart Guide Deep Groove Ball Bearings, on the other hand, are a subclass of ball bearings with a deeper groove in the raceways of both the inner and outer rings. This design enhancement allows them to not only support radial loads but also accommodate axial loads in both directions, making them more versatile than standard ball bearings. Their increased load-bearing capacity makes them suitable for applications involving heavier loads, such as automotive engines, pumps, and conveyors. 4. Environmental sustainability The 25877 bearing's low friction properties lead to reduced energy consumption, making it an environmentally friendly alternative to traditional bearings. One of the most popular series in the tapered roller bearing family is the Metric Series, denoted by the prefix 30000. This series features a 112 taper ratio and is widely used in automotive hubs, transmissions, and differentials due to its ability to handle high radial and axial loads. The American series, denoted by T or TS, follows a similar principle but is designed to meet the specific requirements of the North American market.

high temperature deep groove ball bearing. The impact of the 22313 bearing extends beyond mere operational benefits Spherical Plain Bearings A Comprehensive Size Chart Guide Deep Groove Ball Bearings, on the other hand, are a subclass of ball bearings with a deeper groove in the raceways of both the inner and outer rings. This design enhancement allows them to not only support radial loads but also accommodate axial loads in both directions, making them more versatile than standard ball bearings. Their increased load-bearing capacity makes them suitable for applications involving heavier loads, such as automotive engines, pumps, and conveyors. 4. Environmental sustainability The 25877 bearing's low friction properties lead to reduced energy consumption, making it an environmentally friendly alternative to traditional bearings. One of the most popular series in the tapered roller bearing family is the Metric Series, denoted by the prefix 30000. This series features a 112 taper ratio and is widely used in automotive hubs, transmissions, and differentials due to its ability to handle high radial and axial loads. The American series, denoted by T or TS, follows a similar principle but is designed to meet the specific requirements of the North American market. A deep groove in a ball bearing refers to the specific design feature of the bearing's inner and outer raceways, which allows it to accommodate radial and axial loads while enabling smooth and efficient rotation. The deep groove is a critical aspect of the ball bearing's construction and contributes to its performance in various applications.

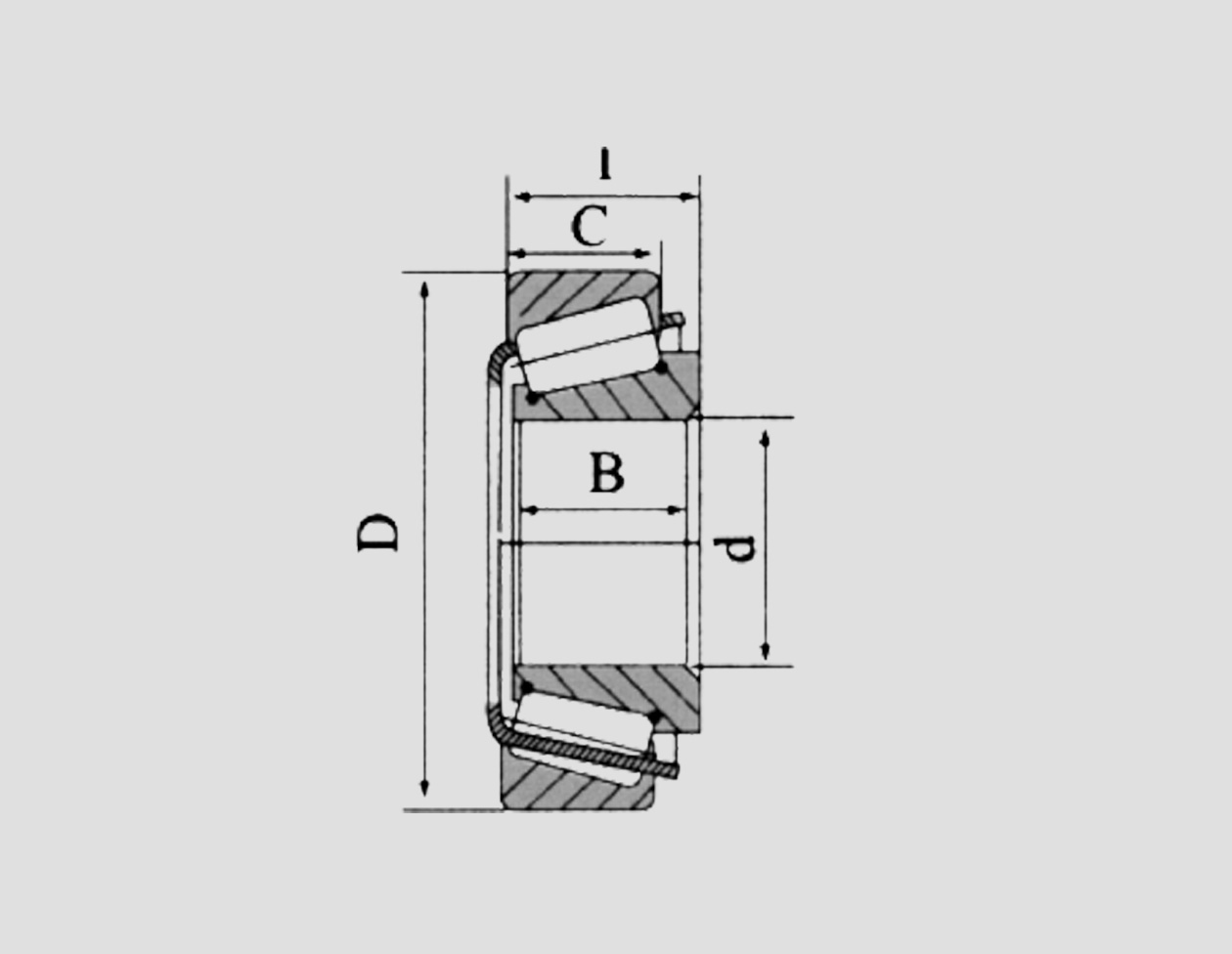

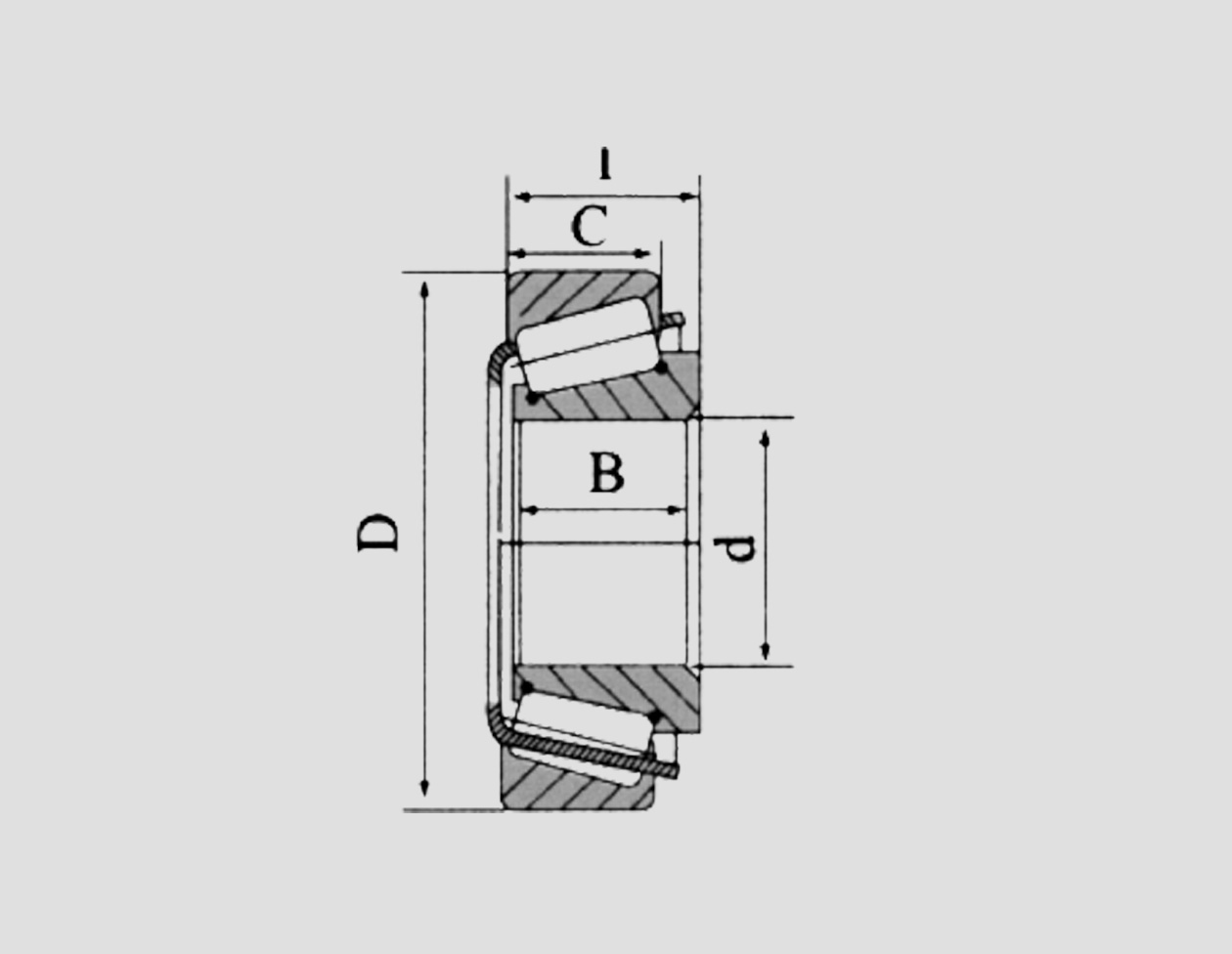

1. Inside diameter (d) The diameter of the inner race, measured in millimeters or inches. One of the key features of the 6206 bearing is its versatility. It can be used in a wide range of applications, including machinery, automotive components, electric motors, pumps, and fans. The 6206 bearing is often used in applications where high speeds and heavy loads are present, thanks to its robust construction and ability to handle both radial and axial loads. In addition to their high load capacity and durability, NTN cylindrical roller bearings are also easy to install and maintain The 6201Z bearing is a widely utilized deep groove ball bearing type, designed to support both radial and axial loads with high efficiency. This bearing model is an essential component in various mechanical applications due to its robustness, durability, and versatility. In conclusion, the 6228 bearing, with its specified dimensions, is a robust and versatile component designed to meet the demands of diverse industrial applications. Its dimensions, along with its design features, contribute to its ability to handle heavy loads and provide smooth rotation. Understanding these dimensions is key to selecting the right bearing for a specific application, ensuring optimal performance, and maximizing machinery efficiency. Whether in automotive, aerospace, or general engineering, the 6228 bearing stands as a testament to the importance of precise engineering and meticulous dimensioning in the world of bearings. The 30232 bearing is a type of roller bearing that consists of inner and outer rings with cylindrical rollers. It is designed to handle heavy radial and axial loads, making it ideal for applications where high performance and reliability are required. * C is the radial clearance In industries like automotive, aerospace, machinery, and even in household appliances, deep groove ball thrust bearings are widely employed. They find usage in engine components, gearboxes, pumps, compressors, and even in conveyor systems, where they help reduce friction, enhance efficiency, and ensure smooth operation. 6310 2rs bearing. Conclusion

6310 2rs bearing. Conclusion

6305 2rs bearing dimensions. Bearing is a critical component in various machinery systems, including automobiles, industrial equipment, and aerospace. Its primary function is to reduce friction between moving parts, ensuring smooth operation and extending the life of the equipment. However, bearing quality can significantly impact pricing, and understanding this relationship is essential for both manufacturers and consumers. In addition to their quiet operation, deep groove ball bearings are also easy to install and maintain. With proper lubrication and regular inspection, these bearings can provide reliable performance over an extended period of time.

4

Another advantage of NUP cylindrical roller bearings is their ability to accommodate misalignment. The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment

Another advantage of NUP cylindrical roller bearings is their ability to accommodate misalignment. The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment

The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common. In the medical field, where accuracy and reliability are paramount, SRDG ball bearings find application in surgical instruments, diagnostic machines, and prosthetics. Their precise movement and low noise characteristics contribute significantly to the overall performance of these devices.

nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common. In the medical field, where accuracy and reliability are paramount, SRDG ball bearings find application in surgical instruments, diagnostic machines, and prosthetics. Their precise movement and low noise characteristics contribute significantly to the overall performance of these devices.