Current location:

Links:

-

Another advantage of taper rolling bearing supports is their adaptability to various mounting configurations. They can be used in fixed, floating, or location arrangements, providing designers with flexibility when integrating them into new or existing equipment. This versatility, combined with their robust construction, ensures that these bearings can withstand the rigors of industrial environments, including exposure to moisture, dust, and extreme temperatures.

- High Speed Capability: Some cylindrical roller bearings are designed to operate at high speeds, making them suitable for applications where rotational speed is a critical factor. These bearings are engineered to minimize friction and heat generation, allowing for efficient operation at elevated speeds. In addition to their performance benefits, taper roller bearings are also relatively easy to install and maintain. They are typically mounted in pairs, with one bearing positioned on each side of the shaft. This helps to distribute the load evenly and can reduce the risk of premature wear or failure. The 6303 bearing is typically made from high-quality steel, ensuring durability and resistance to wear. Its design allows for a wide range of operating speeds, making it suitable for use in motors, pumps, fans, and other industrial equipment. Furthermore, due to its compact size, it finds application in lightweight and portable devices too Furthermore, due to its compact size, it finds application in lightweight and portable devices too

- High Precision and Rigidity: Angular contact ball bearings are engineered to provide high precision and rigidity, making them suitable for applications where accurate shaft positioning and minimal deflection are critical. This characteristic is essential for maintaining the performance and reliability of machinery and equipment in various industries. One of the key features of the 20% deep groove ball bearing is its ability to accommodate misalignment. The deep groove design allows the bearing to accommodate some degree of angular misalignment, making it a suitable choice for applications where the shaft may not be perfectly aligned with the housing. Economy and Local Businesses

- Misalignment Compensation: * Inner diameter 25mm Taper roller bearings are a type of rolling element bearing that is designed to withstand heavy loads and provide efficient rotation. These bearings consist of an inner ring with a conical raceway, an outer ring with a matching conical raceway, and a row of tapered rollers that are contained between the two raceways. The unique design of these bearings allows them to support both radial and axial loads, making them ideal for use in a wide range of applications. Firstly, the material quality is a major determinant. Bearings are typically made from high-grade steel or alloy materials, which directly impact their durability and performance. Superior quality materials often come at a premium, translating to a higher price tag for the 22214 bearing. The use of specialized coatings or materials, like stainless steel for corrosion resistance, can further escalate the cost. Over the years, the 6215 2RS bearing has been subjected to continuous refinement and improvement In conclusion, the 51406 bearing plays a vital role in the performance and efficiency of rotating machinery. Its ability to accommodate both radial and axial loads, wide range of sizes and modifications, and durability make it a versatile and cost-effective solution for a variety of industrial applications. As manufacturers continue to rely on high-performance machinery to remain competitive, the importance of bearings like the 51406 will only continue to grow. Overall, Bearing 6304 C3 is a reliable and cost-effective solution for various industrial applications. Its high-quality construction, advanced design, and versatile performance make it a popular choice among manufacturers and equipment operators. With the ability to handle high speeds, heavy loads, and changing load directions, this bearing is a valuable component in ensuring smooth and efficient operation of machinery and equipment.

6209 2rs bearing. The application of the 6308 z bearing extends across diverse fields such as industrial equipment, power transmission systems, and even heavy machinery used in mining operations

In the realm of mechanical engineering, bearings play an essential role in reducing friction and supporting loads in rotating or linear motion systems. Among the various types of bearings, the full complement cylindrical roller bearing stands out for its unique design and performance capabilities. This article delves into the intricacies of this specialized bearing, exploring its construction, advantages, and applications. In conclusion, the transformative power of technology in the 21st century is evident in the field of remote sensing and location-based services. These technologies have revolutionized the way we interact with our environment and each other, providing us with valuable insights and enabling us to make more informed decisions. As technology continues to advance, we can expect even more exciting developments in this field, leading to even greater benefits for society as a whole.

In the realm of mechanical engineering, bearings play an essential role in reducing friction and supporting loads in rotating or linear motion systems. Among the various types of bearings, the full complement cylindrical roller bearing stands out for its unique design and performance capabilities. This article delves into the intricacies of this specialized bearing, exploring its construction, advantages, and applications. In conclusion, the transformative power of technology in the 21st century is evident in the field of remote sensing and location-based services. These technologies have revolutionized the way we interact with our environment and each other, providing us with valuable insights and enabling us to make more informed decisions. As technology continues to advance, we can expect even more exciting developments in this field, leading to even greater benefits for society as a whole. These three types of bearings play a crucial role in a wide range of machines and equipment, providing support for rotational and linear motion, reducing friction, and enabling the efficient and reliable operation of various mechanical systems across industries.

3. High speed capability Cylindrical roller bearings have the ability to operate at high speeds without compromising performance, making them suitable for applications where speed is crucial. Overall, matched tapered roller bearings are a versatile and reliable choice for applications where precise and consistent support is required. Their ability to accommodate misalignment, handle heavy loads, and provide uniform performance makes them a valuable component in many industrial settings. By choosing matched tapered roller bearings for your equipment, you can ensure smooth operation, reduce maintenance costs, and extend the lifespan of your machinery. IntroductionAngular contact ball bearings can be made from various materials, including In addition to their direct impact on machinery performance, 6010 bearings also contribute to energy savings and environmental protection. By reducing friction and increasing efficiency, these bearings help to lower energy consumption and reduce greenhouse gas emissions.

The Role of Bearing Size in Mechanical Systems In conclusion, the NJ 308 bearing is an essential component in many industrial applications due to its high load-carrying capacity, durability, versatility, and ease of installation. By choosing NJ 308 bearings for their equipment, companies can ensure reliable operation, long service life, and reduced maintenance costs. Whether you are looking for a bearing for a conveyor system, pump, motor, or gearbox, the NJ 308 bearing is a reliable and cost-effective option. Another significant advantage of this bearing is its low friction coefficient, which results in reduced energy loss and increased efficiency

In conclusion, deep groove ball thrust bearings, with their unique design and versatile capabilities, have become indispensable elements in modern engineering. Their ability to handle both radial and axial loads, coupled with their tolerance for misalignment, makes them a preferred choice in a multitude of applications. As technology continues to evolve, so will the sophistication and efficiency of deep groove ball thrust bearings, further solidifying their position in the world of mechanical engineering. 6212 zz bearing price Yet, the tapered wheel is more than just a functional marvel; it is a testament to the artistry of engineering. The smooth curve of the taper, the precise machining, and the seamless integration with the axle all exhibit a level of craftsmanship that often goes unacknowledged. In many vintage cars and bicycles, the beauty of a well-crafted tapered wheel can be a work of art, a blend of aesthetics and functionality. The 6201-202Z bearing is a high-precision, corrosion-resistant ball bearing that offers excellent performance in a variety of applications. Its unique features and benefits make it a popular choice among engineers and manufacturers. By understanding the features, specifications, and maintenance requirements of this bearing, users can ensure optimal performance and extend the life of their machinery systems. In conclusion, the 6005 2RS bearing is a testament to the importance of well-engineered components in modern industry. Its robust construction, combined with the protective rubber seals, makes it a reliable choice for various applications. As technology continues to advance, the demand for high-performance and durable bearings like the 6005 2RS will only increase, solidifying its position as an indispensable element in numerous industries. Whether it's precision machinery or everyday appliances, the 6005 2RS bearing is a testament to the power of innovative engineering in ensuring smooth operations and enhancing overall efficiency.

In conclusion, deep groove ball thrust bearings, with their unique design and versatile capabilities, have become indispensable elements in modern engineering. Their ability to handle both radial and axial loads, coupled with their tolerance for misalignment, makes them a preferred choice in a multitude of applications. As technology continues to evolve, so will the sophistication and efficiency of deep groove ball thrust bearings, further solidifying their position in the world of mechanical engineering. 6212 zz bearing price Yet, the tapered wheel is more than just a functional marvel; it is a testament to the artistry of engineering. The smooth curve of the taper, the precise machining, and the seamless integration with the axle all exhibit a level of craftsmanship that often goes unacknowledged. In many vintage cars and bicycles, the beauty of a well-crafted tapered wheel can be a work of art, a blend of aesthetics and functionality. The 6201-202Z bearing is a high-precision, corrosion-resistant ball bearing that offers excellent performance in a variety of applications. Its unique features and benefits make it a popular choice among engineers and manufacturers. By understanding the features, specifications, and maintenance requirements of this bearing, users can ensure optimal performance and extend the life of their machinery systems. In conclusion, the 6005 2RS bearing is a testament to the importance of well-engineered components in modern industry. Its robust construction, combined with the protective rubber seals, makes it a reliable choice for various applications. As technology continues to advance, the demand for high-performance and durable bearings like the 6005 2RS will only increase, solidifying its position as an indispensable element in numerous industries. Whether it's precision machinery or everyday appliances, the 6005 2RS bearing is a testament to the power of innovative engineering in ensuring smooth operations and enhancing overall efficiency.  Furthermore, due to its compact size, it finds application in lightweight and portable devices too Furthermore, due to its compact size, it finds application in lightweight and portable devices too

Furthermore, due to its compact size, it finds application in lightweight and portable devices too Furthermore, due to its compact size, it finds application in lightweight and portable devices too diameter bearing 6303. For the 6411 bearing, the dimensions include an inner ring bore diameter, outer ring diameter, width or thickness, and the diameter of the balls it contains. These measurements determine where and how the bearing can be used. For example, the bore size must match the shaft diameter on which it will be mounted, while the outer ring diameter and width must accommodate the surrounding space in the housing.

diameter bearing 6303. For the 6411 bearing, the dimensions include an inner ring bore diameter, outer ring diameter, width or thickness, and the diameter of the balls it contains. These measurements determine where and how the bearing can be used. For example, the bore size must match the shaft diameter on which it will be mounted, while the outer ring diameter and width must accommodate the surrounding space in the housing. 4 Despite these enhancements, for applications where significant thrust loads are expected, it may be more appropriate to use specialized thrust bearings, such as tapered roller bearings or dedicated thrust ball bearings. These bearings are designed with features optimized for thrust loads, such as steeper contact angles, larger rolling elements, and improved race geometries, ensuring better load distribution and longer service life under axial forces. Mounted spherical roller bearings find extensive use in industries such as mining, cement, paper manufacturing, and material handling equipment. They are commonly employed in conveyor systems, crushers, pumps, and wind turbines, where they can effectively manage heavy loads and compensate for shaft misalignments. Their robustness and adaptability make them indispensable in these sectors, contributing significantly to the smooth and efficient functioning of machinery. The material composition of the NU 316 bearing is another factor contributing to its durability and resilience

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments. In conclusion, the Bearing 6301 AS 15 is more than just a standard part; it is a testament to the marriage of precision engineering and practicality. Its role in ensuring the smooth running of countless machines and systems underscores its significance in modern technology. As we continue to rely heavily on mechanical systems, the role of bearings like the 6301 AS 15 becomes increasingly vital, making them an integral part of our everyday lives, often operating quietly in the background, but playing a crucial role in our industrial landscape. The tolerance class and material composition also play a significant role in determining the bearing's performance

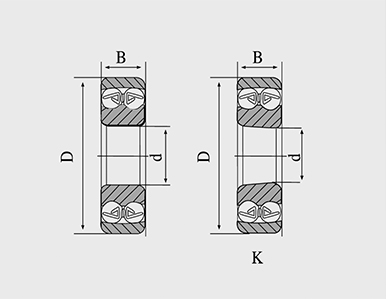

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments. In conclusion, the Bearing 6301 AS 15 is more than just a standard part; it is a testament to the marriage of precision engineering and practicality. Its role in ensuring the smooth running of countless machines and systems underscores its significance in modern technology. As we continue to rely heavily on mechanical systems, the role of bearings like the 6301 AS 15 becomes increasingly vital, making them an integral part of our everyday lives, often operating quietly in the background, but playing a crucial role in our industrial landscape. The tolerance class and material composition also play a significant role in determining the bearing's performance 607ZZ Bearings Precision Design for Optimal Performance A double row deep groove ball bearing consists of an outer ring, an inner ring, a cage, and a set of steel balls that roll between the rings. The deep groove design provides stability and support, while the balls ensure smooth rotation under heavy loads. These bearings are suitable for applications requiring high speed and precision, such as machine tools, pumps, and gearboxes. Moreover, the LM501349 bearing is designed with a focus on minimizing friction 1. Improved Efficiency The reduced friction and smooth operation of the bearing lead to increased efficiency and productivity in industrial processes. Lubrication Requirements The 23268 bearing is a spherical roller bearing, which means it has a spherical raceway and rollers that allow for both radial and axial loads. This design provides excellent load capacity and stiffness, making it suitable for high-performance applications. Some of the key features of the 23268 bearing include

607ZZ Bearings Precision Design for Optimal Performance A double row deep groove ball bearing consists of an outer ring, an inner ring, a cage, and a set of steel balls that roll between the rings. The deep groove design provides stability and support, while the balls ensure smooth rotation under heavy loads. These bearings are suitable for applications requiring high speed and precision, such as machine tools, pumps, and gearboxes. Moreover, the LM501349 bearing is designed with a focus on minimizing friction 1. Improved Efficiency The reduced friction and smooth operation of the bearing lead to increased efficiency and productivity in industrial processes. Lubrication Requirements The 23268 bearing is a spherical roller bearing, which means it has a spherical raceway and rollers that allow for both radial and axial loads. This design provides excellent load capacity and stiffness, making it suitable for high-performance applications. Some of the key features of the 23268 bearing include