Links:

3. Reduced Noise PK belts have been specifically designed to operate quietly, reducing the noise associated with traditional belt systems.

pk belt for car

Applications of the B60 V-Belt

v-belt b60

Additionally, rubber belts are typically quiet during operation, reducing noise pollution in industrial settings and contributing to a more pleasant environment in household applications. Their ability to absorb vibrations also plays a role in extending the lifespan of both the belts and the machinery they serve.

- Enhanced Performance The design of the 8PK belt allows it to maintain optimal tension and grip, ensuring that all components it drives operate efficiently. This translates to improved engine performance and fuel efficiency.

يعتبر حزام التوقيت والبكرات جزءًا أساسيًا في نظام نقل الحركة في محركات الاحتراق الداخلي. يلعب هذا النظام دورًا حيويًا في ضمان تشغيل المحرك بكفاءة وأداء جيد. في هذا المقال، سنستعرض أهمية حزام التوقيت، مكوناته، وأسباب الحاجة إلى صيانته.

Understanding 5PK 970

The ribbed belt is crucial for the seamless functioning of the W211's engine and its auxiliary systems. It connects the crankshaft with various engine components, thereby ensuring that they operate in harmony. A well-functioning ribbed belt ensures that accessories receive adequate power, enhancing the vehicle's reliability and performance. When in proper working condition, the W211 can deliver a smooth driving experience, excellent fuel efficiency, and optimal engine performance.

Conclusion

The Legal Aspect

car belt

Tooth v belts play a pivotal role in the efficient operation of various mechanical systems, particularly in automotive engines. Their unique design allows for precise power transmission, making them integral to maintaining the timing of engine cycles. With various types available to suit different applications, tooth v belts present numerous advantages, including efficiency, reduced maintenance, and versatility. Regular inspections and maintenance are vital to ensuring their longevity, thereby guaranteeing optimum performance in any application they serve.

Why Choose OEM Timing Belts?

The Legal Aspect

car belt

Understanding Heavy Duty Serpentine Belts A Comprehensive Guide

Conveyor belts come in a variety of designs to accommodate different operational needs. Some of the most common types include

There are mainly two types of belts in a vehicle the serpentine belt and the timing belt.

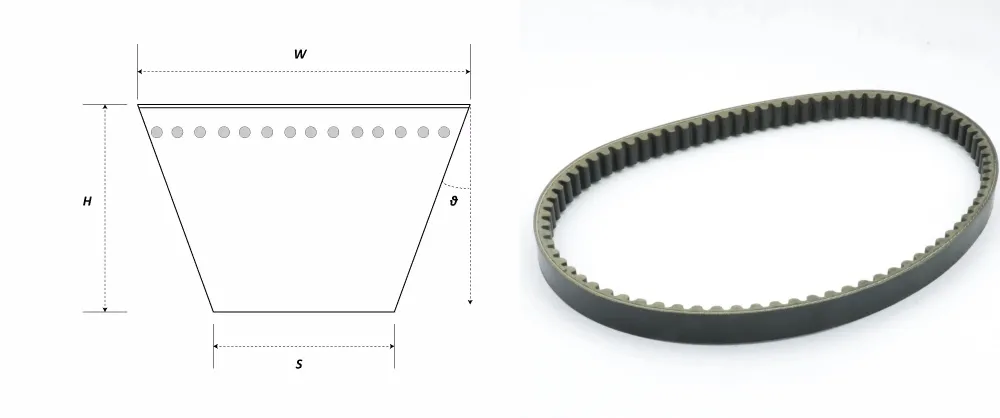

V-belts are named for their trapezoidal cross-section, which resembles the letter V. This design enables V-belts to fit snugly into the grooves of sheaves or pulleys, ensuring a strong grip during operation. The primary function of a V-belt is to transmit power from one shaft to another, typically in mechanical systems that require a high level of torque transmission.

Maintenance Tips

4. Easy Replacement The modular design of PK belt systems makes it relatively easy to replace belts, contributing to lower maintenance costs and quicker service times for vehicle owners.

- Squealing Noises A high-pitched squeal when starting the engine or turning the steering wheel can indicate a worn or loose belt.

Understanding the Parts of an ATV Belt

3. Additional Repairs When replacing a timing belt, many mechanics recommend replacing other components while the engine is apart, including the water pump and pulleys. This precaution can prevent potential failures and save on future repair costs. Bundling these services can further escalate the initial costs, bringing the total bill to $800 or more in some cases.

engine belt cost

Motorbike belts are primarily found in two types of systems the timing belt and the final drive belt. The timing belt is responsible for synchronizing the movement of the engine’s camshaft and crankshaft, ensuring that the engine operates smoothly. On the other hand, the final drive belt transmits power from the engine to the rear wheel, translating engine power into motion.

Moreover, the ease of installation and removal of these belts makes them user-friendly. Technicians can quickly replace or service a rubber PK belt, minimizing downtime in production or operation.

Dây đai poly V đang ngày càng được ưa chuộng trong nhiều lĩnh vực khác nhau nhờ vào những ưu điểm nổi bật của nó. Từ khả năng truyền động mạnh mẽ, tiết kiệm không gian lắp đặt đến việc giảm thiểu chi phí bảo trì và tiết kiệm năng lượng, dây đai poly V thật sự là một giải pháp tối ưu cho các doanh nghiệp trong thời đại công nghệ phát triển hiện nay.

Conclusion

1. Visual Inspection Check for cracks, fraying, or glazing on the belt surface. If you notice any of these signs, it’s time to replace the belt.

4. Round belts These belts are circular in cross-section and are often used in applications where flexibility and bending are required. Round belts are typically used in small machinery and conveyor systems.

drive belts

The Importance of Regular Maintenance

Conclusion

- Engine Overheating If the serpentine belt is not functioning properly, it can cause the water pump to fail, leading to engine overheating.

2. Increased Power Transmission Double sided timing belts can handle higher loads due to their ability to engage with two pulleys simultaneously. This characteristic allows for more efficient power transmission, which is vital in high-performance environments.

With the old belt removed, it’s time to install the new one. Consult the routing diagram or your reference image to ensure that the new belt is positioned correctly around all pulleys, making sure to follow the same path as the old belt. Make sure it's seated properly in the grooves of each pulley.

The motorcycle zip belt is more than just an accessory; it’s a testament to the blend of style, durability, and functionality tailored specifically for the motorcycle enthusiast. As motorcycling continues to evolve, so do the innovations in gear and accessories that enhance the experience. For riders seeking to combine practicality with personal flair, the motorcycle zip belt stands as an ideal choice that envelopes the essence of freedom and adventure, making every ride not only safe but also stylish. As more riders embrace this blend of function and fashion, the motorcycle zip belt is sure to remain a staple in the world of motorcycle gear.

In a world where every detail counts, Hino auto parts exemplify the standards that all automotive manufacturers should aspire to achieve.

4. Reduced Noise The design of the 4PK belt also helps in reducing operational noise, which is beneficial in maintaining a quieter work environment.

The Evolution of Belt Driven Motorbikes

What is a 207PK Belt?

- Smart Sensors Integrating sensors with flat rubber belts allows for real-time monitoring of wear and load. This data can facilitate predictive maintenance, reducing downtime and ensuring operational efficiency.

4. Align the Markings Before removing the old timing belt, align the timing marks on the crankshaft and camshaft. This ensures that everything will be in the correct position upon replacement.

3. Agricultural Machinery Agriculture is a cornerstone of Thailand’s economy. The agricultural sector utilizes various machinery that employs v-belts for equipment such as tractors, harvesters, and irrigation systems. As farmers adopt more advanced machinery for higher productivity, the demand for reliable v-belts continues to grow.

4. Preventive Maintenance By taking care of your vehicle and addressing minor issues early, you can avoid major repairs that can escalate costs.

Maintenance Tips

Conclusion

3. Slipping If the belt is old or worn out, it may slip off the pulleys, causing a decrease in the washing machine’s efficiency. A slipping belt can also result in strange noises and vibrations during operation.

3. Consider Used Options If you’re looking to save money, consider purchasing a used timing belt. While not always recommended, some used parts can still be in good condition. Ensure you check the part thoroughly for any signs of wear before purchasing.

- Material Quality Many belts are made from rubber composites or reinforced materials. Higher quality materials often lead to increased durability.

- HVAC Systems V-belts help power fans and blowers in heating, ventilation, and air conditioning systems, ensuring they operate efficiently.

In the realm of mechanical engineering and industrial applications, drive belts play a pivotal role in power transmission. Among the various types of drive belts, flat leather drive belts have carved a niche for themselves due to their unique properties, historical significance, and continued relevance in modern machinery.

Understanding V-Belts The Backbone of Power Transmission