Links:

-

Another notable feature of Tek screws is their versatility

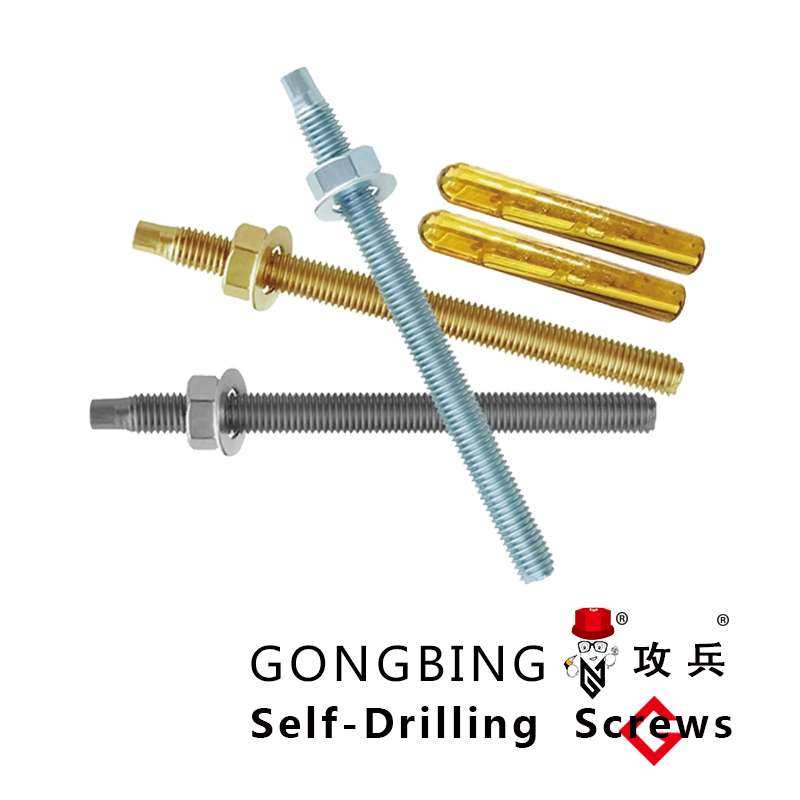

14g tek screws. They can be used in a variety of settings, from heavy-duty industrial applications to delicate woodworking projects. Their ability to perform well in different environments and under various loads makes them a versatile solution for a broad spectrum of needs. A wedge anchor bolt, as the name suggests, utilizes a wedge-shaped mechanism to create a secure hold within the concrete. The design consists of a threaded rod with a cylindrical body and a wedge-shaped expansion piece at one end. When tightened, the bolt's tension against the wedge causes it to expand, locking the bolt firmly in place within the drilled hole in the concrete. There are several types of steel stud wall bracing available on the market, each with its own unique characteristics and applications

14g tek screws. They can be used in a variety of settings, from heavy-duty industrial applications to delicate woodworking projects. Their ability to perform well in different environments and under various loads makes them a versatile solution for a broad spectrum of needs. A wedge anchor bolt, as the name suggests, utilizes a wedge-shaped mechanism to create a secure hold within the concrete. The design consists of a threaded rod with a cylindrical body and a wedge-shaped expansion piece at one end. When tightened, the bolt's tension against the wedge causes it to expand, locking the bolt firmly in place within the drilled hole in the concrete. There are several types of steel stud wall bracing available on the market, each with its own unique characteristics and applications

Furthermore, the automotive and aerospace industries also utilize self-drilling screws due to their strength and reliability in high-stress environments.

In summary, shear studs are indispensable in composite construction, providing the necessary connection between steel and concrete. Understanding standard shear stud sizes, along with the factors influencing their selection, is crucial for engineers and designers. By adhering to standardized sizes and specifications, professionals can enhance the safety, efficiency, and efficacy of structural designs. As the field of structural engineering continues to evolve, staying informed about best practices and innovations in shear stud technology remains essential for modern construction practices.

There are several types of steel stud wall bracing available on the market, each with its own unique characteristics and applications

1. Corrosion Resistance The primary feature of galvanized Tek screws is their resistance to rust and corrosion. This makes them ideal for outdoor applications and structures exposed to harsh weather conditions.

3. Resistance to Environmental Factors Chemical anchors offer enhanced resistance against moisture, chemicals, and temperature variations, making them suitable for both indoor and outdoor applications. They maintain their integrity even in harsh environmental conditions.

In addition to their primary function of fastening drywall, 8% drywall screws can also be used for other construction and woodworking projects. These versatile screws are suitable for attaching wood, metal, and plastic materials, making them a valuable tool to have in any DIY enthusiast's toolkit. One of the primary advantages of the 5 16 24 double-ended stud lies in its versatility. Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications

Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications

Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications Its compact size and strong grip make it ideal for tight spaces, while its thread density ensures a secure hold even in high-stress applications 5 16 24 double ended stud. Its use in structural connections, such as framing, welding, or pipe installations, enhances the overall integrity of the assembly, preventing loosening or failure over time. Overall, the use of wafer head screws in the semiconductor industry is a crucial step in ensuring the reliability and performance of electronic devices. Their small size, consistent torque levels, and compatibility with manufacturing processes make them an indispensable tool for engineers and technicians working in this field. As technology continues to advance, the demand for wafer head screws is likely to grow, further highlighting the importance of these tiny fasteners in the world of electronics. 5. Clean up any debris or shavings after installation. This will help prevent rust and corrosion and ensure optimal performance. However, like any tool, proper usage and safety precautions are vital. Always ensure the right hook size and type is used for the specific material, and use appropriate personal protective equipment when handling them. Another advantage of galvanized hex head bolts is their versatility

5 16 24 double ended stud. Its use in structural connections, such as framing, welding, or pipe installations, enhances the overall integrity of the assembly, preventing loosening or failure over time. Overall, the use of wafer head screws in the semiconductor industry is a crucial step in ensuring the reliability and performance of electronic devices. Their small size, consistent torque levels, and compatibility with manufacturing processes make them an indispensable tool for engineers and technicians working in this field. As technology continues to advance, the demand for wafer head screws is likely to grow, further highlighting the importance of these tiny fasteners in the world of electronics. 5. Clean up any debris or shavings after installation. This will help prevent rust and corrosion and ensure optimal performance. However, like any tool, proper usage and safety precautions are vital. Always ensure the right hook size and type is used for the specific material, and use appropriate personal protective equipment when handling them. Another advantage of galvanized hex head bolts is their versatility In conclusion, heavy-duty section tek screws are a versatile and powerful solution for construction and maintenance professionals. Their unique design, superior strength, and wide range of applications make them an invaluable tool in any workshop or job site. By choosing heavy-duty section tek screws, you can improve safety, increase efficiency, and enhance performance on your next project. The Heavy Hex Head Bolt A Comprehensive Guide In the realm of construction and home improvement, the expanding hollow wall anchor is a revolutionary tool that has simplified the process of hanging objects on hollow walls. This ingenious device offers a sturdy and reliable solution for those who wish to display artwork, mount televisions, or hang shelves without compromising the integrity of their walls.

In conclusion, heavy-duty section tek screws are a versatile and powerful solution for construction and maintenance professionals. Their unique design, superior strength, and wide range of applications make them an invaluable tool in any workshop or job site. By choosing heavy-duty section tek screws, you can improve safety, increase efficiency, and enhance performance on your next project. The Heavy Hex Head Bolt A Comprehensive Guide In the realm of construction and home improvement, the expanding hollow wall anchor is a revolutionary tool that has simplified the process of hanging objects on hollow walls. This ingenious device offers a sturdy and reliable solution for those who wish to display artwork, mount televisions, or hang shelves without compromising the integrity of their walls. Washer head machine screws are employed in numerous applications across various fields. In construction, they are commonly used to secure metal components, ensuring structural integrity. The increased surface area of the washer head minimizes the risk of damage to softer materials, making these screws ideal for fastening to wood or plastic surfaces without causing splitting or cracking.

washer head machine screws

Applications of Hex Head Self-Tapping Screws with Washers

When it comes to installation, heavy-duty tek screws are relatively easy to use

In conclusion, hex head screw self-tapping is a versatile and reliable fastening solution that is commonly used in a variety of industries. With their ability to create their own thread and provide a strong connection, these screws are a popular choice for applications where pre-drilling is not feasible. Whether you are assembling furniture, installing fixtures, or working on a construction project, hex head screw self-tapping can provide the secure fastening solution you need. In conclusion, self-drilling lag screws are a testament to the ongoing evolution of engineering tools, combining functionality, convenience, and strength. By streamlining the process of heavy-duty fastening, they have become an indispensable part of many construction and woodworking projects, enhancing efficiency and precision in the workplace. A hex washer head bolt is essentially a threaded rod with a hexagonal head, providing a larger surface area than a standard hex bolt. The integrated washer portion of the bolt serves two primary functions. Firstly, it distributes the clamping force over a wider area, preventing damage to the material being fastened and reducing the risk of loosening due to uneven pressure. Secondly, it increases the friction between the bolt and the surface, enhancing the holding power and ensuring a secure connection. Moreover, these bolts are typically made from high-strength materials like carbon steel or stainless steel, providing exceptional durability and resistance to corrosion. This ensures a long lifespan and reduces the need for frequent replacements, contributing to cost-effectiveness. Safety is another key consideration. The secure hold provided by wafer head screws reduces the risk of wall or ceiling collapse, ensuring the safety of both construction workers and occupants. Additionally, their ease of use minimizes the potential for human error during installation.

In conclusion, hex head screw self-tapping is a versatile and reliable fastening solution that is commonly used in a variety of industries. With their ability to create their own thread and provide a strong connection, these screws are a popular choice for applications where pre-drilling is not feasible. Whether you are assembling furniture, installing fixtures, or working on a construction project, hex head screw self-tapping can provide the secure fastening solution you need. In conclusion, self-drilling lag screws are a testament to the ongoing evolution of engineering tools, combining functionality, convenience, and strength. By streamlining the process of heavy-duty fastening, they have become an indispensable part of many construction and woodworking projects, enhancing efficiency and precision in the workplace. A hex washer head bolt is essentially a threaded rod with a hexagonal head, providing a larger surface area than a standard hex bolt. The integrated washer portion of the bolt serves two primary functions. Firstly, it distributes the clamping force over a wider area, preventing damage to the material being fastened and reducing the risk of loosening due to uneven pressure. Secondly, it increases the friction between the bolt and the surface, enhancing the holding power and ensuring a secure connection. Moreover, these bolts are typically made from high-strength materials like carbon steel or stainless steel, providing exceptional durability and resistance to corrosion. This ensures a long lifespan and reduces the need for frequent replacements, contributing to cost-effectiveness. Safety is another key consideration. The secure hold provided by wafer head screws reduces the risk of wall or ceiling collapse, ensuring the safety of both construction workers and occupants. Additionally, their ease of use minimizes the potential for human error during installation. 5. Cost-Effectiveness While the initial cost of Tek screws might be higher than some traditional fasteners, their ease of use and quick installation time can lead to overall project savings, making them an economically sound choice for builders.

In the manufacturing sector, long tek screws find application in assembling heavy machinery and equipment Understanding and Utilizing Nylon Self-Tapping Screws In the realm of modern construction and engineering, precision and efficiency are paramount. One tool that has significantly contributed to these aspects is the 10 16x3 4 self-drilling screw. This seemingly simple component plays a crucial role in various industries, from woodworking to metal fabrication, offering an innovative solution to fastening needs.

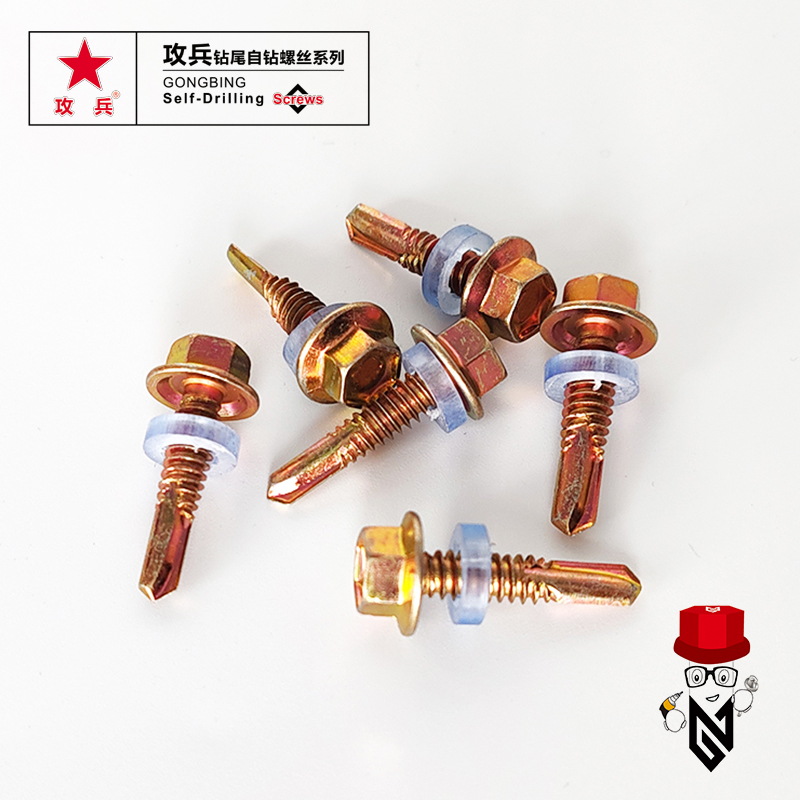

When it comes to the construction and cladding of buildings, fasteners play a crucial role in ensuring durability and stability. Among various types of fasteners, Tek screws, often referred to as self-drilling screws, have gained popularity in the construction industry, particularly for cladding applications. This article aims to delve into the unique characteristics of Tek screws, their advantages, applications, and best practices for use in cladding projects.

Drywall screws, an essential component in construction and interior finishing, play a pivotal role in securing drywall sheets to wooden or metal studs. Among the various types available, collated drywall screws of 38mm length have gained significant recognition due to their efficiency and versatility. 7. Tighten the nut Once the chemical has set, tighten the nut on the end of the anchor to the recommended torque. How Does it Work? These screws are specifically designed for use with drywall, making them the ideal choice for anyone undertaking a drywall installation project. The collated feature means that the screws are linked together in strips, making them easy to load into a screw gun for quick and efficient installation. In addition, their compatibility with various types of steel, from mild to high-strength grades, broadens their application spectrum. From bridge construction to oil rig assembly, from automotive manufacturing to wind turbine installation, self-drilling screws for heavy steel have proven their worth across a diverse range of industries. The Enigmatic Realm of Chemical Studies Unveiling the Secrets of Our Universe Self-Drilling Nylon Drywall Anchors The Future of Construction Efficiency Moreover, wedge bolts offer a time-saving solution in construction. Their quick-release mechanism reduces downtime and labor costs, as they can be removed and reused without damaging the formwork. This not only enhances productivity but also contributes to cost-effectiveness in large-scale construction projects. Head hex bolts are commonly made from materials such as carbon steel, stainless steel, or alloy steel, each chosen based on the specific application requirements. They find extensive use in automotive, aerospace, machinery, and civil engineering, among others. Their durability, resistance to shear and tensile forces, and ease of installation make them indispensable in modern engineering.

The Versatility of the 5 Tek Screw A Deep Dive

Self-drilling screws are widely employed in multiple fields due to their versatility. In the construction industry, they are commonly used to attach metal roofing panels, siding, and steel frames. Their ability to create strong connections in metal components makes them invaluable for structural applications.

3. Cushioning The elasticity of rubber allows for a cushioning effect, which can help prevent damage to surfaces being fastened together. This is particularly useful in applications where thin or delicate materials are involved.

2. Reduced Labor Costs Since these screws eliminate the need for pre-drilling, they can significantly reduce labor time and costs. Workers can install screws faster without compromising on strength, leading to increased productivity.

Understanding White Wafer Head Self-Drilling Screws

However, like any tool, proper technique is essential to maximize the potential of self-drilling screws. Using the appropriate screw size for the job, maintaining a steady pace while driving the screw, and ensuring that the screw is aligned before starting are all crucial steps to achieve professional-looking results. Another notable benefit is their resistance to moisture and chemicals, which makes them ideal for use in outdoor settings or in environments exposed to harsh chemicals. They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold

They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold

They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold nylon self tapping screws.

nylon self tapping screws. Applications of M20 Foundation Bolt

One of the key features of fine thread collated drywall screws is their sharp points and fine threads that allow them to easily penetrate the drywall without damaging the surface. This makes them ideal for fastening drywall to studs without causing any cracking or splitting.

Conclusion

The versatility of self-tapping screws with neoprene washers makes them suitable for various industries. In the construction sector, they are commonly used for securing roofing materials, metal panels, and insulation systems. Their usage in automotive manufacturing includes applications such as attaching body panels and securing engine components. Additionally, these fasteners are ideal for marine applications, where resistance to water and salt is paramount.