Links:

At the core of a variable speed belt system is the drive mechanism, typically involving an electric motor. The speed of the motor can be controlled using various techniques, such as

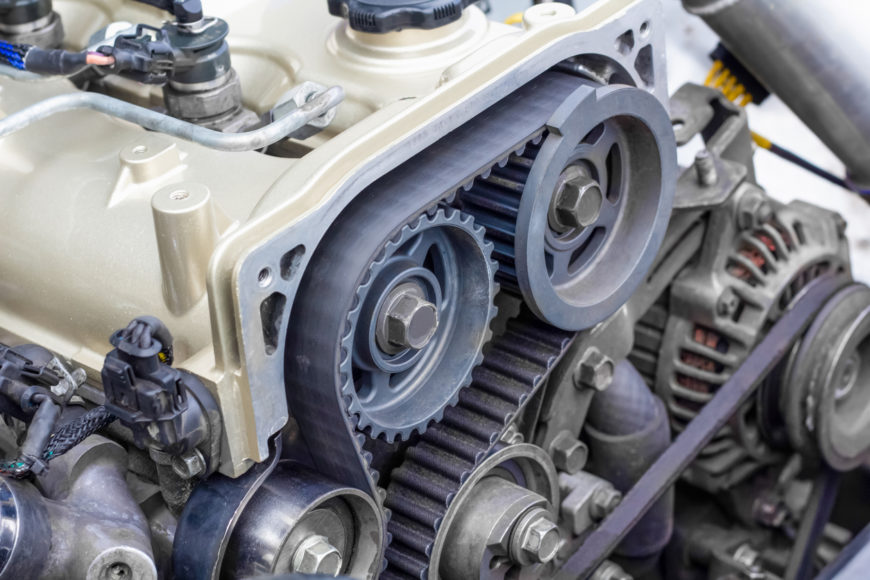

2. Lubrication Although timing belts do not require excessive lubrication, certain components in their vicinity, like gears and pulleys, may need periodic greasing to minimize friction.

Another significant benefit of V-belts is their ability to absorb shock loads. The elasticity of the belt can help dampen vibrations, protecting other components in the system from potential damage. Additionally, V-belts can operate in a wide range of temperatures and environmental conditions, making them suitable for both indoor and outdoor applications.

3. Engine Overheating A malfunctioning fan belt can lead to the failure of the water pump, resulting in engine overheating. If the car's temperature gauge rises unexpectedly, it’s worth checking the fan belt as a potential culprit.

- Oil leaks near the timing belt cover

- Agricultural Equipment Flat rubber belts are also found in various agricultural machinery, including combines and tractors, where they help transfer power efficiently to different operational parts.

3. Install the New Belt Follow the belt routing diagram often found under the hood or in the owner's manual. Ensure that the belt is seated properly on all pulleys.

Conclusion

The 6PK 2140/6PK belt is commonly utilized in automotive applications, especially in driving components such as alternators, water pumps, power steering pumps, and air conditioning compressors. In modern vehicles, where multiple systems must operate seamlessly together, the reliability of these belts is crucial to ensure optimal performance and efficiency.

Toyota recommends replacing the timing belt at specific intervals, usually between 60,000 to 100,000 kilometers, depending on driving conditions and engine type. Always consult your vehicle’s owner’s manual for the manufacturer’s guidelines.

The fan belt is also integral in maintaining the engine's cooling system. It drives the water pump, which circulates coolant throughout the engine to prevent overheating. Without an operational fan belt, the cooling system could fail, leading to catastrophic engine damage.

Conclusion

Understanding EPDM Rubber Properties, Applications, and Benefits

Signs of Timing Belt Wear

However, direct sales come with their own set of challenges. Building a reliable sales team requires investment in training and support. Additionally, there can be high turnover rates among sales representatives, leading to inconsistencies in customer experience. The model also relies heavily on the individual performance of sales agents, which can lead to significant variability in results.

v drive belts

Maintaining lathe belts is essential for the longevity and performance of the machine. Proper tensioning is critical; belts that are too loose may slip, leading to inconsistent machining results, while belts that are too tight can strain the motor and cause premature wear. Regular inspection for wear, fraying, or cracking is crucial. If a belt shows signs of damage, it should be replaced immediately to avoid further complications.

3. Reduced Slip The design minimizes slippage, providing better transfer of power and improved efficiency in operations.

When it comes to maintaining a vehicle, few components are as critical as the engine belt. This seemingly simple part plays a vital role in the operation of your car, connecting various engine components and ensuring everything runs smoothly. However, when it comes time to replace a worn or damaged engine belt, many car owners are left wondering about the costs involved. In this article, we will explore the factors that influence car engine belt prices, what you should expect to pay, and how to make informed decisions regarding maintenance and replacement.

- Tooth Height Approximately 1mm

Finding high-quality V-belts for sale is easier than ever, thanks to the diverse options available both online and in physical stores. Here are some recommended sources

The Era of Environmental Awareness

Understanding Belt Sizing

- Pliers

Another key benefit is their efficiency. By adjusting the speed and torque to match the specific requirements of an application, variable belt drives can help reduce fuel consumption and energy waste, contributing to more sustainable operating practices.

Conclusion

- Tension Checks Ensure that the belt is appropriately tensioned. A belt that is too loose or too tight can lead to premature wear or failure. Many vehicles come equipped with automatic belt tensioners, but periodic checks are recommended.

1. Regular Inspections Periodically check the belt for signs of wear, such as fraying, cracking, or glazing. These indicators suggest that the belt may need replacement.

Another significant application is in HVAC (Heating, Ventilation, and Air Conditioning) systems. Here, V-belts are used to drive fans and compressors, providing the necessary airflow and pressure for efficient heating or cooling. The adaptability of V-belt and pulley combinations allows for effective operation across varying environmental conditions.

Replacement Process

Factors to Consider When Buying Flat Belts

flat belts for sale

Advantages of Poly V Belts

- Støjreduktion Den kilestruktur, som V-bælter har, gør dem betydeligt mere stillegående end andre former for energioverføring som kæder og remme.

Tips for Reducing Alternator Belt Costs

Most ATV belts are equipped with wear indicators, which serve as helpful guides for maintenance. These markings show when the belt has worn down and needs replacement, which is essential for preserving the ATV’s drivetrain integrity.

PK belts come in various sizes, which are defined by their length, width, and pitch. The sizing system for PK belts is straightforward, enabling users to select the appropriate size for their machinery. The designation of a PK belt size often includes a letter P followed by a number that indicates the belt's width in millimeters. For instance, a PK belt labeled as PK 100 may have a width of 10mm.

5. Visual Inspection If you can access the timing belt, look for cracks, fraying, or other signs of wear.

V-belt manufacturers play a vital role in various industries by providing essential components that ensure the smooth operation of machinery. Their commitment to quality, innovation, and adaptability to market trends positions them as key players in the manufacturing landscape. As industries continue to evolve, the importance of reliable V-belts, coupled with the expertise of manufacturers, will remain indispensable in driving efficiency and productivity.

2. Unusual Noises A failing timing belt can produce a ticking or slapping sound from the engine compartment, often associated with belt wear or misalignment.

Motorcycles inherently require riders to maintain specific physical positions, which can sometimes lead to discomfort over time. A lumbar support belt provides stability and support for the lower back, helping to absorb some of the shocks experienced while riding. This added stability allows riders to focus more on the road and their bike's performance rather than on their discomfort. As a result, the overall riding experience is improved significantly.

motorcycle lumbar support belt

Maintenance Tips for Poly V-Belts

.

Over time, drive belts can wear down, crack, or become glazed due to heat and friction. Recognizing the signs of a failing belt is essential for preventing vehicle malfunction. Common symptoms of a worn drive belt include

Maintenance and Longevity

2. Pitch The pitch is the distance between the centers of two consecutive teeth. Different engines may require different pitches to ensure smooth operation. A mismatch in pitch can cause excessive wear, noise, and ultimately failure.

A Brief History

The Significance of Ribbed Belts

5. Versatility These belts can be utilized in a multitude of applications, ranging from automotive systems to industrial machinery, making them a staple in various sectors.

2. Versatility The SPC260's compatibility with various machinery and equipment makes it suitable for diverse applications. It can be used in manufacturing, agricultural machinery, automotive systems, and more.