Links:

-

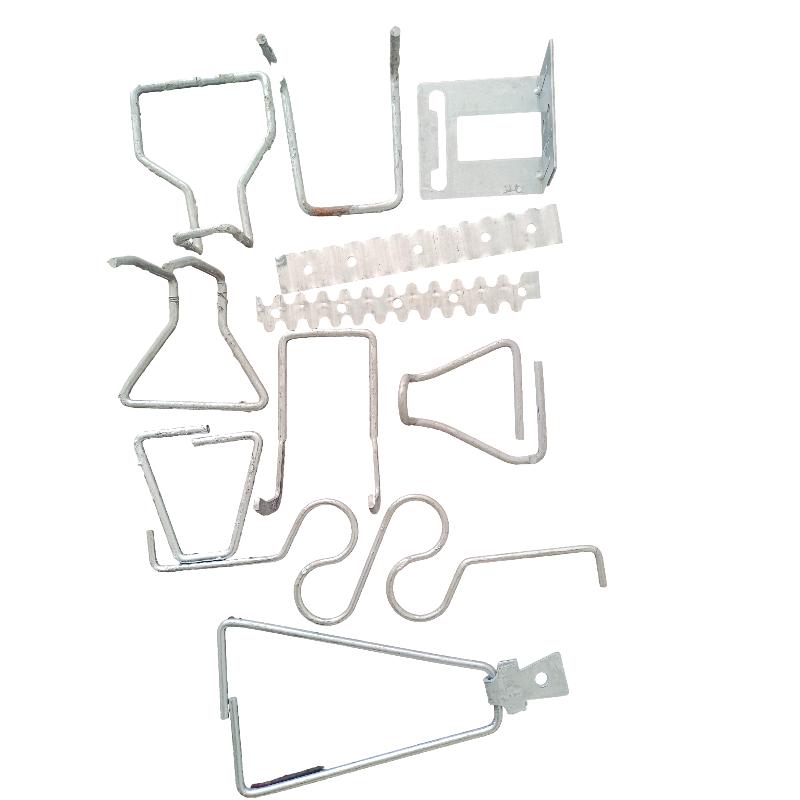

Despite their seemingly minor role, the impact of faulty or deteriorating steel wall ties can be catastrophic. Over time, due to factors like corrosion or incorrect installation, wall ties can lose their effectiveness, leading to cracking, bowing, or even structural failure. Therefore, regular inspections and maintenance are crucial to ensure their continued efficiency. In conclusion, small wire grid panels, though seemingly unassuming, play a significant role in optimizing storage and display systems. Their compact size, versatility, durability, and aesthetic appeal make them a go-to solution for businesses and individuals alike. Whether it's streamlining a retail store, decluttering a home, or enhancing workplace efficiency, these panels prove that sometimes, the most effective tools are those that are simple, well-designed, and adaptable. Despite their small stature, they have a big impact, demonstrating that less is truly more in the world of organizational tools. Beyond commercial settings, metal grid panel stands find their way into homes as well. They can be used as room dividers, displaying plants, books, or decorative items. In the kitchen, they can hold pots, pans, and utensils, while in the garage, they can organize tools and equipment. Moreover, wire mesh garden fences offer excellent visibility, allowing you to enjoy the beauty of your garden from within while deterring potential intruders, be it curious pets or unwelcome wildlife. They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments

They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments

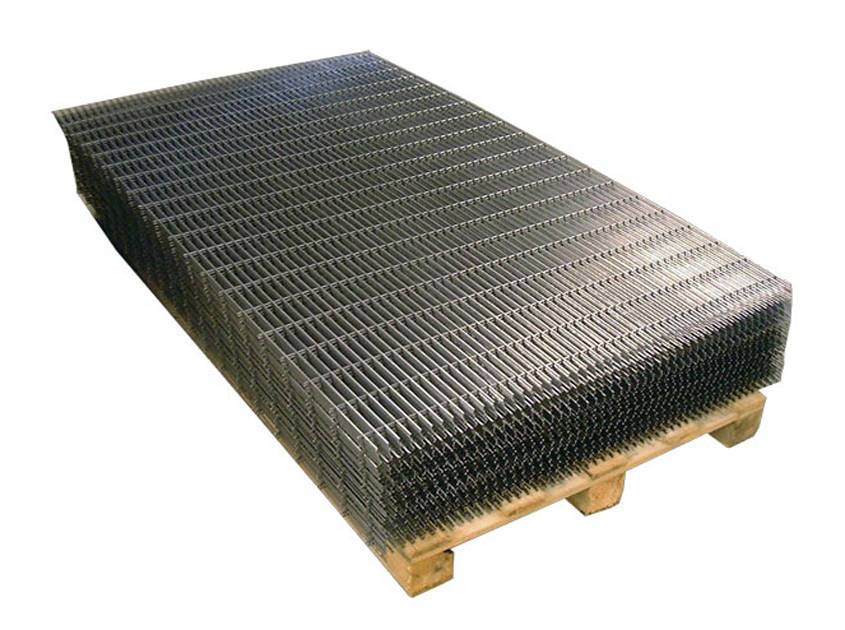

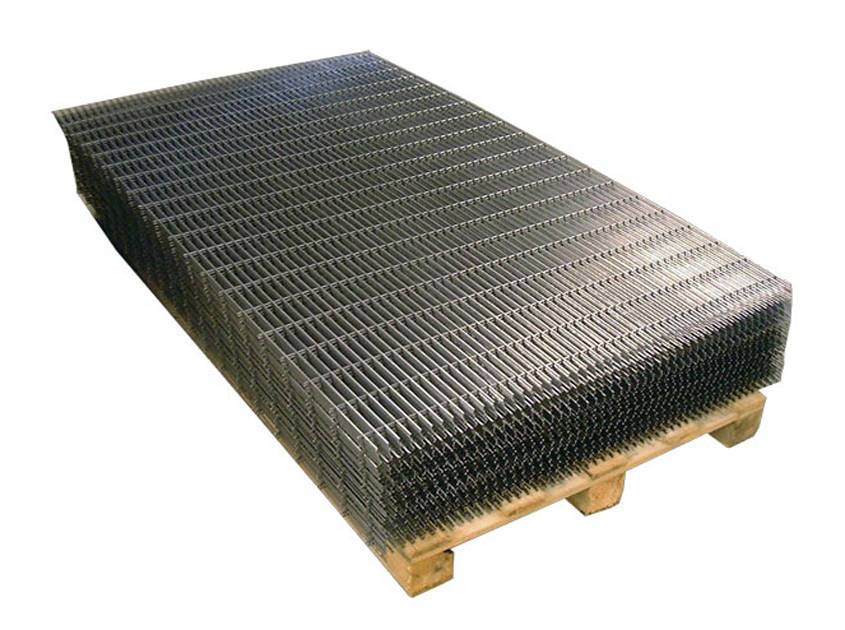

They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments wire mesh garden fence. Brick reinforcement mesh is an essential component in the construction industry, providing strength and stability to brick walls. Made from high-quality galvanized steel wire, this mesh is specifically designed to reinforce brickwork and prevent cracking and crumbling. The wavy tail wall tie features a distinctive wave-like pattern along its length, giving it a dynamic and eye-catching appearance. This design not only adds visual interest to the wall but also creates a sense of movement and flow within the room. The tails of the tie are typically longer than traditional wall ties, which adds an extra element of drama and sophistication to the overall look. Another advantage of metal grids is their versatility. They can be used to display a wide range of artworks, from paintings and photographs to sculptures and installations. The open design of metal grids allows viewers to appreciate the artwork from multiple angles, enhancing the overall viewing experience. Conclusion Spiral torsion springs are a type of spring that is designed to store and release energy when twisted. They are commonly used in a variety of applications, including in mechanical devices, clocks, and watches. In conclusion, galvanized wire fence stands as a symbol of durability, versatility, and practicality. Its zinc coating ensures a long lifespan, while its adaptability allows it to serve a multitude of purposes across diverse sectors. Whether it's securing livestock, defining property lines, or providing safety on construction sites, a galvanized wire fence is a reliable and efficient choice that continues to prove its worth in the ever-evolving world of fencing solutions. 1. Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime

wire mesh garden fence. Brick reinforcement mesh is an essential component in the construction industry, providing strength and stability to brick walls. Made from high-quality galvanized steel wire, this mesh is specifically designed to reinforce brickwork and prevent cracking and crumbling. The wavy tail wall tie features a distinctive wave-like pattern along its length, giving it a dynamic and eye-catching appearance. This design not only adds visual interest to the wall but also creates a sense of movement and flow within the room. The tails of the tie are typically longer than traditional wall ties, which adds an extra element of drama and sophistication to the overall look. Another advantage of metal grids is their versatility. They can be used to display a wide range of artworks, from paintings and photographs to sculptures and installations. The open design of metal grids allows viewers to appreciate the artwork from multiple angles, enhancing the overall viewing experience. Conclusion Spiral torsion springs are a type of spring that is designed to store and release energy when twisted. They are commonly used in a variety of applications, including in mechanical devices, clocks, and watches. In conclusion, galvanized wire fence stands as a symbol of durability, versatility, and practicality. Its zinc coating ensures a long lifespan, while its adaptability allows it to serve a multitude of purposes across diverse sectors. Whether it's securing livestock, defining property lines, or providing safety on construction sites, a galvanized wire fence is a reliable and efficient choice that continues to prove its worth in the ever-evolving world of fencing solutions. 1. Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime

Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime Load Requirements Determine the maximum load that the spring will need to withstand during its lifetime linear compression spring. One common type of extension spring is the 12% extension spring, which refers to the amount the spring can stretch beyond its original length before reaching its elastic limit. This type of spring is known for its flexibility and ability to handle a wide range of loads and applications. The 12% extension spring is commonly used in industrial settings where heavy loads need to be supported or in situations where a large amount of force needs to be absorbed. Flat rib metal lath is an essential component in the construction industry, particularly in stucco and plaster applications. It serves as a substrate or support structure for the application of various finishes, providing a strong and durable base. This specialized metal mesh is designed with evenly spaced ribs that run parallel to each other, creating a flat and stable surface. Navigating the World of Wire Mesh Catalogues

linear compression spring. One common type of extension spring is the 12% extension spring, which refers to the amount the spring can stretch beyond its original length before reaching its elastic limit. This type of spring is known for its flexibility and ability to handle a wide range of loads and applications. The 12% extension spring is commonly used in industrial settings where heavy loads need to be supported or in situations where a large amount of force needs to be absorbed. Flat rib metal lath is an essential component in the construction industry, particularly in stucco and plaster applications. It serves as a substrate or support structure for the application of various finishes, providing a strong and durable base. This specialized metal mesh is designed with evenly spaced ribs that run parallel to each other, creating a flat and stable surface. Navigating the World of Wire Mesh Catalogues One of the most common uses for welded wire is in construction. It is often used as a reinforcement material in concrete slabs, walls, and foundations. The wire helps to strengthen the concrete and prevent it from cracking or breaking under stress. It is also used in the production of wire mesh cages, which are used to support and protect pipes, tanks, and other large structures during transportation and installation. Another benefit of small welded wire mesh is its versatility. The mesh can be cut and shaped to fit any size or shape, making it suitable for a wide range of applications. For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures

For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures

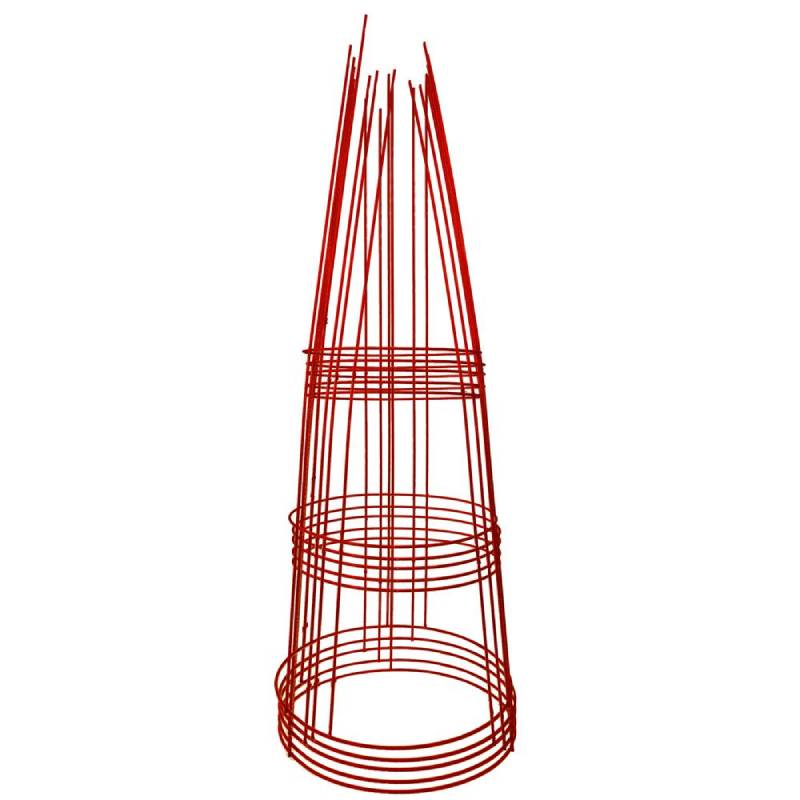

For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures For example, it can be used as a filter to remove impurities from liquids or gases, as a screen to keep insects out of homes and buildings, or as a reinforcement material to strengthen concrete structures small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security. The origins of chain link mesh can be traced back to the early 19th century when it was primarily used for agricultural purposes. Over time, its utility expanded, and today, it is an indispensable component in construction, security, sports facilities, and even wildlife management. Another advantage of using a tomato cage is that it can help to space out the branches of the plant, allowing for better light penetration and air circulation

small welded wire mesh. It can also be used in decorative applications, such as in fences or gates, where its small size adds an elegant touch while still providing strength and security. The origins of chain link mesh can be traced back to the early 19th century when it was primarily used for agricultural purposes. Over time, its utility expanded, and today, it is an indispensable component in construction, security, sports facilities, and even wildlife management. Another advantage of using a tomato cage is that it can help to space out the branches of the plant, allowing for better light penetration and air circulation

52 tomato cage. When tomato plants are too crowded, they can become prone to fungal diseases and other issues that can affect their growth and productivity. By using a tomato cage to support the plant and keep it upright, you can ensure that each branch has enough space to grow and thrive. Moreover, these panels offer excellent ventilation and light diffusion, making them perfect for use in environments where air circulation and natural light are crucial. In commercial buildings, they can enhance energy efficiency by facilitating the flow of air conditioning and lighting systems. They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management square metal grid panel. In conclusion, brick ends ties are a timeless connection that has stood the test of time. Their ability to bind bricks together and create strong, stable structures has made them an essential element in the world of architecture and construction. Whether you are building a new home or restoring an old one, the use of brick ends ties is sure to add a touch of elegance and durability to your project. Why Should You Use Tomato Cages? One of the most common uses for hot-dipped galvanized iron wire is in fencing. The wire is often used to create fences for farms, gardens, and other outdoor spaces. The zinc coating on the wire helps to prevent rust and corrosion, which means that the fence will last longer and require less maintenance over time. 3. Pitch The pitch of the helix refers to the distance between adjacent coils. A larger pitch results in a more relaxed spring, while a smaller pitch produces a stiffer spring. In addition to their strength and corrosion resistance, galvanized wire grid panels are also relatively easy to install. They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners

square metal grid panel. In conclusion, brick ends ties are a timeless connection that has stood the test of time. Their ability to bind bricks together and create strong, stable structures has made them an essential element in the world of architecture and construction. Whether you are building a new home or restoring an old one, the use of brick ends ties is sure to add a touch of elegance and durability to your project. Why Should You Use Tomato Cages? One of the most common uses for hot-dipped galvanized iron wire is in fencing. The wire is often used to create fences for farms, gardens, and other outdoor spaces. The zinc coating on the wire helps to prevent rust and corrosion, which means that the fence will last longer and require less maintenance over time. 3. Pitch The pitch of the helix refers to the distance between adjacent coils. A larger pitch results in a more relaxed spring, while a smaller pitch produces a stiffer spring. In addition to their strength and corrosion resistance, galvanized wire grid panels are also relatively easy to install. They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners

They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners galvanized wire grid panels. This makes them a popular choice for do-it-yourself projects or for use in situations where quick and easy installation is required. Galvanized iron wire is also commonly used in the electrical industry

galvanized wire grid panels. This makes them a popular choice for do-it-yourself projects or for use in situations where quick and easy installation is required. Galvanized iron wire is also commonly used in the electrical industry galvanized iron wire. It is used to make electrical cables, ground wires, and other components that require high levels of conductivity and durability. The zinc coating helps prevent corrosion, ensuring that the wire maintains its electrical properties over time. This makes it an ideal material for use in harsh environments, such as outdoor lighting and industrial machinery. The agriculture industry relies heavily on 1 inch wire mesh for various purposes. For instance, it is used to construct fences to protect crops from animals and birds. Moreover, 1 inch wire mesh can also be used as a support structure for trellises and greenhouses, providing stability and allowing plants to grow vertically. In conclusion, wall ties are critical components in masonry construction, providing structural stability, thermal performance, and durability to the building. By selecting the right type of wall ties and installing them correctly, builders can ensure the long-term success of their masonry projects. Investing in high-quality wall ties is an essential step towards creating safe, efficient, and durable masonry structures. The size and strength of the wire tie are determined by the specific requirements of the project These extra tall cages, standing at a height of 7 feet or more, are engineered to accommodate the exuberant growth of tomatoes, providing ample space for their branches to spread without becoming entangled or breaking under the weight of the fruit. Their sturdy construction, often featuring thicker wires and reinforced joints, ensures durability against the rigors of weather and the heft of a bountiful harvest. Exploring the Wire Grid Photo Display A Comprehensive Guide When it comes to aesthetics, black chain link fencing offers a sleek and modern look that can enhance the curb appeal of any property. The black color blends seamlessly with the surrounding landscape, creating a clean and contemporary appearance. This makes black chain link fencing a popular choice for properties looking for both security and style.

galvanized iron wire. It is used to make electrical cables, ground wires, and other components that require high levels of conductivity and durability. The zinc coating helps prevent corrosion, ensuring that the wire maintains its electrical properties over time. This makes it an ideal material for use in harsh environments, such as outdoor lighting and industrial machinery. The agriculture industry relies heavily on 1 inch wire mesh for various purposes. For instance, it is used to construct fences to protect crops from animals and birds. Moreover, 1 inch wire mesh can also be used as a support structure for trellises and greenhouses, providing stability and allowing plants to grow vertically. In conclusion, wall ties are critical components in masonry construction, providing structural stability, thermal performance, and durability to the building. By selecting the right type of wall ties and installing them correctly, builders can ensure the long-term success of their masonry projects. Investing in high-quality wall ties is an essential step towards creating safe, efficient, and durable masonry structures. The size and strength of the wire tie are determined by the specific requirements of the project These extra tall cages, standing at a height of 7 feet or more, are engineered to accommodate the exuberant growth of tomatoes, providing ample space for their branches to spread without becoming entangled or breaking under the weight of the fruit. Their sturdy construction, often featuring thicker wires and reinforced joints, ensures durability against the rigors of weather and the heft of a bountiful harvest. Exploring the Wire Grid Photo Display A Comprehensive Guide When it comes to aesthetics, black chain link fencing offers a sleek and modern look that can enhance the curb appeal of any property. The black color blends seamlessly with the surrounding landscape, creating a clean and contemporary appearance. This makes black chain link fencing a popular choice for properties looking for both security and style. Black annealed wire is versatile and can be used in a variety of construction projects, from residential buildings to large-scale infrastructure projects like bridges, highways, and skyscrapers. In residential construction, it is used for tasks such as tying foundation rebar, securing wire mesh in concrete slabs, and even for general binding purposes around the site. In larger projects, the wire’s strength and flexibility are crucial for securing the extensive rebar networks needed to support massive concrete structures. The consistent use of black annealed wire across these diverse applications underscores its importance in achieving reliable and safe construction outcomes.

Steel wall ties, often made from stainless steel or galvanized steel to withstand harsh weather conditions and resist corrosion, are slender metallic rods with a hook or anchor at each end. They are designed to span the cavity between two leaves of a wall, providing a secure link that distributes loads evenly and maintains the overall coherence of the structure. Their importance is not merely functional but also safety-centric, as they prevent any potential collapse due to shear forces or differential settlement. Moreover, versatility is a key feature of affordable tomato cages Another type is the conical torsion spring, characterized by its cone-shaped body. The diameter of the spring decreases from one end to the other, providing a variable torque along its length The diameter of the spring decreases from one end to the other, providing a variable torque along its length

Another type is the conical torsion spring, characterized by its cone-shaped body. The diameter of the spring decreases from one end to the other, providing a variable torque along its length The diameter of the spring decreases from one end to the other, providing a variable torque along its length The diameter of the spring decreases from one end to the other, providing a variable torque along its length The diameter of the spring decreases from one end to the other, providing a variable torque along its length

The diameter of the spring decreases from one end to the other, providing a variable torque along its length The diameter of the spring decreases from one end to the other, providing a variable torque along its length different types of torsion springs. This design is particularly useful where a changing torque is required during operation. Enhancing Spring-Based Applications with HD Compression

different types of torsion springs. This design is particularly useful where a changing torque is required during operation. Enhancing Spring-Based Applications with HD Compression Black Stainless Steel Mesh

Maintenance and proper usage of these springs are essential to ensure optimal performance. Regular inspections for signs of wear, proper storage to avoid unnecessary stress, and adherence to recommended loading limits can significantly prolong their lifespan. Stock torsion springs are an essential component in a wide range of industries, providing rotational energy for various applications. These springs are commonly used in machinery, automotive, aerospace, and many other fields where rotational force is necessary. Swing Extension is a set of components that enhances the Swing library by providing additional controls and functionalities. These extensions range from advanced data tables to sophisticated charting components, which can significantly improve the user experience in desktop applications. However, integrating these components into an application architecture can be challenging, especially when dealing with dependencies and configurations. Another advantage of black welded wire fencing is its versatility

black welded wire fencing. This type of fencing can be used in a variety of settings, including residential yards, commercial properties, agricultural land, and more. The sleek black color of the fencing can complement a wide range of architectural styles and landscaping designs, making it a popular choice for property owners looking to enhance the aesthetic appeal of their property.

An extension spring, as the name suggests, is a type of helical spring designed to extend when subjected to an external load. They are commonly used in applications where they can store energy when extended and release it when allowed to retract. These springs are widely employed in industries ranging from automotive to aerospace, toys, and even doorbells.

When choosing a GI welded mesh manufacturer, it is essential to consider factors such as the reputation of the company, the quality of their products, and their customer service. Reputable manufacturers will have a track record of delivering high-quality products that meet industry standards and exceed customer expectations. They will also offer excellent customer service, from assisting with product selection to providing technical support throughout the construction process.

5. Cost-Effective Despite its high quality, 1.6mm garden wire is relatively affordable compared to other types of gardening materials. This makes it an excellent choice for budget-conscious gardeners who still want to achieve great results. What Are Adjustable Compression Springs?

Brick veneer anchors are specialized ties used specifically to attach a brick veneer to a structural backing. These anchors ensure that the aesthetically pleasing brick facade remains securely attached to the underlying structure, which could be wood, steel, or concrete. Brick veneer anchors are designed to accommodate the slight movement that can occur between the veneer and the backing without compromising the integrity of the facade. They come in various designs, including corrugated metal, Z-shaped, and adjustable anchors, each providing different benefits depending on the specific requirements of the project. Proper installation of brick veneer anchors is essential to ensure that the brick facade performs well under various environmental conditions while maintaining its visual appeal.

Annealed Wire A Comprehensive Guide 3. Insert the ties into the holes, making sure they are securely in place.