Links:

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.

3. Versatility A single stitch machine can handle various types of leather, from soft lambskin to heavy saddle leather. This versatility makes it ideal for a wide range of projects, from bags and wallets to belts and outdoor gear.

Another advantage of double needle stitching is its versatility. This technique can be used with a wide range of fabrics, from lightweight silks to heavy denims

double needle stitch. It can also be used with different types of threads, allowing for endless creative possibilities. Double needle stitching can be done with both regular sewing machines and industrial sewing machines, making it accessible to sewists of all skill levels.

The zigzag stitch is another defining feature of this sewing machine. This stitch offers incredible flexibility, enabling seamstresses to create a variety of finishes and designs. It can be used to secure seams, finish raw edges, create decorative patterns, and even appliqué. The ability to adjust the width and length of the zigzag also means that sewing enthusiasts can customize stitches to suit their projects—whether that’s heavy upholstery, delicate garments, or quilting.

At its core, the double needle coverstitch uses two needles threaded through a single needle plate to create two parallel rows of stitching on the top side of the fabric while forming a chain stitch on the back. This stitch offers superior stretch, which is particularly beneficial for knit fabrics and activewear. Its construction flexibility allows for a neat, professional finish that maintains the elasticity of highly stretchy materials — an aspect crucial in modern garment creation.

Stitch machine embroidery designs have revolutionized the way we customize fabrics and garments. These intricate designs are created using automated embroidery machines that can stitch out complex patterns with precision and speed. From intricate floral motifs to bold typography, stitch machine embroidery designs have endless possibilities for creative expression.

5. Feed Dogs A good set of feed dogs will assist in the movement of fabric through the machine, which can be especially beneficial when handling slippery or heavy materials. High-quality feed dogs will prevent fabric bunching and ensure smooth, consistent sewing.

In conclusion, using a twin stretch needle can help you achieve professional-looking results when sewing stretch fabrics. By following these steps and practicing with your twin stretch needle, you'll be able to create beautiful hems and seams that maintain the stretchiness of your fabric. So go ahead and give it a try – you'll be surprised at how easy and effective it can be!

When selecting a sewing machine quilt pattern, consider factors such as your skill level, the type of fabric you want to use, and the overall look you hope to achieve. For beginners, simple block patterns or straight-line designs can be an excellent starting point. More advanced quilters may want to explore intricate patterns such as applique, paper piecing, or curves.

Troubleshooting Common Issues

It could be a hint of something big on the horizon, waiting to be unveiled to the world in all its glory It could be a hint of something big on the horizon, waiting to be unveiled to the world in all its glory

It could be a hint of something big on the horizon, waiting to be unveiled to the world in all its glory It could be a hint of something big on the horizon, waiting to be unveiled to the world in all its glory gsc367td .

gsc367td . One of the significant advantages of walking foot sewing machines is their ability to handle difficult materials. In industries where durability is essential, such as in the production of workwear, tents, and tarpaulins, the walking foot machine excels. It provides a robust solution for sewing together thick layers, ensuring that seams are not only secure but also aesthetically pleasing. By minimizing puckering and distortion, these machines contribute to the high standards required in commercial sewing.

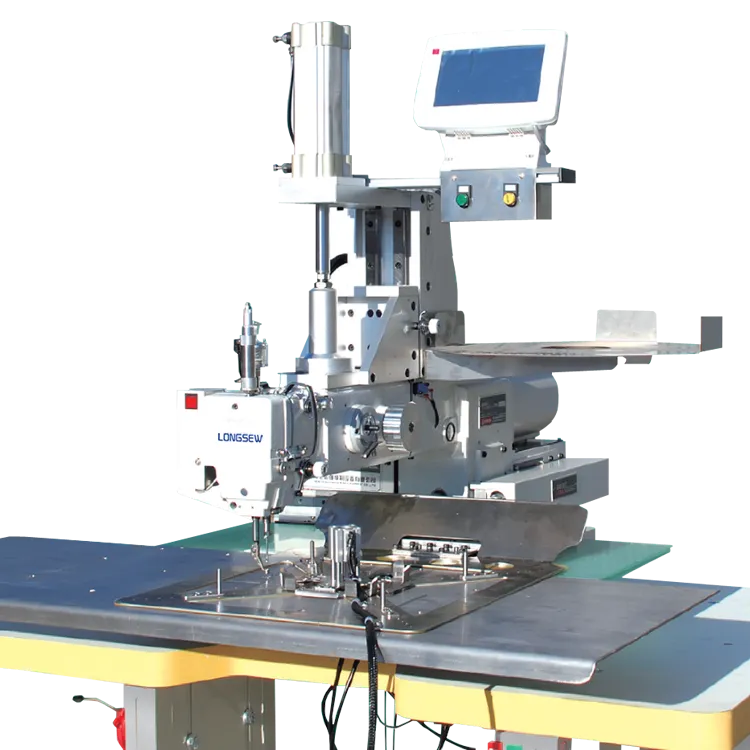

industrial walking foot sewing machine

In the world of sewing, the tools and machines we use can dramatically influence our creations. Among these tools, the dual needle sewing machine stands out for its versatility and ability to produce intricate and professional-looking finishes. This article explores the features, benefits, and applications of dual needle sewing machines, making it clear why they are a valuable investment for both amateur sewers and seasoned professionals.

1. Versatile Stitching Options Dual needle sewing machines can produce a variety of stitch types, including straight stitches, zigzag stitches, and decorative stitches. The ability to create multiple lines of stitching opens up new creative possibilities for garment finishing, quilting, and crafting projects.

Sewing Machine Needle for Faux Leather

These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times

These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times