Links:

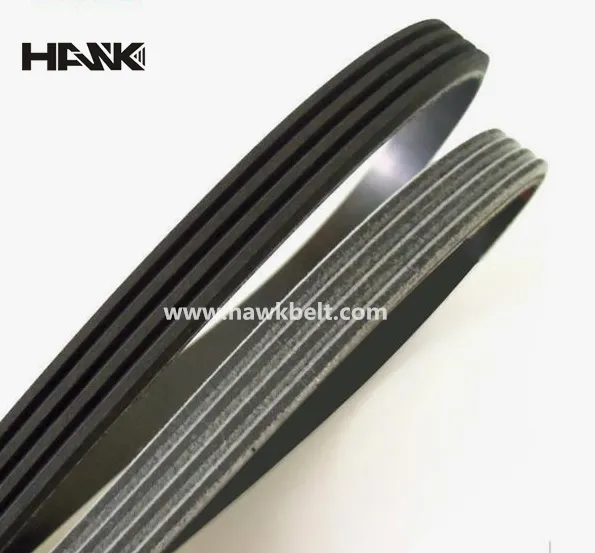

The 5PK belt is a specific type of serpentine belt characterized by its design and dimensions. The term 5PK refers to the number of ribs on the belt. The 5 indicates that the belt has five ribs, while PK signifies a specific profile that is commonly used in automotive applications. These ribs are essential for enhancing grip and ensuring that the belt can effectively transfer power between pulleys.

3. Total Cost Hence, the overall cost of replacing a timing belt might range from approximately $500 to $1,500, with many consumers reporting an average cost closer to $800. It’s advisable to get multiple quotes from different mechanics to ensure you’re getting a fair price.

- Regular Inspections Check V-belts regularly for signs of wear, such as cracks, fraying, or glazing. Catching these issues early can prevent more significant problems down the line.

Maintenance Tips

Flat Belts Design and Functionality

Role in Automation

Conclusion

Types of Belts Used in Rubber Washing Machines

Types of V-Belts

3. Loss of Accessory Function If the vehicle's alternator fails to charge the battery or the air conditioning stops working, it could be due to a malfunctioning drive belt.

drive belt for car

Like all automotive components, car belt pulleys require maintenance to ensure longevity and reliability. Regular inspections for wear and tear, including checking for cracks, alignment issues, and bearing failures, are essential. A worn pulley can lead to a loose belt, resulting in poor performance of engine accessories, such as reduced charging from the alternator or inadequate cooling from the water pump, which can lead to overheating.

Applications of B Series Timing Belts

To determine the optimal dimensions, engineers utilize formulas that account for the distance between the drive and driven pulleys, as well as the pulley diameters. These calculations must also consider the tension in the belt to ensure that it operates efficiently without excessive wear.

timing belt design

Conclusion

What is a 4PK Belt?

The V-belt factory stands at the forefront of industrial engineering, crafting resilient products that are pivotal to the functionality of countless machines. As industries continue to evolve, the significance of high-quality V-belts will undoubtedly remain a priority. With a strong commitment to innovation, sustainability, and quality assurance, the V-belt factory is poised to meet the demands of the future, ensuring the smooth operation of machinery across the globe. Whether in automotive, agricultural, or manufacturing sectors, these factories will continue to play a key role in powering progress.

The Importance of Toothed Belts in Modern Machinery

निष्कर्ष

1. Energy Efficiency One of the primary benefits of variable speed systems is their ability to adjust energy consumption based on load conditions. By operating at lower speeds during lighter loads, companies can significantly reduce energy costs and minimize wear and tear on equipment.

Step 3 Release the Belt Tension

installing new serpentine belt

In the realm of automotive engineering, the efficiency of vehicle operation largely hinges on a plethora of mechanical components that work in tandem. One such component is the V-ribbed belt, an integral element in many vehicles’ engine systems. The belt’s unique design and material qualities play a crucial role in ensuring smooth power transmission from the engine to various engine accessories, thereby influencing overall vehicle performance.

Replacing the timing belt in your Land Rover is a crucial maintenance task that should not be overlooked. By understanding the importance of this component, recognizing the signs of wear, adhering to replacement intervals, and following proper procedures, you can keep your engine running smoothly and avoid the costly repercussions of a timing belt failure. Regular maintenance and proactive care will ensure that your Land Rover remains a reliable vehicle for years to come. If in doubt, don’t hesitate to consult a professional mechanic to ensure the best care for your vehicle.

3. Listen to Your Engine Pay attention to how your engine sounds. Unusual noises can indicate problems with the timing belt. If you hear anything out of the ordinary, have it checked out promptly.

4. Fabric-reinforced Materials These belts combine layers of fabric with rubber or synthetic materials to enhance strength and flexibility. They are commonly used where heavy dynamic loads are present.

Maintenance and Replacement

The Role of Timing Belts in 3D Printing

Potential buyers can easily find a range of images showcasing the various color options available for the Civic Hatchback. Whether you're drawn to classic colors like crystal black pearl or vibrant shades like rallye red, these images highlight the versatility of the Civic's design. Furthermore, the hatchback's rear design is equally striking, featuring a sleek spoiler that enhances the vehicle's sporty look and improves aerodynamics.

- Cost-effectiveness While it may be tempting to choose the cheapest option, consider the long-term costs associated with frequent replacements. A more expensive, durable V-belt may offer better value over time.

To ensure optimal performance and longevity, regular maintenance of V-belt clutches is crucial. This includes checking the belt tension and condition, as a worn or loose belt can lead to slippage and decreased efficiency. Additionally, pulleys should be inspected for wear and proper alignment to avoid uneven load distribution and potential mechanical failure.

Additionally, certain parts are essential for compliance with regulations. For example, brake pads and lights must function correctly to meet safety standards. Neglecting these components can lead to substantial fines or even accidents. Therefore, staying informed about the condition of spare parts is crucial for any vehicle owner.

auto spare parts

Design Features

Finally, consider the manufacturer's reputation and the availability of support services. A reliable supplier can provide valuable assistance, whether through guidance on installation, maintenance, or sourcing replacement parts.

What Is a Poly V Belt?

Key Features to Consider

Maintaining your Toyota’s timing belt is crucial for ensuring the longevity and performance of your vehicle. Investing time and resources into regular inspections and timely replacements can save you a significant amount of money and prevent frustrating breakdowns.

Maintenance and Replacement

Once the belt is in position, reattach the tensioner according to the manufacturer’s specifications. Make sure the belt is taut but not overly tight.

6. Conclusion

- Cost-Effectiveness While the initial investment in a conveyor system can be significant, the long-term savings in labor and increased efficiency often justify the cost, making them a worthwhile investment.

Conclusion

Applications in Industry

5. Conveyor Systems Many conveyor systems utilize XL timing belts to move products through various stages of production. Their durability and reliability make them an ideal choice for these applications.

The Importance of Engine Drive Belts

engine drive belt cost

1. High Efficiency Wrapped V-belts are known for their efficiency in power transmission, often achieving over 90% power transfer from the motor to the driven component. This efficiency is crucial in various industrial applications, where maximizing power output is essential.

V belts, named for their trapezoidal cross-section, are designed to fit snugly in the grooves of pulleys. This design allows for a higher friction surface area, which enables the belt to efficiently transmit power between the driving and driven pulleys without slipping. V belts are primarily used in a wide array of industrial machinery, including conveyor systems, fans, pumps, and compressors.

3. Simplicity in Maintenance Maintenance schedules dictate timely replacement of the timing belt before it fails, which is critical for all engines. Non-interference engines, however, allow mechanics to work with a bit more leeway when timing belt replacement is overdue, in comparison to their interference counterparts. While regular checks are still essential, the consequences of a missed replacement are far less dire.

- Agricultural Equipment Tractors and other farming machinery utilize these belts for optimal performance, ensuring that agricultural processes run smoothly.

The Role of V Belts