Links:

Moreover, the design of jute bag closer machines has evolved over time. Modern models feature user-friendly interfaces, adjustable settings for different bag sizes, and enhanced sealing mechanisms to ensure the utmost quality. Many machines are also designed with safety features that protect operators while increasing productivity. This blend of innovation and practicality makes jute bag closer machines an indispensable asset for businesses looking to improve their packaging operations.

Tips for Sewing Vinyl

In conclusion, commercial zig zag sewing machines represent a perfect blend of functionality, efficiency, and creativity in the sewing industry. Their ability to handle a variety of projects—from simple hems to intricate designs—makes them an essential piece of equipment for both sewing enthusiasts and professional businesses. With their advanced features and sturdy construction, these machines not only enhance productivity but also inspire innovation in textile creation.

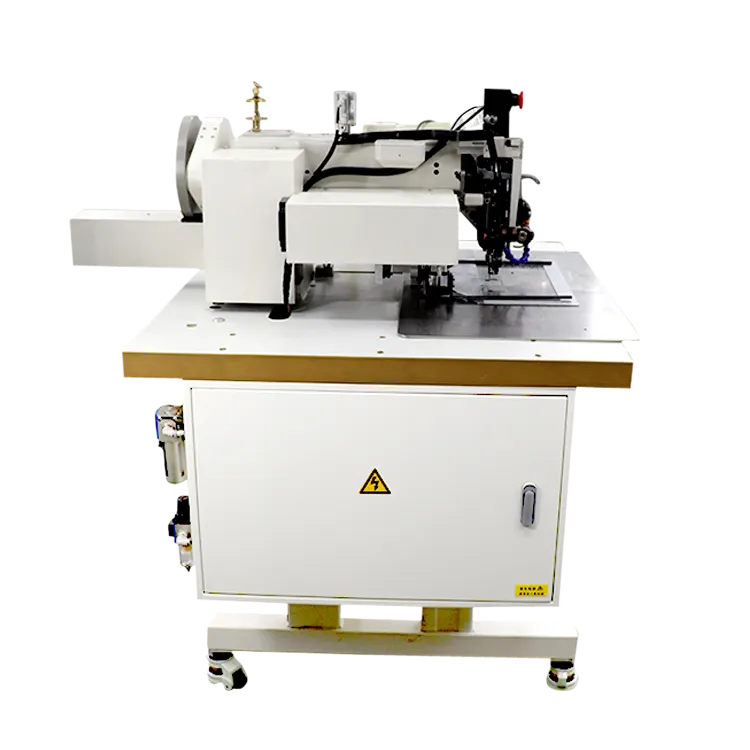

Efficiency is at the heart of the mini bag closer machine. With its automated functionality, it significantly reduces manual labor, thereby increasing productivity and reducing the risk of human error. It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually

It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually

It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually mini bag closer machine. This not only saves time but also cuts down on labor costs, contributing to a more cost-effective production process.

mini bag closer machine. This not only saves time but also cuts down on labor costs, contributing to a more cost-effective production process. Automatic bag closer machines are designed to seal bags of various materials, including those used for food, chemicals, textiles, and more. By automating the bag closing process, manufacturers can significantly increase their output while maintaining a high standard of quality. These machines can handle different types of closures, such as heat sealing, ultrasonic sealing, and stitching, making them versatile solutions that can be adapted to various products and industries.

Moreover, raised bed sewing machines typically come with a variety of features and accessories that cater to the diverse needs of sewing enthusiasts. Many models boast advanced technology, such as automatic needle threading, adjustable speed settings, and a range of stitch options, making them suitable for various sewing projects. Additionally, many raised bed machines are equipped with a larger throat space, which is particularly advantageous for quilting, as it allows for easy maneuverability while sewing intricate patterns or handling bulky layers of fabric.

In addition to their efficiency and versatility, saddle stitch machines also produce a professional-looking finished product

Investing in a compound feed heavy duty sewing machine can greatly enhance your sewing capabilities, enabling you to tackle a wide range of materials with ease and precision. As industries continue to seek efficiency and quality, these machines are poised to remain indispensable tools in the evolving landscape of sewing technology. Whether for personal projects or professional needs, a compound feed heavy duty sewing machine is a valuable addition to any sewing arsenal.

Another important factor to consider is the type of needle. There are different types of needles designed for specific tasks, such as straight stitching, zigzag stitching, or topstitching. For upholstery sewing, a heavy-duty needle with a sharp point is typically recommended. This type of needle can easily penetrate through thick layers of fabric and ensure secure stitching.

Advantages of Using Lock Stitch Machines

3. Second-Hand Market If you’re on a budget, don’t overlook platforms like Facebook Marketplace, Craigslist, or local thrift shops. Many sewing enthusiasts sell their machines when upgrading, providing opportunities to find quality machines at lower prices.

2. Ultrasonic Sealing Machines These machines use high-frequency ultrasonic vibrations to agitate the material at the seam, generating heat that fuses the edges together. Ultrasonic sealing is known for its speed and efficiency and is commonly used for non-woven and thermoplastic materials.

One of the primary advantages of using an industrial overlock sewing machine is its efficiency. These machines operate at high speeds, often exceeding 7,000 stitches per minute. This rapid production capability allows garment manufacturers to meet the high demands of the fashion industry while maintaining consistent quality. In a world where fast fashion dominates, the ability to quickly produce items without compromising on the integrity of the seams is crucial.

Furthermore, advancements in sewing technology have made zigzag foot sewing machines increasingly user-friendly. Many modern machines come equipped with various zigzag stitch options, automatic settings for stitch width and length, and even built-in tutorials that guide users through various techniques. Consequently, whether you are a seasoned professional or a complete beginner, the zigzag foot sewing machine has something to offer everyone.

The 2% needle industrial sewing machine is a powerful and reliable machine that is suitable for a wide range of sewing tasks. Its ability to use two needles simultaneously allows for greater flexibility in sewing different types of fabrics and materials. This machine is perfect for sewing projects that require a high level of accuracy and attention to detail.

In conclusion, the zig zag stitch machine has become an essential component of the modern sewing experience. Its ability to secure edges, accommodate elastic fabrics, and foster creative expression makes it a versatile tool for seamstresses of all levels. Whether you are embarking on a quilting project, crafting clothing, or exploring the realms of decorative stitching, the zig zag stitch machine promises to enhance your sewing journey with endless possibilities. Embracing this tool can lead to innovative creations and a deeper appreciation of the art of sewing.

When considering the price of a three-thread overlock machine, it is important to also factor in the long-term costs associated with maintenance and repairs. Machines that are made with high-quality materials and components may require less frequent repairs, which can result in cost savings over time. Additionally, it is important to consider the warranty and after-sales service provided by the manufacturer, as these can affect the overall value of the machine.

In the realm of textile manufacturing and garment production, efficiency and precision are paramount. Among the various types of sewing machines used in industrial settings, the walking foot sewing machine stands out as a crucial tool that has revolutionized how complex fabrics are stitched together. Renowned for its unique feeding mechanism and exceptional versatility, this machine has become indispensable in the sewing industry.

What is a Compound Feed Heavy Duty Sewing Machine?

Conclusion

The Importance of Heavy Duty Sewing Machines

In the world of textile and leather crafting, the hand crank sewing machine remains a cherished tool for artisans and hobbyists alike. With its vintage charm and mechanical simplicity, this machine allows for precision work while connecting the user to a rich history of craftsmanship. Specifically, when it comes to sewing leather, the hand crank sewing machine presents several advantages that make it a preferred choice for many.

When choosing a heavy-duty sewing machine, consider your specific sewing needs and preferences. Research different models read reviews, and compare features to find the one that best suits your requirements.

The Long Arm Zig Zag Sewing Machine A Seamstress’s Best Friend

Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors

Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors