Links:

- Tensioning Over time, belts can stretch and lose tension, leading to inaccuracies in print quality. Regularly check and adjust the tension of the belts to prevent slippage.

Ribbed V-belts are made from a combination of rubber and various synthetic materials, which offer durability and flexibility. The ribs on the belts help improve traction on the pulleys, reducing slippage and wear while providing a noiseless operation. Additionally, the engineering behind these belts ensures they are resistant to heat, oil, and environmental factors, which is particularly important in Hyundai vehicles that operate under a range of driving conditions.

Functionality of the PK Belt in Toyota Vehicles

Conclusion

2. Measure Length Use a tape measure or a ruler to measure the length of the belt from one end to the other.

Conclusion

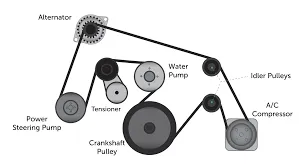

Rubber ribbed belts, also known as serpentine belts or ribbed drive belts, play a crucial role in a variety of mechanical systems, particularly in automotive applications. They are a type of belt designed to transfer power from the engine's crankshaft to various components, such as the alternator, power steering pump, water pump, and air conditioning compressor. The design and functionality of these belts have evolved over the years, becoming more sophisticated and efficient.

Understanding Toothed Conveyor Belts Mechanism, Applications, and Benefits

1. Durability PU belts are known for their excellent durability. Unlike traditional rubber belts, PU belts exhibit superior resistance to abrasion, cutting, and gouging. This results in a longer lifespan, reducing the frequency of replacements and maintenance costs.

5. Suspension and Steering Components

daihatsu terios parts

Design and Features

Мақолаи мақсад оид ба мити-стелузи флатси V-белт

The Significance of the Timing Belt

1. Efficiency Thanks to their large contact surface area and minimal slippage, small flat belts can efficiently transfer power with reduced energy loss compared to other belt types.

small flat belts

1. Customizability One of the primary benefits of an open timing belt is that it can be cut to the desired length. This feature allows for precise integration into different systems without the need for custom-made components.

The distribution channels chosen to deliver products significantly impact consumer accessibility and convenience. The COVID-19 pandemic accelerated the shift toward e-commerce, and in 2023, omnichannel strategies are more vital than ever. Brands must integrate physical stores with digital platforms to create seamless shopping experiences. Social media platforms are also becoming viable sales channels, allowing brands to meet consumers where they are.

6pk 2390

Advanced materials, such as synthetic rubber and reinforced fibers, enhance the durability and heat resistance of these belts. By investing in high-quality power transmission belts, vehicle owners can ensure reliable performance and a longer lifespan for their engine components.

What are Small Flat Belts?

4. Low Maintenance Most power transmission belts require minimal maintenance, making them user-friendly and efficient over the life of the machinery.

Operating Principles

Conclusion

- Xe Quá Nóng Nếu nhiệt độ động cơ thường xuyên ở mức cao, có thể dây curoa không truyền động hiệu quả đến quạt làm mát.

Small machine belts can be found in a myriad of applications across various industries. In the manufacturing sector, they are integral components in conveyor systems, lathes, and milling machines, where they facilitate movement and power transfer. In automotive contexts, these belts are critical for operating alternators, water pumps, and air conditioning compressors.

Conclusion

Accurate timing ensures that the valves open and close in harmony with the piston movements. If the timing is off—either due to a worn-out belt or improper installation—serious engine problems can arise. An out-of-sync engine might experience misfires, loss of power, or even catastrophic failure, such as valve-to-piston contact in interference engines.

4. Metal In some applications, especially those involving high loads or extreme environmental conditions, metal belts may be employed. These are usually made of stainless steel or other alloys to provide exceptional durability and resistance to corrosion. Metal flat belts can be found in industries like mining and heavy machinery, where robust solutions are necessary for longevity and reliability.

flat belt material

Sourcing Auto Spare Parts

auto spare parts

Auto parts are the building blocks of any vehicle, comprising everything from the engine and transmission to smaller components like spark plugs and brake pads. Each part plays a vital role in the overall function of a vehicle, ensuring safety, performance, and efficiency. In the modern automotive market, the demand for high-quality auto parts has escalated, driven by consumer expectations for reliability and longevity.

What is a Poly V Belt?

3. Oil Leaks If the seals around the timing cover fail, you may notice oil leaks.

- Battery Warning Light A flickering battery light on the dashboard could mean that the alternator is not functioning properly due to a failing fan belt.

Poly V belt manufacturers play a critical role in ensuring the availability of high-quality belts that meet the diverse requirements of modern machinery. These manufacturers are devoted to research and development, constantly improving the materials and manufacturing processes to produce belts that offer longer service life, better performance, and greater resilience under challenging conditions.

In today's digital age, staying connected while on the road is essential. A reliable phone mount allows you to use your smartphone for navigation without compromising your safety. Many models fit perfectly in the C5, offering secure placement and easy access to your device. Look for mounts that enable both portrait and landscape viewing, making them versatile for various applications.

2. Design and Material Washing machine belts are usually crafted from specially formulated rubber compounds designed to handle the specific stress and strain associated with laundry cycles, including moisture exposure and constant tension. On the other hand, rubber belts can vary widely in composition based on their intended use, which may not involve the same environmental challenges.

Advantages of XL Timing Belts

1. V-Belts This is one of the most common types of van belts and features a trapezoidal cross-section. V-belts are highly efficient in power transmission and are commonly used in automotive engines, industrial machinery, and agricultural equipment.

2. Manufacturing Costs The production process of poly belts involves several stages, including mixing, extrusion, curing, and finishing. Any change in labor costs, energy prices, or technological advancements in manufacturing can affect the overall production cost. For example, automation in manufacturing might reduce labor costs but require significant upfront investment in technology.

2. Space-Saving Design The compact design of double-sided serpentine belts allows for a more streamlined engine layout. This is particularly advantageous in tightly packed engine compartments where space is a premium. It enables manufacturers to design smaller vehicles without compromising engine performance.

The Role of V-Belts in Chinese Industry

3. Decreased Performance If you notice a decrease in the performance of power steering, air conditioning, or any accessories powered by the belt, this may suggest that the PK belt isn’t functioning effectively.

1. Squeaking or Slipping Sounds A loud squeaking noise when you start the engine may indicate that the belt is slipping or misaligned.

3. Idler Pulley Helps guide and maintain the tension on the belt.Timing belts are an essential component in many machinery and automotive engines, serving the critical function of synchronizing the rotation of various parts. They are typically made from a combination of materials designed to withstand wear, heat, and stress while ensuring optimal performance. Understanding the different materials used in timing belts, their properties, and advancements in technology is vital for engineers, mechanics, and automotive enthusiasts alike.

An OEM (Original Equipment Manufacturer) timing belt is a component made by the same company that manufactured the original timing belt included in your Honda vehicle when it was first built. OEM parts are designed to match the specifications and quality of the original parts, ensuring a proper fit and reliable performance.

5. Specialized Options Depending on your specific application, you might need specialized belts designed for unique conditions like high temperatures or specific environmental factors. Research options that suit your particular requirements.

Conclusion

Rubber canvas flat belts are typically composed of a combination of rubber and fabric (often made from cotton or polyester). The rubber provides a flexible yet strong surface while the fabric enhances tensile strength, enabling the belt to handle substantial loads without stretching or breaking. The manufacturing process involves layering the rubber over the canvas, ensuring a strong bond that maximizes durability. This design not only minimizes friction but also enhances grip, making it suitable for various speed and load requirements.

Common Issues with Power Steering Belts

In the age of online shopping, acquiring a motorcycle chain belt has never been easier. Several platforms offer a wide range of options

Rubber canvas flat belts are indispensable in today's industrial landscape, combining the rich history of mechanical innovation with modern technology. Their versatility, durability, and cost-effectiveness make them an essential component across various sectors. As technology progresses, the future of rubber canvas flat belts looks promising, ensuring that they will continue to be a cornerstone in the machinery of industry for years to come.