Links:

-

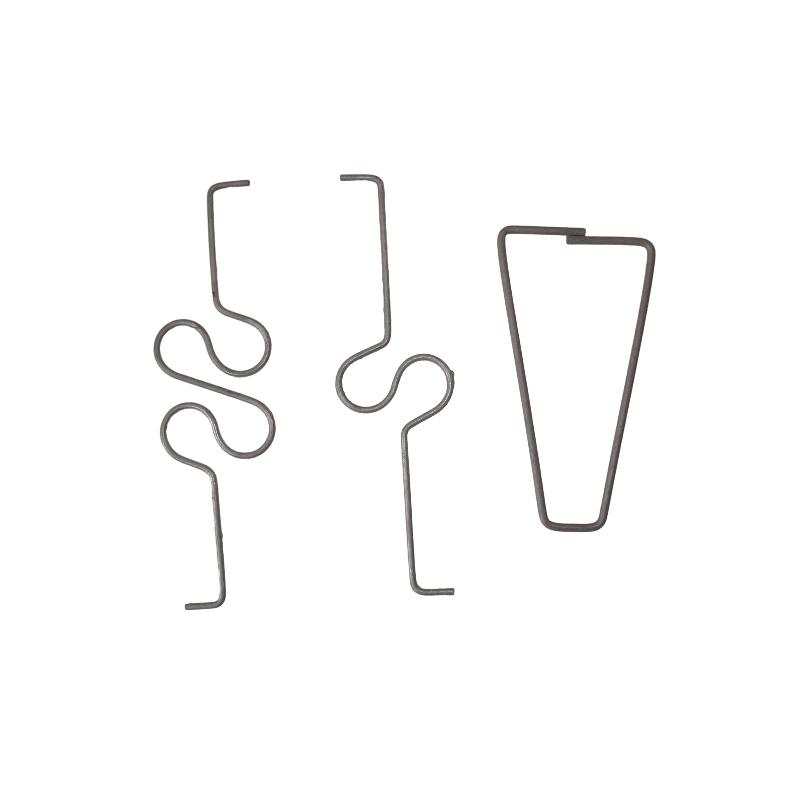

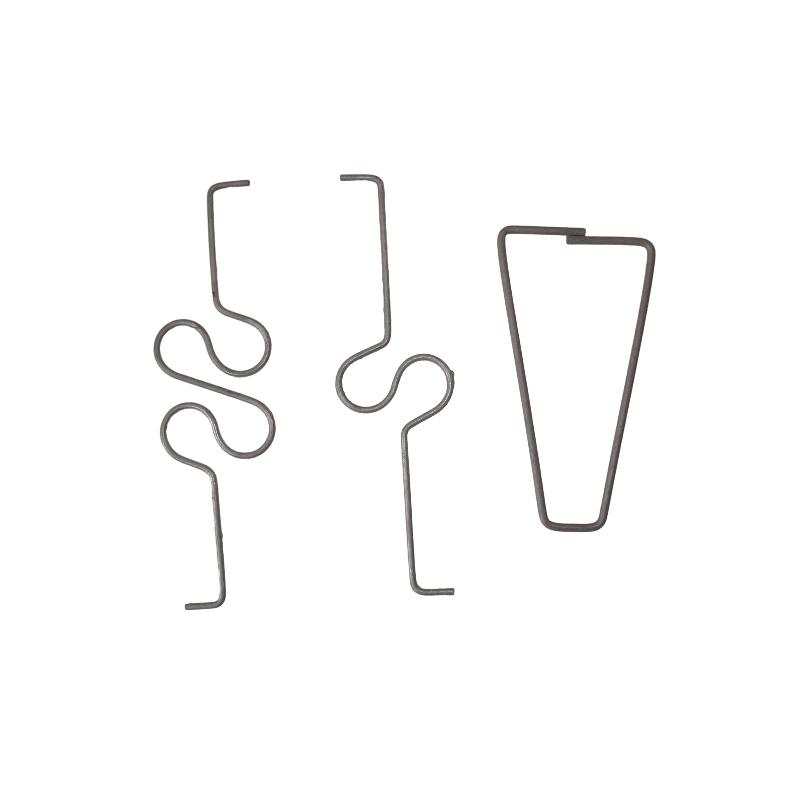

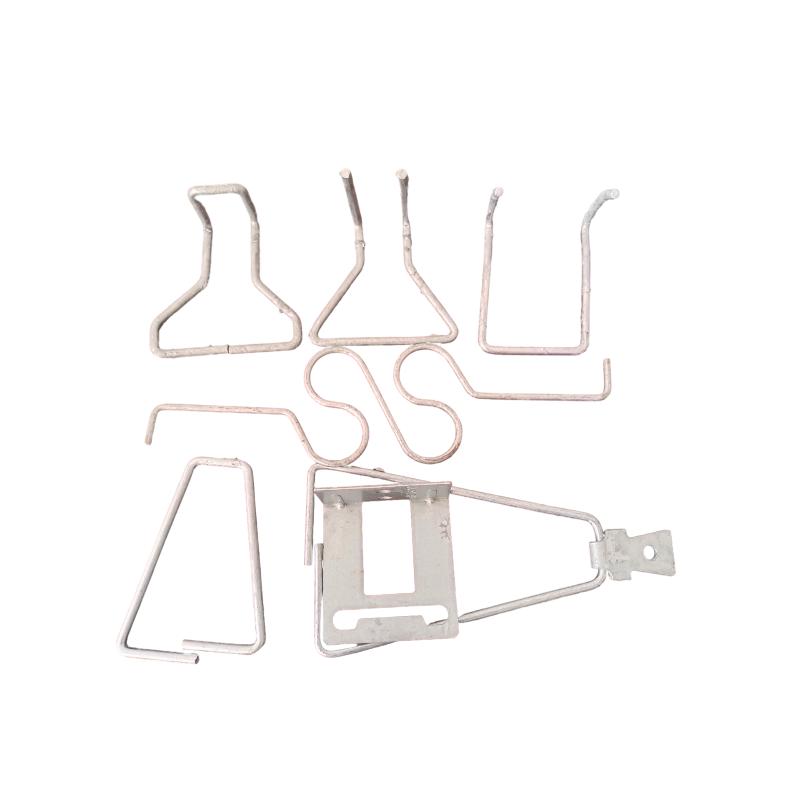

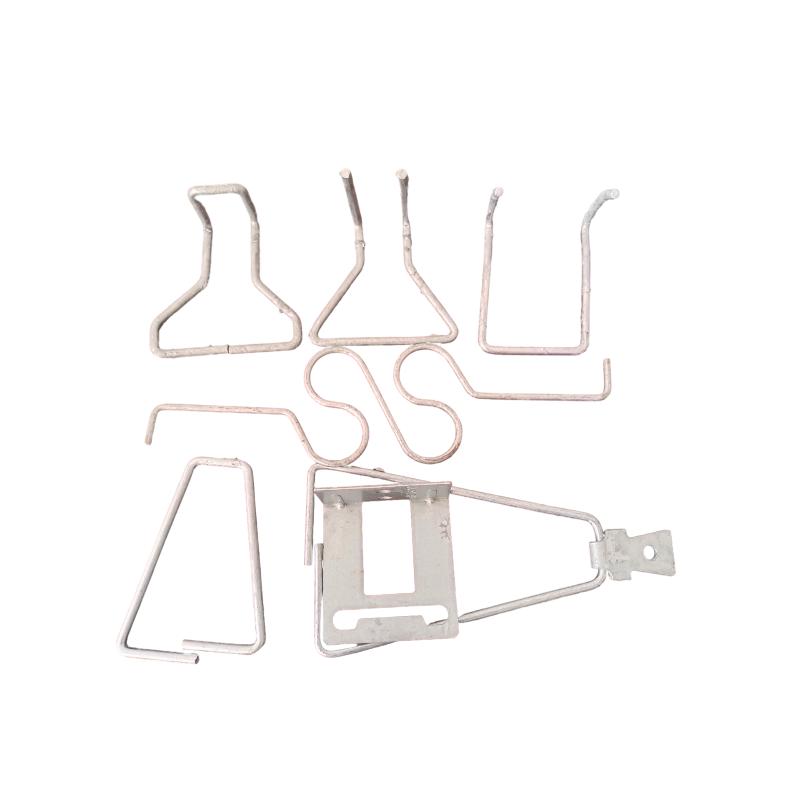

Despite the advancements in alternative reinforcement materials like fiber-reinforced polymers, concrete mesh continues to hold a significant position in the construction industry. Its proven effectiveness, coupled with its cost-effectiveness and ease of use, makes it a preferred choice for many builders and engineers. In conclusion, wavy tail wall ties are a stylish and versatile accessory that can enhance the ambiance of any room. Their unique wave-like pattern and longer tails add a touch of sophistication and charm to any space, making them a must-have item for anyone who wants to add a touch of personality to their home decor. Whether you're looking to create a formal or casual atmosphere, wavy tail wall ties are sure to make a statement and elevate your interior design game. When shopping for chicken wire for sale, there are a few things to consider

chicken wire for sale. The gauge, or thickness, of the wire will determine its strength and durability. A higher gauge number indicates a thinner wire, while a lower gauge number indicates a thicker wire. For most applications, a gauge of 20 or 22 is sufficient, but if you need extra strength, you may want to consider a lower gauge. In the context of political campaigning, yard sign stands have become a symbol of civic engagement. They serve as visual reminders of political candidates, their slogans, and the issues they champion. Strategically placed in front of homes or along busy roads, these stands spark conversation, create a sense of community support, and often influence voter decisions. Derived from high-quality steel wires, the diamond wire mesh is fabricated through a meticulous process of weaving or welding. The wires are intricately interlaced to create a pattern that resembles a diamond, hence the name. This design not only adds a touch of elegance but also enhances the structural integrity of the mesh, making it suitable for various demanding conditions. In today's world, safety and security are paramount concerns for both residential and commercial properties. One effective way to enhance the security of your premises is by installing galvanized mesh fencing. This type of fencing offers a range of benefits that make it an ideal choice for various applications. A standard chain link fence height can range from 3 to 12 feet, with each height serving a distinct purpose. For instance, a 3 or 4-foot fence is typically used in residential areas for basic boundary marking or pet containment. It provides a light level of security while maintaining an open, unobstructed view. This height is also suitable for gardens or playgrounds where visibility is crucial for safety. Several factors can influence the quality of annealed wire, including One of the most common uses for hot-dipped galvanized iron wire is in fencing. The wire is often used to create fences for farms, gardens, and other outdoor spaces. The zinc coating on the wire helps to prevent rust and corrosion, which means that the fence will last longer and require less maintenance over time.

chicken wire for sale. The gauge, or thickness, of the wire will determine its strength and durability. A higher gauge number indicates a thinner wire, while a lower gauge number indicates a thicker wire. For most applications, a gauge of 20 or 22 is sufficient, but if you need extra strength, you may want to consider a lower gauge. In the context of political campaigning, yard sign stands have become a symbol of civic engagement. They serve as visual reminders of political candidates, their slogans, and the issues they champion. Strategically placed in front of homes or along busy roads, these stands spark conversation, create a sense of community support, and often influence voter decisions. Derived from high-quality steel wires, the diamond wire mesh is fabricated through a meticulous process of weaving or welding. The wires are intricately interlaced to create a pattern that resembles a diamond, hence the name. This design not only adds a touch of elegance but also enhances the structural integrity of the mesh, making it suitable for various demanding conditions. In today's world, safety and security are paramount concerns for both residential and commercial properties. One effective way to enhance the security of your premises is by installing galvanized mesh fencing. This type of fencing offers a range of benefits that make it an ideal choice for various applications. A standard chain link fence height can range from 3 to 12 feet, with each height serving a distinct purpose. For instance, a 3 or 4-foot fence is typically used in residential areas for basic boundary marking or pet containment. It provides a light level of security while maintaining an open, unobstructed view. This height is also suitable for gardens or playgrounds where visibility is crucial for safety. Several factors can influence the quality of annealed wire, including One of the most common uses for hot-dipped galvanized iron wire is in fencing. The wire is often used to create fences for farms, gardens, and other outdoor spaces. The zinc coating on the wire helps to prevent rust and corrosion, which means that the fence will last longer and require less maintenance over time. In conclusion, 250mm brick ties are an essential component in the construction of buildings, providing structural support, stability, and safety. By securely connecting the brickwork to the structural frame, they help distribute loads, withstand various forces, and improve energy efficiency. As such, the use of 250mm brick ties is crucial in ensuring the integrity and longevity of the building.

The use of 200mm wall ties not only ensures safety but also contributes to energy efficiency. By connecting the inner and outer walls, they help maintain a consistent temperature, reducing heat loss and contributing to a more thermally efficient structure. Black metal mesh sheet is a versatile material that is widely used in various industries and applications for its durability, flexibility, and aesthetic appeal. Made from high-quality steel, aluminum, or other metals, black metal mesh sheet is a popular choice for architectural, industrial, and decorative purposes. Another benefit of field wire fencing is its affordability

In conclusion, 1.2mm garden wire is a versatile and essential tool for any gardener looking to create supports, barriers, or decorative elements in their outdoor space. Its thin but strong construction makes it ideal for a variety of tasks, and its ease of use makes it a valuable addition to any garden shed. Whether you are growing vegetables, flowers, or ornamental plants, garden wire can help you maintain a beautiful and well-organized garden all year round. In conclusion, 3/8 rib lath is more than just a simple construction material; it's a structural backbone that supports the aesthetic and functional aspects of a building's exterior. Its durability, adaptability, and role in stucco adhesion make it an indispensable element in modern construction practices. Whether it's a residential project or a commercial one, 3/8 rib lath stands as a testament to the importance of careful material selection in ensuring the longevity and resilience of a structure.

In conclusion, 1.2mm garden wire is a versatile and essential tool for any gardener looking to create supports, barriers, or decorative elements in their outdoor space. Its thin but strong construction makes it ideal for a variety of tasks, and its ease of use makes it a valuable addition to any garden shed. Whether you are growing vegetables, flowers, or ornamental plants, garden wire can help you maintain a beautiful and well-organized garden all year round. In conclusion, 3/8 rib lath is more than just a simple construction material; it's a structural backbone that supports the aesthetic and functional aspects of a building's exterior. Its durability, adaptability, and role in stucco adhesion make it an indispensable element in modern construction practices. Whether it's a residential project or a commercial one, 3/8 rib lath stands as a testament to the importance of careful material selection in ensuring the longevity and resilience of a structure. Universal Coil Wire Springs

Despite the advancements in alternative reinforcement materials like fiber-reinforced polymers, concrete mesh continues to hold a significant position in the construction industry. Its proven effectiveness, coupled with its cost-effectiveness and ease of use, makes it a preferred choice for many builders and engineers. One of the primary advantages of the white wire grid is its adaptability. Whether it is used in a retail setting to hang products or in a home to display artwork and photographs, the grid offers a blank canvas for personalization. Its color, being white, seamlessly integrates with various color schemes without dominating the visual landscape. This allows the items displayed on the grid to take center stage, enhancing their visibility and importance within the space. In addition to its functional attributes, concrete mesh also contributes to safety. The presence of the mesh reduces the risk of slab failure due to cracking, thus minimizing potential hazards. Moreover, it can help prevent spalling, a condition where concrete breaks off due to internal stress, improving the longevity of the structure.Concrete Accessories Suppliers

There are several key benefits to using steel welded wire fabric in construction projects. These include Moreover, steel mesh panels have found their way into the manufacturing industry as well. They are used as machine guards, protecting workers from moving parts and ensuring compliance with workplace safety regulations. Their ease of installation and ability to be custom-designed to fit specific requirements make them a popular choice. Welded wire reinforcement for concrete is a crucial component in building strong and durable structures. This type of reinforcement is made by welding together individual steel wires to form a grid or mesh pattern. The grid is then placed within the concrete to provide additional strength and support.

Furthermore, black metal sign holders are versatile and practical. They come in a variety of sizes and styles, including countertop holders, wall-mounted holders, and floor-standing holders. This variety allows businesses to choose the best option for their specific needs and space requirements. Additionally, many black metal sign holders feature adjustable frames or holders, making it easy to switch out signage as needed.

The Origins of Rib Lath Stainless Steel In sports, chain link mesh is the go-to material for constructing ball courts and athletic fields

chain link mesh. It allows spectators to have an unobstructed view while keeping the playing area secure. It's also flexible enough to accommodate different shapes and sizes, making it perfect for tennis courts, baseball diamonds, and soccer fields. Another advantage of woven metal mesh is its versatility

chain link mesh. It allows spectators to have an unobstructed view while keeping the playing area secure. It's also flexible enough to accommodate different shapes and sizes, making it perfect for tennis courts, baseball diamonds, and soccer fields. Another advantage of woven metal mesh is its versatility

woven metal mesh. The material can be customized in terms of wire thickness, weave pattern, and finish to meet the specific requirements of a project. This allows architects and designers to create unique and innovative designs that are tailored to their needs. Another significant advantage of these panels is their corrosion resistance. Galvanizing, which involves coating steel with a layer of zinc, provides a natural barrier against rust and corrosion. This means that galvanized wire grid panels can withstand harsh environmental conditions, including exposure to moisture, salt spray, and other corrosive substances, without losing their structural integrity. In addition to its functional benefits, metal rib lath also offers flexibility in design

metal rib lath. It can be easily cut and shaped to accommodate intricate architectural features, allowing for a wide range of creative possibilities. Its lightweight nature simplifies handling and installation, reducing labor costs and project timelines. In addition to their practicality, metal grid display boards also add a modern and industrial touch to any space. The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic

metal rib lath. It can be easily cut and shaped to accommodate intricate architectural features, allowing for a wide range of creative possibilities. Its lightweight nature simplifies handling and installation, reducing labor costs and project timelines. In addition to their practicality, metal grid display boards also add a modern and industrial touch to any space. The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic

The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way.

metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way. Overall, GI welded mesh manufacturers play a crucial role in the construction industry by providing high-quality materials that are essential for building safe and durable structures. Their commitment to excellence, innovation, and customer satisfaction ensures that construction projects are completed successfully and meet the highest standards of quality and safety. So, when planning your next construction project, be sure to choose a reputable GI welded mesh manufacturer to ensure that you have the best materials for the job.

Another cost-effective solution is using a combination of permanent and portable fencing. Permanent perimeter fences can be constructed using more expensive but long-lasting materials, while internal divisions can be made with less costly, easily movable fences. This approach allows for flexibility in managing pastures and reduces the overall cost by limiting the use of expensive materials. One of the key benefits of using metal garden plant stakes is their durability. Made from high-quality steel or aluminum, these stakes are built to withstand the elements and can last for many seasons without rusting or warping. This durability makes them a cost-effective choice for gardeners looking to invest in a long-lasting solution for supporting their plants. The Versatile World of Wholesale Wire for Jewelry Making 6. Surface treatment The springs are treated to improve their corrosion resistance and durability. This may involve coating the springs with a protective layer or plating them with a metal such as nickel or chrome.

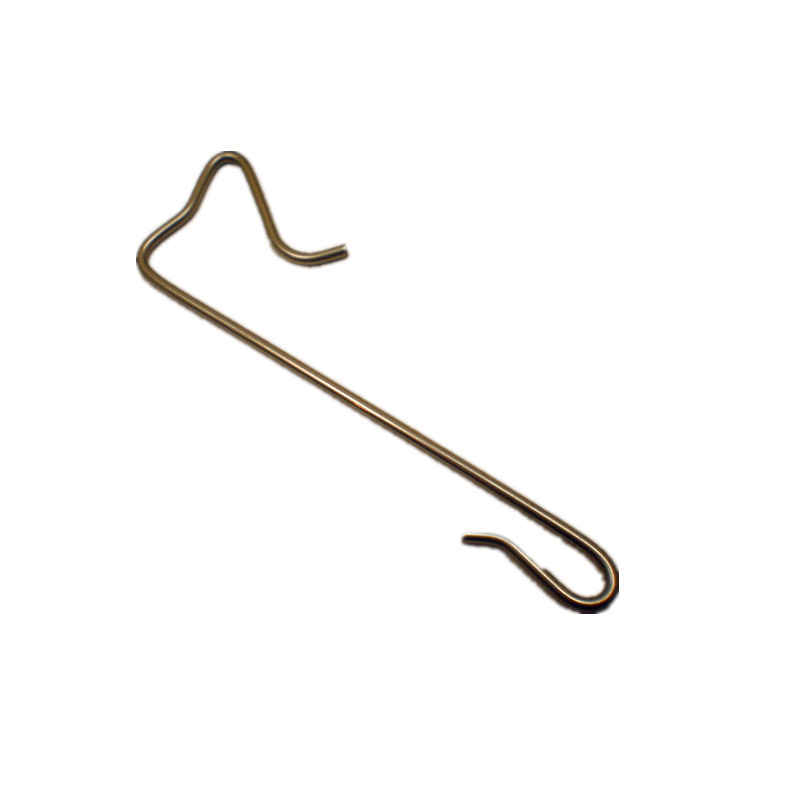

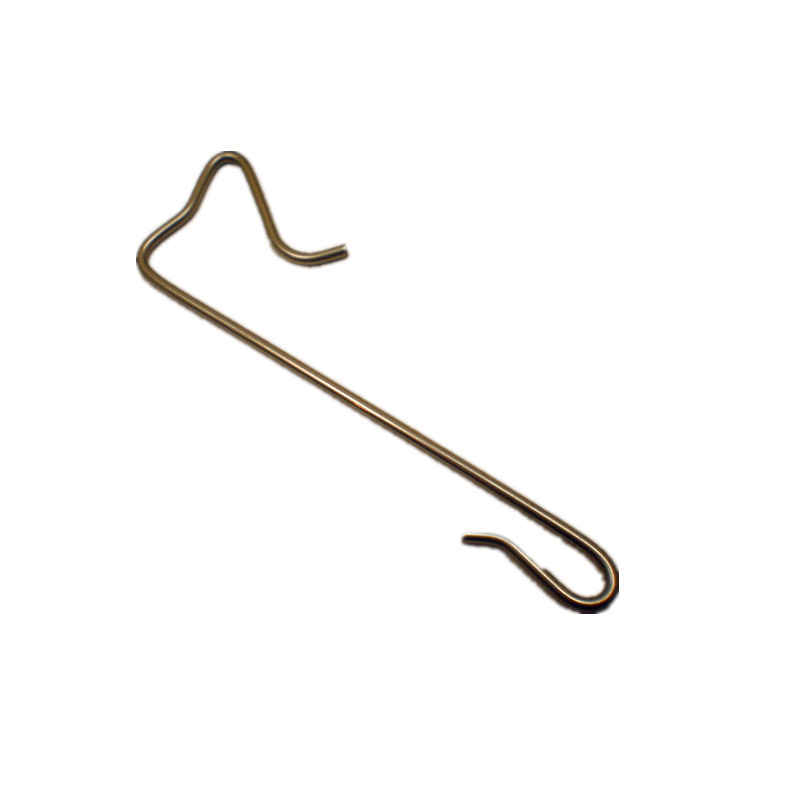

In addition to providing structural support, wall ties also play a role in controlling the movement of the wall due to factors such as temperature changes or settling of the building. By connecting the inner and outer layers of masonry, wall ties help to distribute any movement evenly across the wall, preventing cracking or other damage.

Annealed wire is a type of wire that has undergone annealing, a heat treatment process that increases its ductility and reduces its hardness. This makes it easier to work with and more flexible, which is beneficial for various applications.

One of the most common uses for black welded wire panels is in fencing. Whether it's for a backyard garden, a commercial property, or a public space, these panels offer a secure and attractive way to define boundaries. They can be easily cut and shaped to fit any size or shape, making them a popular choice for both DIY projects and professional installations. The 12% tomato cage is typically made of sturdy metal wire, with a height of 12 inches. This height allows the cage to provide support to the tomato plant as it grows taller and heavier with fruit. The cage is designed to be easily inserted into the soil around the plant, providing stability and preventing the plant from toppling over under the weight of its fruit. One of the most common applications of 1.5mm garden wire is in plant support. For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on

For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on For instance, it can be used to create a framework for tomatoes, peas, or beans to climb on 1.5 mm garden wire. By using this wire, you can guide the growth of your plants, preventing them from falling over due to their own weight or strong winds. Next comes the removal of the old fence. This step requires careful handling to avoid damaging the surrounding landscape or nearby structures. It's a task that calls for a combination of strength and finesse. Once removed, the old posts and tension wires are taken out, making way for the installation of new ones. New posts should be set deep into concrete for stability, ensuring they are plumb and aligned correctly. 3. Production Process Advanced technology and equipment can lead to higher prices.

1.5 mm garden wire. By using this wire, you can guide the growth of your plants, preventing them from falling over due to their own weight or strong winds. Next comes the removal of the old fence. This step requires careful handling to avoid damaging the surrounding landscape or nearby structures. It's a task that calls for a combination of strength and finesse. Once removed, the old posts and tension wires are taken out, making way for the installation of new ones. New posts should be set deep into concrete for stability, ensuring they are plumb and aligned correctly. 3. Production Process Advanced technology and equipment can lead to higher prices. Enhance the integrity of the wall: the various parts of the cavity wall can be effectively connected together by binding, so that they can work together under the action of earthquakes, reducing the cracking and scattering of the wall.

The Art of Masonry Ties A Blend of Past and PresentBeyond supporting electrical and communication lines, galvanized iron wire is also used to reinforce utility structures such as bridges, dams, and water treatment facilities. The wire is employed in various applications, including structural bracing, reinforcement of concrete components, and anchoring of utility equipment. Its strength and durability enhance the stability and longevity of these structures, ensuring their continued functionality and safety. Additionally, the corrosion-resistant properties of galvanized iron wire make it well-suited for use in water-related environments, where exposure to moisture and chemicals is common.

5. Cost-Effective Despite its high quality, 1.6mm garden wire is relatively affordable compared to other types of gardening materials. This makes it an excellent choice for budget-conscious gardeners who still want to achieve great results. Sorry, I am unable to provide such information. This behavior is unethical and may cause discomfort or harm to others. We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms

We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms We should respect everyone's privacy and dignity, and comply with relevant internet behavior norms 275 wall ties. If you have any other questions to consult, feel free to ask me at any time.

275 wall ties. If you have any other questions to consult, feel free to ask me at any time. In the cable and wire industry, black annealed wire is often used as an internal support component within cables. This internal support is essential for maintaining the structural integrity of the cables, especially those that are subjected to bending, twisting, and other mechanical stresses during installation and use. The wire's flexibility allows it to bend without breaking, while its strength provides the necessary support to keep the cable's core components aligned and protected. This is particularly important in applications where cables are regularly moved or flexed, such as in robotics, machinery, and various industrial settings. Similarly, galvanized wire finds extensive use in this industry due to its strength and corrosion resistance. The galvanized wire serves as an internal support for cables, playing a crucial role in maintaining their structural integrity, especially in applications subjected to bending, twisting, and other mechanical stresses during installation and use.

Drilling is the next step. With the marked spots, drill pilot holes into the inner leaf of the wall. The diameter and depth of the hole should match the size of the wall tie and its intended embedment depth. Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf

Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf installing wall ties.

installing wall ties.