Links:

-

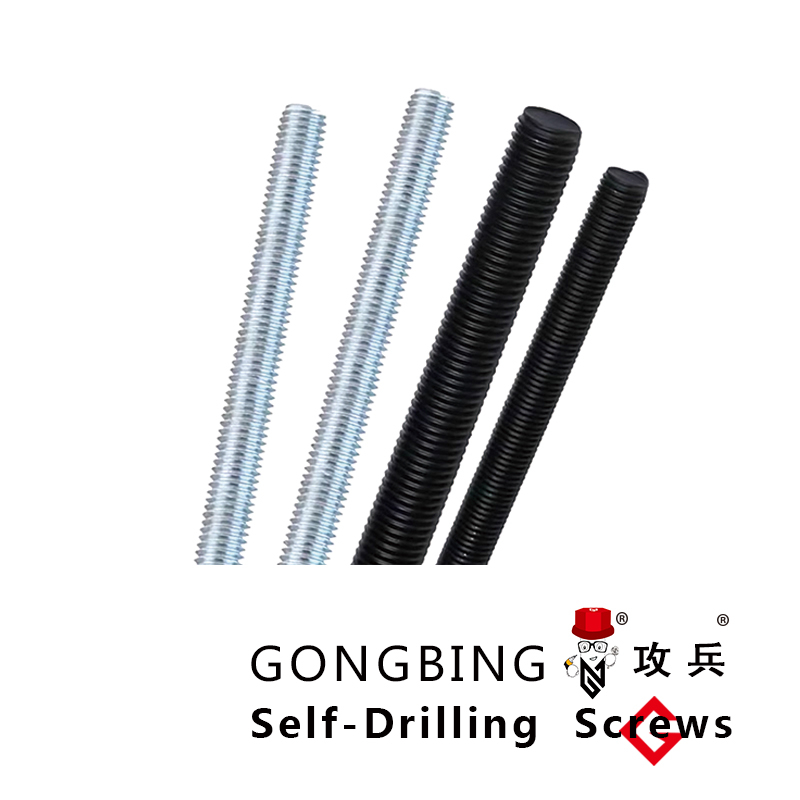

Another important consideration in the design of foundation bolts is the material from which they are made. In general, foundation bolts are made from high-strength steel to ensure that they can withstand the loads placed upon them

foundation bolts design. The bolts may also be coated with a corrosion-resistant material to protect them from the elements and extend their lifespan. However, chemical anchors also come with their own set of considerations. The selection of the right type of resin and hardener is crucial, as different chemicals have varying cure times, strengths, and compatibility with specific substrates. Moreover, environmental factors such as temperature and humidity can impact the curing process, necessitating careful planning and execution.

The white wafer head of these self-drilling screws is characterized by a broad, flat surface that provides a wide bearing area. This design helps distribute the load more evenly, reducing the risk of damage to the material being fastened. The head is typically finished in a white coating that not only enhances aesthetic appeal but also offers a degree of corrosion resistance, which is particularly beneficial in outdoor applications or areas exposed to moisture.

Firstly, the material of the workpiece is a crucial factor to consider when selecting the correct wedge, bolt, and drill size. Different materials have different strengths and hardness levels, which can affect the holding power of the fasteners. For example, softer materials like wood or plastic may require smaller fasteners with lower holding power, while harder materials like metal may require larger fasteners with higher holding power. Another key benefit of using a 14 x 1 tek screw is the speed and ease of installation

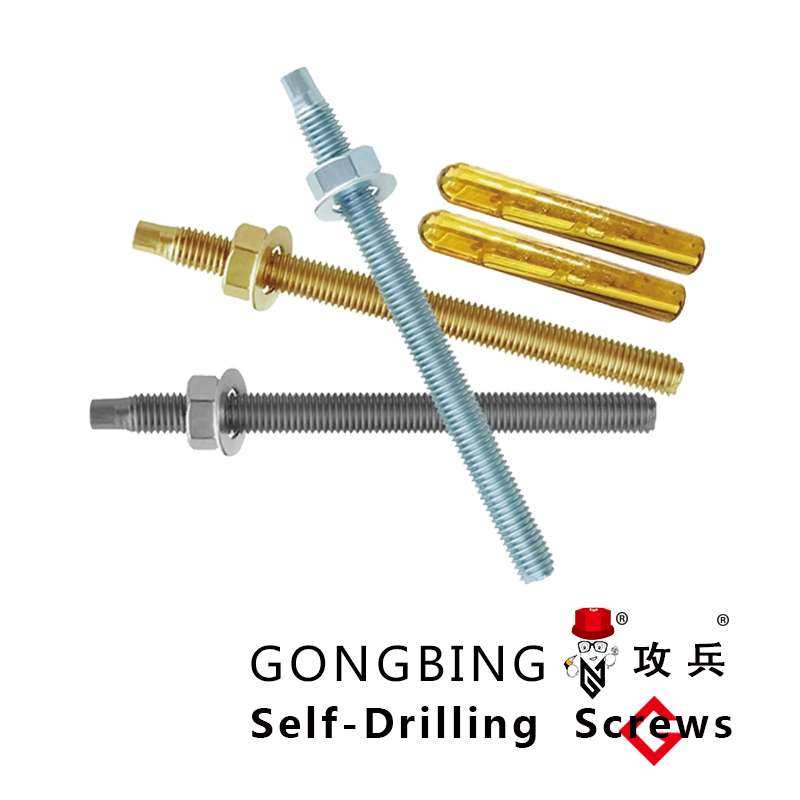

14 x 1 tek screw. Because these screws are self-tapping, they eliminate the need for pre-drilling holes, saving time and effort. Simply place the screw on the surface you want to attach, apply pressure with a drill or screwdriver, and watch as the tek screw effortlessly cuts its own path into the material. Moreover, self-drilling flat head metal screws are available in various materials, including steel, stainless steel, and aluminum, each tailored to specific applications. Stainless steel screws, for instance, are corrosion-resistant and suitable for outdoor or marine environments, while steel screws offer excellent strength for heavy-duty applications. Introduction M10 resin anchor bolts are designed to provide a secure and reliable anchor point for various fixtures, such as handrails, machinery, and structural elements. These bolts are made of high-quality materials that ensure durability and long-term performance. The resin material used in these anchor bolts provides excellent bonding strength, making them suitable for use in both indoor and outdoor environments.

Advantages

t head screw

When used together, wedge anchors and bolts form a powerful combination for enhancing construction stability

- Construction Often used in metal roofing and siding installations, where durability and waterproofing are critical.

Despite their compact size, these screws pack a powerful punch. Their strength, durability, and time-saving properties make them a go-to choice for engineers and tradespeople alike. The 10 16x3 4 self-drilling screw embodies the fusion of technology and practicality, revolutionizing the way we approach construction and assembly tasks. Resin anchors work by combining a resin compound with a hardener, creating a durable adhesive that sets within the anchor's body, firmly anchoring the fixture in place. The key advantage of resin anchors lies in their ability to provide high load-bearing capacity even in challenging environments or when dealing with irregular surfaces.

Understanding Self-Drilling Screws

2. Strong Hold Tek screws provide a robust connection, ensuring that cladding materials remain securely fastened. Their design allows them to create strong threads in the substrate, which prevents loosening over time due to temperature fluctuations or structural movement.

What Are Hex Screws?

3. Insert the Butterfly Screws Locate the holes in the mounting bracket where the butterfly screws will be inserted. Thread the screws into the holes until they are flush with the surface of the bracket. In conclusion, wafer head self-drilling screws with a black finish are a versatile and practical choice for anyone looking for a strong and reliable fastening solution. Their unique design, high-quality materials, and corrosion-resistant coating make them a popular choice for both indoor and outdoor applications. So next time you have a project that requires secure and durable fastening, consider using wafer head self-drilling screws for a professional finish that will stand the test of time. In addition to their tamper-proof design, security tek screws are also known for their durability and strength. These screws are typically made from high-quality materials such as stainless steel or hardened steel, which makes them resistant to corrosion and damage. This durability ensures that security tek screws will hold up in even the most demanding environments, providing long-lasting security and protection.

1. Time Efficiency The self-drilling capability of tek screws saves significant time during installation. No pre-drilling means fewer tools and less manual labor.

Overall, stainless steel cross bracing is an essential component in modern construction, offering strength, durability, corrosion-resistance, aesthetics, and sustainability. Its ability to provide stability and support in buildings and bridges, combined with its low-maintenance requirements and eco-friendly properties, make it a top choice for engineers, architects, and designers. One of the main advantages of using a 14 x 1 tek screw is its versatility. This size is suitable for a wide range of materials, including wood, metal, and plastic. Whether you are building a deck, installing drywall, or assembling furniture, a 14 x 1 tek screw is likely to be the perfect size for the job.

Understanding 3% and 4% Concrete Anchor Bolts An Overview

Another advantage of galvanized hex head bolts is their versatility

galvanised hex head bolts. They can be used in a wide range of applications, including attaching metal components, constructing scaffolding, and securing machinery and equipment. The versatility of these bolts means that they can be used in both indoor and outdoor settings, making them a popular choice among contractors and DIY enthusiasts alike. These screws are designed with a unique thread pattern that allows them to drill their own holes as they are being driven into the material. This eliminates the need for pre-drilling, saving time and labor costs. Whether you're working with wood, metal, or plastic, self-drilling screws can handle the job with ease.

galvanised hex head bolts. They can be used in a wide range of applications, including attaching metal components, constructing scaffolding, and securing machinery and equipment. The versatility of these bolts means that they can be used in both indoor and outdoor settings, making them a popular choice among contractors and DIY enthusiasts alike. These screws are designed with a unique thread pattern that allows them to drill their own holes as they are being driven into the material. This eliminates the need for pre-drilling, saving time and labor costs. Whether you're working with wood, metal, or plastic, self-drilling screws can handle the job with ease. Another benefit is the ease of installation. Steel pipes can be prefabricated off-site, allowing for quicker assembly once they reach the construction site. This efficiency can significantly reduce project timelines, enabling faster completion of structures.

3. Infrastructure Projects Roadways, bridges, and tunnels often employ resin anchor bolts to secure fixtures and reinforcements that are critical for the integrity of these complex structures.

Furthermore, high tensile hex head bolts are resistant to corrosion and rust, increasing their longevity and performance. This is particularly important in industries where bolts are exposed to moisture, chemicals, and other corrosive agents. With high tensile hex head bolts, you can trust that your connections will remain strong and secure over time. Thread pitch, the distance between threads on the bolt, impacts the ease of assembly and the bolt's holding power In addition to their mechanical advantages, self-drilling lag screws offer practical benefits too

self drilling lag screws. They reduce the need for multiple tools, simplifying the installation process and minimizing the potential for user error. Their ease of use also makes them an attractive choice for DIY enthusiasts and professionals alike. When selecting a heavy hex head bolt, it is essential to consider factors such as the specific application requirements, load capacity, and material compatibility Self-drilling screws have a sharp point at the tip, designed to pierce through metal, wood, or plastic without requiring pre-drilled holes. This feature significantly reduces installation time and effort, thereby increasing efficiency on the job site. The thread of these screws is specifically designed to cut into the substrate, providing a strong and secure hold. They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects

self drilling lag screws. They reduce the need for multiple tools, simplifying the installation process and minimizing the potential for user error. Their ease of use also makes them an attractive choice for DIY enthusiasts and professionals alike. When selecting a heavy hex head bolt, it is essential to consider factors such as the specific application requirements, load capacity, and material compatibility Self-drilling screws have a sharp point at the tip, designed to pierce through metal, wood, or plastic without requiring pre-drilled holes. This feature significantly reduces installation time and effort, thereby increasing efficiency on the job site. The thread of these screws is specifically designed to cut into the substrate, providing a strong and secure hold. They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects

They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects They are particularly useful in situations where speed and convenience are paramount, such as in the assembly of furniture, automotive parts, or even in home renovation projects nylon head self drilling screws. Nylon Self-Tapping Screws A Versatile and Efficient Solution Despite their robustness, Flange Head Self-Drilling Screws should be used with caution. The thickness of the material and the size of the screw must be carefully matched to ensure optimal performance and prevent potential damage. Additionally, proper torque control is necessary to avoid over-tightening, which could lead to stripped threads or damaged components. However, it's essential to note that while these anchors offer convenience, they may not be suitable for every situation. Heavyweight items or installations in load-bearing walls might require more robust anchoring solutions. Always refer to the manufacturer's guidelines for weight capacity and appropriate usage. In conclusion, stainless steel self-tapping screws for plastic have revolutionized the way we approach fastening in various industries. Their unique combination of strength, corrosion resistance, and adaptability makes them an indispensable tool for engineers and technicians alike. As technology advances and new materials emerge, the role of stainless steel self-tapping screws in plastic applications will only continue to grow, solidifying their position as a go-to solution in modern manufacturing. When using hex head self-drilling screws, it is important to choose the right size and type for the job at hand. Using the wrong screw can result in a weak or insecure connection, leading to potential safety hazards or structural issues. It is also essential to ensure that the screws are driven in straight and at the correct angle to avoid stripping the material or damaging the screw. Another advantage of security tek screws is their versatility. These screws come in a variety of sizes and styles, making them suitable for a wide range of applications

nylon head self drilling screws. Nylon Self-Tapping Screws A Versatile and Efficient Solution Despite their robustness, Flange Head Self-Drilling Screws should be used with caution. The thickness of the material and the size of the screw must be carefully matched to ensure optimal performance and prevent potential damage. Additionally, proper torque control is necessary to avoid over-tightening, which could lead to stripped threads or damaged components. However, it's essential to note that while these anchors offer convenience, they may not be suitable for every situation. Heavyweight items or installations in load-bearing walls might require more robust anchoring solutions. Always refer to the manufacturer's guidelines for weight capacity and appropriate usage. In conclusion, stainless steel self-tapping screws for plastic have revolutionized the way we approach fastening in various industries. Their unique combination of strength, corrosion resistance, and adaptability makes them an indispensable tool for engineers and technicians alike. As technology advances and new materials emerge, the role of stainless steel self-tapping screws in plastic applications will only continue to grow, solidifying their position as a go-to solution in modern manufacturing. When using hex head self-drilling screws, it is important to choose the right size and type for the job at hand. Using the wrong screw can result in a weak or insecure connection, leading to potential safety hazards or structural issues. It is also essential to ensure that the screws are driven in straight and at the correct angle to avoid stripping the material or damaging the screw. Another advantage of security tek screws is their versatility. These screws come in a variety of sizes and styles, making them suitable for a wide range of applications

security tek screws. Whether you need to secure a critical infrastructure or protect valuable assets, security tek screws can provide the strength and reliability you need. Expansion anchor plastics are designed to provide a robust hold in a wide range of materials, including concrete, brick, and stone. They operate on the principle of expansion, which allows them to securely anchor into the substrate by expanding when a screw is tightened into them. This expansion creates a strong frictional force that resists pull-out and shear loads, ensuring the anchored object remains steadfast. Self-drilling screws for UPVC, or unplasticized polyvinyl chloride, have revolutionized the construction and manufacturing industries due to their exceptional performance and efficiency. These specialized screws are designed specifically for use with UPVC materials, which are widely used in windows, doors, and other construction applications. It's crucial to note that while this article provides a general overview, specific project requirements may necessitate deviations from these standard practices. Therefore, it's always best to consult engineering guidelines and work closely with professionals to determine the most suitable shear stud sizes for a given construction project. Moreover, the durability of neoprene washers, coupled with the robustness of hex head screws, extends the lifespan of the joint, reducing maintenance costs and downtime. Their compatibility with a wide range of materials, from metal to plastic, further expands their usability across diverse sectors. Moreover, nuts and bolts offer an advantage over (welding) due to their removable nature. This allows for easy assembly and disassembly, facilitating maintenance and repairs. They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors construction nuts and bolts. 3. Failure to Set Sometimes, resin anchors may fail to set properly, resulting in a weak bond or no bond at all. This can be caused by using too much or too little adhesive, not mixing the components correctly, or using an incompatible adhesive. In conclusion, resin anchors are an effective solution for securing blockwork to a variety of substrates. By choosing the right type of anchor and following the installation instructions carefully, you can ensure a strong and durable bond that will withstand the test of time.

construction nuts and bolts. 3. Failure to Set Sometimes, resin anchors may fail to set properly, resulting in a weak bond or no bond at all. This can be caused by using too much or too little adhesive, not mixing the components correctly, or using an incompatible adhesive. In conclusion, resin anchors are an effective solution for securing blockwork to a variety of substrates. By choosing the right type of anchor and following the installation instructions carefully, you can ensure a strong and durable bond that will withstand the test of time. - Decking These screws are perfect for decking projects, where strength and durability are essential. Their ability to withstand elements makes them ideal for outdoor structures that face moisture and temperature fluctuations.

In conclusion, the Metal Butterfly Screw is more than just a functional component; it is a symbol of the fusion between engineering and artistry. It represents the human desire to create objects that not only serve a purpose but also evoke emotions and admiration. As technology continues to evolve, it is fascinating to see how a simple piece like the butterfly screw can evolve, maintaining its charm and functionality while embracing new materials and designs. So the next time you come across one, take a moment to appreciate the intricate balance of form and function that makes the Metal Butterfly Screw a true engineering delight.

When considering a fastening solution for your next project, be sure to explore the benefits of stainless steel hex head self-tapping screws. With their durability, corrosion resistance, and ease of installation, these screws are sure to provide a secure and long-lasting hold for all of your fastening needs.

The installation of resin anchors involves several steps to guarantee optimal performance. First, a suitable hole is drilled into the concrete using a hammer drill. The diameter and depth of the hole must correspond to the specifications of the resin anchor. After cleaning the hole of dust and debris, the two-part resin is mixed and injected into the hole. The anchor rod is then inserted before the resin starts curing, ensuring a strong bond as the resin hardens.

Overall, self screw black is a game-changer in the world of home improvement and DIY projects. Their ease of use, versatility, and durability make them a popular choice for anyone looking to add a modern touch to their projects. Whether you are a seasoned DIY enthusiast or just starting out, self screw black is a must-have tool for your toolkit.