Links:

-

Another significant benefit of igu window glass is its impact on natural light penetration The term 'low' might refer to the subdued nature of the light that passes through this type of glass, casting a gentle glow rather than harsh, direct rays

Grey Float Glass A Timeless Beauty I couldn't help but think about the history of this mirror, wondering where it had come from and who had owned it before me. Had it hung in a grand ballroom, reflecting the laughter and romance of a bygone era? Or had it been tucked away in a dusty attic, waiting to be discovered and appreciated once again? OEM Tempered Glass The Ultimate Protection for Your Devices In conclusion, toughened float glass is a versatile and practical material that is used in a variety of industries due to its superior strength and durability. Whether it's used in buildings, vehicles, or furniture, toughened glass provides a cost-effective solution that prioritizes safety and longevity. Its unique properties make it a valuable option for any application that requires a strong and reliable glass material. Overall, low e glass double glazing offers a wide range of advantages for modern buildings, including energy efficiency, improved insulation, soundproofing, UV protection, and enhanced safety and security. With its numerous benefits and aesthetic appeal, it is no wonder that this type of glass is becoming increasingly popular in the construction industry. Whether for residential, commercial, or industrial applications, low e glass double glazing is a smart choice for any building looking to improve its energy efficiency and overall performance.

Grey Float Glass A Timeless Beauty I couldn't help but think about the history of this mirror, wondering where it had come from and who had owned it before me. Had it hung in a grand ballroom, reflecting the laughter and romance of a bygone era? Or had it been tucked away in a dusty attic, waiting to be discovered and appreciated once again? OEM Tempered Glass The Ultimate Protection for Your Devices In conclusion, toughened float glass is a versatile and practical material that is used in a variety of industries due to its superior strength and durability. Whether it's used in buildings, vehicles, or furniture, toughened glass provides a cost-effective solution that prioritizes safety and longevity. Its unique properties make it a valuable option for any application that requires a strong and reliable glass material. Overall, low e glass double glazing offers a wide range of advantages for modern buildings, including energy efficiency, improved insulation, soundproofing, UV protection, and enhanced safety and security. With its numerous benefits and aesthetic appeal, it is no wonder that this type of glass is becoming increasingly popular in the construction industry. Whether for residential, commercial, or industrial applications, low e glass double glazing is a smart choice for any building looking to improve its energy efficiency and overall performance. Photovoltaic glass is a kind of packaging material used in photovoltaic modules, usually used as the cover glass of photovoltaic modules, the cover plate of double-glass components, the backplane glass and the substrate glass of thin film components are widely used, and its role is mainly to protect the battery from moisture and gas oxidation and corrosion electrodes, and extend the service life.

The 8mm frosted glass is favored for its versatility and moderate thickness, which provides a good combination of stability and a subtle, diffused look that can transform ordinary windows into pieces of art. This particular thickness is ideal for areas requiring a certain level of privacy without sacrificing natural light. Office conference rooms, bathroom enclosures, and partition walls frequently use this type of glass to maintain an open feel while ensuring discretion. The Low E Glass Revolution Factors Affecting the Price of 5mm Frosted Glass However, the production and use of thin mirror glass are not without challenges. Ensuring consistent quality during manufacturing requires exacting standards and rigorous quality control measures. Furthermore, the reflective nature of this material can sometimes pose issues related to glare and light pollution, necessitating careful consideration in its application.When considering decorative glass for a project, the choice of supplier is paramount. A reputable decorative glass supplier should offer a wide range of products, from standard designs to custom solutions. They should also be knowledgeable about the latest trends, materials, and techniques in the industry.

Slumping is a technique employed to reshape existing glass into a new form. It involves heating a flat sheet of glass to a temperature that softens it without melting it completely. This temperature typically ranges between 1,200°F to 1,500°F (about 650°C to 800°C). Once the glass reaches this pliable state, it is placed over or into a mold. As it cools, the glass adopts the shape of the mold, creating a variety of forms, from simple bowls to complex sculptures.

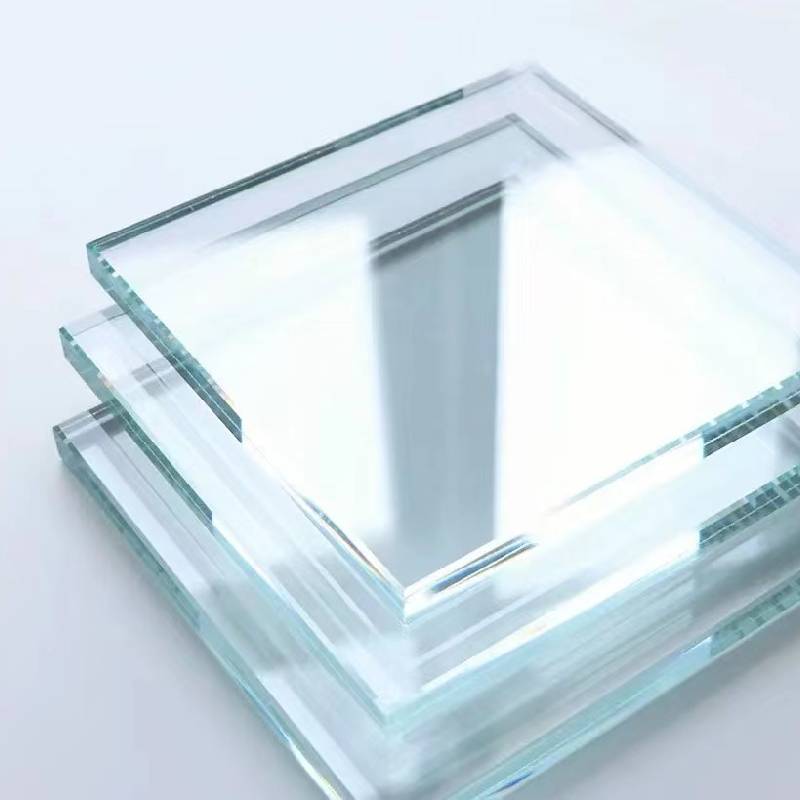

Overall, clear float glass is a versatile and cost-effective option for a wide range of applications. Its high optical clarity, durability, and versatility make it a popular choice for architects, designers, and homeowners alike. Whether you are looking to install new windows, create a custom glass display, or add a touch of elegance to your home or business, clear float glass is a reliable and stylish choice. The large silver Victorian mirror stood proudly in the corner of the grand living room, reflecting the opulence and elegance of its surroundings. The intricate embellishments of the mirror frame added a touch of old-world charm to the modern décor of the room, making it a focal point for anyone who entered. In conclusion, decorative glass is not just a functional element but a design statement in itself. Each type brings its unique charm and purpose, allowing architects and designers to craft visually stunning spaces that cater to both aesthetics and functionality. Whether it's the timeless appeal of stained glass or the contemporary allure of dichroic glass, the world of decorative glass is a rich tapestry of creativity and innovation. Aluminum mirror sheet is a highly reflective material that has found widespread applications in various fields due to its unique properties. This versatile material is not only corrosion-resistant but also lightweight and easy to process, making it an ideal choice for a wide range of applications.

Before delving into the slumping process, it's essential to understand what float glass is. Float glass is produced by pouring molten glass onto a bed of molten tin. This method results in a smooth, flat surface and uniform thickness, making it ideal for various applications, from windows to mirrors and decorative items. Its clarity and optical properties position float glass as a preferred choice in both commercial and residential settings.

Low Iron Float Glass A Comprehensive Guide In the domain of interior design, materials often carry an ethereal weight, shaping spaces not just with their physical presence but also with the intangible essence they exude. Among such materials, black frosted glass stands out as a mysterious veil, draping rooms in an allure that is both subtle and profound. Its surface, etched with a delicate pattern that scatters light into a soft, diffuse glow, embodies a paradox of transparency and opacity. This unique characteristic allows it to simultaneously reveal and conceal, creating layers of visual intrigue. Automatic frosted glass, also known as switchable glass or smart glass, utilizes a special film or coating that can change from transparent to translucent with the flip of a switch. This revolutionary technology allows for instant privacy and can be controlled remotely, making it ideal for a variety of applications. Moreover, these tinted surfaces invite us to reconsider our relationship with transparency and opacity. They offer a glimpse into another realm, blurring the boundaries between the interior and the exterior, yet they maintain a veil of mystery, prompting the viewer to question what lies beyond. It is this dual nature that makes them such compelling elements in both practical and philosophical discussions about design. Supply and demand dynamics within the market can also influence pricing

The Louis leaner mirror derives its name from the ornate style popularized during the reign of King Louis XIV of France, known as the Baroque period. This era was characterized by grandeur and opulence, and these values are evident in the mirror's intricate carvings that adorn its frame. Each curve and flourish is a testament to the skill of the artisans who painstakingly create each piece, imbuing it with a sense of timeless elegance.

The Louis leaner mirror derives its name from the ornate style popularized during the reign of King Louis XIV of France, known as the Baroque period. This era was characterized by grandeur and opulence, and these values are evident in the mirror's intricate carvings that adorn its frame. Each curve and flourish is a testament to the skill of the artisans who painstakingly create each piece, imbuing it with a sense of timeless elegance. Ultra clear glass, often referred to as low iron glass, has become increasingly popular in various industries due to its remarkable transparency and aesthetic appeal. This type of glass is produced with a modified composition that significantly reduces the iron content typically found in standard glass. As a result, it showcases a higher level of clarity, allowing for maximum light transmission and minimal distortion. In this article, we will delve into the characteristics, manufacturing process, benefits, and applications of ultra clear glass.

Furthermore, building codes and standards are evolving, with many regions encouraging or even mandating the use of energy-efficient materials. By integrating low-E glass into new constructions or retrofitting existing buildings, property owners not only comply with regulations but also enhance their property’s market value.

Soft Coat Low-E glass, on the other hand, is produced by applying a thin layer of silver sandwiched between two layers of metal oxide coatings on a cool glass surface. This process results in a higher energy efficiency, as it has a lower U-factor (a measure of heat loss) compared to hard coat. However, it's more delicate and requires protection from moisture and abrasion, typically used in double or triple glazed units.

Conclusion

As an art form, cut frosted glass continues to evolve and adapt to the changing tastes and needs of contemporary society. With its timeless beauty and versatility, it is sure to remain a popular choice for generations to come. Reflective Blue Glass A Unique Perspective In the realm of interior design, the subtle yet significant influence of glass and mirrors cut to size cannot be overstated. These seemingly simple elements carry with them an uncanny ability to transform spaces, imbuing them with light, depth, and a reflective quality that can make even the most mundane room feel magical. The Enchanting Wave Pattern Glass A Symphony of Colors and Light Fully tempered glass is commonly used in a variety of applications, including windows, doors, shower enclosures, and table tops

fully tempered glass. Its strength and safety features make it an ideal choice for these applications, providing both protection and aesthetic appeal. Fully tempered glass is also used in the automotive industry for windshields and side windows, as well as in commercial buildings for exterior facades and interior partitions. In conclusion, low iron tempered glass combines form and function, offering both superior clarity and robust durability. It is a material that caters to the demand for visual purity and safety in contemporary design. As technology continues to advance, the application of such glass will undoubtedly continue to expand, bringing a touch of elegance to our built environments while ensuring they are protected and energy efficient. Low-E Glass The Ultimate Window Solution for Energy Efficiency

In addition to its practicality, float glass also offers aesthetic advantages. Its clean, modern look complements various architectural styles, from minimalist designs to more intricate constructions. Furthermore, the ability to create large expanses of glass enhances the connection between indoor and outdoor environments, blurring the lines and creating a more inviting atmosphere. The seamless integration of float glass in design encourages more vibrant and dynamic spaces, attracting homeowners and designers aimed at creating inviting environments.

In addition to improved thermal performance, low-E glass also offers superior UV protection. The same coating that reflects infrared radiation also blocks a significant amount of ultraviolet (UV) rays from the sun. This feature is crucial for protecting furniture, carpets, and artwork from fading and damage caused by prolonged exposure to sunlight. By using low-E glass, homeowners and business owners can preserve the aesthetics and longevity of their interiors.

low emissivity glass

Once the glass has been tempered, it undergoes a series of rigorous quality control checks to ensure that it meets the highest standards of safety and performance. This includes visual inspections, optical testing, and strength assessments, all of which are performed by skilled technicians using advanced equipment. From a design perspective, brown frosted glass also offers a great deal of flexibility. It can be used in combination with other materials, such as wood or metal, to create a custom look that suits the style of the space. Whether used as a standalone feature or as part of a larger design scheme, brown frosted glass is a versatile and adaptable material that can be tailored to fit any aesthetic. Collectors and historians alike would gather around the booth, each hoping to possess this relic of a bygone era. To them, the bronze mirror represented not merely an object of vanity but a conduit through which they could connect with the past, a tangible link to the lives lived and loves lost throughout the centuries.

Improved Comfort and Aesthetics

Despite the challenges posed by global competition and fluctuating raw material prices, the patterned glass manufacturing sector continues to thrive. The increasing demand for unique architectural features and the resurgence of Art Deco and vintage styles have fueled the growth of this niche market.

In contemporary life, most of us rely on glass more than we think: glass is not only used in our windshields and Windows, but also in the optical cables beneath our feet, which are of great significance. Now we look at each other through a glass screen, Mauro said in an interview. It made me acutely aware of the fragility of our connection. We spoke via Zoom, a remote online video conferencing software. Mauro continued: Without glass, we would not have tablets, mobile phones, a range of information terminals. All of this is transmitted by light signals using ultra-fine glass wires that we call fiber optics. Without glass, he says, we wouldn't be able to appreciate modern architecture, artificial light, natural light, cars, and most importantly, such a wealth of information.

02

In the realm of interior design, where aesthetics and practicality intertwine, the modern aluminum alloy thin framed full-length mirror has emerged as a standout feature. This innovative piece not only serves its primary function of reflecting one's image but also adds a touch of sophistication and minimalism to any space. In addition to the heat treatment process and raw material quality, other factors that can affect the quality of tempered glass include the production equipment, process control, and quality inspection. Advanced production equipment and precise process control are necessary to ensure consistent quality and performance of tempered glass. Moreover, regular quality inspections throughout the production process are crucial to identify and address any potential issues promptly, thus maintaining the desired quality standards.Decorative glass panels for walls can add a touch of elegance and beauty to any space. Whether you are looking to add a unique design element to your home or office, decorative glass panels are a versatile option that can enhance the overall aesthetic of a room.

Low-E Glass Panels Revolutionizing Energy Efficiency in Buildings