Links:

Future Trends in Aluminium Foil Roofing Solutions

Apex Metal Roofing stands out in its commitment to sustainability. Metal roofing is typically made from recycled materials and is 100% recyclable at the end of its life cycle. By choosing metal roofing, homeowners contribute to a reduction in landfill waste and the preservation of natural resources. This eco-friendliness aligns with the growing trend of sustainable living and construction practices, appealing to environmentally-conscious consumers.

Tin food cans have been a popular choice for packaging due to their durability and resistance to corrosion. Made primarily from tinplate, these cans offer an airtight seal, which is crucial for maintaining the quality of stored food. Unlike other packaging materials, tin cans can easily withstand physical impacts, making them perfect for shipping and handling. As a result, manufacturers are increasingly investing in advanced technology to enhance the production process of tin cans, ensuring that they meet the growing demands of the food industry.

In de afgelopen jaren heeft de vraag naar duurzame bouwmaterialen in Seattle een aanzienlijke toename gekend. Een van de meest opmerkelijke trends op dit gebied is het gebruik van metaaldaken, met name die afkomstig uit China. Deze daken zijn niet alleen esthetisch aantrekkelijk, maar bieden ook tal van voordelen op het gebied van duurzaamheid en energie-efficiëntie.

While the initial investment for China Meridian metal roofing may be higher than that of traditional roofing materials, its cost-effectiveness becomes apparent over time. Thanks to its durability, energy efficiency, and minimal maintenance requirements, metal roofing can lead to significant savings in replacement and utility costs in the long run. The value added to the property can also increase, making it a savvy investment for homeowners.

Durability is another significant benefit. Made from materials like steel, aluminum, and copper, metal roofing can withstand extreme weather conditions, including high winds, hail, and heavy snowfall. Many manufacturers offer coatings that provide additional resistance to rust and corrosion, ensuring that the roof remains functional and attractive for decades. Moreover, metal roofs have a lifespan that can exceed 50 years with proper maintenance, making them a cost-effective choice over time.

- Local Manufacturers Don’t overlook local manufacturers who may provide competitive pricing and the advantage of lower shipping costs.

3. Finishing Touches After galvanization, the frames may undergo additional processes such as painting or powder coating. This not only enhances aesthetic appeal but also provides an extra layer of protection against environmental elements.

While Lubbock offers a range of local suppliers, businesses may also explore online options that could provide a broader selection of products and potentially more competitive pricing. However, working with local suppliers has its perks, including face-to-face interaction, easier logistics for shipping, and supporting the local economy.

Economic Impact

Before diving into the advantages of choosing a galvanized corrugated iron supplier, it's essential to comprehend what galvanization entails. Galvanization is the process of coating iron or steel with a layer of zinc to protect it from rusting and corrosion. This protective layer allows galvanized iron to withstand outdoor elements, making it ideal for roofing, siding, and various other applications. The corrugated design adds to its strength, providing a lightweight yet sturdy material that can handle significant stress.

Choosing the Right Slip Sheet

The next phase involves cutting the galvanized wire to specific lengths, which may vary depending on customer requirements. Quality assurance is extremely important during this stage, as even minor defects can disqualify the product from meeting industry standards. Many factories utilize automated systems to inspect the wire for uniformity, adhesion of the zinc coating, and mechanical properties.

3. Local Building Codes Before making a purchase, it's essential to confirm that the chosen materials comply with local building codes and regulations to ensure safety and performance standards are met.

1. Reputation Look for suppliers with a proven track record. Reviews and testimonials from past clients can provide insights into the quality of the products and the service offered.

In conclusion, metal cash boxes play a vital role in enhancing security and efficiency for various users. As the market for these products continues to evolve, manufacturers are likely to innovate and expand their offerings to meet the changing needs of consumers. With a focus on durability, security, and customization, metal cash box manufacturers are well-positioned to thrive in the foreseeable future, meeting the demands of a cash-dependent world.

Lenox is a well-established name in the dinnerware and tableware industry, known for its high-quality materials and exquisite designs. Founded in 1889 in New Jersey, the brand has a long-standing tradition of craftsmanship and attention to detail. Lenox products often feature intricate patterns and are made from fine china, offering both beauty and practicality. The brand has evolved over the years, introducing innovative designs such as the tin can dessert plate, which combines modern aesthetics with traditional craftsmanship.

Galvanized steel pipes are manufactured by coating steel pipes with a layer of zinc, a process known as galvanization. This protective zinc coating helps prevent rust and corrosion, significantly enhancing the pipe's lifespan. As a result, galvanized steel pipes are widely used in various applications, including water supply lines, irrigation systems, and even in residential homes for plumbing.

In conclusion, printed tinplate sheets are essential components in the canned food manufacturing process. Their durability, aesthetic appeal, sustainability, and ability to provide crucial information make them an ideal choice for food packaging. As the industry continues to evolve, printed tinplate sheets will likely play an increasingly prominent role in meeting consumer demands and promoting brand loyalty. Ultimately, investing in high-quality printed tinplate packaging can lead to significant benefits for both manufacturers and consumers alike.

In agricultural settings, galvanized pipes are often utilized in irrigation systems and animal fencing. Their corrosion resistance is especially beneficial in environments where they might be exposed to chemicals and varying weather conditions. Furthermore, in industrial settings, galvanized black iron pipes are used in the transportation of various fluids, making them essential components in manufacturing and processing plants.

1. Metal Sales Manufacturing Corporation Known for its commitment to quality and sustainability, Metal Sales offers a wide range of metal roofing products that are not only environmentally friendly but also customizable to fit various aesthetic preferences. Their panels are made from recycled materials and are designed to be energy efficient.

green metal roofing panels manufacturers

Moreover, high-quality base sheets can improve the energy efficiency of a building. Some manufacturers offer base sheets with reflective or insulating properties, which can help regulate indoor temperatures and reduce energy costs over time. This is particularly valuable in regions with extreme climates, where energy savings can significantly impact overall operating costs.

roof base sheet manufacturer

Conclusie

Once the materials are prepared, they undergo a meticulous extrusion process where they are shaped into sheets of various thicknesses and sizes. Cutting-edge machinery allows for precise measurements, ensuring that the slip sheets are custom-fit for different roofing applications. After shaping, the sheets are subjected to rigorous quality control tests, checking for durability, flexibility, and the ability to withstand environmental stresses.

metal roof slip sheet factory

The raw materials used in the production of roof sheet fixings are critical for their performance and durability. Commonly used materials include stainless steel, carbon steel, and galvanized steel, all of which provide resistance to corrosion and wear. Once the materials are selected, they undergo a detailed process that usually begins with cutting and shaping. Factories utilize a variety of machines, such as lathes, presses, and CNC (Computer Numerical Control) machines, to create precisely engineered fixings that meet the stringent demands of the roofing industry.

As time progresses, the value of Chinese vintage metal lunch boxes has surged in the collectibles market. Collectors are drawn to their aesthetic appeal, historical significance, and the stories each one carries. Auctions for rare pieces often see fierce bidding, as enthusiasts and collectors vie for ownership of these charming relics. The rarity and condition of the lunch boxes heavily influence their market value, making it a thrilling pursuit for those interested in hunting down the perfect piece.

La popularidad de las cajas de metal vintage se ha visto impulsada por su presencia en las redes sociales, donde decoradores y entusiastas del estilo retro comparten ideas de uso creativo. Este tipo de publicidad boca a boca y la influencia de los medios digitales están contribuyendo al crecimiento de este nicho de mercado. Cada vez más personas buscan incorporar elementos vintage en sus espacios, y las cajas de metal ofrecen una manera accesible y atractiva de hacerlo.

- HVAC Systems Its ability to allow airflow makes it ideal for ductwork and other heating, ventilation, and air conditioning applications.

The Rise of Sheet Metal Roof Covering Factories Innovation in Construction

In the construction industry, roofing plays a pivotal role in a building's structural integrity, aesthetic appeal, and energy efficiency. Among various roofing materials, corrugated metal roofing has gained immense popularity due to its durability, lightweight nature, and cost-effectiveness. This article delves into the world of corrugated metal roofing, with a particular focus on the factories that manufacture this essential product.

Металл батарея ящиклари яратиш жараёнида замонавий технологиялардан фойдаланиш, ишлаб чиқариш самарадорлигини ошириш ва маҳсулот сифатига ката таъсир қилиши мумкин. Монтаж ва ҳимоя параметрларини тайёрлашда моддийларнинг сифати, инсон саломатлигини муҳофаза қилиш усуллари ҳамда атроф-муҳитга зiyon келтирмаслик принциплари жуда муҳимдир. Бу жиҳатлар эса маҳсулотнинг бозордаги ўрнини белгилаб беради.

metal battery boxes manufacturer

Manufacturers of galvanized iron pipes invest in advanced technology and quality control systems to ensure that their products meet the rigorous standards demanded by the construction and plumbing industries. The process of manufacturing these pipes involves several steps raw material selection, heating and stretching, galvanization, quality testing, and ultimately, distribution.

Díky své kvalitě a jedinečnému designu se plechové boxy John Deere udržují v oblibě nejen u starších generací, ale i u mladších sběratelů, kteří hledají něco originálního. Tímto způsobem symbolizují spojení mezi minulostí a současností, kdy se staré tradice setkávají s moderními potřebami. John Deere tak i nadále prokazuje, že je mnohem více než jen výrobcem zemědělských strojů – stal se symbolem trvalé hodnoty, kvality a tradice v zemědělství.

2. Product Range A diverse product range allows for greater flexibility. Consider manufacturers that offer various types of base sheets to match specific project needs and requirements.

In the ever-evolving world of packaging and food preservation, baret ware tin plates have emerged as a crucial player. These versatile, durable, and often aesthetically pleasing tin plates are not only essential for food storage but also hold significance in the culinary presentation. As such, the manufacturers of baret ware tin plates play a vital role in ensuring quality, sustainability, and innovation.

As consumers become more environmentally conscious, the demand for sustainable packaging solutions increases. Tin is a recyclable material, and many wholesale tin box manufacturers emphasize sustainability in their production processes. By choosing tin packaging, businesses can not only enhance their brand image but also appeal to eco-minded consumers.

1. Material Quality The type of material used in cooling sheets significantly impacts their price. Higher quality materials tend to be more expensive but usually offer better durability and efficiency. For instance, sheets with advanced reflective technology may cost more upfront but can save homeowners money in the long run due to reduced energy consumption.

In conclusion, the thickness of galvanized iron sheets plays a crucial role in determining their performance, durability, and application suitability. When selecting galvanized iron sheets, it is vital to consider both the sheet and zinc coating thicknesses and choose reputable manufacturers that guarantee quality products. Whether for construction, manufacturing, or decorative purposes, understanding the importance of thickness can lead to better choices and enhanced project outcomes.

The manufacturing process at a galvanized corrugated iron factory involves several critical steps

Hollow Roof Sheet Suppliers Klíčoví hráči v oboru konstrukčních materiálů

Energy efficiency is a significant concern for many when selecting roofing materials, especially in regions that experience extreme temperatures. 26 gauge sheet metal roofing reflects a considerable amount of solar energy, reducing heat absorption. This reflective property can help keep homes cooler in the summer, leading to lower air conditioning costs. Additionally, many manufacturers offer energy-efficient coatings that further enhance the insulation properties of metal roofing, making it a perfect choice for eco-conscious homeowners seeking to reduce their carbon footprint.

The Importance of Perforated Galvanized Angle Iron in Modern Manufacturing

One of the factory's most popular items is the Batty Lunch Buddy, a lunchbox that showcases a cheerful bat character, complete with glittering wings and an adorable smile. This design has captivated the hearts of children, encouraging them to embrace healthier eating habits by packing nutritious meals. Alongside these playful designs, the factory also creates sophisticated options for adults, recognizing the need for stylish and functional containers in the workplace or during travel.

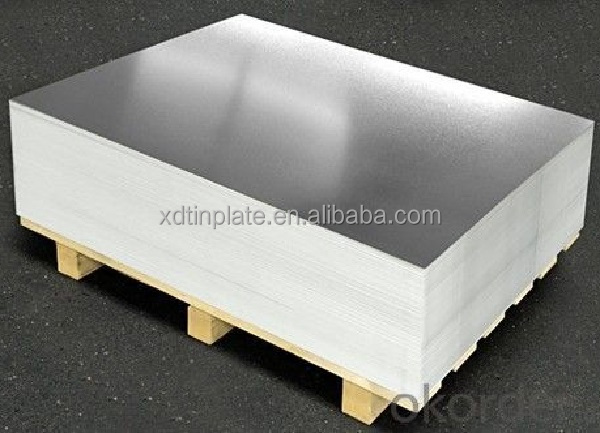

Tin plate sheet metal manufacturers play a crucial role in ensuring the availability and quality of this vital material. These manufacturers are responsible for various stages of production, from sourcing raw materials to processing and distribution. They utilize advanced technologies and methodologies, such as cold rolling and annealing, to produce high-quality sheets that meet the stringent demands of different industries.

Galvanization is a crucial step in the production of galvanized iron tubes. The process typically involves cleaning the iron surface to remove any impurities, followed by dipping the iron in molten zinc. This zinc coating forms a protective barrier that prevents oxidation and rust, which can diminish the mechanical properties of the metal over time. The effectiveness of this process is particularly evident in harsh environments where unprotected metals would corrode quickly.

2. Variety of Options Different projects have different requirements; a good supplier will offer a wide range of products to meet diverse needs. This includes various thicknesses, colors, finishes, and UV protection levels. Having options allows you to choose the right fit for your specific application and aesthetic preferences.

plastic roof sheet supplier

Lightweight and Easy to Install

buy chrome plated plastic name plate

Galvanized ductile iron fittings are components used in piping systems, derived from ductile iron—an alloy known for its exceptional strength and flexibility. The term galvanized refers to the process of applying a protective zinc coating to inhibit corrosion. This combination yields fittings that are not only robust but also resistant to rust and deterioration, making them ideal for a wide range of applications, including plumbing, drainage, and heating systems.

Nestled in the heart of a bustling city, The Tin Plate Café stands out not only for its cozy ambiance but also for its commitment to delivering exceptional food and beverages. As a supplier of culinary delights, this café has become a beloved spot for locals and visitors alike, known for its unique offerings and dedication to quality ingredients.

In the world of culinary arts, spices play an indispensable role in enhancing flavors and elevating dishes to new heights. As the global demand for spices continues to rise, the packaging industry has evolved to meet this need, with spice tin box factories emerging as vital players in this domain. This article explores the significance of spice tin box factories, their manufacturing processes, and the broader impact they have on both consumers and the environment.