Current location:

Links:

-

Benefits of Using the 6310 RS Bearing

Spherical roller bearings and cylindrical roller bearings are both important types of rolling-element bearings, each with distinct design features and applications. Here are the key differences between the two:

One of the key benefits of the NJ 308 bearing is its high load-carrying capacity. Due to its design, this type of bearing can handle both radial and axial loads without compromising performance. This makes it an ideal choice for heavy-duty applications where reliable operation is crucial. The low maintenance requirements of deep groove ball bearings are another key selling point. They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary

They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary They are designed to operate smoothly with minimal wear, and their simple structure means that they are easy to inspect and replace if necessary deep ball groove bearing. This reduces downtime and maintenance costs, making them a cost-effective solution for many industries. The 607ZZ bearing is a high-performance, reliable solution for a variety of applications. Its precision design, double-shielded construction, and excellent quality materials make it a popular choice among engineers and manufacturers. Whether you need a bearing for a small motor or a large industrial system, the 607ZZ bearing is sure to meet your requirements and provide long-lasting performance. 62211 bearing dimensions refer to the specific measurements of a type of bearing that is commonly used in various machinery and equipment. A bearing is a crucial component in most mechanical systems as it helps reduce friction between moving parts, thus enabling smooth and efficient operation. In conclusion, four-row tapered roller bearings are specialized components designed to handle demanding conditions and significant loads. Their unique structure provides superior load distribution and misalignment accommodation, making them ideal for use in heavy machinery and industrial applications. While they require careful installation and maintenance, their benefits in terms of performance and durability are well worth the effort. Conclusion The Enigma of 6207 2rsr A Comprehensive Analysis

deep ball groove bearing. This reduces downtime and maintenance costs, making them a cost-effective solution for many industries. The 607ZZ bearing is a high-performance, reliable solution for a variety of applications. Its precision design, double-shielded construction, and excellent quality materials make it a popular choice among engineers and manufacturers. Whether you need a bearing for a small motor or a large industrial system, the 607ZZ bearing is sure to meet your requirements and provide long-lasting performance. 62211 bearing dimensions refer to the specific measurements of a type of bearing that is commonly used in various machinery and equipment. A bearing is a crucial component in most mechanical systems as it helps reduce friction between moving parts, thus enabling smooth and efficient operation. In conclusion, four-row tapered roller bearings are specialized components designed to handle demanding conditions and significant loads. Their unique structure provides superior load distribution and misalignment accommodation, making them ideal for use in heavy machinery and industrial applications. While they require careful installation and maintenance, their benefits in terms of performance and durability are well worth the effort. Conclusion The Enigma of 6207 2rsr A Comprehensive Analysis The 6206 Z bearing's design, with its deep groove raceways, allows for a larger load capacity while maintaining a smaller cross-section. The shield also helps reduce friction, thus contributing to energy efficiency. Regular maintenance, including proper lubrication and cleaning, can significantly enhance the bearing's performance and service life. The 6909 bearing is a precision component that plays a crucial role in maintaining the smooth operation of machinery. These bearings are designed to withstand high speeds, heavy loads, and harsh operating conditions, making them an ideal choice for a wide range of industrial applications. Deep groove ball bearings are a type of rolling element bearing that have been pivotal in the advancement of machinery performance. These bearings, characterized by their deep and wide grooves in the inner ring, provide superior support and stability to rotating shafts. This design not only improves the overall operational efficiency of machines but also extends their service life. In the world of engineering and mechanics, the role of a bearing is paramount. It facilitates motion by reducing friction between moving parts, thus enhancing efficiency and longevity. Among various types of bearings, the L44610 model stands out as a testament to innovation and precision. This particular bearing, with its unique specifications and applications, has redefined the standards in modern mechanics. C = d - (D + d1) / 2 1. Machinery The bearing is commonly used in machines that require high speed and precision, such as lathes, grinders, and presses. At its core, the LM501349 is a quad operational amplifier, featuring four independent, high-gain amplifiers in a single package. Its design is optimized to cater to a wide range of applications, making it a go-to choice for engineers across various industries. With its ability to operate from a single 3V to 32V supply voltage, it extends usability beyond conventional limits, accommodating low-voltage systems effectively. One of the key advantages of deep groove ball bearings is their ability to operate smoothly under high-speed conditions. The design minimizes friction, allowing the shaft to rotate freely with minimal resistance. This makes them ideal for applications such as electric motors, gearboxes, and pumps, where smooth operation is critical.

6002 bearing size. For example, bearings with different ID and OD sizes may not fit properly into the machine's housing, leading to misalignment and increased wear. Therefore, it is important to ensure that the bearing's size is compatible with the rest of the machine's components. 5. Wide Range of Applications The versatility of the 33112 bearing allows it to be used in a wide range of industries, including automotive, aerospace, heavy machinery, and more. Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation

6002 bearing size. For example, bearings with different ID and OD sizes may not fit properly into the machine's housing, leading to misalignment and increased wear. Therefore, it is important to ensure that the bearing's size is compatible with the rest of the machine's components. 5. Wide Range of Applications The versatility of the 33112 bearing allows it to be used in a wide range of industries, including automotive, aerospace, heavy machinery, and more. Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation

Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation 33112 bearing. In the intricate world of machinery, where precision and efficiency reign supreme, the single roller bearing stands as a testament to engineering's quest for minimalism without compromising functionality. Unlike its cousin, the dual-row roller bearing, which boasts two rows of rollers for added load capacity, the single roller bearing embodies simplicity and is designed with just one row of cylindrical or spherical rollers encased within an inner and outer ring. In addition to their high load capacity and durability, NTN cylindrical roller bearings are also easy to install and maintain

33112 bearing. In the intricate world of machinery, where precision and efficiency reign supreme, the single roller bearing stands as a testament to engineering's quest for minimalism without compromising functionality. Unlike its cousin, the dual-row roller bearing, which boasts two rows of rollers for added load capacity, the single roller bearing embodies simplicity and is designed with just one row of cylindrical or spherical rollers encased within an inner and outer ring. In addition to their high load capacity and durability, NTN cylindrical roller bearings are also easy to install and maintain ntn cylindrical roller bearing catalogue. This makes them a cost-effective solution for many industrial applications, as they require minimal maintenance and have a long service life. Overall, the 626 RS bearing is an indispensable component in a wide variety of machinery and equipment. Its ability to reduce friction, support heavy loads, withstand high speeds, and provide precise motion control make it an essential part of many different applications. By choosing a high-quality 626 RS bearing, manufacturers can ensure that their equipment operates at peak performance and enjoys a long service life. The LM501349 bearing is a part of the linear ball bearing series, designed to provide exceptional support and motion control in linear motion systems. Its unique dimensions, with a width of 49mm and a specific design, cater to the needs of industries where precise movement and reduced friction are paramount. From robotics to aerospace, this bearing finds its application across a broad spectrum. Material Composition The LM11949 is a low-dropout (LDO) regulator, known for its ability to maintain a stable output voltage even when the input voltage is close to the output voltage. This feature makes it particularly useful in scenarios where power supply margins are tight or battery-powered devices require high efficiency. With a low dropout voltage and a wide input voltage range, the LM11949 ensures consistent performance under varying conditions, making it an ideal choice for demanding applications such as portable electronics, communication systems, and automotive electronics. Spherical Bearing Manufacturers Pioneers in Engineering Precision In addition to its load-bearing capabilities, the 30203 bearing is also known for its smooth operation and low friction. This is important in applications where efficiency and precision are key, as the smooth operation of the bearing can help to reduce wear and tear on other components of the machinery. The low friction design of the bearing also helps to minimize heat generation and energy loss, making it an efficient choice for many different applications. Furthermore, the 6207 2RS bearing requires minimal maintenance, thanks to its sealed design that keeps lubrication in and contaminants out

ntn cylindrical roller bearing catalogue. This makes them a cost-effective solution for many industrial applications, as they require minimal maintenance and have a long service life. Overall, the 626 RS bearing is an indispensable component in a wide variety of machinery and equipment. Its ability to reduce friction, support heavy loads, withstand high speeds, and provide precise motion control make it an essential part of many different applications. By choosing a high-quality 626 RS bearing, manufacturers can ensure that their equipment operates at peak performance and enjoys a long service life. The LM501349 bearing is a part of the linear ball bearing series, designed to provide exceptional support and motion control in linear motion systems. Its unique dimensions, with a width of 49mm and a specific design, cater to the needs of industries where precise movement and reduced friction are paramount. From robotics to aerospace, this bearing finds its application across a broad spectrum. Material Composition The LM11949 is a low-dropout (LDO) regulator, known for its ability to maintain a stable output voltage even when the input voltage is close to the output voltage. This feature makes it particularly useful in scenarios where power supply margins are tight or battery-powered devices require high efficiency. With a low dropout voltage and a wide input voltage range, the LM11949 ensures consistent performance under varying conditions, making it an ideal choice for demanding applications such as portable electronics, communication systems, and automotive electronics. Spherical Bearing Manufacturers Pioneers in Engineering Precision In addition to its load-bearing capabilities, the 30203 bearing is also known for its smooth operation and low friction. This is important in applications where efficiency and precision are key, as the smooth operation of the bearing can help to reduce wear and tear on other components of the machinery. The low friction design of the bearing also helps to minimize heat generation and energy loss, making it an efficient choice for many different applications. Furthermore, the 6207 2RS bearing requires minimal maintenance, thanks to its sealed design that keeps lubrication in and contaminants out

6207 2rs bearing. This reduces the need for frequent lubrication and inspection, saving time and resources for the operator. Conclusion 2. Low Friction The rolling motion of the rollers reduces friction between the bearing components, resulting in lower heat generation and longer bearing life. Machinery Bearings Lubricants Essential for Smooth Operation * Automotive industry In engines, transmissions, and suspension systems, where high speeds, loads, and vibrations are common. Despite their robustness, axial angular contact ball bearings are susceptible to failure if subjected to excessive loads or improper installation. Thus, understanding the specific requirements of the application and selecting the right bearing with the appropriate dimensions, load rating, and speed capability is paramount. In conclusion, the deep groove ball bearing represents an economical and efficient solution for a myriad of mechanical needs. Its universal applicability, coupled with its robust construction and competitive pricing, makes it an indispensable component for those seeking reliability and performance. As you scour the market for your next purchase, remember that the unassuming deep groove ball bearing may just be the unsung hero your project needs. In the realm of mechanical engineering, precision bearings play a pivotal role in ensuring smooth operation and longevity of machinery. One such bearing that has garnered significant attention is the 6207 2RS. This unique identifier denotes a specific type of ball bearing, known for its exceptional performance and reliability. The 6010 ZZ bearing, a precision component integral to various industrial machinery, has undergone significant advancements since its inception. This bearing, characterized by its double shields and steel balls, offers superior performance and reliability in high-speed and heavy-duty applications. Applications

Deep groove ball bearings are commonly used in a wide range of applications, including electric motors, pumps, gearboxes, conveyors, and various machinery and equipment. Their ability to handle both radial and axial loads, combined with their low friction and high efficiency, makes them versatile and widely utilized in industrial, automotive, and consumer products.

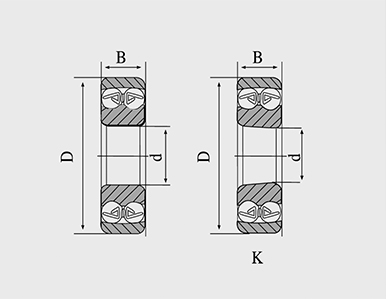

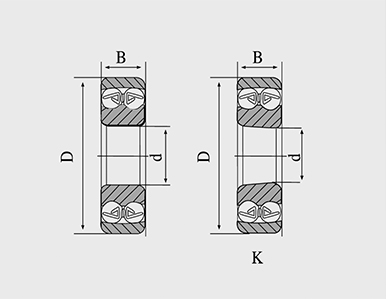

Thrust Ball Bearing Installation A Comprehensive Guide In terms of installation, double-row deep groove ball bearings are slightly more complex than single-row bearings due to their additional row of balls deep groove ball bearings double row. However, this complexity is often outweighed by the benefits they provide in terms of load capacity, stiffness, and heat dissipation. Additionally, many manufacturers offer pre-assembled double-row deep groove ball bearings that simplify the installation process. Environmental considerations are also increasingly important in modern industry, and the 6004z bearing aligns well with sustainability efforts Potential Applications of the 25877 Bearing The 6305 ZZ bearing, characterized by its outer diameter of 62mm, inner diameter of 25mm, and width of 17mm, is widely used in various applications due to its robustness and efficiency. The 'ZZ' suffix indicates that it has two metal shields on either side of the bearing, preventing contamination and reducing friction, thus enhancing its performance. A double row deep groove ball bearing consists of an outer ring, an inner ring, a cage, and a set of steel balls that roll between the rings. The deep groove design provides stability and support, while the balls ensure smooth rotation under heavy loads. These bearings are suitable for applications requiring high speed and precision, such as machine tools, pumps, and gearboxes. Taper roller bearings are a type of rolling-element bearing that is designed to handle both radial and axial loads. They are commonly used in machine tool spindles, automotive applications, and other machinery where precise rotation is required.

deep groove ball bearings double row. However, this complexity is often outweighed by the benefits they provide in terms of load capacity, stiffness, and heat dissipation. Additionally, many manufacturers offer pre-assembled double-row deep groove ball bearings that simplify the installation process. Environmental considerations are also increasingly important in modern industry, and the 6004z bearing aligns well with sustainability efforts Potential Applications of the 25877 Bearing The 6305 ZZ bearing, characterized by its outer diameter of 62mm, inner diameter of 25mm, and width of 17mm, is widely used in various applications due to its robustness and efficiency. The 'ZZ' suffix indicates that it has two metal shields on either side of the bearing, preventing contamination and reducing friction, thus enhancing its performance. A double row deep groove ball bearing consists of an outer ring, an inner ring, a cage, and a set of steel balls that roll between the rings. The deep groove design provides stability and support, while the balls ensure smooth rotation under heavy loads. These bearings are suitable for applications requiring high speed and precision, such as machine tools, pumps, and gearboxes. Taper roller bearings are a type of rolling-element bearing that is designed to handle both radial and axial loads. They are commonly used in machine tool spindles, automotive applications, and other machinery where precise rotation is required.