Links:

-

The installation process of M16 concrete anchors is relatively simple and straightforward

- Time Efficiency As previously mentioned, these bolts eliminate the need for pre-drilling, significantly reducing installation time and labor costs.

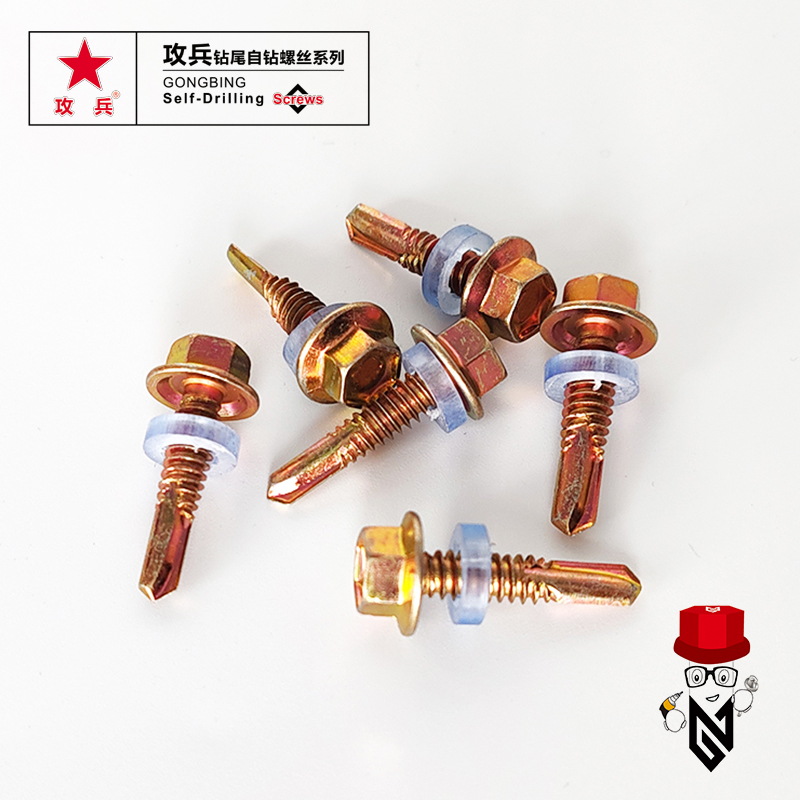

Quantity is also a significant factor in determining the price of full threaded rod 3/8. Bulk orders typically receive discounts, as suppliers can save on packaging and shipping costs when selling larger quantities. It is advisable to calculate the exact quantity needed for the project to take advantage of potential cost savings. The Pivotal Role of Hex Head Self-Drilling Screws in Modern Construction and Manufacturing

- Framing and Structural Work In construction, hex drive timber screws can be used to secure framing elements, ensuring that walls and roof structures remain stable and secure.

The applications of double end threaded studs with wrench flats are extensive. In the automotive industry, they are commonly utilized for securing engine components, frames, and suspension systems. Their use in high-stress environments demands reliability and strength, which these studs can provide.

What are 14g Tek Screws?

In conclusion, the 3/8 self-drilling screw is not just a tool, but a testament to the evolution of fastening technology. It exemplifies the fusion of functionality, convenience, and performance, streamlining processes and enhancing productivity in various industries. As such, understanding the specifications and benefits of these screws is crucial for making informed decisions in construction and engineering tasks. A wafer head screw, as the name suggests, features a flat, round head that is slightly larger than the shank, providing a broader surface area for better load distribution. This design not only ensures a clean and flush finish but also adds to the stability of the fixture. The 'self-drilling' aspect refers to the screw's ability to penetrate materials without requiring a pre-drilled hole, thanks to its sharp, threaded tip. The Versatile World of Self-Fastening Bolts

Conclusion

Advantages of the 7% 2016 Self-Drilling Screw

The 10 x 1 tek screw stands as a testament to the advancements in fastening technology. Its design not only facilitates ease of use but also offers reliability and durability across a range of applications. As construction and manufacturing processes continue to evolve, the role of such innovative fasteners becomes increasingly vital. The efficiency, strength, and versatility of tek screws make them an indispensable tool in the toolkit of builders, manufacturers, and technicians alike. Investing in quality fasteners like the 10 x 1 tek screw ensures that projects are completed more efficiently, safely, and with longevity in mind.

With a length of 75mm, these tek screws are ideal for fastening materials such as metal, wood, and plastic. They are commonly used in roofing, fencing, decking, and metal framing projects. The sharp point and threaded design of tek screws make them easy to install without the need for pre-drilling, saving time and effort during the construction process. Versatility Moreover, the Shield Anchor Projecting Bolt is highly adaptable

shield anchor projecting bolt. Its design can be customized to suit various geological conditions, making it a versatile tool in the engineer's arsenal. It can withstand immense pressures and forces, making it ideal for applications where traditional anchoring methods may fail. The Versatile Hex Head Self-Tapping Screw with Rubber Washer A Comprehensive Overview Secondly, 'V-Bracing' or 'Delta Bracing' is another prevalent type, where diagonal members meet at the top and bottom nodes, resembling the Greek letter V or the Delta symbol. It is typically employed in structures with limited floor space or where aesthetics are a concern. One of the key benefits of hex tek screws is their superior holding power compared to traditional screws. The hexagonal head provides a larger contact area with the material being fastened, resulting in a more secure and stable connection. This makes hex tek screws ideal for heavy-duty applications that require a strong and reliable fastening solution. The M4 hex head bolt is a metric bolt with a diameter of 4 millimeters. It is available in various lengths and materials, such as stainless steel, carbon steel, and alloy steel, to suit different applications and environmental conditions. The hexagonal head of the bolt is designed to be easily tightened and loosened with a wrench, providing a strong and lasting connection. One of the most common types of screws used in woodworking is the flathead screw. These screws have a flat head and a straight shank, making them ideal for a variety of applications. They are commonly used for attaching pieces of wood together, such as in cabinetry or furniture building. The flathead screw is also a good choice for situations where you need to hide the screw head, such as when installing trim or molding. Benefits of Using Heavy-Duty Section Tek Screws

shield anchor projecting bolt. Its design can be customized to suit various geological conditions, making it a versatile tool in the engineer's arsenal. It can withstand immense pressures and forces, making it ideal for applications where traditional anchoring methods may fail. The Versatile Hex Head Self-Tapping Screw with Rubber Washer A Comprehensive Overview Secondly, 'V-Bracing' or 'Delta Bracing' is another prevalent type, where diagonal members meet at the top and bottom nodes, resembling the Greek letter V or the Delta symbol. It is typically employed in structures with limited floor space or where aesthetics are a concern. One of the key benefits of hex tek screws is their superior holding power compared to traditional screws. The hexagonal head provides a larger contact area with the material being fastened, resulting in a more secure and stable connection. This makes hex tek screws ideal for heavy-duty applications that require a strong and reliable fastening solution. The M4 hex head bolt is a metric bolt with a diameter of 4 millimeters. It is available in various lengths and materials, such as stainless steel, carbon steel, and alloy steel, to suit different applications and environmental conditions. The hexagonal head of the bolt is designed to be easily tightened and loosened with a wrench, providing a strong and lasting connection. One of the most common types of screws used in woodworking is the flathead screw. These screws have a flat head and a straight shank, making them ideal for a variety of applications. They are commonly used for attaching pieces of wood together, such as in cabinetry or furniture building. The flathead screw is also a good choice for situations where you need to hide the screw head, such as when installing trim or molding. Benefits of Using Heavy-Duty Section Tek Screws Why 25mm Tek Screws?

When it comes to installation, heavy-duty tek screws are relatively easy to use

Wedge anchor bolts, a type of fastener that finds its utility in various construction and woodworking applications, play a pivotal role in ensuring structural integrity and stability. Primarily designed to secure heavy loads or anchor objects to concrete, these bolts have also found their niche in wood applications, offering a robust and reliable fixing solution. One of the main advantages of drywall butterflies is their ability to support heavier loads than traditional drywall anchors. This makes them ideal for hanging objects like shelves, mirrors, and artwork that require a more secure mounting solution.

Wedge anchor bolts, a type of fastener that finds its utility in various construction and woodworking applications, play a pivotal role in ensuring structural integrity and stability. Primarily designed to secure heavy loads or anchor objects to concrete, these bolts have also found their niche in wood applications, offering a robust and reliable fixing solution. One of the main advantages of drywall butterflies is their ability to support heavier loads than traditional drywall anchors. This makes them ideal for hanging objects like shelves, mirrors, and artwork that require a more secure mounting solution. 2. Pre-drill the Hole For toggle bolts and expansion screws, it’s important to pre-drill the hole according to the manufacturer’s specifications to facilitate proper expansion.

In conclusion, self-tapping screws are a versatile and effective solution for joining two or more materials in a wide range of applications. Their ability to cut their own path into the material and create a strong and secure joint makes them an ideal choice for situations where time and convenience are paramount. By carefully selecting the appropriate screws and considering the specific requirements of the application, engineers and manufacturers can ensure that their joints are strong, reliable, and durable. In conclusion, the head hex bolt, with its distinctive hexagonal head and threaded shaft, is a testament to the marriage of functionality and efficiency in engineering design. Its simplicity belies its strength and versatility, making it a go-to solution for countless assembly and construction tasks. Whether holding together a car engine or securing a bridge, the humble head hex bolt plays a vital role, quietly ensuring the integrity and stability of our built environment. Perhaps one of the most significant benefits of the full threaded rod 3/8 is its ease of installation

full threaded rod 3 8. Unlike some other fasteners, it does not require pre-drilling or tapping, making it a quick and convenient solution for a wide range of projects. Additionally, its thread design allows for easy tightening and adjustment, ensuring a secure and reliable connection every time.

full threaded rod 3 8. Unlike some other fasteners, it does not require pre-drilling or tapping, making it a quick and convenient solution for a wide range of projects. Additionally, its thread design allows for easy tightening and adjustment, ensuring a secure and reliable connection every time. Additionally, bracing elements contribute to the overall aesthetic of a building. Architects often incorporate visible bracing into their designs, transforming a structural necessity into a defining feature of the building's appearance. Creative integration of bracing systems not only serves to enhance stability but also adds to the architectural character of the structure.

bracing steel beams

A wedge anchor bolt, as the name suggests, utilizes a wedge-shaped mechanism to create a secure hold within the concrete. The design consists of a threaded rod with a cylindrical body and a wedge-shaped expansion piece at one end. When tightened, the bolt's tension against the wedge causes it to expand, locking the bolt firmly in place within the drilled hole in the concrete. - Metal Roofing They are extensively used in metal roofing systems, ensuring panels are securely fastened to the underlying structure. The self-drilling feature is particularly advantageous in this application, allowing quick installation onto steel purlins or framing. Moreover, self-drilling flat head metal screws are available in various materials, including steel, stainless steel, and aluminum, each tailored to specific applications. Stainless steel screws, for instance, are corrosion-resistant and suitable for outdoor or marine environments, while steel screws offer excellent strength for heavy-duty applications.

Self-drilling framing screws have revolutionized the construction and woodworking industries by providing a reliable and efficient solution for connecting materials. These specialized fasteners, designed with a drill bit-like point, eliminate the need for pre-drilling holes, saving time and effort during the assembly process. In this article, we will delve into the features, benefits, and applications of self-drilling framing screws.

- Construction In building frameworks, self-drilling bolts streamline the assembly process, particularly for metal structures that require quick and reliable fastening.

Benefits of Using Chemical Anchor Bolts 3. **Corrosion** Self-drilling screws can rust or corrode if not stored properly. Store them in a dry, cool place to prevent this issue.In addition to their efficiency, countersunk self-drilling screws for steel offer excellent holding power. The sharp drill point and thread design of these screws create a secure connection that resists loosening over time. This reliability is essential for structural applications where the integrity of the connection is crucial.

Moreover, the sleek and clean appearance of stainless steel complements modern architectural designs

stainless steel tek screws. In construction, they are often used in structural steel connections, HVAC systems, and even in the assembly of furniture and appliances. Their aesthetic appeal, combined with their functional benefits, makes them a popular choice for both industrial and residential projects. In conclusion, pricing chemical anchor fasteners requires a thorough understanding of the various factors that influence their cost. By considering factors such as material quality, size, load capacity, and application requirements, you can make an informed decision and select the most suitable fasteners for your project. Remember to always consult with a qualified professional to ensure that you are getting the best value for your money. Another benefit of hexagon self-drilling screws is their versatility What Are Threaded Rod Chemical Anchors? Moreover, their versatility is another key selling point. They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications

stainless steel tek screws. In construction, they are often used in structural steel connections, HVAC systems, and even in the assembly of furniture and appliances. Their aesthetic appeal, combined with their functional benefits, makes them a popular choice for both industrial and residential projects. In conclusion, pricing chemical anchor fasteners requires a thorough understanding of the various factors that influence their cost. By considering factors such as material quality, size, load capacity, and application requirements, you can make an informed decision and select the most suitable fasteners for your project. Remember to always consult with a qualified professional to ensure that you are getting the best value for your money. Another benefit of hexagon self-drilling screws is their versatility What Are Threaded Rod Chemical Anchors? Moreover, their versatility is another key selling point. They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications

They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications They can be used in a wide range of soil conditions, from soft to hard, and in both onshore and offshore applications self drilling anchor. This adaptability has made self-drilling anchors a preferred choice for numerous construction projects, from small-scale building renovations to large-scale civil engineering ventures like bridge construction and mine shaft support.

self drilling anchor. This adaptability has made self-drilling anchors a preferred choice for numerous construction projects, from small-scale building renovations to large-scale civil engineering ventures like bridge construction and mine shaft support. 3. Cushioning The elasticity of rubber allows for a cushioning effect, which can help prevent damage to surfaces being fastened together. This is particularly useful in applications where thin or delicate materials are involved.

Bracing steel beams are integral components in modern construction, providing essential support and stability to various structures. These beams are designed to withstand lateral forces, which are particularly critical in regions prone to seismic activity or high winds. Through the strategic use of bracing techniques, engineers can ensure that buildings and infrastructures not only meet safety standards but also achieve optimal functionality and longevity.

The Pivotal Role of Continuously Threaded Rod in Modern Construction and Engineering In addition to saving time, self-drilling trailer deck screws also provide a more secure and stable foundation for the deck. The self-drilling feature ensures that the screws penetrate the wood with precision, creating a tight and secure connection. This can help prevent the deck boards from shifting or becoming loose over time, resulting in a more durable and long-lasting deck. 2. Cost-Effectiveness With reduced labor time and fewer tools needed, overall project costs can be significantly lowered.

Specifications of Chemical Anchor Bolts