Links:

-

In conclusion, the 400mm pull handle is a testament to the power of thoughtful design meeting functionality. It serves as a silent workhorse in our homes and workplaces, blending form with function to create a beautiful yet practical addition to everyday life. Next time you glide open a drawer or door with ease, consider the unsung hero that makes it possible the versatile 400mm pull handle.

- The rolling window is directly exposed to the natural environment. The use of A-grade aluminum materials ensures the durability of the product. In addition to their functional role, pocket door tracks and rollers also contribute to the aesthetic appeal. With various designs and finishes, they can complement or contrast with the overall interior style, adding a touch of sophistication or a minimalist touch, depending on the preference.

Durability and Strength

In conclusion, aluminum window extrusion profiles have revolutionized the window industry with their unique blend of form and function. They not only provide structural integrity and aesthetic appeal but also contribute significantly to energy efficiency and environmental sustainability. As we continue to push the boundaries of architectural design, aluminum window extrusions remain a preferred choice for architects, builders, and homeowners alike, shaping the future of modern construction. Functionality aside, the door sliding wheel also contributes to the overall aesthetics of a space. Concealed within the door frame, they maintain a sleek, uncluttered look, enhancing the minimalist design philosophy prevalent in modern architecture. Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters door sliding wheel. However, this interconnectedness also brings new challenges. Security and privacy concerns loom large as more personal data is shared. The risk of hacking and data breaches increases with every connected device The risk of hacking and data breaches increases with every connected device

door sliding wheel. However, this interconnectedness also brings new challenges. Security and privacy concerns loom large as more personal data is shared. The risk of hacking and data breaches increases with every connected device The risk of hacking and data breaches increases with every connected device The risk of hacking and data breaches increases with every connected device The risk of hacking and data breaches increases with every connected device

The risk of hacking and data breaches increases with every connected device The risk of hacking and data breaches increases with every connected device hings. Moreover, the sheer volume of data generated by IoT requires robust data management and analytics capabilities.

hings. Moreover, the sheer volume of data generated by IoT requires robust data management and analytics capabilities. 8. Regular Maintenance To prevent future issues, conduct regular maintenance on your sliding doors. Clean the tracks and rollers every few months and inspect for any signs of wear or damage.

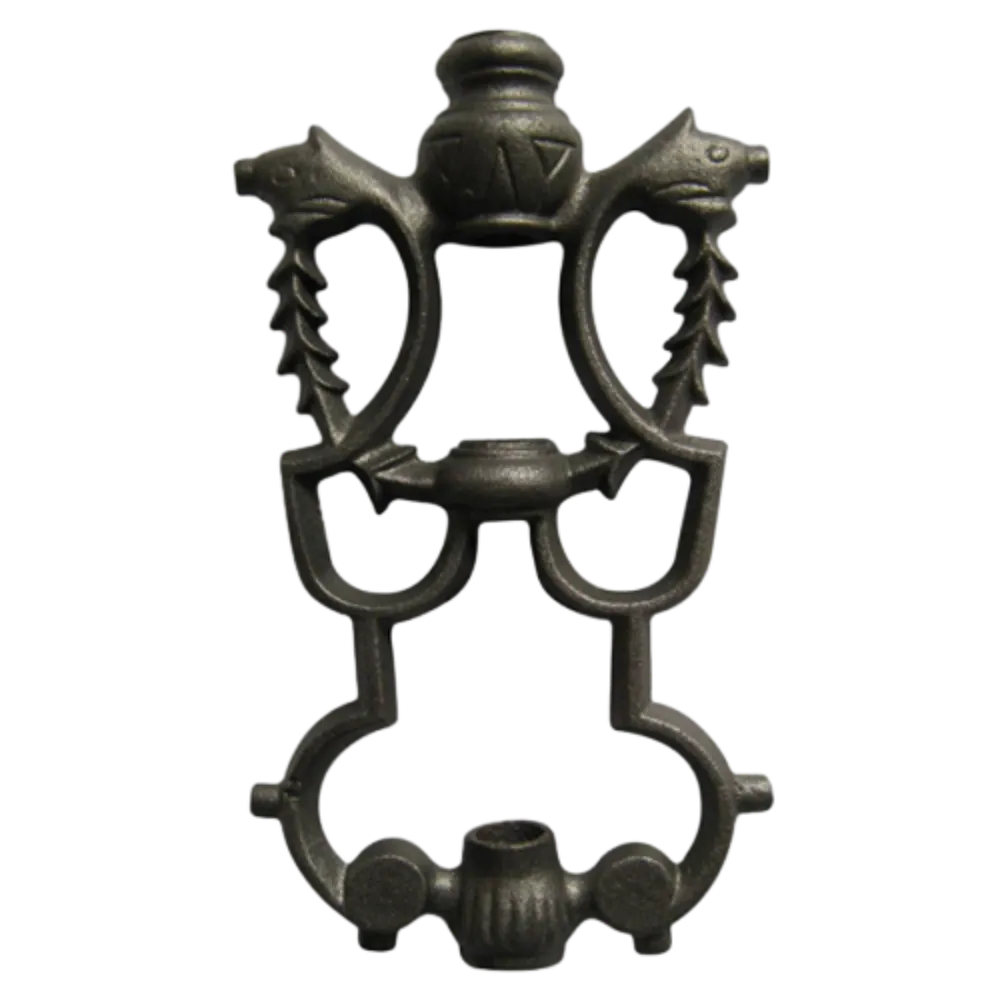

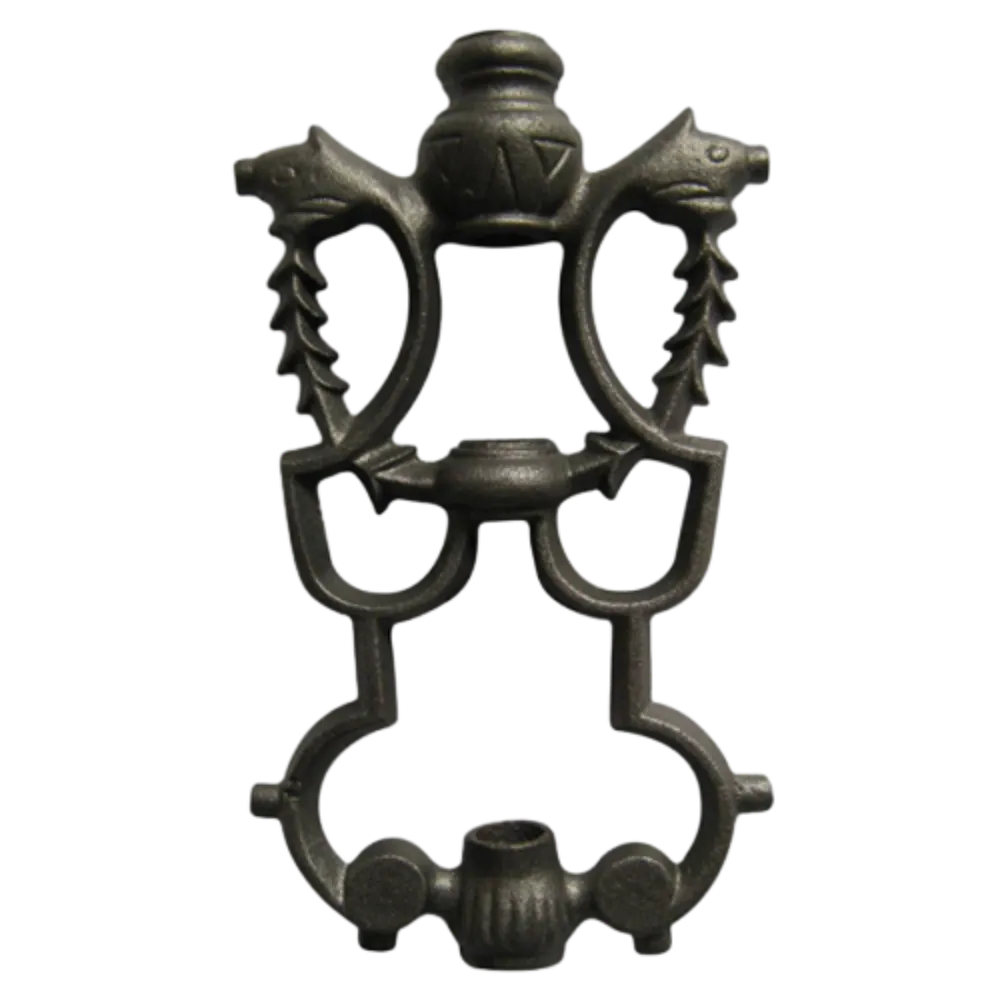

Overall, steel sliding door wheels are an excellent choice for any sliding door system. Their durability, strength, and smooth operation make them a reliable option that can enhance the functionality and convenience of any space. Whether in a home, office, or commercial setting, steel sliding door wheels provide a high-quality solution for ensuring that doors can be easily and efficiently opened and closed. With their long lifespan and dependable performance, steel sliding door wheels are a smart investment that can improve the usability and efficiency of any sliding door system. Designing Secure and Efficient Gateways for Network Traffic Management The construction of these sliding wheels is often a study in engineering elegance. Featuring a central hub that secures the wheel to an axle, they boast a robust rim designed to withstand the demands of constant motion and varying loads. The sliding mechanism itself is usually facilitated by precision-fitted bearings that ensure a smooth rotation with minimal friction, thereby extending the lifespan of the wheel and improving its efficiency. When it comes to sourcing cast iron picket castings, there are a variety of suppliers and manufacturers that offer a wide selection of designs and styles to choose from. Whether you are looking for a traditional Victorian-inspired design or a more contemporary and minimalist look, there is sure to be a casting that fits your needs and budget.

aluminium cill profile. This means that aluminium profiles will not deteriorate over time and will continue to look great for years to come.

One of the key advantages of aluminum window extrusion profiles is their strength. Aluminum is a highly durable material that can withstand harsh weather conditions, such as heavy rain, strong winds, and extreme temperatures. This makes aluminum windows a great choice for homes in areas prone to inclement weather. Additionally, aluminum is resistant to rust and corrosion, ensuring that the windows will maintain their appearance and functionality over time.

You can drill, weld, stamp, bend, cut, and deep draw 6061 aluminum grade quite easily using cold working methods when in the annealed state.

Benefits of simple iron fencing

Design features also play a significant role in a window profile

what is a window profile. This includes the style of the window, such as casement, double-hung, or picture windows. The type of opening mechanism, hardware, and finish options are all part of the window profile. These design features can enhance the aesthetics of a window, as well as its functionality and ease of use. In the world of interior design, hardware elements often serve as the subtle yet significant accents that elevate a space from ordinary to extraordinary. Among these, the round bar pull handle stands out as a classic choice, embodying both functionality and aesthetic appeal.

FINDING ATTRACTIVE FENCING THAT LOOKS LIKE WROUGHT IRON

Aluminum construction (window and door / wall curtain)

Types of Mosquito Net Aluminium ProfileIt involves a chemical electrolytic process, which brightens the aluminum surface without leaving any debris or deposits on it. The brightness extent is influenced by type of aluminum alloy and original surface finish of aluminum profile being processed.

Sliding doors have become an integral part of modern architecture, offering sleek design and optimal space utilization. Their smooth operation largely relies on a critical component - the heavy duty sliding door wheels. These wheels are the unsung heroes that ensure the seamless movement of doors, transforming the way we access and navigate through our living and working spaces.Metal Taps Strength and Versatility

In today's world, home security has become a paramount concern for homeowners. A vital component that often goes unnoticed in this context is the security screen door roller. These rollers play a crucial role in ensuring the functionality and effectiveness of your security screen doors, providing an additional layer of protection to your residence. Furthermore, cast iron corner castings are relatively easy to install and maintain Moreover, advancements in technology have led to the development of more sophisticated roller systems. Some modern designs incorporate self-aligning features, allowing the door to adjust its position as it moves. Others have built-in dampening mechanisms that control the speed of the door's closing, adding an extra layer of safety and convenience.

One of the most significant advantages of wrought iron is its strength and longevity. Unlike steel, which can rust and deteriorate over time, wrought iron, when properly maintained, can last for generations. This makes it a wise investment for homeowners looking for lasting beauty and security. Additionally, wrought iron is recyclable, making it an environmentally friendly choice for those conscious of their carbon footprint.

Welding, an integral part of the manufacturing and engineering world, often brings to mind images of fiery sparks and molten metal. However, the process is not just about joining pieces together; it's a symphony of art and science, where even the most minute details, like metal leaves, play a crucial role. In this context, 'metal leaves for welding' refers to the technique of using thin, metallic sheets or 'leaves' as a part of the welding process, particularly in artistic and intricate welding applications.

Another advantage of the door roller bracket is its adjustable design, which allows for easy installation and customization. This feature is particularly useful when retrofitting old doors or replacing damaged roller brackets. With the ability to adjust the height and angle of the bracket, it is possible to achieve a perfect fit that ensures the door glides effortlessly along the track

door roller bracket. Furthermore, cast iron wood burning stoves are aesthetically pleasing and can enhance the overall look of a room

cast iron wood burning stoves. The intricate designs and decorative details of these stoves add a touch of elegance and sophistication to any living space. Whether placed in a rustic cabin or a modern home, a cast iron wood burning stove can become a focal point of the room and create a warm and inviting atmosphere.

What Are The Main Components Of A Wrought Iron Fence?

Metal storage lock box with lock hasp is a convenient and secure way to store your valuable items. Whether you need to keep important documents safe or want to secure your jewelry, a lock box with a lock hasp is the perfect solution. In conclusion, changing the wheels on a sliding screen door is a practical home maintenance task that can save you the cost of a professional repair. With patience, the right tools, and a little bit of know-how, you can restore your door's functionality and enjoy the fresh air without the annoyance of a sticking or noisy door. Always prioritize safety and consult the manufacturer's instructions if unsure about any steps, and remember, prevention is key - regular cleaning and lubrication can help prolong the life of your screen door's wheels.Selling old wrought iron fences to artists or crafters can be a fulfilling way to give new life to what might otherwise be discarded. Artists and crafters often look for unique materials that can be transformed into art pieces or functional items.

Beyond its practical applications, the metal box with lid and lock holds a certain nostalgic charm. It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal.

metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal. Installation of door sliding rollers is relatively simple and can be done by DIY enthusiasts or professionals. Most rollers come with easy-to-follow instructions and can be installed in a matter of minutes. Regular maintenance of the rollers, such as cleaning and lubricating them, can help to prevent them from becoming stiff or worn out.

Energy efficiency is another feather in the cap of sliding window rollers. Their tight seals prevent air leaks, ensuring optimal insulation during both hot summers and cold winters. This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills

This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills

This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills This not only contributes to a more comfortable indoor environment but also helps reduce energy consumption, translating into lower utility bills sliding window roller. Overall, decorative iron gates are a beautiful and practical addition to any property. Their timeless elegance, durability, and versatility make them a worthwhile investment for homeowners looking to enhance the aesthetic appeal and security of their homes. Whether used as a grand entrance or a charming garden accent, decorative iron gates are sure to make a statement that will be admired by all who see them. Another advantage of steel sliding door wheels is their smooth operation. The steel material allows the wheels to move along the track with minimal friction, making it easy to open and close the door with a simple push or pull. The smooth operation of the wheels also reduces the amount of noise created when the door is in motion, creating a quieter and more peaceful environment in the space. This is especially important in residential settings where a noisy door can be disruptive to daily activities.

sliding window roller. Overall, decorative iron gates are a beautiful and practical addition to any property. Their timeless elegance, durability, and versatility make them a worthwhile investment for homeowners looking to enhance the aesthetic appeal and security of their homes. Whether used as a grand entrance or a charming garden accent, decorative iron gates are sure to make a statement that will be admired by all who see them. Another advantage of steel sliding door wheels is their smooth operation. The steel material allows the wheels to move along the track with minimal friction, making it easy to open and close the door with a simple push or pull. The smooth operation of the wheels also reduces the amount of noise created when the door is in motion, creating a quieter and more peaceful environment in the space. This is especially important in residential settings where a noisy door can be disruptive to daily activities.