Links:

-

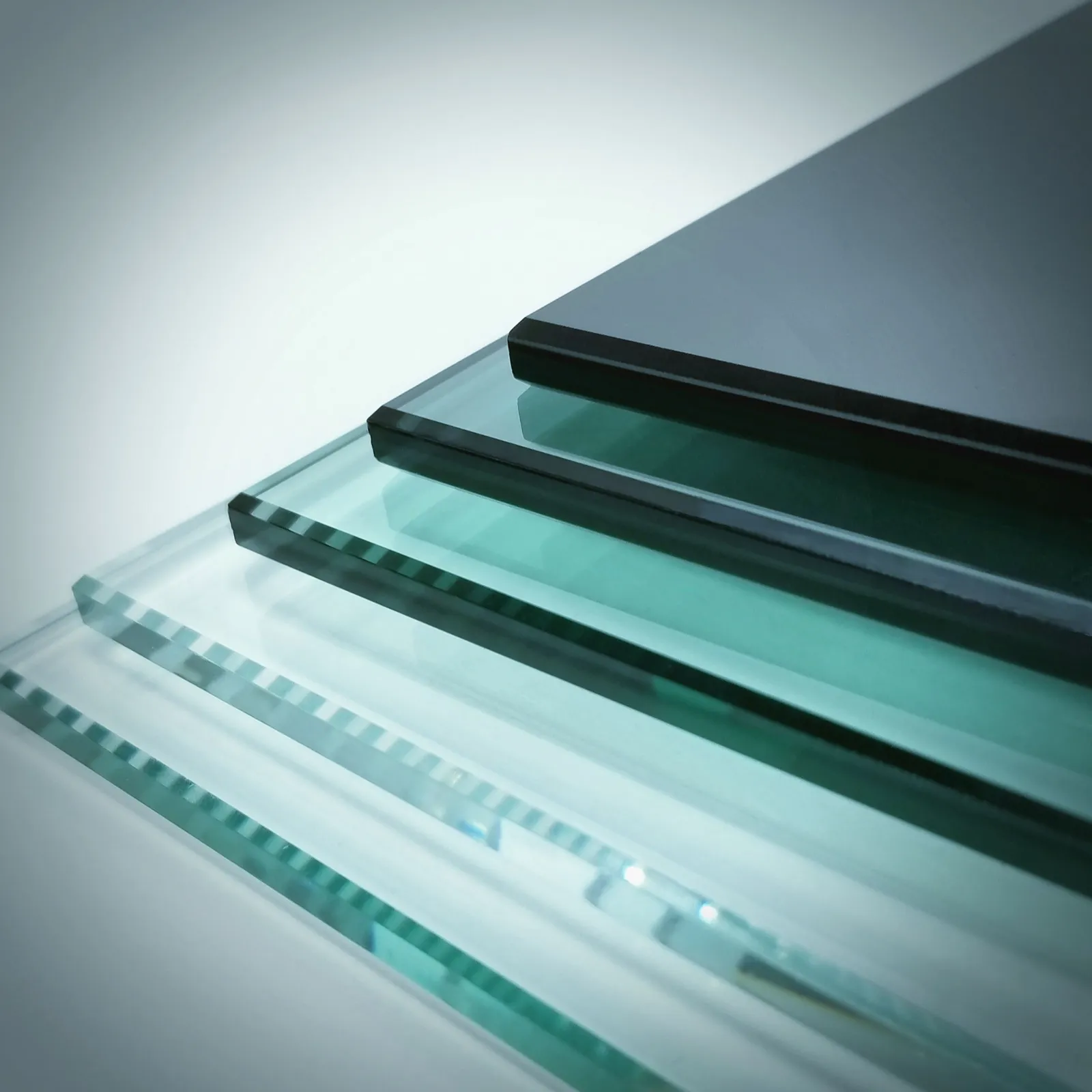

Overall, tempered glass is a highly sought-after product in the wholesale market due to its strength, durability, and versatility. Whether it's for protecting electronic devices, enhancing the aesthetic of a space, or providing security and safety, tempered glass is a reliable and cost-effective option. With a wide range of sizes, finishes, and customization options available, tempered glass is a practical choice for a variety of applications. The properties of this glass are as intriguing as they are diverse. During the day, its reflective nature serves as an energy-efficient shield, warding off solar heat and reducing cooling demands within buildings. It creates a visual barrier, ensuring privacy for occupants without compromising on natural light infiltration. However, when night falls and interior lights come alive, the glass undergoes a magical transformation. It reveals a subtle, warm glow from within, tantalizing the outside world with glimpses of activity sheltered behind its shimmering veil. Frosted opaque glass is also a practical choice for spaces where natural light is desired but privacy is still important. By diffusing light as it passes through the glass, frosted opaque glass can help to reduce glare and create a soft, inviting atmosphere in a room. This makes frosted opaque glass a popular choice for offices, restaurants, and other commercial spaces where a balance of natural light and privacy is key. Frosted toughened glass is a versatile material that can be used in a wide range of applications The Luminous Reflections of Sterling Silver Mirrors Overall, providing an iguana with a replacement can significantly improve its quality of life and allow it to thrive despite its condition. With the right care and support, iguanas with replacements can lead happy and fulfilling lives, just like any other healthy iguana. Dark reflective glass is a popular choice for modern architectural design as it offers a sleek and stylish appearance while also serving practical purposes. This type of glass is coated with a thin layer of metal oxide that allows it to reflect light and give off a dark, mirror-like appearance. The frame of the Louis Leaner Mirror in Silver is a testament to artisanal skill On chilly winter evenings, when the fireplace roars with life, the mirror transforms into a captivating spectacle. Flames dance and shadows play upon its surface, creating a mesmerizing display of light and reflection. It mirrors the warm glow of the fire, multiplying the heat and comfort, turning the room into a sanctuary of warmth and intimacy. One of the most significant advantages of decorative glass is its versatility. Manufacturers use a wide range of techniques and materials to create a diverse array of styles and effects. From etched, sandblasted, and stained glass to laminated, textured, and patterned glass, the possibilities are virtually endless. Each technique imparts its own distinctive character and visual impact, allowing designers to tailor glass elements to suit their specific design vision. Low iron float glass, also known as ultra-clear glass, is a type of glass that has undergone a special manufacturing process to reduce the iron content. This results in a product that is almost transparent, with very low levels of iron oxide impurities. This characteristic makes it an ideal choice for a wide range of applications where maximum visibility and clarity are paramount. In conclusion, low-rated windows offer a practical and cost-effective alternative to their higher-rated counterparts. With their affordability, durability, environmental friendliness, and potential for personalization, these windows are well worth considering for anyone looking to improve their home without sacrificing style or quality.

1. Safety and Durability One of the most significant advantages of tempered glass is that it is much tougher than regular glass. When shattered, tempered glass breaks into small, blunt pieces, reducing the risk of injury. This safety feature makes it an ideal choice for various applications, including windows, doors, and shower enclosures.

At first glance, reflective float glass appears as a lucid barrier, its surface a polished mirror ready to catch the ephemeral interplay of light and shadow. Yet, it is in its subtlety that this type of glass reveals its true nature—a chameleon capable of shifting moods and atmospheres at the behest of its surroundings.

Crystal and glass are very similar in appearance, but they are two completely different substances. The main differences are as follows:

Another significant factor that influences the cost of tempered glass is its size. Larger sheets of glass are more difficult and expensive to produce than smaller ones, as they require more raw materials and energy during the manufacturing process. Additionally, larger sheets of glass may also require special handling and transportation, which can further increase their cost. Therefore, when calculating the price per square foot, it's essential to take into account the dimensions of the glass you need. The quality of the frosting process itself is another determining factor. Some processes may offer higher quality finishes, such as consistent opacity and smooth textures, which can command a premium price. Furthermore, the type of glass used—whether it's standard window glass or a more durable, tempered alternative—will affect the overall cost. One of the most common types of reflective glass is tinted reflective glass. As the name suggests, this type of glass has a tinted coating that helps to reduce glare and heat from the sun. It is commonly used in buildings with large windows or glass facades to improve energy efficiency and provide a more comfortable indoor environment. Tinted reflective glass is available in a range of colors, allowing designers to achieve a specific look or match the overall color scheme of a building. The float process, which was first introduced in the 1950s, revolutionized the glass industry. It ensures unparalleled optical clarity, uniform thickness, and superior strength compared to traditional sheet glass production methods. The use of tin as a float medium allows the glass to cool slowly and evenly, minimizing internal stresses and resulting in a distortion-free, high-quality product. Decorative glass is an art form that has been cherished for centuries, transforming ordinary spaces into aesthetic marvels. It is a versatile material that adds a touch of elegance, sophistication, and often, a dash of color to architectural designs. There are numerous types of decorative glass, each with its unique characteristics and applications.02

Another important consideration in the wholesale float glass market is quality. Not all float glass is created equal, and it is essential for buyers to source materials from reputable manufacturers who adhere to industry standards and regulations. High-quality float glass not only enhances the aesthetic value of a project but also contributes to its durability and safety. Buyers should conduct thorough research and vet potential suppliers to ensure that they provide certified products that meet or exceed quality benchmarks.

Toughened plain glass, also known as tempered glass, is a type of safety glass that is processed using thermal or chemical treatments. This glass is known for its increased strength and durability compared to regular glass, making it a popular choice for various applications.

Suppliers of silver mirrors come in various sizes and cater to diverse needs. They offer custom-made solutions, from standard rectangular shapes to intricate, artistic designs. Some specialize in antique silver mirrors, replicating the vintage charm of yesteryears, while others focus on modern, minimalist styles.

Colors profoundly impact human emotions and behavior, and blue is often associated with calmness and serenity. Incorporating blue reflective glass in architecture can provide psychological benefits, promoting a sense of peace and relaxation. This makes it an excellent choice for spaces designed for leisure, such as spas, meditation centers, and even residential areas. The soothing tones of blue also resonate well with outdoor environments, fostering a connection between the inside and outside.

In the commercial sector, silver mirror suppliers cater to retail chains, hotels, and corporate establishments seeking to impress clients and customers with stylish and functional decor. The durability of silver mirrors also makes them a preferred choice for public spaces, ensuring they maintain their luster despite frequent use. The door, the mirror, and the glass are three seemingly ordinary objects that we often encounter in our daily lives. However, if we look deeper into their symbolic meanings, we can discover profound insights about life. The Enchanting Charm of Colored Frosted Glass

Maintenance and Care

One of the key advantages of aluminum mirror looking trim is its durability. Unlike glass mirrors, which can be easily shattered, aluminum is a strong and resilient material that can withstand the test of time. It is also lightweight, making it an ideal choice for large-scale applications where added weight could be a concern. However, the development of the frosted glass that changes to clear did not come without its challenges. Engineers had to ensure that the switching mechanism was durable and long-lasting, capable of enduring thousands of transitions without degradation. They also faced the task of integrating the complex electronics into the glass without compromising its structural integrity or aesthetic appeal. One of the main advantages of acid etched glass is its versatility. It can be used in a variety of applications, from shower doors and partitions to tabletops and cabinets. The etching process creates a frosted appearance that diffuses light, adding a touch of elegance to any space. 2. Environmental Friendliness This type of glass contributes to the reduction of greenhouse gas emissions by improving building insulation and reducing the need for artificial heating and cooling. The versatility of black float glass extends beyond construction. It finds application in automotive industries for sleek car windows, in furniture design for stylish tabletops, and even in the tech sector for sophisticated smartphone screens. Its durability, scratch resistance, and ease of processing make it a favorite among designers and manufacturers alike. The low e in low e glass refers to its low emissivity characteristics, which means it emits less radiative heat than traditional glass panes. This unique property enables the glass to maintain an even temperature inside buildings, reducing the need for excessive heating or cooling systems. In essence, low e glass acts like a thermal insulator, trapping warmth in winter and keeping it out during summer, thereby saving significant amounts of energy. In the realm of artistry and craftsmanship, few objects hold as much allure and sophistication as a solid silver mirror. This exquisite piece, a testament to the finesse of skilled artisans, is not just an ordinary reflective surface; it is a portal to self-reflection, a symbol of luxury, and a timeless embodiment of elegance. If you are in the market for insulated glass units for sale, there are a few key factors to consider before making a purchase. First and foremost, it is important to choose a reputable supplier with a track record of providing high-quality products. Look for a supplier that offers a variety of options in terms of glass thickness, gas fill, and coatings to ensure that the units meet your specific needs and requirements. The concept of a self-frosting glass revolves around its ability to frost over or become opaque when triggered by specific external factors such as temperature changes or an electrical charge. Unlike traditional windows that remain clear, these glasses can switch between transparent and translucent states, providing privacy and controlling heat transfer. Milky frosted glass, also known as opal or diffused glass, is created through a process that involves frosting the surface of clear glass, resulting in a delicate veil of opacity. It is this frosting that gives the glass its signature milk-like appearance, diffusing light in a way that creates an ambiance of tranquility and mystery. Unlike clear glass, it obscures details while still allowing light to pass through, striking a perfect balance between privacy and illumination. As sustainability gains prominence, suppliers are also focusing on energy efficiency. Acid-etched glass can contribute to improved insulation properties, reducing heat loss and energy consumption. This not only benefits the environment but also adds value to the end product. White reflective glass is a versatile and modern building material that is becoming increasingly popular in architectural design. This type of glass not only provides a sleek and contemporary finish to buildings, but also offers practical benefits in terms of energy efficiency and light control. The tempering process involves heating the float glass to a specific temperature and then quickly cooling it. This is done to remove internal stresses within the glass and to improve its mechanical properties. The temperature at which the glass is heated depends on its thickness and the desired properties of the final product.

The Aesthetic and Functional Appeal of Decorative Frosted Glass

One of the most captivating aspects of patterned glass sheets is their versatility. Designers can employ a vast array of motifs ranging from subtle, elegant swirls to bold, geometric forms. This diversity allows the glass to seamlessly integrate into various architectural styles, enhancing modern minimalism or adding a vintage charm to classic settings.

Floral pattern glass is also a great way to add a pop of color to a room. The vibrant hues of the flowers on the glass can instantly brighten up a space and create a cheerful and welcoming atmosphere. Whether you choose a piece with bold and bright colors or a more subtle and muted palette, floral pattern glass is a great way to add some visual interest to a room.

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets

The performance and safety of tempered glass are of utmost importance in various applications, including architectural glazing, automotive windshields, and solar panels. To ensure the desired performance and safety standards, it is essential to carefully select high-quality raw materials, implement advanced production techniques, and conduct rigorous quality control measures. By doing so, manufacturers can produce top-notch tempered glass that not only meets but exceeds industry standards, providing added peace of mind for users and stakeholders alike. The term 5mm refers to the thickness of the glass, a standard measurement in the glass industry. This dimension makes it suitable for a broad range of applications, from architectural designs to everyday household items. The 5mm thickness strikes an ideal balance between durability and transparency, offering both strength and visual appeal. Additionally, float glass manufacturers can explore new applications for their products, such as in the automotive and aerospace industries. Float glass can be used to create lightweight, shatter-resistant windshields and windows for vehicles, as well as for aircraft cabins, where safety and durability are paramount.