Links:

Increasingly, safety standards and regulations require businesses to implement measures that protect workers and the general public. Anti-skid grating meets many of these standards, helping organizations comply with Occupational Safety and Health Administration (OSHA) guidelines and other local safety regulations. By investing in anti-skid solutions, companies not only prioritize the well-being of their employees but also reduce their liability risk associated with workplace accidents.

In conclusion, stainless steel floor grating is more than just a practical flooring option. Its durability, corrosion resistance, safety features, ease of maintenance, and visual appeal make it a valuable investment for any industry. As businesses seek sustainable and long-lasting solutions, the incorporation of stainless steel floor grating into their operations will continue to gain traction, ensuring a safe and efficient working environment for all.

Safety is a critical concern when it comes to handrails. Modular stainless steel handrails can be designed to meet or exceed building codes, providing peace of mind to property owners and occupants alike. They can include features such as non-slip surfaces and rounded edges to enhance safety. The visibility of stainless steel also contributes to a safe environment; its shine can improve visibility in low-light situations, which is especially beneficial in outdoor areas.

Moreover, educating family members and guests about deck safety is vital. Deck Safe Solutions encourages homeowners to establish rules, such as not allowing excessive weight on the deck, ensuring children are supervised, and keeping the space free from clutter. By fostering a culture of safety and awareness, homeowners can make their outdoor spaces more enjoyable and secure for everyone.

Floor grating is typically composed of materials like steel, aluminum, or fiberglass, each chosen based on the specific requirements of the application. Steel grating is renowned for its high strength and durability, making it ideal for industrial environments where heavy loads are common. Aluminum grating, on the other hand, is lighter and resistant to corrosion, which makes it suitable for marine and outdoor applications. Fiberglass grating is known for its non-conductive properties and resistance to corrosion, chemicals, and UV radiation, making it an excellent choice for environments where these factors are a concern.

FRP grating is composed of a polymer matrix reinforced with fibers, typically glass or carbon. This composite structure offers unique characteristics, combining high tensile strength with low weight. The process of manufacturing FRP grating usually involves pultrusion or molding techniques, allowing for customized forms and sizes to suit diverse needs. The resulting product is strong, corrosion-resistant, and lightweight, making it an attractive alternative to conventional grating materials.

Expanded metal grating is also highly customizable, allowing for tailored solutions that meet specific project requirements. It is available in various materials, including steel, aluminum, and stainless steel, making it suitable for different environmental conditions. Each material has its unique properties, such as corrosion resistance (in the case of stainless steel) or lightweight flexibility (as seen with aluminum), enabling engineers and architects to select the most appropriate option for their projects.

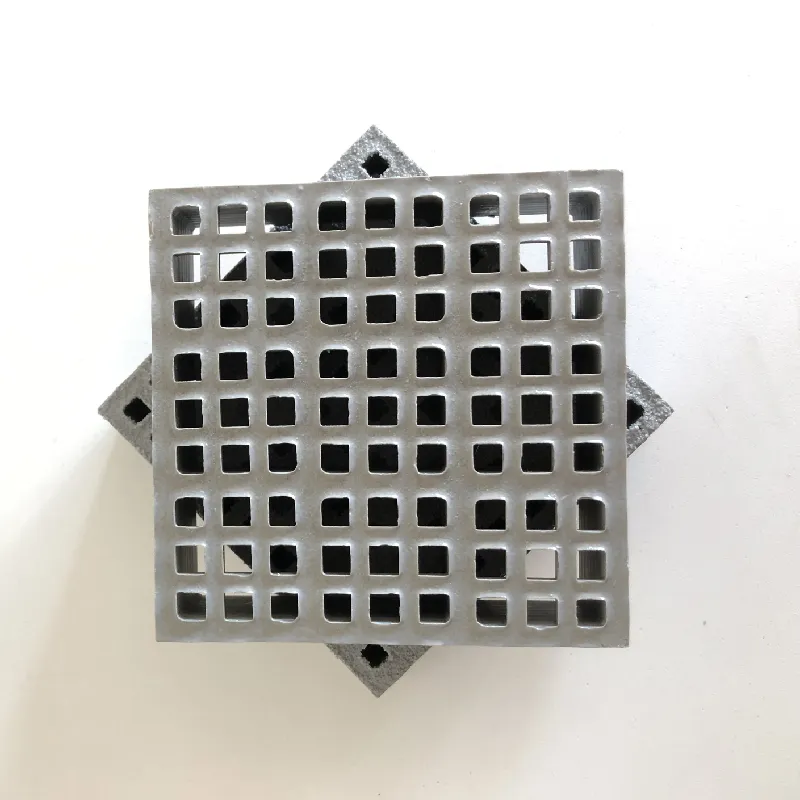

expanded metal floor grating

In summary, understanding the factors influencing the cost of FRP grating per square foot is essential for effective project planning. By assessing individual needs, considering long-term benefits, and comparing options, businesses can make informed decisions. As industries continue to recognize the advantages of FRP grating, its demand is likely to grow, making it a forward-thinking choice for modern installations.

Moreover, the non-magnetic nature of FRP bars makes them suitable for applications in situations where magnetic interference is a concern, such as in certain medical facilities or data centers. Their low thermal conductivity is another asset that helps prevent issues related to heat transfer within structures.

frp bar

One of the remarkable features of GRP grating is its non-conductive nature. Unlike metal grating, GRP does not conduct electricity, making it a safer option in environments where electrical hazards may occur. Additionally, its slip-resistant surface enhances safety for workers, reducing the risk of accidents in both dry and wet conditions.

Understanding Water Vessel Filters Importance and Applications

Conclusion

Benefits of GRP Palisade Fencing

Comparative Pricing GFRP vs. Traditional Materials

gfrp bars price

Applications of GRP Palisade Fencing

One of the standout benefits of GRP insulated water tanks is their energy efficiency. By minimizing heat loss in hot water systems or maintaining the cool temperature of chilled water, these tanks significantly reduce energy consumption. This is not only beneficial for operational costs but also aligns with global sustainability goals, as organizations strive to decrease their carbon footprint.

1. Durability and Strength FRP materials are resistant to corrosion, chemical damage, and UV degradation, making them incredibly suitable for outdoor settings. This durability translates into lower maintenance costs and a longer lifespan compared to traditional materials.

frp walkway solar

Increased Property Value

In commercial settings, such as shopping centers, parking garages, and outdoor walkways, anti-skid grating provides safety for pedestrians. It is especially useful in regions prone to rain or snow, where wet surfaces can become hazardous. By incorporating anti-skid grating into these designs, architects and planners can create safer environments for the public.

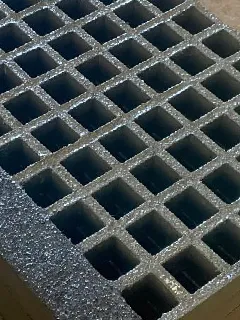

anti skid grating

In addition to health and environmental benefits, the economic impact of water vessel filters cannot be overlooked. Clean drinking water enhances productivity by reducing illness among workers and decreasing the burden on healthcare systems. In terms of agriculture, filtered water improves crop yields and reduces the costs associated with treating contaminated water sources.

Fibreglass walkway grating has emerged as a popular choice in various sectors, from industrial applications to recreational environments. This material, known for its durability, versatility, and safety features, has transformed the approach to constructing walkways in places where traditional materials might fall short. Here, we’ll explore the benefits and features of fibreglass walkways, making them an increasingly preferred option for many projects.

What is GRP Grating?

In industrial applications, aluminum bar grating excels in manufacturing plants, refineries, and chemical processing facilities, where durability and resistance to harsh chemicals are critical. The lightweight nature of aluminum also aids in compliance with weight restrictions, which can be particularly crucial in facilities that rely on overhead lifting systems or where weight-bearing capabilities are a concern.

In addition to durability, FRP stair nosing also offers excellent slip resistance. The surface of the FRP material is designed to provide traction and grip, reducing the risk of slips and falls on the stairs. This is particularly important in areas where the stairs may be exposed to water, oil, or other liquids that can make them slippery. By installing FRP stair nosing, you can create a safer environment for users and minimize the chances of accidents.

frp stair nosing

Every project has unique requirements, and having a supplier that can offer customized solutions is crucial. Look for suppliers who can tailor their products to meet specific dimensions, colors, and properties needed for your application. This flexibility can enhance project efficiency and aesthetic appeal.

frp grating suppliers

The Price Dynamics of 1465 FRP Vessels

Furthermore, advancements in manufacturing techniques, such as 3D printing and laser cutting, have made it easier and more cost-effective to produce custom mesh gratings tailored to specific needs. This adaptability is a significant draw for researchers and engineers looking to push the boundaries of current technologies.

Furthermore, the ease of installation cannot be overstated. GRP grating can be cut and customized on-site, allowing for quick adjustments and modifications as needed. This flexibility is especially valuable in industries where layouts and requirements may change frequently.

Exploring FRP Grate Decking A Sustainable Solution for Modern Applications

Overall, sectional tanks offer a reliable and efficient solution for storing liquids in a wide range of applications. Their flexibility, durability, and ease of maintenance make them a popular choice for industries such as agriculture, manufacturing, and construction.

In addition to safety, modular handrails can significantly enhance the functionality of a space. For instance, they can be integrated with other elements such as glass panels, lighting features, or even automated systems that can provide additional support in public environments. This adaptability makes them ideal for both residential staircases and commercial buildings.

Fibre Reinforced Plastic tanks and vessels represent a significant advancement in storage technology. With their exceptional properties, including corrosion resistance, lightweight, strength, thermal insulation, and design flexibility, they are revolutionizing how industries approach storage and containment solutions. As industries continue to seek ways to improve efficiency and reduce costs, the use of FRP tanks and vessels is likely to grow, highlighting their essential role in modern manufacturing and processing environments.

Moreover, GRP mesh grating is well-known for its corrosion resistance. In environments exposed to chemicals, moisture, and harsh weather conditions, traditional materials may degrade over time. In contrast, GRP maintains its structural integrity and appearance, proving to be exceptionally durable. This resilience makes it ideal for use in industries such as wastewater treatment, chemical processing, and oil and gas.

Agriculture is another major sector that benefits from sectional tanks. Farmers use these tanks for irrigation purposes, ensuring a steady supply of water for crops and livestock. The tanks can be strategically placed to optimize water distribution, improving the efficiency of water usage in farming practices.

The construction and manufacturing industries are continuously evolving, with materials and technologies advancing rapidly to meet the demands of modern projects. One such material that has gained significant attention in recent years is Fiber Reinforced Polymer (FRP), particularly in the context of FRP channels. Understanding the pricing dynamics of FRP channel products is essential for both manufacturers and consumers, as it influences procurement decisions, project budgets, and ultimately, the success of various applications.

- Residential Properties Homeowners benefit from the aesthetic appeal and low maintenance of FRP railings for decks, balconies, and patios, improving safety without compromising style.

Square water tanks with cages are versatile and cater to a wide range of applications. In residential settings, they are commonly used for rainwater harvesting, irrigation systems, and potable water storage. Homeowners can benefit from the tank’s ability to blend seamlessly into their property while providing essential water storage solutions.

Benefits of Implementing Anti-Slip Stair Nosing

anti slip stair nosing

Large galvanized water tanks are also incredibly versatile. They can be used for various purposes, including agricultural irrigation, livestock watering, fire suppression systems, and even as part of rainwater harvesting systems. Their large capacity allows them to hold significant amounts of water, making them ideal for farms that require a steady supply of irrigation or for communities that need a dependable source of water for firefighting efforts. Additionally, they can be customized in terms of size and design, catering to the specific needs of different users.

large galvanized water tanks

Walkway FRP grating is available in a range of designs, colors, and dimensions, allowing for customization to suit specific needs and aesthetic preferences. Whether for industrial walkways, pedestrian access paths, or platform decking, FRP grating can be tailored to meet diverse requirements. This versatility makes it an appealing choice for architects and engineers who seek both functionality and style in their designs.

Fiberglass reinforced plastic is a composite material made from a polymer matrix reinforced with fibers, typically glass. The 1054 designation refers to a specific type or grade of FRP vessel designed to provide strength, durability, and resistance to corrosion. These vessels are often employed in environments where traditional materials, such as steel or aluminum, would corrode or degrade quickly. The advantages of 1054 FRP vessels include lightweight construction, reduced maintenance costs, and excellent insulation properties.

Industrial water filter systems are designed to remove suspended solids, bacteria, chemicals, and other impurities from water to ensure that it is safe and suitable for industrial use. These systems utilize various filtration methods such as sedimentation, media filtration, reverse osmosis, ultrafiltration, and ion exchange to effectively purify water.

3. Corrosion Resistance Unlike metals, FRP is resistant to corrosion from environmental factors, such as moisture, chemicals, and salt. This property extends the lifespan of structures, particularly in harsh environments like marine applications or chemical processing plants.

This versatility extends to industries ranging from construction and aviation to energy and telecommunications. In every sector, fibreglass access platforms can adapt to different heights and configuration needs, providing effective solutions across different operational contexts.

While water softeners tackle hardness, water filtration systems focus on removing contaminants that can pose health risks or negatively affect taste and odor. Contaminants can include chlorine, lead, sediments, bacteria, and other harmful substances, which may originate from municipal sources or private wells.

Another significant advantage of modular stainless steel handrails is their ease of installation. Unlike traditional handrail systems that may require extensive labor and time, modular systems are designed for rapid assembly. They often come with pre-fabricated components that can be easily connected, reducing both installation time and costs. This attribute is particularly beneficial in commercial settings where minimizing downtime is crucial, as it enables the completion of projects in a timely manner.

modular stainless steel handrail

As industries become more environmentally conscious, suppliers who prioritize sustainability are increasingly desirable. Look for those that utilize eco-friendly materials and processes in their manufacturing of FRP grating. Suppliers committed to sustainable practices not only meet regulatory requirements but also enhance your company’s green credentials.

4. Versatility in Design

1. Corrosion Resistance FRP tanks do not rust or corrode, which is a common problem with metal tanks, thereby requiring less maintenance and enhancing their service life.

Beyond their functional benefits, FRP stair treads also offer a range of aesthetic options. Available in various colors, textures, and finishes, they can be customized to fit the design and branding of a business or personal taste in a home. Whether one is looking for a modern, sleek look for a corporate office or a rustic finish for a residential space, FRP stair treads can accommodate a wide spectrum of design preferences.