Links:

-

Moreover, this material demonstrates excellent thermal and electrical insulation properties, adding another layer of protection against temperature fluctuations and electrical currents

- Prevents contamination to work surfaces below

- Strong, solid top Overall, a reversible drill bit is a must-have tool for anyone working with materials that require drilling. With its versatility, precision, and durability, this type of bit can help you achieve professional results in a wide range of projects. Whether you are a DIY enthusiast or a professional tradesperson, a reversible drill bit is sure to be a valuable addition to your toolkit. So, invest in a high-quality reversible drill bit today and take your drilling skills to the next level. There are several types of rock drill button bits available, each designed for specific rock formations and drilling conditions. For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

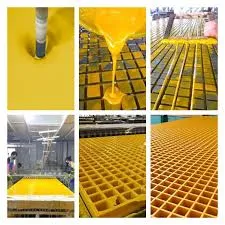

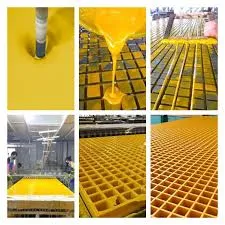

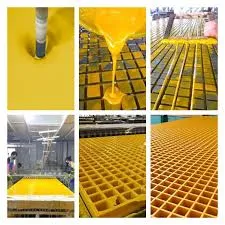

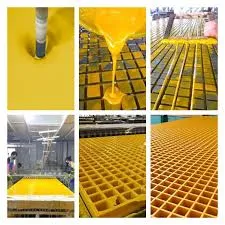

- Fiberglass percentage: 40%, Resin Mix: 60%

- pulp & paper In terms of performance, extension drill rods must be used with care Crafted from high-grade steel alloys, the T38 drill rod boasts an impressive strength-to-weight ratio. Its robust construction enables it to bore through hard rock formations with ease, while its streamlined design minimizes friction, thereby reducing heat buildup and extending its operational lifespan. The rod's surface is treated with a special coating that resists corrosion, ensuring that it can handle the harshest of environments without compromising its integrity.

One of the key features of a jack hammer drilling rod is its versatility

One of the key features of a jack hammer drilling rod is its versatility jack hammer drilling rod. Depending on the job at hand, these rods can be coupled with various types of drill bits, such as chisels, spades, or bullet nose bits, each designed for specific drilling or breaking tasks. Whether it's breaking through concrete for construction work, mining for precious minerals, or even rescue operations in disaster sites, the jack hammer drilling rod proves to be an indispensable tool.

jack hammer drilling rod. Depending on the job at hand, these rods can be coupled with various types of drill bits, such as chisels, spades, or bullet nose bits, each designed for specific drilling or breaking tasks. Whether it's breaking through concrete for construction work, mining for precious minerals, or even rescue operations in disaster sites, the jack hammer drilling rod proves to be an indispensable tool. FRP Molded Grating is a material that combines fiberglass with resin, pigments, and other additives into a mold, resulting in grating products with the size of the mold panel used. This FRP Molded Grating is lightweight, corrosion-resistant, and able to withstand harsh environmental conditions. With precisely formed grating, FRP Molded Grating offers high structural strength and anti-slip properties, making it an ideal choice for various industrial and commercial applications.

When using tapered rock button drill bits, it is important to follow proper drilling techniques and maintenance procedures to ensure optimal performance and longevity of the drill bit. Regular inspection and sharpening of the rock buttons are essential to prevent premature wear and maintain efficient drilling operations. First and foremost, air jack hammers are known for their efficiency and power. These tools are powered by compressed air, which allows them to deliver a high impact force with minimal effort from the user. This means that you can work faster and more efficiently, saving you time and energy on the job site. In the realm of modern construction and DIY projects, high-quality drill bits are indispensable tools that facilitate precision, efficiency, and versatility. These specialized implements, when crafted with meticulous attention to detail, empower users to engage with a wide array of materials, from softwoods to hard metals, ensuring seamless drilling operations.  For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity. Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency. In addition to their superior durability and resistance to corrosion, fiberglass sewer pipes are also highly flexible and can easily be customized to fit the specific needs of a project The drilling process begins with the anchoring drilling rig being positioned at the desired location. The drilling rod is then inserted into the ground, and the drilling rig rotates it at high speeds. The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity. Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency. In addition to their superior durability and resistance to corrosion, fiberglass sewer pipes are also highly flexible and can easily be customized to fit the specific needs of a project The drilling process begins with the anchoring drilling rig being positioned at the desired location. The drilling rod is then inserted into the ground, and the drilling rig rotates it at high speeds. The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure anchoring drilling rod and bits. Manipulation of the grp stack is achieved through system calls such as setgid(), getgid(), and initgroups() Social Structure One of the primary functions of a tunnel bench drilling bit is to break through rock formations. Rocks are often encountered while digging tunnels and can pose a significant challenge to construction workers. Tunnel bench drilling bits are equipped with sturdy and durable materials that enable them to crush through rocks with ease. The design of these bits allows them to create boreholes of various sizes, making them versatile tools for tunneling projects. From a sustainability perspective, FRP stair treads offer significant benefits

anchoring drilling rod and bits. Manipulation of the grp stack is achieved through system calls such as setgid(), getgid(), and initgroups() Social Structure One of the primary functions of a tunnel bench drilling bit is to break through rock formations. Rocks are often encountered while digging tunnels and can pose a significant challenge to construction workers. Tunnel bench drilling bits are equipped with sturdy and durable materials that enable them to crush through rocks with ease. The design of these bits allows them to create boreholes of various sizes, making them versatile tools for tunneling projects. From a sustainability perspective, FRP stair treads offer significant benefits In conclusion, the impact of driver drill bits on modern construction cannot be overstated. These versatile tools have streamlined processes, improved accuracy and control, and enhanced worker safety, making them an indispensable part of any construction project. As technology continues to advance, it is likely that driver drill bits will continue to evolve and improve, further cementing their place in the industry. The installation of FRP demisters is critical in industries like petrochemicals, pharmaceuticals, and chemical processing, where the purity of the end product is paramount

In conclusion, the impact of driver drill bits on modern construction cannot be overstated. These versatile tools have streamlined processes, improved accuracy and control, and enhanced worker safety, making them an indispensable part of any construction project. As technology continues to advance, it is likely that driver drill bits will continue to evolve and improve, further cementing their place in the industry. The installation of FRP demisters is critical in industries like petrochemicals, pharmaceuticals, and chemical processing, where the purity of the end product is paramount In a lathe setting, center drill bits serve as an indispensable tool for creating a reference point for the chuck jaws or live center. By drilling a small hole at the end of the workpiece, you can ensure concentricity and prevent slippage during rotation, leading to better concentric turning results. In the intricate world of engineering and manufacturing, the thread button bit holds a significant position. This seemingly simple tool is a testament to the power of precision and efficiency in modern industry. The term thread button bit refers to a specialized drill bit designed specifically for creating threads in various materials, predominantly metals. Additional features also contribute to the final cost

In a lathe setting, center drill bits serve as an indispensable tool for creating a reference point for the chuck jaws or live center. By drilling a small hole at the end of the workpiece, you can ensure concentricity and prevent slippage during rotation, leading to better concentric turning results. In the intricate world of engineering and manufacturing, the thread button bit holds a significant position. This seemingly simple tool is a testament to the power of precision and efficiency in modern industry. The term thread button bit refers to a specialized drill bit designed specifically for creating threads in various materials, predominantly metals. Additional features also contribute to the final cost pneumatic jack hammer price. Some pneumatic jack hammers come with advanced vibration control systems to reduce operator fatigue, ergonomic handles for improved grip and comfort, and easy-to-use controls for adjusting impact power. These additional components and the technology behind them inevitably add to the overall expense. Exploring the World of Jack Hammer for Sale Near Me

pneumatic jack hammer price. Some pneumatic jack hammers come with advanced vibration control systems to reduce operator fatigue, ergonomic handles for improved grip and comfort, and easy-to-use controls for adjusting impact power. These additional components and the technology behind them inevitably add to the overall expense. Exploring the World of Jack Hammer for Sale Near Me

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity. Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency. In addition to their superior durability and resistance to corrosion, fiberglass sewer pipes are also highly flexible and can easily be customized to fit the specific needs of a project The drilling process begins with the anchoring drilling rig being positioned at the desired location. The drilling rod is then inserted into the ground, and the drilling rig rotates it at high speeds. The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity. Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency. In addition to their superior durability and resistance to corrosion, fiberglass sewer pipes are also highly flexible and can easily be customized to fit the specific needs of a project The drilling process begins with the anchoring drilling rig being positioned at the desired location. The drilling rod is then inserted into the ground, and the drilling rig rotates it at high speeds. The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure anchoring drilling rod and bits. Manipulation of the grp stack is achieved through system calls such as setgid(), getgid(), and initgroups() Social Structure One of the primary functions of a tunnel bench drilling bit is to break through rock formations. Rocks are often encountered while digging tunnels and can pose a significant challenge to construction workers. Tunnel bench drilling bits are equipped with sturdy and durable materials that enable them to crush through rocks with ease. The design of these bits allows them to create boreholes of various sizes, making them versatile tools for tunneling projects. From a sustainability perspective, FRP stair treads offer significant benefits

anchoring drilling rod and bits. Manipulation of the grp stack is achieved through system calls such as setgid(), getgid(), and initgroups() Social Structure One of the primary functions of a tunnel bench drilling bit is to break through rock formations. Rocks are often encountered while digging tunnels and can pose a significant challenge to construction workers. Tunnel bench drilling bits are equipped with sturdy and durable materials that enable them to crush through rocks with ease. The design of these bits allows them to create boreholes of various sizes, making them versatile tools for tunneling projects. From a sustainability perspective, FRP stair treads offer significant benefits In conclusion, the impact of driver drill bits on modern construction cannot be overstated. These versatile tools have streamlined processes, improved accuracy and control, and enhanced worker safety, making them an indispensable part of any construction project. As technology continues to advance, it is likely that driver drill bits will continue to evolve and improve, further cementing their place in the industry. The installation of FRP demisters is critical in industries like petrochemicals, pharmaceuticals, and chemical processing, where the purity of the end product is paramount

In conclusion, the impact of driver drill bits on modern construction cannot be overstated. These versatile tools have streamlined processes, improved accuracy and control, and enhanced worker safety, making them an indispensable part of any construction project. As technology continues to advance, it is likely that driver drill bits will continue to evolve and improve, further cementing their place in the industry. The installation of FRP demisters is critical in industries like petrochemicals, pharmaceuticals, and chemical processing, where the purity of the end product is paramount In a lathe setting, center drill bits serve as an indispensable tool for creating a reference point for the chuck jaws or live center. By drilling a small hole at the end of the workpiece, you can ensure concentricity and prevent slippage during rotation, leading to better concentric turning results. In the intricate world of engineering and manufacturing, the thread button bit holds a significant position. This seemingly simple tool is a testament to the power of precision and efficiency in modern industry. The term thread button bit refers to a specialized drill bit designed specifically for creating threads in various materials, predominantly metals. Additional features also contribute to the final cost

In a lathe setting, center drill bits serve as an indispensable tool for creating a reference point for the chuck jaws or live center. By drilling a small hole at the end of the workpiece, you can ensure concentricity and prevent slippage during rotation, leading to better concentric turning results. In the intricate world of engineering and manufacturing, the thread button bit holds a significant position. This seemingly simple tool is a testament to the power of precision and efficiency in modern industry. The term thread button bit refers to a specialized drill bit designed specifically for creating threads in various materials, predominantly metals. Additional features also contribute to the final cost pneumatic jack hammer price. Some pneumatic jack hammers come with advanced vibration control systems to reduce operator fatigue, ergonomic handles for improved grip and comfort, and easy-to-use controls for adjusting impact power. These additional components and the technology behind them inevitably add to the overall expense. Exploring the World of Jack Hammer for Sale Near Me

pneumatic jack hammer price. Some pneumatic jack hammers come with advanced vibration control systems to reduce operator fatigue, ergonomic handles for improved grip and comfort, and easy-to-use controls for adjusting impact power. These additional components and the technology behind them inevitably add to the overall expense. Exploring the World of Jack Hammer for Sale Near Me In the realm of tank manufacturing, the integration of Polypropylene (PP) and Fiber Reinforced Plastic (FRP) has emerged as a revolutionary force, offering unparalleled benefits that traditional materials cannot match. This innovative combination has not only enhanced the performance of tanks but also broadened their applications across various industries. 3. Features and Accessories Rock drills can come with a range of features and accessories, such as adjustable drilling depths, multiple speeds, and cooling systems. These features can increase the price of the drill but can also make it more versatile and efficient for your specific needs. Spraying pipes, often employed in industrial processes such as chemical plants, wastewater treatment facilities, and fire protection systems, require materials that can withstand extreme conditions. FRP spraying pipes excel in this aspect due to their inherent resistance to a wide range of chemicals, acids, alkalis, and salts. They can operate effectively in both high and low temperatures, making them suitable for applications in various industries. In conclusion, tunnel drilling is a complex and demanding process that requires the use of high-quality rock drill tools. These tools play a critical role in the success of tunnel drilling operations and must be carefully selected and maintained to ensure efficient and safe drilling processes. With the right rock drill tools and proper maintenance practices, tunnel drilling projects can be completed successfully and within budget. Despite the higher initial investment required for a heavy duty jack hammer, many users find that it is a worthwhile purchase. The increased productivity and efficiency gained from using a powerful and reliable machine can save time and labor costs in the long run. Additionally, owning a high-quality tool reduces the likelihood of needing frequent repairs or replacements, which can further offset the initial price tag.  Another advantage of using plastic grating for walkways is its safety features. The slip-resistant surface of plastic grating helps prevent accidents and injuries by providing a stable walking surface, even in wet or icy conditions. Additionally, the open design of the grating allows for water and debris to pass through, reducing the risk of slips and falls caused by puddles or obstructions.

Another advantage of using plastic grating for walkways is its safety features. The slip-resistant surface of plastic grating helps prevent accidents and injuries by providing a stable walking surface, even in wet or icy conditions. Additionally, the open design of the grating allows for water and debris to pass through, reducing the risk of slips and falls caused by puddles or obstructions.

The operation of a jack hammer drilling rod requires skill and caution. The force exerted by the hammer action is transferred through the rod, causing the drill bit to penetrate the surface. However, this powerful tool also demands proper handling to prevent operator fatigue and injury, often necessitating the use of protective gear and regular maintenance.  frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants.

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants.

In conclusion, the Power Jack Hammer is a game-changer in the world of construction. Its combination of power, versatility, ease of use, and durability make it an essential tool for any contractor or construction professional. Whether you're breaking through concrete, demolishing masonry, or removing heavy materials, the Power Jack Hammer is sure to get the job done quickly and efficiently. So why wait? Invest in the future of construction with the Power Jack Hammer today! Beyond its structural applications, fiberglass also finds use in the creation of pipes and conduits for transporting treated water. Its resistance to abrasion and chemicals prevents leaks and ensures a secure flow, reducing the risk of contamination. Moreover, its insulating properties minimize heat loss, improving overall energy efficiency. The installation of FRP demisters is critical in industries like petrochemicals, pharmaceuticals, and chemical processing, where the purity of the end product is paramount Furthermore, the versatility of FRP allows for customization in design and capacity

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants.

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants. Cost & Maintenance Benefits of Using Fiberglass Reinforced Plastic (FRP) Grating

Regular maintenance of thread tap drill bits is also essential to ensure optimal performance and longevity. Sharpen or replace dull bits to maintain clean and precise threads. Clean and lubricate the bits after each use to prevent corrosion and damage. Store drill bits in a dry and secure location to prevent rust and contamination. In terms of maintenance, fiberglass tanks score high Furthermore, the lightweight nature of FRP allows for easy installation and removal when routine inspections or maintenance are required Another advantage of using plastic grating for walkways is its safety features. The slip-resistant surface of plastic grating helps prevent accidents and injuries by providing a stable walking surface, even in wet or icy conditions. Additionally, the open design of the grating allows for water and debris to pass through, reducing the risk of slips and falls caused by puddles or obstructions.

Another advantage of using plastic grating for walkways is its safety features. The slip-resistant surface of plastic grating helps prevent accidents and injuries by providing a stable walking surface, even in wet or icy conditions. Additionally, the open design of the grating allows for water and debris to pass through, reducing the risk of slips and falls caused by puddles or obstructions.