Current location:

Links:

-

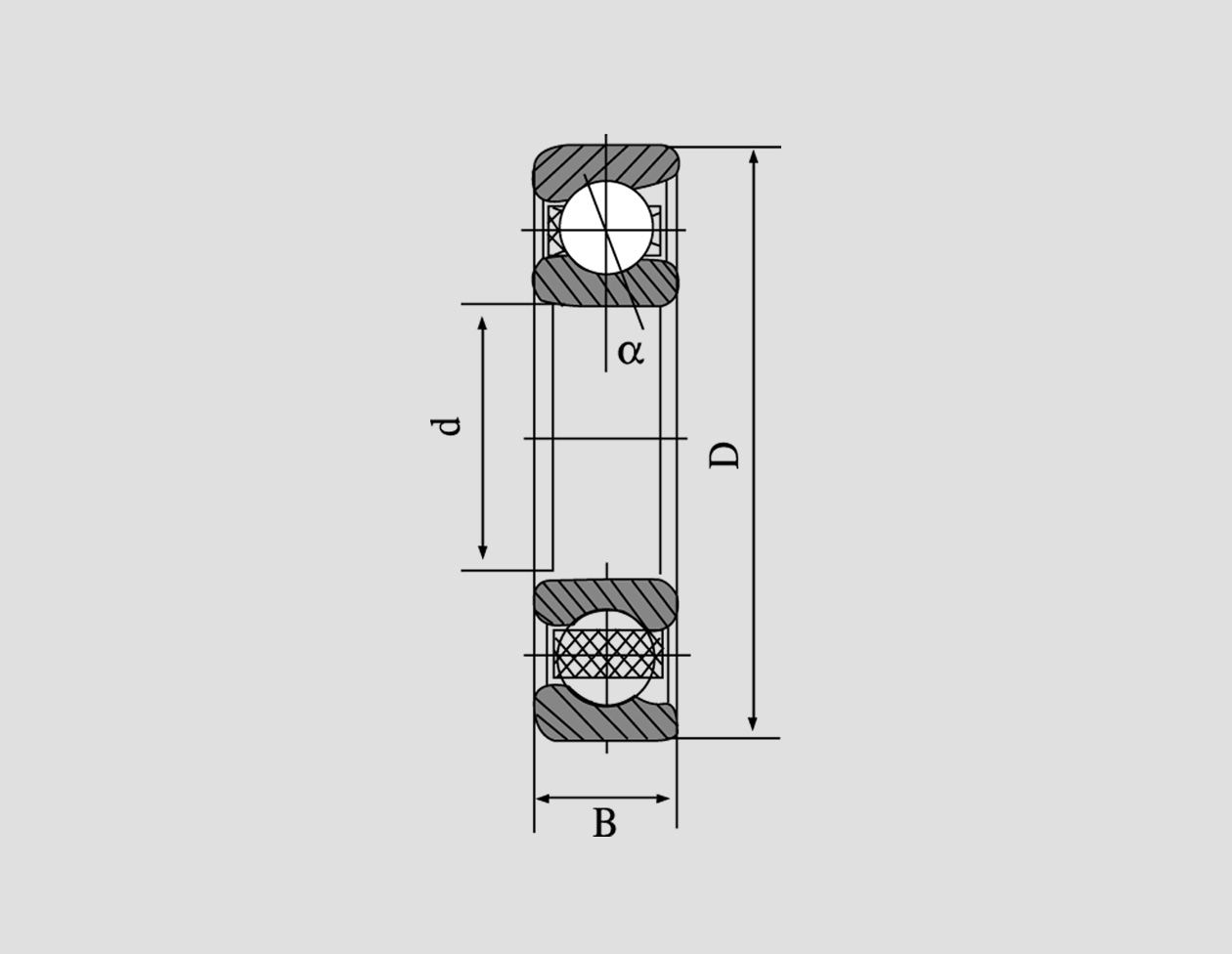

Thrust bearings, an essential component in mechanical systems, play a pivotal role in managing axial loads and ensuring smooth operation. These specialized bearings are designed to withstand forces that act parallel to the shaft, rather than radial loads which are perpendicular to it. The significance of thrust bearings lies in their capacity to handle high-speed rotating machinery, marine propulsion systems, and even everyday appliances where precision and stability are crucial.

- Construction and Heavy Equipment: Spherical roller bearings are used in construction machinery, including excavators, cranes, and compactors. Their robust design and ability to handle dynamic and static loads make them well-suited for the heavy-duty conditions found in construction and earthmoving equipment. In the automotive industry, SRDG ball bearings are instrumental in improving vehicle performance and fuel efficiency 3

In summary, the key difference between thrust ball bearings and radial ball bearings lies in the direction of the loads they are designed to support. Radial ball bearings primarily support radial loads, while thrust ball bearings are specifically designed to support axial loads. Each type of bearing is tailored to meet specific operational requirements and environmental conditions in diverse industrial applications.

* Pumps and compressors These bearings are used in pumps and compressors to ensure efficient operation and reduce wear and tear. One of the key features of the NN3020K bearing is its high precision and accuracy. This bearing is designed to operate at high speeds and can accommodate both radial and axial loads. The precision of the bearing ensures smooth and efficient operation, making it ideal for applications where precise motion control is essential. Overall, the 4T L44649 bearing is a versatile and reliable component that plays a crucial role in ensuring the smooth operation of various systems. Its high-quality materials, precision engineering, and durability make it a popular choice for a wide range of industries. Whether it is used in automotive, aerospace, construction, or manufacturing, this bearing delivers consistent performance and long-lasting results. The ID taper ratio, another critical aspect, determines the bearing's load distribution and performance

When selecting a taper roller bearing size, it is crucial to consider the application requirements, including the expected load, speed, and operating conditions. It is important to choose a bearing that can handle the specific demands of the application to ensure reliable performance and longevity.

When selecting a taper roller bearing size, it is crucial to consider the application requirements, including the expected load, speed, and operating conditions. It is important to choose a bearing that can handle the specific demands of the application to ensure reliable performance and longevity. The 6008 ball bearing is commonly used in electric motors, pumps, fans, and other machinery where precise rotational motion is required

6008 ball bearing. Its versatility and durability make it a popular choice among engineers and manufacturers looking for a reliable bearing solution.

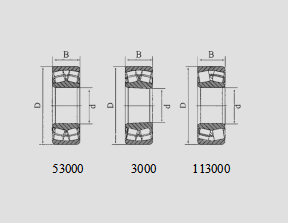

These three types of bearings play a crucial role in a wide range of machines and equipment, providing support for rotational and linear motion, reducing friction, and enabling the efficient and reliable operation of various mechanical systems across industries.

Roller thrust bearings are a crucial component in various mechanical systems, providing support against axial loads while allowing rotational movement. These specialized bearings are designed to handle heavy loads and high speeds, making them essential in industries such as construction, mining, and transportation. Overall, Fafnir angular contact ball bearings are a versatile and reliable choice for a wide range of applications. With their high-speed capability, load-bearing capacity, and durability, these bearings are ideal for demanding industrial environments where precision and performance are critical. Whether used in automotive transmissions, aircraft landing gear, or precision machining equipment, Fafnir angular contact ball bearings are a trusted solution for engineers and designers worldwide. * Renewable energy Wind turbines, hydroelectric generators, and other renewable energy systems that require reliable and efficient bearings. One of the key features of ball thrust bearings is their ability to support axial loads in a specific direction. This makes them ideal for applications where heavy loads need to be transmitted in a straight line, such as in gearboxes, automotive transmissions, and machine tool spindles. By utilizing the rolling action of the balls, ball thrust bearings can handle much higher loads than plain bearings or sleeve bearings. One of the most significant advantages of cylindrical roller bearings is their durability. They can operate under harsh conditions, including extreme temperatures and heavy vibration, without significant wear and tear. Additionally, they offer improved rigidity and resistance to misalignment due to their robust construction. The 6308 z Bearing A Revolutionary Innovation in Rotary SystemsPower generation plants, especially those involving turbines, heavily rely on cylindrical roller bearings due to their capacity to handle massive loads and operate under extreme temperatures

Overall, double-row full complement cylindrical roller bearings are a reliable and efficient solution for handling heavy loads in a variety of applications. Their ability to handle both radial and axial loads, combined with their high rigidity and durability, make them an ideal choice for many industrial applications. The town of Bearing, NJ, was originally settled in the 17th century by the Dutch and has since retained its historical charm. The Bearing Historical Society Museum, located in the heart of the town, showcases artifacts and documents dating back to the 17th century, providing visitors with a glimpse into the community's rich history. Ball bearings are essential components in a wide range of machinery, from household appliances to industrial equipment. Their primary function is to reduce friction between moving parts, which in turn increases efficiency, extends the life of the machine, and reduces maintenance costs. In the realm of mechanical engineering, precision bearings play a pivotal role in ensuring smooth operation and longevity of machinery. One such bearing that has garnered significant attention is the 6207 2RS. This unique identifier denotes a specific type of ball bearing, known for its exceptional performance and reliability. Next, the inner and outer diameters determine the bearing's fit within the housing or shaft

Overall, double-row full complement cylindrical roller bearings are a reliable and efficient solution for handling heavy loads in a variety of applications. Their ability to handle both radial and axial loads, combined with their high rigidity and durability, make them an ideal choice for many industrial applications. The town of Bearing, NJ, was originally settled in the 17th century by the Dutch and has since retained its historical charm. The Bearing Historical Society Museum, located in the heart of the town, showcases artifacts and documents dating back to the 17th century, providing visitors with a glimpse into the community's rich history. Ball bearings are essential components in a wide range of machinery, from household appliances to industrial equipment. Their primary function is to reduce friction between moving parts, which in turn increases efficiency, extends the life of the machine, and reduces maintenance costs. In the realm of mechanical engineering, precision bearings play a pivotal role in ensuring smooth operation and longevity of machinery. One such bearing that has garnered significant attention is the 6207 2RS. This unique identifier denotes a specific type of ball bearing, known for its exceptional performance and reliability. Next, the inner and outer diameters determine the bearing's fit within the housing or shaft One of the main advantages of four-row tapered roller bearings is their ability to handle high radial loads due to the increased number of rolling elements. Additionally, because the rollers can move along the length of the raceway, they can accommodate slight misalignments without causing damage to the bearing. This feature makes them particularly useful in situations where precision alignment might be challenging to maintain. Taper roller bearings are a type of rolling element bearing that is widely used in various industries due to its numerous advantages. These bearings consist of an inner ring, an outer ring, and a series of tapered rollers that are arranged between them. The unique design of these bearings allows for efficient operation under heavy loads and at high speeds.

One of the main advantages of four-row tapered roller bearings is their ability to handle high radial loads due to the increased number of rolling elements. Additionally, because the rollers can move along the length of the raceway, they can accommodate slight misalignments without causing damage to the bearing. This feature makes them particularly useful in situations where precision alignment might be challenging to maintain. Taper roller bearings are a type of rolling element bearing that is widely used in various industries due to its numerous advantages. These bearings consist of an inner ring, an outer ring, and a series of tapered rollers that are arranged between them. The unique design of these bearings allows for efficient operation under heavy loads and at high speeds. Moreover, the 6312 zz bearing offers a competitive edge in terms of installation and replacement ease. Its design allows for simple insertion into housings and removal when necessary, minimizing downtime and potential damage during maintenance procedures. The Unparalleled Performance of 33895 Bearing A Revolution in Mechanical Engineering It's crucial to note that the size chart serves as a reference tool; actual bearing selection should consider factors such as operating speed, lubrication conditions, and environmental factors. Always consult the manufacturer's recommendations for specific applications to ensure the correct bearing choice.