Links:

-

It is important to regularly inspect and maintain the trunk weather stripping to ensure that it is functioning properly. Over time, weather stripping can become worn or damaged, leading to gaps that allow water and debris to enter the trunk. By checking the weather stripping regularly and replacing it when necessary, you can help to keep your trunk and vehicle in top condition. One of the main functions of rubber car door seal strips is to prevent water from seeping into the interior of the car during rain or car washes. Without these strips, water can easily enter through the gaps around the doors and windows, leading to damp carpets, musty odors, and potential damage to electronic components. The rubber material used in these strips is designed to create a watertight seal, ensuring that the interior of the car remains dry even in wet conditions.

The Importance of Self-Adhesive Foam Seals in Modern Applications

In addition to keeping out drafts and noise, door seals can play a crucial role in pest control. Small insects, rodents, and other pests can find their way through even the smallest gaps around your door. By sealing these openings, you create a barrier that can help prevent infestations, reducing the need for chemical pest control methods. This is particularly important for families with pets or children, where safety is a prime concern.

The Importance of Mechanical Seal Dimensions

Mechanical seals play a crucial role in the operation of oil pumps across various industrial applications. They are designed to prevent leaks between rotating and stationary components, ensuring the efficient conveyance of oil without loss of pressure or contamination from external environments. As modern technology progresses, the design and functionality of mechanical seals in oil pumps continue to evolve, enhancing performance and reliability.

Easy Installation and Maintenance

Conclusion

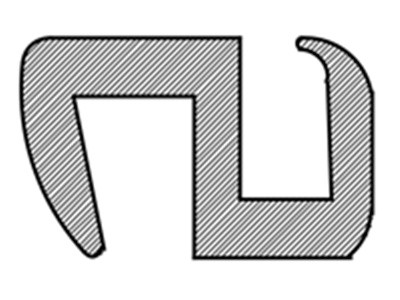

One of the main functions of glass edge rubber is to provide a watertight seal around the edge of the glass, preventing water leakage and damage. This is especially important in automotive applications, where a leak in the windshield or windows can lead to water damage inside the vehicle. Glass edge rubber is also used to protect the edges of glass from damage, such as chipping or cracking, which can occur from contact with other materials or from impact.

The Unsung Hero of Vehicle Safety The Rubber Strip Under Your Car During heavy rain or snow, the weather seal car prevents water from seeping into the interior of your vehicle, keeping it dry and comfortable. Without a proper seal, the interior of your car can become damp and musty, leading to mold and mildew growth. This can not only cause unpleasant odors but also damage the upholstery and electronics of your car.

Mechanical seals are critical components in various rotating equipment, ensuring that fluids do not leak between stationary and rotating parts. Among the various types of mechanical seals, the Type 2021 is widely used due to its reliability and effectiveness in different applications. This article will delve into the dimensions and design considerations of the Type 2021 mechanical seal, which can be crucial for engineers and maintenance professionals working with pumps, compressors, and other machinery.

4. Measure and Cut New Rubber Measure the dimensions of the window frame and cut the new rubber weather stripping to size.

One of the primary benefits of self-adhesive foam weatherstrip seals is their ability to improve energy efficiency. Homes lose a significant amount of heating and cooling through gaps and cracks. By applying these weatherstrips, homeowners can reduce their energy costs by ensuring that their heating and cooling systems do not have to work harder to maintain the desired temperature. According to the U.S. Department of Energy, sealing gaps and cracks can lead to energy savings of up to 20%.

In today's busy world, noise pollution is a common concern for many. A door bottom sealing strip guard can help reduce the transmission of sound between rooms or from outside. By filling those gaps, these strips create a more tranquil indoor environment, making it easier for families to relax and enjoy time together without distractions from the outside world.

1. Gather Your Tools You will need a utility knife, a flathead screwdriver, new rubber weather stripping (sized correctly for your windows), and a cleaning solution.

Foam weather seals also have a long lifespan, often lasting several years before needing replacement. This durability makes them a worthwhile investment for any homeowner looking to enhance energy efficiency. When combined with other energy-saving measures, such as proper insulation and energy-efficient windows, the effectiveness of foam seals can be maximized.

Advantages of Proper Sealing

The Art of Black Foam Window Seal Aesthetics Meets Efficiency

Conclusion

2. Disassembly Start by removing the pump's outer casing and any associated components to gain access to the mechanical seal. Take care to mark or tag components to ensure correct reassembly.

Conclusion

Exterior door weather seals play a crucial role in protecting your home from the elements. These seals serve as a barrier between your home's interior and the outdoor environment, helping to keep out drafts, water, insects, and noise. By properly installing and maintaining your exterior door weather seal, you can ensure that your home remains comfortable and energy-efficient year-round. To ensure the effectiveness of foam tape, it is important to regularly inspect and replace any worn or damaged strips. Over time, the adhesive backing may weaken, causing the tape to lose its seal. By checking the condition of your foam tape regularly, you can maintain a tight seal around your doors and windows, maximizing energy efficiency and comfort in your home. In essence, the window seal strip rubber represents a small but vital aspect of architectural detailing. Its simple presence ensures comfort, efficiency, and often goes unnoticed until its absence is felt. As we look to our homes and buildings, let us not forget to appreciate the silent guardians that keep our interiors comfortable and dry, one strip of rubber at a time.

In today’s fast-paced world, innovation continually emerges across various industries, leading to the development of a multitude of materials tailored for specific needs. One such remarkable innovation is the self-adhesive silicone strip. This versatile product has garnered attention across multiple fields, ranging from home improvement and automotive applications to electronics and healthcare.

Black foam weather stripping is a versatile and cost-effective solution for sealing gaps around doors and windows to prevent drafts and save on energy costs. This type of weather stripping is made from closed-cell foam that is both durable and easy to install.

Versatility and Applications

- Material Choose a durable material that can withstand various weather conditions. Rubber and metal are popular for their longevity and effectiveness.

Like any other component of a vehicle, weather seals are subject to wear and tear over time. Factors such as ultraviolet (UV) exposure, extreme temperatures, and mechanical stress can degrade the material. Here are some common signs that your car's window weather seals may need attention

A door foam strip is a flexible, adhesive-backed material designed to seal gaps around doors. Made from various types of foam, these strips come in different sizes and thicknesses to accommodate various door frames and gaps. They are engineered to compress and expand, ensuring a tight fit that minimizes air leakage and moisture entry.

3. Easy Installation Most foam insulation strips come with adhesive backing, making them simple to install without the need for professional assistance. Homeowners can complete the task in a matter of minutes, enhancing their homes with minimal effort.

Additionally, rubber seals contribute to energy efficiency in vehicles equipped with climate control systems. A good seal around the door frame helps maintain the desired interior temperature by preventing heated or cooled air from escaping. This efficiency not only enhances comfort but also reduces the load on the vehicle’s heating and cooling systems, potentially improving fuel efficiency and lowering emissions. In an era focusing on sustainability, maintaining energy efficiency in vehicles is more important than ever.

2. Versatility The 50mm foam tape is suitable for a wide range of materials, including wood, metal, glass, plastic, and more. This versatility makes it an ideal choice for crafts, construction, automotive applications, and even everyday household tasks.

In addition to providing protection, metal edge protection strips also enhance the overall appearance of the materials they are applied to. They come in a variety of finishes, including chrome, brushed aluminum, and black, which can complement the design of the materials and add a touch of sophistication to the finished product

metal edge protection strip. Furthermore, metal edge protection strips can be customized to fit specific dimensions and shapes, making them suitable for a wide range of applications.

Dry mechanical seals represent a significant advancement in sealing technology, offering enhanced reliability, efficiency, and lifespan in various applications. As industries continue to evolve and face increasing demands for safety and efficiency, the importance of dry mechanical seals is likely to grow. As a result, engineers and operators should remain informed about advancements in seal technology to leverage the benefits of dry mechanical seals effectively.

Benefits of Adhesive Door Weather Stripping

5. Regular Maintenance Periodically check the weather stripping for wear and tear, replacing damaged sections as needed to maintain effectiveness.

4. Spray Paint For a smooth, even finish, spray paint can be a great option. However, it's important to follow up with a sealant to protect the surface.

sealing cabinet paint

Signs of Deterioration

In today's world, energy efficiency and comfort are at the forefront of homeowners' concerns. One often-overlooked aspect of maintaining a comfortable and energy-efficient home is the proper sealing of doors. Door sealing strips play a crucial role in preventing drafts, moisture intrusion, and energy loss, making them an essential component of any home's weatherproofing strategy.

Car maintenance involves numerous components that contribute to the overall performance and longevity of a vehicle. One aspect that often goes overlooked is the door seal and rubber beading, essential elements that play a vital role in ensuring a comfortable and safe driving experience. This article delves into the significance of door seals and rubber beading, their functions, and how to maintain them for optimal performance.

In addition to keeping water out, weather stripping also helps to insulate the interior of the vehicle from outside temperature fluctuations. By creating a barrier between the interior and exterior of the car, weather stripping helps to keep the cabin comfortable and maintain a consistent temperature. This is especially important in extreme weather conditions, such as hot summers or cold winters, where a properly sealed car can help to save on energy costs by reducing the need for heating or air conditioning.

Moisture Resistance

One common type is the compression weatherstripping, typically made from vinyl or rubber. This versatile option relies on pressure to seal gaps between the door and the frame. Installation is straightforward, often involving a self-adhesive backing that secures it to the door jamb. The compression strip's effectiveness is proportional to the force applied when closing the door, making it an economical choice for moderate climates where extreme temperatures are less of a concern.

4. Pest Prevention Sealing your doors with weather strips can also act as a deterrent to insects and other pests looking for entry points into your home. By minimizing gaps, you reduce the likelihood of infestations, ultimately promoting a healthier living space.

Given the critical nature of mechanical seals, quality assurance is paramount. Mechanical seal companies adhere to stringent quality control processes to ensure that their products meet international standards. Many companies obtain certifications such as ISO 9001, which demonstrates their commitment to producing high-quality products. Additionally, they often invest in state-of-the-art testing equipment to validate the performance and reliability of their seals under various conditions.

The Importance of Expandable Foam Weatherseal for Doors

Moreover, the durability of these seals is commendable

self adhesive flexible seal. They are designed to withstand extreme temperatures, UV exposure, and various chemicals, ensuring long-lasting performance in harsh environments. From automotive applications to marine uses, and from construction sites to electronics manufacturing, their resilience makes them a top choice for sectors that demand reliability.

self adhesive flexible seal. They are designed to withstand extreme temperatures, UV exposure, and various chemicals, ensuring long-lasting performance in harsh environments. From automotive applications to marine uses, and from construction sites to electronics manufacturing, their resilience makes them a top choice for sectors that demand reliability. What Is Foam Weather Stripping?