Links:

-

In conclusion, masonry tie-backs are more than just anchoring devices; they are silent guardians of structural integrity. They provide the necessary stability, especially in masonry structures, which might otherwise succumb to external forces. As we continue to push the boundaries of architectural design, the role of masonry tie-backs will only grow in importance, ensuring our buildings stand tall and strong against the tests of time and nature. Plaster beading, a traditional craft that has been practiced for centuries, is enjoying a resurgence in popularity. This delicate and intricate art form involves creating intricate designs using small pieces of plaster or gypsum, which are then attached to a surface to create a decorative effect. Furthermore, plastic render corner beads come in a variety of profiles and finishes, catering to diverse architectural preferences. From rounded edges for a softer look to more angular designs for a contemporary aesthetic, there is a bead suitable for every project. They can also be painted to match the final render color, ensuring a cohesive and professional finish.

The first step in designing a compression spring is to determine the required spring rate, which is the amount of force required to compress the spring a certain distance. This calculation is based on the load requirements of the application and the expected deflection of the spring. By knowing the required spring rate, engineers can calculate the wire diameter, number of coils, and free length of the spring to achieve the desired performance. In technical terms, the spring constant (k) represents the force required per unit length to extend the spring. It is determined by the material properties, the diameter of the wire, the number of coils, and the coil pitch. The spring's extension (x) can be calculated using the formula F = k * x, where F is the force applied.

Ladder joint reinforcement is a crucial component in ensuring the stability and strength of a structure. This type of reinforcement is typically used in masonry construction to enhance the overall durability of a wall by providing additional support at the joints.

When selecting a welded mesh supplier, it's important to consider several factors Another advantage of woven metal mesh is its versatility

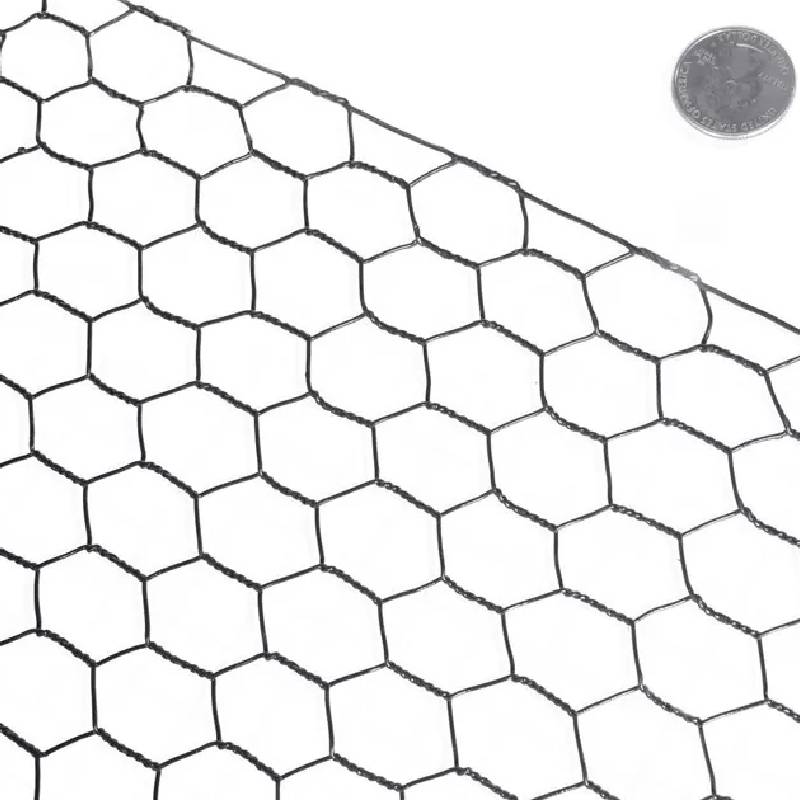

woven metal mesh. The material can be customized in terms of wire thickness, weave pattern, and finish to meet the specific requirements of a project. This allows architects and designers to create unique and innovative designs that are tailored to their needs. One of the key advantages of rotary springs is their ability to store and release energy in a controlled manner. When a rotary spring is wound up, it stores potential energy that can be released gradually as the spring unwinds. This allows for smooth and continuous rotation, which is important for many applications where jerky or abrupt movements would be problematic. In conclusion, the strategic use of bulk stakes can be a powerful tool for online gamers seeking to enhance their performance and achieve greater success. By harnessing the benefits of increased control, financial advantages, and psychological motivation, players can gain a competitive edge and enjoy a more fulfilling gaming experience. However, it is crucial to approach this tactic with caution and to always prioritize responsible financial management. In addition to their durability, brick mesh walls are also highly versatile. They can be customized to fit any design aesthetic, whether you prefer a more traditional look or a modern and sleek appearance. The bricks come in a variety of colors, sizes, and textures, allowing for endless design possibilities. In addition to their aesthetic appeal, black wire panels are also extremely functional. They can be used in a variety of ways, from creating partitions in open-concept spaces to serving as decorative elements on walls or ceilings. Their sturdy construction means that they can support heavy objects, making them a practical choice for both decorative and practical applications. Gardening is an enjoyable and rewarding activity that allows individuals to connect with nature, grow their own food, and enhance the aesthetic appeal of their outdoor spaces. However, achieving optimal gardening results requires the use of high-quality tools and materials. One such essential item is garden wire, which is used for various purposes such as supporting plants, creating boundaries, and managing pests. In this article, we will discuss the benefits of using 1.6mm garden wire for effective gardening. PVC coated galvanized wire, a versatile material, is widely used in various applications due to its unique properties. This type of wire is made by coating a layer of polyvinyl chloride (PVC) over a galvanized steel core. The zinc coating on the steel provides corrosion resistance, while the PVC coating offers additional protection against weathering, UV radiation, and chemical exposure. Innovative designs like foldable cages are another affordable option to explore. These cages collapse flat when not in use, making storage and transportation effortless. They often come with user-friendly handles and are lightweight, yet sturdy enough to handle the heaviest of tomato plants. In conclusion, welded wire mesh sheets are a highly adaptable and resilient material with a wide range of applications. Their strength, versatility, and customization options make them a preferred choice in construction, agriculture, industry, and architecture. As technology advances, we can expect even more innovative uses for this indispensable engineering marvel. Despite its affordability, wholesale chicken wire fencing is still highly effective at keeping animals contained. The small mesh size prevents animals from squeezing through or getting caught in the fence, while the galvanized steel construction resists rust and corrosion, ensuring the longevity of the fencing even in harsh weather conditions

wholesale chicken wire fencing. In architectural applications, diamond wire mesh serves as a decorative element, adding a modern and sophisticated touch to facades, interior partitions, and even furniture designs. Its transparency allows for unobstructed views while providing a sense of privacy and security. The mesh can be coated in different colors, further enhancing its visual impact. The primary function of brick ties is to transfer horizontal loads from the outer leaf to the inner leaf of the cavity wall. This is critical during high wind conditions or seismic activities, as they prevent the outer leaf from being blown out or collapsing. They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability

They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability

They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability what do brick ties do. One of the primary uses of galvanized iron wire is in construction. It is commonly used as reinforcement in concrete structures, such as rebar in concrete slabs and beams, to increase their strength and durability. The zinc coating on the wire prevents rusting, which can weaken the concrete over time. Additionally, galvanized iron wire is also used in the installation of fences, gates, and other outdoor structures due to its resistance to corrosion and durability. Brick ladder reinforcement is a popular technique used in the construction of brick walls to enhance structural stability and increase load-bearing capacity. This method involves embedding horizontal rows of steel bars or wires at regular intervals within the brickwork to prevent cracking and improve overall durability. The reinforcement is placed between layers of bricks and mortar, creating a ladder-like structure that adds strength to the wall. How to Implement Truss Type Reinforcement in Masonry Construction 1. Heating Rate The rate at which the wire is heated can affect its microstructure and properties. Slow heating allows the wire to achieve a more uniform temperature distribution, resulting in better quality. - **Case Study 2 Architecture Photography** - An architectural photographer uses wire grid photo display to highlight the structure and design of a building, creating a striking visual representation of the space. Moreover, bulk compression springs are also employed in everyday items such as mattresses, where they provide support and comfort, and in watches, where they power the timekeeping mechanism. They are also crucial in industrial settings, such as in presses and lifts, where they manage and control the force applied. One of the main advantages of chain link security fences is their strength and durability. The steel wires used in these fences are designed to withstand harsh weather conditions, impacts, and attempts to breach the fence. This makes them an effective barrier for keeping intruders out and preventing unauthorized access to a property. Cheap chicken wire mesh is also utilized in construction projects for reinforcement and support. Its lightweight design makes it easy to handle and install, while its strength and durability make it an effective material for reinforcing concrete, plaster, and other building materials

what do brick ties do. One of the primary uses of galvanized iron wire is in construction. It is commonly used as reinforcement in concrete structures, such as rebar in concrete slabs and beams, to increase their strength and durability. The zinc coating on the wire prevents rusting, which can weaken the concrete over time. Additionally, galvanized iron wire is also used in the installation of fences, gates, and other outdoor structures due to its resistance to corrosion and durability. Brick ladder reinforcement is a popular technique used in the construction of brick walls to enhance structural stability and increase load-bearing capacity. This method involves embedding horizontal rows of steel bars or wires at regular intervals within the brickwork to prevent cracking and improve overall durability. The reinforcement is placed between layers of bricks and mortar, creating a ladder-like structure that adds strength to the wall. How to Implement Truss Type Reinforcement in Masonry Construction 1. Heating Rate The rate at which the wire is heated can affect its microstructure and properties. Slow heating allows the wire to achieve a more uniform temperature distribution, resulting in better quality. - **Case Study 2 Architecture Photography** - An architectural photographer uses wire grid photo display to highlight the structure and design of a building, creating a striking visual representation of the space. Moreover, bulk compression springs are also employed in everyday items such as mattresses, where they provide support and comfort, and in watches, where they power the timekeeping mechanism. They are also crucial in industrial settings, such as in presses and lifts, where they manage and control the force applied. One of the main advantages of chain link security fences is their strength and durability. The steel wires used in these fences are designed to withstand harsh weather conditions, impacts, and attempts to breach the fence. This makes them an effective barrier for keeping intruders out and preventing unauthorized access to a property. Cheap chicken wire mesh is also utilized in construction projects for reinforcement and support. Its lightweight design makes it easy to handle and install, while its strength and durability make it an effective material for reinforcing concrete, plaster, and other building materials

cheap chicken wire mesh. When working with garden wire, it is important to choose a high-quality product that is both durable and easy to work with. The 1.2mm size is a good option for most gardening tasks, as it strikes a balance between strength and flexibility. Additionally, make sure to wear gloves when handling the wire to protect your hands from sharp edges and potential injuries. Factors Affecting Cattle Panel Fence Price Black welded wire fencing is also an effective security solution for properties of all sizes. The sturdy construction of the fencing makes it difficult for intruders to breach, providing peace of mind for property owners looking to protect their assets. Additionally, the open design of the fencing allows for visibility, making it easy to monitor the perimeter of your property and detect any potential security threats. Conclusion One of the key benefits of stock torsion springs is their versatility. They can be easily adapted to suit different needs by adjusting the number of coils, the wire diameter, and the material used in their construction. This flexibility makes them a popular choice for engineers and designers looking for a reliable and cost-effective solution for their projects. Metal grid display boards are versatile and stylish tools that can be used in a variety of settings, from retail stores to craft fairs to home offices. These boards consist of a metal grid with evenly spaced holes that allow for easy hanging of various items such as photos, artwork, and small shelves. codersetTimeBase(new Rational(1, 25)); Moreover, metal rib lath contributes significantly to energy efficiency. Its reflective properties help to minimize heat transfer, thereby assisting in maintaining consistent indoor temperatures. This can lead to reduced energy consumption and lower utility bills for homeowners and building occupants.

Coil Springs for Sale Understanding Their Importance and Selection Criteria There are several types of wide cavity wall ties available on the market, each with its own unique characteristics and applications. Some of the most common types include In addition to their security benefits, metal chain link fences are also very low maintenance. Unlike wooden fences that require periodic painting or staining, metal chain link fences only need occasional cleaning to keep them looking new. This makes them a cost-effective option for property owners who want a long-lasting fence that requires minimal upkeep. However, it's important to note that proper staking technique is vital. Overstressing the plant by tying it too tightly can be detrimental. The tie should be loose enough to allow some movement, mimicking natural swaying, which strengthens the stem over time. Regular monitoring and adjusting of ties as the plant grows are necessary. Construction Industry Ease of Use Small compression coil springs, often overlooked, play an indispensable role in our daily lives and across a multitude of industries. These compact, yet powerful components are the unsung heroes of engineering, providing essential functionality in various devices and mechanisms. In addition to its corrosion resistance and electrical insulation properties, PVC coated iron wire is also highly durable

GI welded mesh manufacturers are vital players in the construction industry, providing high-quality materials for various applications

. GI welded mesh, also known as galvanized welded mesh, is a popular choice for construction projects due to its durability, strength, and corrosion resistance.Secondly, concrete mesh wire is incredibly flexible, allowing it to be easily shaped and molded to fit any size or shape required. This makes it perfect for use in complex projects where traditional materials may struggle to conform to the desired specifications. Whether you need to create intricate patterns or simply need a reliable solution for reinforcing walls or floors, concrete mesh wire is up to the task. In the world of mechanical engineering, the conical extension spring is a remarkable piece of equipment that has revolutionized the way forces are absorbed and released in various applications. This unique type of spring, characterized by its tapering coils that decrease in diameter from one end to the other, offers several advantages over traditional cylindrical springs. The 200mm cavity wall also offers acoustic advantages. The separation between the two leaves dampens sound transmission, providing a quieter living or working environment. Additionally, it provides a degree of fire resistance, as the cavity can inhibit the spread of flames between rooms or floors. Jewelry making is an art form that combines creativity with precision, and at the heart of this craft lies the importance of quality materials. Wholesale wire for jewelry making stands out as a fundamental component, offering artists a myriad of possibilities to express their vision. This versatile material comes in various types, gauges, and finishes, each serving a unique purpose in the realm of handmade adornments.