Current location:

Links:

- 3’ x 10’ In the realm of modern engineering and construction, Fiberglass Reinforced Pipes (FRP) have emerged as a revolutionary material due to their exceptional strength-to-weight ratio and corrosion resistance. This innovative technology has transformed the way pipelines are designed, manufactured, and implemented across various industries.

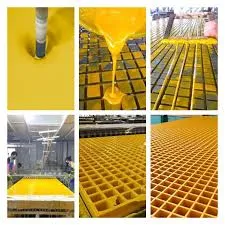

- Safety surface: Molded Grating offers an outstanding skid-resistant concave surface as an option. A molded-in grit surface is also available to provide sure footing for worker safety, yet its non-porous qualities help eliminate bacterial breeding areas in food applications. Hand held jack hammers are powerful and versatile tools that are used in a variety of construction and demolition projects. These compact machines pack a punch when it comes to breaking through tough materials like concrete, asphalt, and rock. With their portable design, hand held jack hammers are an essential tool for workers who need to access tight or hard-to-reach spaces. In conclusion, the pneumatic drilling machine is more than just a tool; it's a testament to human ingenuity and the power of applied physics. Its effectiveness, versatility, and safety features make it an indispensable asset in drilling and mining operations worldwide. As technology continues to evolve, we can expect even more advanced versions of this machinery, further enhancing productivity and safety in these sectors. The Versatility and Benefits of Fiberglass Tanks

- Lightweight Materials: The FRP grating is light in weight, with a specific gravity of only 1.9, which is equivalent to 1/4 of that of steel. Therefore, the transportation cost is lower and the installation speed is faster. One of the most significant advantages of FRP fittings is their exceptional resistance to corrosion. Unlike traditional metal piping components, which can erode over time when exposed to certain chemicals or moisture, FRP maintains its integrity even in the harshest environments. This attribute not only extends the lifespan of the fitting but also reduces maintenance costs and potential downtime associated with replacements. Understanding the Functionality and Importance of FRP Demisters in Industrial Processes The roots of rock drilling can be traced back to ancient civilizations, where primitive methods such as pounding and fire were used to break through solid rock. These methods were labor-intensive and slow, limiting the scale of excavations. However, they laid the foundation for future developments in drilling technology.

- Proyek Infrastruktur: FRP grating dapat digunakan di proyek infrastruktur seperti jembatan, trotoar, tangga, dan platform pejalan. HI-Grid FRP Grating memberikan kekuatan dan tahan korosi yang tinggi, dan ringan. HI-Grid FRP Grating juga memiliki sifat anti-slip yang penting untuk menjaga keselamatan pengguna. The drill motor, or hammer, is the powerhouse of the rock drill. It generates the force needed to drive the bit into the rock. In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

Lightweight

But this grating may only be ideal for some kinds of construction projects. So you will want to understand fiberglass grating and how FRP grating is often used.

Implications of Anchor Bar Bits When choosing a 34mm drill bit, quality is paramount. Look for bits made from high-speed steel (HSS), which offers excellent heat resistance and durability, ensuring a longer lifespan. Alternatively, carbide-tipped bits provide enhanced hardness and resistance against wear, making them ideal for drilling through abrasive materials. The rectangular shape of FRP tubes provides several advantages over traditional round pipes. Primarily, they optimize space utilization, making them particularly suitable for applications where width is more critical than depth. For instance, in structural support systems, HVAC ducting, or electrical conduit systems, the rectangular design allows for better alignment and fitting within confined spaces. Fiberglass ducts, an innovative solution in the realm of heating, ventilation, and air conditioning (HVAC) systems, have gained significant traction due to their numerous benefits. This material, composed primarily of glass fibers bonded together with a resin matrix, offers a versatile and efficient option for managing air flow in buildings.  In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency rock drill parts. The Role of Fiberglass in Modern Mining Equipment Fiberglass Products for Steel Smelting Plants A Comprehensive Guide Furthermore, the global nature of the industry means that shank adapter manufacturers often operate on a worldwide scale. They maintain supply chains that reach every corner of the globe, ensuring that no matter where a construction site or factory is located, they can provide the necessary adapters promptly. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants.

rock drill parts. The Role of Fiberglass in Modern Mining Equipment Fiberglass Products for Steel Smelting Plants A Comprehensive Guide Furthermore, the global nature of the industry means that shank adapter manufacturers often operate on a worldwide scale. They maintain supply chains that reach every corner of the globe, ensuring that no matter where a construction site or factory is located, they can provide the necessary adapters promptly. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants.

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency rock drill parts. The Role of Fiberglass in Modern Mining Equipment Fiberglass Products for Steel Smelting Plants A Comprehensive Guide Furthermore, the global nature of the industry means that shank adapter manufacturers often operate on a worldwide scale. They maintain supply chains that reach every corner of the globe, ensuring that no matter where a construction site or factory is located, they can provide the necessary adapters promptly. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants.

rock drill parts. The Role of Fiberglass in Modern Mining Equipment Fiberglass Products for Steel Smelting Plants A Comprehensive Guide Furthermore, the global nature of the industry means that shank adapter manufacturers often operate on a worldwide scale. They maintain supply chains that reach every corner of the globe, ensuring that no matter where a construction site or factory is located, they can provide the necessary adapters promptly. Inside the cabin, the GRP 20 Car offers a futuristic blend of luxury and functionality. The minimalist interior, with its ergonomic seating and intuitive touchscreen interface, provides an immersive driving experience. The use of eco-friendly materials complements the car's green credentials, while the spaciousness and comfort ensure a serene journey for all occupants. The key advantage of using FRP in pipeline architecture is its ability to handle events and state changes in a more deterministic and predictable manner. With FRP, changes in input automatically propagate through the pipeline, updating the output without requiring explicit control flow. This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical

This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical frp pipeline. In conclusion, CPVC and FRP pipes have revolutionized the piping sector with their unique properties and wide range of applications. From residential plumbing to complex industrial infrastructure, these pipes provide a sustainable and efficient solution for fluid transportation. As technology advances, the use of CPVC-FRP composite pipes is expected to expand further, addressing the challenges of modern piping systems while ensuring safety, reliability, and cost-efficiency.

frp pipeline. In conclusion, CPVC and FRP pipes have revolutionized the piping sector with their unique properties and wide range of applications. From residential plumbing to complex industrial infrastructure, these pipes provide a sustainable and efficient solution for fluid transportation. As technology advances, the use of CPVC-FRP composite pipes is expected to expand further, addressing the challenges of modern piping systems while ensuring safety, reliability, and cost-efficiency.

This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical

This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical This 'reactive' behavior makes it ideal for real-time systems, where responsiveness and efficiency are critical frp pipeline. In conclusion, CPVC and FRP pipes have revolutionized the piping sector with their unique properties and wide range of applications. From residential plumbing to complex industrial infrastructure, these pipes provide a sustainable and efficient solution for fluid transportation. As technology advances, the use of CPVC-FRP composite pipes is expected to expand further, addressing the challenges of modern piping systems while ensuring safety, reliability, and cost-efficiency.

frp pipeline. In conclusion, CPVC and FRP pipes have revolutionized the piping sector with their unique properties and wide range of applications. From residential plumbing to complex industrial infrastructure, these pipes provide a sustainable and efficient solution for fluid transportation. As technology advances, the use of CPVC-FRP composite pipes is expected to expand further, addressing the challenges of modern piping systems while ensuring safety, reliability, and cost-efficiency. Available in both square and grid patterns, fiberglass grating is widely used due to its low maintenance cost combined with unmatched resilience. Unlike metal gratings, which in certain environments can require extended product life cycle; fiberglass grating is corrosion and rust free, making it more cost effective. Chemical attacks are also not an issue with fiberglass gratings, ensuring its durability. Ideal for the corrosive environment, FRP gives it the complete value for the money.

It is important to note that carbide tipped drill bits require special handling and maintenance to ensure their longevity and performance. When using these drill bits, it is important to use them at the correct speed and pressure to prevent the carbide tip from chipping or breaking. It is also essential to regularly clean and sharpen the drill bits to maintain their cutting ability. The byproducts of FGD, such as gypsum, can often be recycled and used in products like wallboard or concrete, promoting a more sustainable approach. However, the disposal of these byproducts also requires careful management to prevent environmental impacts. The visual appeal of fiberglass steps should not be underestimated