Links:

-

One of the key benefits of using 35mm collated drywall screws is their length. Measuring at 35mm, these screws are the perfect size for securing drywall to wood or metal studs without penetrating through the surface of the drywall. This helps to prevent damage to the drywall and ensures a clean and professional finish.

Conclusion

Applications

Moreover, expansion anchor plastics are lightweight and easy to handle, simplifying the installation process. Their non-magnetic property also makes them suitable for use in environments where metal objects could interfere with electrical or magnetic fields. Additionally, their plastic composition allows for some flexibility, accommodating slight variations in hole size and surface irregularities.

3. Strong Bond The threading on a self-drilling screw provides a robust hold that is often superior to that of standard screws, particularly in metal applications.

In conclusion, self-tapping screws with neoprene washers represent an essential component in modern fastening technologies. Their combined benefits of ease of use, effective sealing, and vibration resistance make them a reliable choice for many applications across different industries. As technology progresses and materials continue to evolve, the demand for efficient and durable fastening solutions like self-tapping screws with neoprene washers will undoubtedly grow, proving their significance in both everyday tasks and specialized industrial applications. Whether you're a contractor, engineer, or DIY enthusiast, understanding the advantages of these fasteners can lead to better project outcomes and increased reliability in your work.

In conclusion, the M12 chemical anchor is a powerful tool in the construction arsenal, offering a secure and adaptable solution for various fastening needs. Its chemical bonding mechanism, combined with its medium-sized M12 threading, makes it a popular choice for engineers and contractors worldwide. However, its successful implementation requires a deep understanding of the process, materials, and site-specific conditions. As technology advances, we can expect even more innovative developments in chemical anchor technology, further enhancing the efficiency and safety of construction projects. When selecting resin anchors for blockwork, there are several factors to consider. These include the size and type of the anchor, the load it can support, the substrate it will be installed in, and the environmental conditions it will be subjected to. It is essential to choose the right type of anchor for the specific requirements of your project. In addition to their strength and reliability, resin anchor bolts are also highly versatile. They come in a variety of sizes and configurations to suit different project requirements. Some bolts are designed for use in high-load applications, while others are better suited for anchoring lightweight materials. This versatility makes resin anchor bolts a popular choice for a wide range of construction and engineering projects.

In the construction and engineering industries, the importance of fasteners cannot be overstated. Among the various types of fasteners available, A325 fasteners are particularly notable due to their strength and reliability in heavy-duty applications. This article will explore what A325 fasteners are, their specifications, applications, and why they are essential for maintaining structural integrity.

4. Reduced Vibration and Shock Sensitivity Since they engage with the substrate through adhesive rather than mechanical means, they tend to be less sensitive to vibrations and shock loads.

Self-Drilling Screw Dia 6 x 20 mm Truss Screw A Comprehensive Guide Thirdly,the thickness of the material is also an important factor to consider when selecting the correct wedge, bolt, and drill size Cross bracing, as the name suggests, involves the strategic placement of diagonal steel members within a structure, forming an 'X' or 'H' pattern. This configuration creates a tension-compression system that enhances the overall rigidity and resistance to lateral forces such as wind, earthquakes, or even the dynamic loads of machinery in industrial settings. The primary function of steel cross bracing is to provide lateral stability. By transferring forces from horizontal elements to vertical ones, it counteracts any attempts at deformation, thereby maintaining the structural integrity. In high-rise buildings or tall towers, where wind loads can be significant, cross bracing acts like a spring, absorbing and dispersing energy to prevent swaying.

The T-head screw is a testament to innovative engineering in fasteners, combining strength, versatility, and ease of use. Its unique design makes it ideal for a variety of applications, from construction and automotive to machinery. While there are some challenges associated with their use, the advantages often outweigh the drawbacks, solidifying the T-head screw's place as a vital component in modern engineering. As industries continue to evolve and demand more reliable fastening solutions, T-head screws will undoubtedly remain a cornerstone in the world of construction and manufacturing.

- Automotive In automotive assembly, they are used to fasten body panels and components, providing durability and resistance to vibration.

In conclusion, the ribbed wafer head represents a significant step forward in the field of semiconductor manufacturing. Its ability to improve heat transfer efficiency, enhance uniformity, and compatibility with existing equipment make it an attractive option for manufacturers looking to stay ahead of the competition. As the demand for smaller, faster, and more powerful devices continues to grow, the ribbed wafer head is sure to play a crucial role in shaping the future of the semiconductor industry. When it comes to construction and DIY projects, having the right tools and equipment is essential to ensure a job well done. One important component in any project involving wood or metal is the use of screws to securely fasten materials together. One type of screw that is commonly used in these projects is the 4% tek screw.

2. Versatility Butterfly screws can be used in various wall types, including drywall, concrete, and even plaster. This versatility makes them an ideal choice for different installation needs.

To mitigate the risk of loose anchor bolts, several preventive measures can be implemented

Conclusion

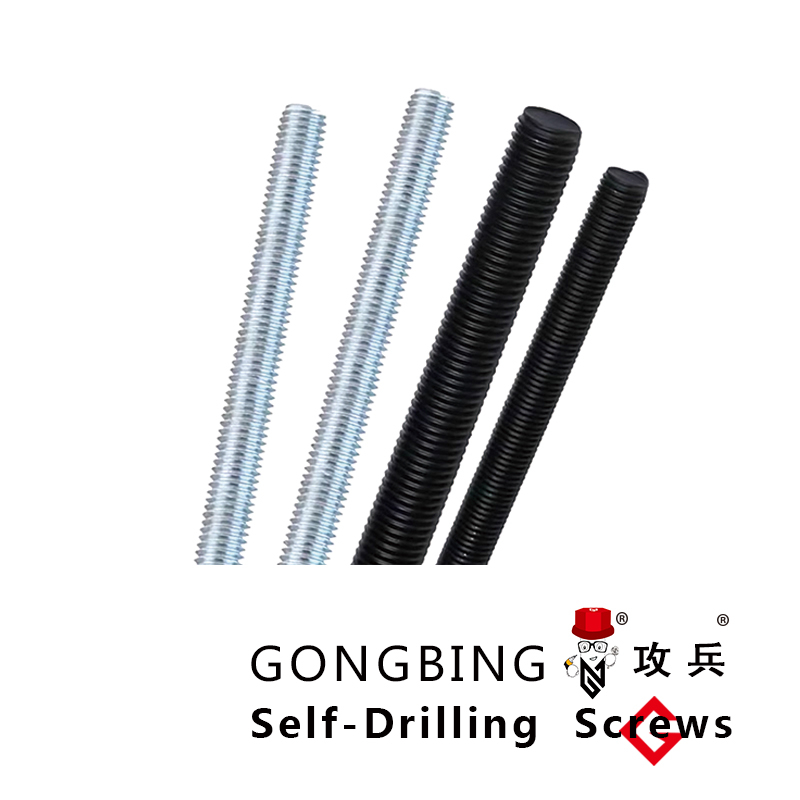

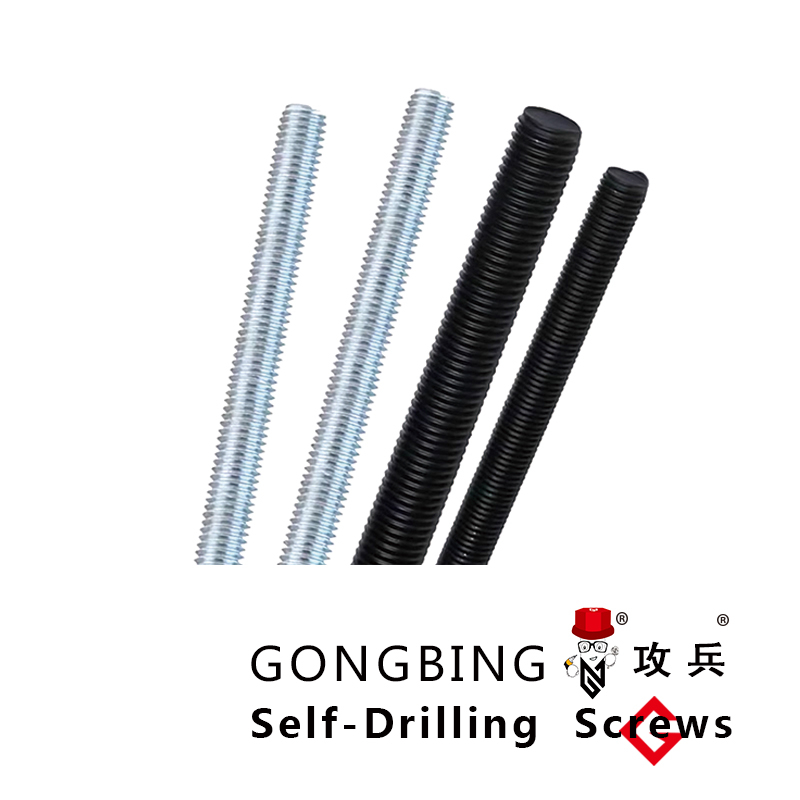

Full threaded rod 10mm is a type of rod that is completely threaded along its length with a diameter of 10mm. This type of rod is commonly used in construction, plumbing, and other industrial applications where strength and durability are important.

Conclusion

In conclusion, plastic expansion bolts serve as an efficient and practical solution for numerous fixing tasks. Their durability, ease of installation, and adaptability make them a staple in construction, home improvement, and manufacturing sectors. However, it is crucial to understand the specific requirements of each project and choose the appropriate bolt type accordingly. Always remember to follow manufacturer guidelines for maximum safety and performance. When choosing tek screws for a project, it is important to consider the material and thickness of the materials being fastened together. For example, tek screws with a 5% thread are ideal for thin materials like sheet metal, while tek screws with a 16% thread are better suited for thicker materials like steel beams. By selecting the right type of tek screw for the job, you can ensure a strong and secure connection that will stand the test of time.

The Advantages of Bonded Fasteners in Modern Manufacturing

Butterfly anchors also offer excellent versatility, making them suitable for use in a wide range of marine environments

3 16 butterfly anchor. Whether you're anchoring your boat in a crowded marina or a secluded cove, these anchors can provide the stability and security you need. Their compact size and lightweight design make them easy to handle and store, making them an excellent choice for both experienced sailors and those who are just starting out. Drywall screws denote their primary application – attaching drywall sheets to wooden or metal studs. These screws have a sharp point and a bugle head, designed to countersink smoothly into the drywall, leaving a clean finish that can be easily taped and finished.

3 16 butterfly anchor. Whether you're anchoring your boat in a crowded marina or a secluded cove, these anchors can provide the stability and security you need. Their compact size and lightweight design make them easy to handle and store, making them an excellent choice for both experienced sailors and those who are just starting out. Drywall screws denote their primary application – attaching drywall sheets to wooden or metal studs. These screws have a sharp point and a bugle head, designed to countersink smoothly into the drywall, leaving a clean finish that can be easily taped and finished. 1. Corrosion Resistance Brass is known for its excellent resistance to corrosion compared to other metals. This property makes brass self-drilling screws particularly suitable for outdoor use or in humid environments, where moisture can lead to rust and degradation over time.

Concrete forms, an integral part of construction sites, play a crucial role in shaping and supporting fresh concrete until it solidifies. In this process, wedge bolts for concrete forms emerge as essential fastening tools that ensure stability, safety, and efficiency. When it comes to installation, flat head chipboard screws are relatively easy to use

In conclusion, the screw, butterfly, and anchor are powerful symbols that encapsulate the complexities of life. They remind us that while challenges and changes are inevitable, we have the strength and resilience to overcome them and emerge stronger and more resilient. By embracing these symbols and their meanings, we can navigate the twists and turns of life with confidence and grace.

In conclusion, the screw, butterfly, and anchor are powerful symbols that encapsulate the complexities of life. They remind us that while challenges and changes are inevitable, we have the strength and resilience to overcome them and emerge stronger and more resilient. By embracing these symbols and their meanings, we can navigate the twists and turns of life with confidence and grace. - Injection Systems These involve injecting the adhesive into a drilled hole before inserting the anchor bolt. This method ensures proper coverage of the bonding agent.

In the construction industry, for instance, Wing Tek screws are often used in panel assembly and modular structures. Their robust design allows them to withstand the stresses associated with various environmental impacts, ensuring durability and longevity. In automotive manufacturing, these screws play a crucial role in securing body panels and interior components, where reliability is paramount.

Furthermore, EPDM washered fasteners find their way into the electrical and plumbing sectors too

What are Tek Screws?

Stitch Tek screws, also known as stitch or track screws, are specifically designed for heavy-duty applications where high tensile strength and resistance to shear forces are paramount. The term 'Stitch Tek' refers to their unique threading pattern and design that allows them to securely anchor into materials, providing an unparalleled level of stability. Their innovative design, characterized by closely spaced threads, enables a faster and more efficient installation process, reducing project timelines and overall costs.

What is a CSK Head Self-Drilling Screw?

Moreover, the sleek and clean appearance of stainless steel complements modern architectural designs Moreover, nuts and bolts offer an advantage over (welding) due to their removable nature. This allows for easy assembly and disassembly, facilitating maintenance and repairs. They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors construction nuts and bolts.

construction nuts and bolts. Understanding Expanding Wall Anchors A Comprehensive Guide

When it comes to securing a sill plate to a concrete surface, one of the best options available is the use of wedge anchors. These anchors provide a reliable and durable solution for attaching heavy loads to concrete, making them an ideal choice for sill plate installation. Resin anchors are a popular choice for installing fixtures and equipment in concrete and masonry surfaces. These anchors provide a strong bond between the fixing point and the substrate, making them ideal for a wide range of applications. However, like any installation process, there may be instances where issues arise. In this article, we will discuss the common problems associated with resin anchors and provide a step-by-step guide on how to fix them. - Automotive Used in manufacturing and repairs where metal components need to be joined securely. Proper installation of self-drilling drywall plastic anchors is essential to ensure that your objects are securely mounted to the wall. To install these anchors, follow these steps 4. Apply Pressure Evenly When installing drilling screws, apply even pressure to the screwdriver to ensure that it is tightened evenly. Over-tightening can strip the threads or damage the material, while under-tightening can result in a loose connection. One of the main advantages of using heavy section tek screws is their versatility. They can be used in a variety of applications, from attaching metal roofing panels to steel framing to securing wooden beams in place. This makes them a popular choice among builders and contractors who need a reliable and efficient fastening solution for their projects. Moreover, these screws are often made from high-quality materials like steel, zinc-coated for added corrosion resistance, ensuring durability and longevity in outdoor or harsh environments. Some variants may also have additional coatings like phosphate or dacromet for enhanced protection against rust and wear. The metal used in crafting these screws adds another layer of intrigue. Ranging from robust stainless steel to resilient titanium, the material choice influences the screw's durability, resistance to corrosion, and overall performance. The metallic sheen, when polished, can lend a touch of elegance to, transforming utilitarian objects into works of art.