Links:

What is HPMC Used For?

Applications of HPMC

In personal care products, such as shampoos, conditioners, and lotions, MHEC is utilized for its thickening and emulsifying properties. It improves the stability of formulations, enhancing the sensory experience for consumers. Moreover, MHEC is used in various cosmetic applications, providing film-forming properties that aid in the longevity of products on the skin or hair.

The performance of HPMC is influenced by several key factors, including its grade, viscosity, and degree of substitution. Higher viscosity grades provide better thickening and gelling properties, while lower viscosity grades are suitable for applications requiring easy flow and spreadability. The degree of substitution refers to the extent to which the hydroxyl groups in cellulose have been replaced by hydroxypropyl and methyl groups. This affects the solubility and functional characteristics of the polymer, making it crucial to select the appropriate grade based on specific requirements.

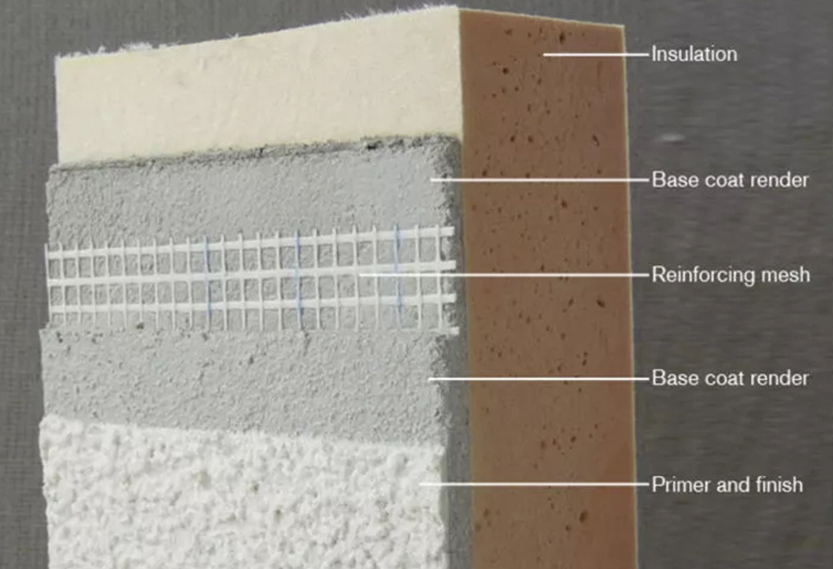

In the construction industry, RDPs play a pivotal role in improving the performance of cement-based materials. For instance, when incorporated into tile adhesives, they enhance adhesion to substrates, reduce shrinkage, and improve the working properties, allowing for more extended open times. In exterior insulation and finish systems (EIFS), RDPs provide superior weather resistance and minimize the risk of cracking and water infiltration.

Hydroxypropyl Methylcellulose (HPMC) is a water-soluble polymer that plays a significant role in various industries, including pharmaceuticals, food, and cosmetics. When discussing HPMC in the context of sodium dodecyl sulfate (SDS), it is essential to understand their properties, interactions, and applications, particularly in areas like drug delivery, emulsification, and stabilization of formulations.

Dissolving hydroxyethyl cellulose requires careful attention to detail to achieve a homogeneous solution. By following the steps outlined above, you can ensure that HEC is effectively dissolved, allowing its beneficial properties to enhance your formulations. Proper handling and understanding of this material will not only save time but will also lead to improved product performance across various applications. Whether you are working in a laboratory or an industrial setting, mastering the art of dissolving HEC is a valuable skill that can enhance your work in numerous ways.

Conclusion

In addition to oral dosage forms, HPMC is also utilized in topical applications. It serves as a thickening agent in creams and gels, providing an ideal texture and stability for dermatological products. Furthermore, it is employed in the formulation of ophthalmic products, where its gel-forming properties enhance the retention time of the medication in the eye, thus improving delivery and efficacy.

hpmc manufacturer

In the food sector, hydroxyethyl cellulose acts as a food additive, commonly used as a thickening and stabilizing agent in various products. It is often found in sauces, dressings, and toppings, where it helps to improve texture and maintain consistency. Additionally, HEC is used in gluten-free products as a way to mimic the elasticity and binding properties of gluten, enhancing the quality and palatability of these foods. Its ability to retain water also assists in preventing moisture loss, ensuring fresher and longer-lasting products.

Hypromellose, also known as hydroxypropyl methylcellulose (HPMC), is a versatile additive commonly used in the pharmaceutical, food, and cosmetic industries. It is a semi-synthetic polymer derived from cellulose and is highly soluble in water. HPMC is available in various types, each with specific characteristics and applications. Overall, HPMC is a versatile and widely used additive in various industries due to its excellent film-forming, binding, thickening, and controlled-release properties. The different types of HPMC offer a range of options for formulators to tailor their formulations based on specific requirements and desired characteristics. Whether used in pharmaceuticals, food products, or cosmetics, HPMC continues to be a valuable ingredient for ensuring the quality and efficacy of various formulations. In conclusion, as a leading manufacturer of Hydroxypropyl Methyl Cellulose, we are dedicated to producing high-quality products that meet the unique needs of our customers. With our commitment to quality, innovation, and customer satisfaction, we are confident that we can provide you with the superior HPMC products you need to succeed in your industry. Contact us today to learn more about our products and how we can help you with your HPMC needs.

In summary, the selection of appropriate redispersible polymer powder is critical for achieving the desired performance in construction materials. Each type, whether VAE copolymers, styrene-acrylate copolymers, polyethylene, polypropylene, pure acrylics, or EVA, offers distinct advantages and is suited for specific applications. Understanding these differences allows manufacturers and developers to optimize their formulations for enhanced performance, durability, and versatility. As technology advances, we can expect further innovations in RDPs, leading to even greater possibilities in the realm of construction and building materials.

HPMC Limited specializes in the production of hydroxypropyl methylcellulose (HPMC), a versatile compound that has numerous applications across various sectors. From pharmaceuticals to construction, HPMC is renowned for its thickening, binding, and film-forming properties. This unique versatility makes it an essential ingredient in the formulation of many products, including paints, adhesives, and food additives.

Understanding HPMC

1. Molecular Weight HPMC grades with lower molecular weights dissolve more readily in water. High molecular weight grades may require heating or longer mixing times to achieve complete dissolution.

In the construction industry, HPMC is used as a water-retaining agent in cement and mortar. By adding HPMC to cement mixtures, builders can improve workability, reduce cracking, and increase the strength of the final product. HPMC also acts as a thickener in paint and coatings, improving their texture and performance.

In the pharmaceutical industry, HPMC plays a pivotal role in drug formulation. Its ability to form gels and control the release of active pharmaceutical ingredients makes it especially valuable in creating sustained-release oral dosage forms. HPMC can be found in tablets, capsules, and granules, where it not only acts as a binder but also aids in the controlled release of the medication over time.

The Evolution and Significance of HPMC 4000 A Versatile Hydroxypropyl Methylcellulose

One of the most significant applications of HPMC is in the pharmaceutical industry. HPMC is utilized as a binder, coating agent, and thickening agent in the formulation of tablets and other solid dosage forms. Its ability to form gels in the presence of water makes it an ideal choice for controlled-release formulations, allowing for a gradual release of active ingredients over time. This property not only enhances the bioavailability of medications but also improves patient compliance, as patients need to take medications less frequently.

MHEC possesses a complex chemical structure that contributes to its multifunctionality. The incorporation of both methyl and hydroxyethyl groups into the cellulose backbone alters its solubility, viscosity, and film-forming properties. This modification allows MHEC to retain water, forming gels that are essential for various applications. Its amphiphilic nature provides excellent thickening, gelling, and stabilizing properties, making it a preferred choice for many formulations.

Conclusion

Is HPMC Safe? An In-Depth Analysis

HPMC is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer sourced from plant fibers. It is a white, odorless powder that has the ability to form a gel-like consistency when mixed with water. Its unique properties, such as water retention, thickening, and emulsifying capabilities, make it an essential component in many formulations.

Hydroxyethyl cellulose, also known as HEC, is a versatile compound that is widely used in various industries including the pharmaceutical, cosmetics, and construction industries. As an Ashland product, hydroxyethyl cellulose is known for its high quality and consistency, making it a popular choice for many manufacturers. Whether you are in the construction, pharmaceutical, food, or cosmetics industry, HPMC Limited is a trusted partner that you can rely on for all your HPMC needs. With its extensive product range, commitment to quality, excellent customer service, and dedication to innovation, HPMC Limited is the ideal choice for businesses looking for a reliable and high-quality HPMC supplier.

Several materials have been tested as a substitute for gelatin capsules. Hydroxypropylmethylcellulose (HPMC) has become a successful alternative material for two-piece capsules and is used for supplements all over the world.

In the pharmaceutical industry, HPMC is commonly used as a binder and film-forming agent in tablets and capsules. Its excellent film-forming properties enhance the mechanical strength of tablets, while its dispersion characteristics ensure uniform distribution of active ingredients. HPMC also serves as a controlled-release agent, allowing for the gradual release of drugs into the bloodstream, thereby improving therapeutic efficacy and minimizing side effects. Moreover, its biocompatibility and non-toxicity make it an ideal choice for pharmaceutical applications.

In the pharmaceutical industry, hydroxyethyl cellulose is used in a variety of formulations, including tablet coatings, ophthalmic solutions, and controlled-release drug delivery systems

buy hydroxyethyl cellulose. Its biocompatibility and non-toxic nature make it a safe and effective option for incorporating into medicinal products. When you buy hydroxyethyl cellulose for pharmaceutical applications, you can be confident that you are using a reliable and compliant ingredient that meets strict quality standards.

One of the primary advantages of redispersible polymer powders is their ability to improve the mechanical properties of end products, such as enhanced adhesion and flexibility

. In construction materials, RPPs provide better bonding between components, which is crucial in applications like tile adhesives, cementitious mortars, and facade coatings. Additionally, RPPs contribute to the durability of these materials, making them more resistant to weathering, humidity, and temperature changes.Considerations When Buying Hydroxyethyl Cellulose

Understanding Hydroxypropyl Methylcellulose Composition, Uses, and Benefits

4. Cosmetic Grade HPMC In personal care products, HPMC is employed as a thickener, film former, and stabilizing agent. It is found in lotions, creams, and gels, enhancing the texture and feel of the products while providing moisture retention benefits.

hpmc grades and uses

In conclusion, RDP powder serves as a critical component in numerous applications, primarily within the construction and coatings industries. Its ability to provide improved adhesion, flexibility, and durability makes it a preferred choice among manufacturers. As the demand for high-performance materials continues to surge, the significance of RDP powder will only grow, further proving its value across various applications while driving innovation in material science.

Cosmetic Applications

Chinese manufacturers excel in producing high-quality HPMC powder due to their investment in advanced technology and strict quality control measures. This allows them to offer various types of HPMC with different viscosity levels and degrees of substitution, catering to specific industry needs.

4. Local Chemical Suppliers

When using redispersible polymer powders, it is essential to consider factors such as the particle size distribution, the formulation pH, and the specific application requirements. Understanding these parameters can help formulators achieve the desired performance characteristics in their end products.

To dissolve hydroxyethyl cellulose effectively, you will need the following materials

Tile adhesive technology has evolved significantly over the years, and one of the most prominent components in this domain is Hydroxypropyl Methylcellulose (HPMC). This cellulose ether has gained immense popularity in the construction and tiling industries due to its unique properties and benefits.

In addition to its thickening properties, hydroxyalkyl cellulose also acts as a film former. When applied to a surface, it forms a thin, transparent film that provides protection and enhances the appearance of the substrate. This makes hydroxyalkyl cellulose a valuable ingredient in coatings, paints, and adhesives.

Significance of Gelation Temperature